Page is loading ...

1

Oxiperm

®

C

166

Fully-automatic Chlorine Dioxide

Preparation System

166-007G, -015G, -025G,

-050G, -075G, -100G

Operation and Service Manual

Read this manual completely and keep it!

No warranty in case of damages caused by incorrect operation.

Other languages

http://net.grundfos.com/qr/i/96709689

2

Oxiperm C 166 G en

Imprint

Oxiperm

®

C 166

Fully-automatic Chlorine Dioxide Preparation System

166-007G, -015G, -025G, -050G, -075G, -100G

Operation and Service Manual

Editor: Grundfos Water Treatment

Reetzstraße 85 • 76327 Pfinztal (Söllingen)

Postfach 1160 • 76317 Pfinztal

Tel. +49 72 40 61-0 / Fax. +49 72 40 61-211

Internet: www.grundfos.com

Subject to change.

3

Oxiperm C 166 G en

15.710018-V3.0

Assembly Information

NOTE Please fill in this form after commissioning. This

allows easy maintenance for you and your GRUNDFOS

service partner.

Operating Authority:

GRUNDFOS customer no.:

Order no.:

Order no. of the device:

Serial no. of the device:

Date of commissioning:

Location of the device:

Used for:

Assembly Sketch

4

Oxiperm C 166 G en

Content

Assembly Information ..................................................................................... 3

Assembly Sketch ............................................................................................. 3

1 Of General Interest ................................................................................ 6

1.1 Introduction .................................................................................................6

1.2 Using this Paper ......................................................................................... 6

1.3 Warranty .....................................................................................................6

2 Safety Instructions ................................................................................ 7

2.1 Application of the Product ........................................................................... 7

2.2 Obligations of the Operating Authority ........................................................7

2.3 Averting Dangers ........................................................................................ 7

3 Technical Data ....................................................................................... 8

3.1 General Data ..............................................................................................8

3.1.1 Data on Performance and Consumption ......................................... 8

3.1.2 Connection Data .............................................................................. 9

3.1.3 Weights and Measures ....................................................................9

3.2 Components .............................................................................................10

3.2.1 Control Panel ................................................................................. 10

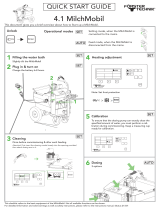

4 Installation............................................................................................ 11

4.1 Transport and Storage .............................................................................. 11

4.2 Unpacking ................................................................................................. 11

4.3 Mounting ................................................................................................... 11

4.3.1 Requirements for Mounting ...........................................................11

4.3.2 Mounting the System ..................................................................... 11

4.4 Connections .............................................................................................. 12

4.5 Electrical Connection ................................................................................ 12

5 Construction

and Function ........................................................................................ 13

5.1 Basics ....................................................................................................... 13

5.1.1 Application of Chlorine Dioxide in Water Treatment ....................... 13

5.1.2 Preparation of

Chlorine Dioxide ............................................................................13

5.2 Components .............................................................................................14

5.3 Course of Function ...................................................................................16

5.4 Operation and Display Elements ..............................................................17

6 Preparations for Commissioning ....................................................... 19

6.1 Checking the Pressure Retention Valve and the Pulsation Damper .........19

6.2 Installation of the Float into the Solution Tank .......................................... 19

6.3 Checking the Flow Limits .......................................................................... 20

6.4 Filling of the Adjusting Vessel of the NaClO2 Dosing Pump ..................... 22

6.5 Filling of the Overflow of the Batch-Tank ..................................................23

5

Oxiperm C 166 G en

15.710018-V3.0

7 Commissioning .................................................................................... 24

7.1 Filling the Reactor

with Water ................................................................................................. 24

7.1.1 Filling the Reactor while the System is switched off ...................... 24

7.1.2 Filling the Reactor while the System is switched on ...................... 24

7.2 Commissioning with Chemicals at Manual Operation Mode ....................26

8 Operation ............................................................................................. 28

8.1 Automatic and

Manual Operation ..................................................................................... 28

8.1.1 Manual Operation .......................................................................... 28

8.1.2 Automatic Operation ...................................................................... 29

8.2 Recording and Calling up the Error Messages ......................................... 29

8.3 Quitting the Error and Alarm Messages ................................................... 30

8.4 Calling up the Level Data .......................................................................... 30

8.4.2 ClO2 Level ..................................................................................... 31

8.4.1 NaClO2 Levelvel ............................................................................31

8.4.3 Cl2 Level ........................................................................................ 32

8.4.4 Replacement

of a Cl2 Battery ............................................................................. 32

8.4.5 Checking the Time-Invariants of the Level Messages .................. 33

8.5 Flow Rates ................................................................................................ 34

8.6 Function "System Extern/Manual On-/Off" .............................................. 36

8.7 System Settings ........................................................................................ 37

8.7.1 Setting of Language ......................................................................37

8.7.2 Setting of Contrast ......................................................................... 38

38

8.7.3 Setting of Date and Time ............................................................... 38

9 Possible Failures ................................................................................. 40

10 Maintenance ......................................................................................... 41

10.1 Differential Pressure

Regulator .................................................................................................. 41

10.2 Other Components ...................................................................................42

11 Spare Parts........................................................................................... 42

11.1 Overview ...................................................................................................43

11.2 Differential Pressure

Regulator .................................................................................................. 44

Appendix: Declaration of conformity

6

Oxiperm C 166 G en

1 Of General Interest

1.1 Introduction

This Operation and Service Manual contains all information necessary for safe

operation of the device being described here.

If you require further information or if any problems arise which are not reflected in

detail in this manual, contact GRUNDFOS directly for the information

needed.

1.2 Using this Paper

❏ Descriptions are written as plain text.

❏ Lists are indicated by squares (❏), sublists by dashes (-).

❏ Operation steps are indicated by bullets (●), substeps by small bullets (•).

❏ Cross-references are indicated by

italic letters

and an arrow

(➜).

❏ The headings

WARNING

,

CAUTION

and

NOTE

have the following meaning:

!

WARNING Danger of injuries and accidents!

CAUTION Danger of incorrect operation or damage to the product!

NOTE There is an exceptional feature.

PACKING MATERIAL Keep packing material or dispose of it according

to local rules.

1.3 Warranty

Warranty in accordance with our general terms of sale and delivery shall only be

valid, if

❏ the product is used according to the information within this paper,

❏ the product is not being opened or used improperly,

❏ maintenance and repair is implemented exclusively by authorized and

qualified personnel,

❏ original spare parts are used for repair.

NOTE In case of changes of hardware or software warranty

will not longer be valid. The software stays property of

Grundfos Water Treatment. Copies are not allowed.

7

Oxiperm C 166 G en

15.710018-V3.0

2 Safety Instructions

2.1 Application of the Product

Oxiperm

®

C 166 serves for preparing chlorine dioxide solution as described in this

manual.

!

WARNING Other applications are not intended and are not

permitted. *UXQGIRV:DWHU7UHDWPHQW accept no

responsibility for damages caused by unintended use.

2.2 Obligations of the Opera-

ting Authority

The operating authority of the system is responsible for

❏ instructing the operation personnel

❏ arranging regular maintenance

2.3 Averting Dangers

!

WARNING Before commissioning, read the GRUNDFOS

information paper "Function and Safety of Chlorination

Plants".

Danger of explosion!

The inner temperature of the reactor may not exceed

30 °C! Observe permissible temperature ranges for

operating water and NaClO

2

!

Only use NaClO

2

solution with a concentration of 24%!

Observe safety precautions for the used chemicals!

Switch off mains switch before doing maintenance

work!

Do not open components of the device! Cleaning,

maintenance and repair may only be executed by

authorized qualified personnel!

8

Oxiperm C 166 G en

3 Technical Data

3.1 General Data

3.1.1 Data on Performance and

Consumption

Order no. Capacity Components Operation water consumption Operation

ClO

2

consumption Injector Dilution Extraction total pressure

Cl

2

NaClO

2

kg/h l/h kg/h l/h l/h l/h l/h l/h bar

166-007G 0.75 245 0.49 3.5 150 90 700 940 5

166-015G 1.5 490 0.99 7.0 280 200 1100 1580 5

166-025G 2.5 815 1.65 11.8 470 340 2400 3200 5

166-050G 5.0 1620 3.3 23.5 940 680 2200 3790 5

166-075G 7.5 2440 4.9 35 1400 1000 3400 5800 5

166-100G 10 3250 6.6 47 1900 1300 4200 7400 5

Concentration of the prepared solution

3 g/l

Permissible concentration of the

NaClO

2

solution

24%

!

WARNING The inner temperature of the reactor may not exceed

40 °C! Observe permissible temperature ranges for

operating water and NaClO

2

!

Only use NaClO

2

solution with a concentration of 24%!

Permissible ambient temperature

5 °C to 40 °C

Permissible temperature of

5 °C to 30 °C

operation water and NaClO

2

Materials

Frame

PP

Screws, disks and nuts

1.4301

Reactor

PVC grey, glass fiber reinforced

Solution tank

PVC grey

Piping

PVC grey

Gaskets

FPM

9

Oxiperm C 166 G en

15.710018-V3.0

3.1.2 Connection Data

Order no. Cl

2

NaClO

2

Operation water Outlet ClO

2

Outlet of extraction injector Press. conn.

PE tube DN DN DN DN of vac. regulator

166-007G 8x11 10 25 20 20 1“

166-015G 8x11 10 25 32 20 1“

166-025G 8x11 10 25 32 20 1“

166-050G 8x11 10 25 32 25 1“

166-075G 10x14 10 32 50 25 1“

166-100G 10x14 10 32 50 25 1“

3.1.3 Weights and Measures

Order no. A B C D E F G H I K L Weight (kg)

166-007G 1500 1800 830 720 255 1440 624 160 97 652 140 210

166-015G 1500 1800 830 720 255 1440 624 160 97 610 140 235

166-025G 1500 1800 830 720 255 1440 624 160 97 610 140 250

166-050G 1500 1800 1400 400 255 1440 1240 160 97 665 140 330

166-075G 1500 1800 1400 400 255 1440 1240 160 97 665 140 370

166-100G 1500 1800 1400 400 255 1440 1240 160 97 665 140 400

Measures in mm.

10

Oxiperm C 166 G en

3.2 Components

3.2.1 Control Panel

Degree of protection

IP 54

Control

optional Description

Control panel with PLC and operation keyboard

(standard version)

Functions:

- comfortable plain-text operator guidance

- complete control of the system

- password protection

- automatic switch off in case of errors

- remote switching

- output contacts for operational state and error messages

- printer connection

- input and monitoring of the delay times for limit switching

functions

without control panel (with terminal box)

Power supply

Index no. Description

V000 / V020 Power supply 230 V (50/60 Hz) (standard version)

V001 / V021 Power supply 115 V (50/60 Hz)

V150 terminal box 115 / 230 V (50/60 Hz)

Operator's language

Index no. Description

F000 Operator's language German (standard version)

F001 Operator's language Englisch

F002 Operator's language French

Maximum permissible load

Ohmic and inductive load 250 V AC1, 2 A

of the potential-free contacts

50 V DC1, 2 A

CAUTION Radioshielding for connected consumers must be

provided by the customer.

Power consumption

Order no. Power consumption (VA)

166-007G approx. 300 VA

166-015G approx. 300 VA

166-025G approx. 300 VA

166-050G approx. 300 VA

166-075G approx. 300 VA

166-100G approx. 550 VA

Further Options

Empty indication for Cl

2

and NaClO

2

Profibus DP-Interface

11

Oxiperm C 166 G en

15.710018-V3.0

4 Installation

4.1 Transport and Storage

!

WARNING Observe weight of the system! Only use suitable lifting

and transportation devices!

Transportation only when the system is empty!

● Handle with care, do not throw!

❏ Dry and cool storage place. Avoid direct sunlight!

4.2 Unpacking

● Check the device for damages.

• Do not mount or install damaged devices!

● Mount as soon as possible after unpacking.

CAUTION Keep packing material or dispose of it according to

local rules.

4.3 Mounting

4.3.1 Requirements for Mounting

!

WARNING The chlorine containers and the vacuum regulator have

to be located in a separate room according to local

safety regulations.

➜

Observe information pater "Function and safety of

Chlorination Plants"!

4.3.2 Mounting the System

Mounting the system

● Erect the system on a horizontal foundation.

!

WARNING Observe maximum floor load!

12

Oxiperm C 166 G en

4.4 Connections

CAUTION Required conditions for the operation water for

trouble-free operation:

❏

constant pressure

(min. 5 bar, max. 6 bar)

❏

drinking water quality

● Connect the operation water line to connection 3.1.

● Connect the NaClO

2

supply line to connection 1.1.

● Connect the Cl

2

supply line (coming from the vacuum regulator) to

connection 2.1.

● Connect the ClO

2

withdrawal line to connection 9.

● Connect the discharge connection of the extraction injector (8) to an

appropriate discharge.

4.5 Electrical Connection

!

WARNING Electrical connection only by authorized qualified

personnel!

Observe local safety regulations!

Mortal danger!

Switch off mains power before connecting the mains

supply!

NOTE Establish electrical connections according to the

enclosed connection chart.

● Lead the mains line to the control panel and connect it according to the

enclosed connection chart.

- Cable cross-section: min. 1.5 mm

2

• Provide a back-up fuse with a capacity of 10 A.

13

Oxiperm C 166 G en

15.710018-V3.0

5 Construction

and Function

5.1 Basics

5.1.1 Application of Chlorine

Dioxide in Water Treatment

Properties of chlorine dioxide

❏ Strong and fast oxidizing and disinfecting agent

❏ Wide range of application in drinking-, service-, cooling- and waste water

treatment

❏ chemically instable compound

- can explosively decompose to chlorine and oxygene when being under

pressure, heated or exposed to UV rays

- has to be produced on demand at the place of use

➜

Observe chap. 2.3 (Averting dangers)!

Advantages of chlorine dioxide in comparison to chlorine

❏ Over the whole pH range of drinking water (pH 6.5-9), chlorine dioxide has a

good to very good bactericidal, virucidal and sporicidal effect.

(The disinfecting effect of chlorine is reduced when the pH value rises!)

❏ No forming of haloforms (trihalomethanes) with decomposable water

contents

❏ No forming of chloramines with ammonia or aminocompounds

❏ Strongly reduced formation potential of higher-molecular organic halogene

compounds

❏ Good stability in water

- suitable bactericidal and bacteriostatic protection of water networks.

5.1.2 Preparation of

Chlorine Dioxide

Chemical reaction

2 NaClO

2

+Cl

2

→→

→→

→ 2 ClO

2

+ 2 NaCl

sodium chlorite chlorine chlorine dioxide sodium chloride

❏ sodium chlorite

- solution with a concentration of 24%, containing 300 g/l NaClO

2

❏ chlorine

- solution of approx. 3.5 g/l Cl

2

❏ chemical reaction in the reactor:

- with the size and construction of the reactor a maximum effectivity in

chlorine dioxide production can be achieved. Nearly 100% of the

components react with each other

❏ Following the reactor: chlorine dioxede solution is diluted to an application-

suiting concentrationof aprox. 2 to 3 g/l

14

Oxiperm C 166 G en

5.2 Components

15

Oxiperm C 166 G en

15.710018-V3.0

1 Dosing system for NaClO

2

1.1 Connection for NaClO

2

1.2 Suction pulsation damper

1.3 Suction aid

1.4 Piston-diaphragm dosing pump

1.5 Pulsation damper

1.6 Flow meter for NaClO

2

with limit switch

2 Dosing system for chlorine gas

2.1 Cl

2

vacuum connection from the vacuum regulator

2.2 Flow meter for Cl

2

with limit switch

2.3 Cl

2

rate valve

2.4 Differential pressure regulator for Cl

2

2.5 Injector for Cl

2

3 Operation water supply

3.1 Connection for operation water

3.2 Water supply for the extraction injector

3.3 Water supply for injector and subsequent dilution

3.4 Flow meter for injector operation water with limit switch

3.5 Flow meter for subsequent dilution with limit switch

3.6 Rate valves for the water flow

4 Panel for PLC and operation keyboard

5 ClO

2

reactor

6 Solution tank with level sensors (min., max., dry-run and overflow)

7 Carbon filter

8 Discharge connection of the extraction injector

9 ClO

2

withdrawal connection

16

Oxiperm C 166 G en

5.3 Course of Function

❏ For preparing a chlorine dioxide solution, four components are necessary:

- Chlorine gas

- Solution water

- Sodium chlorite

- Dilution water

The amounts of these components are determined by the preparation

method and may therefore not be changed. The flow rates of the single

components are monitored by rotameters.

❏ In the injector, the chlorine gas is mixed with the solution water and flows

into the reactor.

❏ The sodium chlorite is also being dosed into the reactor.

❏ In the reactor, the reaction of chlorine solution and sodium chlorite takes

place, forming chlorine dioxide.

❏ The solution formed in the reactor flows into the solution tank and is being

mixed with the dilution water. This produces a ready-to-use chlorine dioxide

solution.

❏ The ready-to-use solution can now being withdrawn from the solution tank.

❏ The extraction injector continuously sucks residual chlorine gas out of the

reactor and leads it to a carbon filter.

❏ The solution tank is equipped with level sensors.

In automatic operation, the system is

- switched on when the min. level is reached.

- switched off when the max. level is reached.

- switched off if at least one of the component's flows is out of the

permissible limits. This switching-off takes place after a time delay.

Injector

Reactor

Solution

tank

Chlorine

gas

Solution water NaClO

2

Dilution water

ClO

2

solution WithdrawalChlorine solution

17

Oxiperm C 166 G en

15.710018-V3.0

5.4 Operation and Display

Elements

Operation keyboard

SIEMENS

SIMATIC OP 7

F1 F2 F3

F4

K1 K2

K3 K4

!

HELP

SHIFT

4 5 6

1 2 3

7

8 9

. 0 +/-

SHIFT

INS

DEL

HELP

ACK

ESC

ENTER

D

E F

A B C

Keys

F1

to

F4

(soft keys)

These keys lead to actions which are being displayed above the corresponding

key. Their function depends on the current state of the device, e.g. a certain

submenu.

NOTE Keep keys pressed down until the selected function

has been activated/deactivated.

Function keys

K1

On/off automatic operation, LED on the key lights up while automatic operation

K2

On/off manual operation, LED on the key lights up while manual operation

K3

Shows error messages

K4

Resets alarm messages which are to be acknowledged (FSA +/-). In this case the

LED on the key is flashing.

18

Oxiperm C 166 G en

System keys

These keys have fixed basic functions of the PLC.

The cursor keys are used for moving the cursor to a place on the display where a

parameter has to be changed.

4 5 6

1 2 3

7

8 9

.

0 +/-

D E F

A B C

The numerical keys are used for the input of numeric values, like numbers or

passwords.

NOTE Always double-click on ESC (Escape) to activate.

ESC

The ESC key (Escape) is used for

- interrupting the current action without changing any values resp. without

overtaking values that have been changed,

- to exit help pages.

ENTER

The ENTER key is used for

- confirming changed values,

- activating the input of symbolic values.

ACK The ACKNOWLEDGE key is used for acknowleding error messages.

HELP

The HELP key is used for calling help pages on the current display situation.

19

Oxiperm C 166 G en

15.710018-V3.0

6 Preparations for

Commissioning

CAUTION Before commissioning, all components of the system

must be ready to start.

➜➜

➜➜

➜

Observe chap. 4.4 (connections)

6.1 Checking the Pressure

Retention Valve and the

Pulsation Damper

Pressure retention valve for versions C 166-050 to C-166-100

● Verify the setting measure 7 mm.

Pulsation damper for the piston-diaphragm dosing pump

● Adjust the following pressure values:

- C 166-007 to C 166-025: 1,5 - 1,7 bar

- C 166-050 to C 166-100: 1,5 - 1.7 bar

● Check the density

➜

Observe the operation and service manual of this device!

6.2 Installation of the Float

into the Solution Tank

● Install the float into the transparent guide pipe

• Slatten the union nut at the guide pipe (at the bottom and at the top)

• Remove the guide pipe

• Install the float.

CAUTION Observe the fitting position!

• Screw the union nut

20

Oxiperm C 166 G en

6.3 Checking the Flow Limits

NOTE The setting points of the limit contacts "max/min" are

at the top of these contacts.

➜➜

➜➜

➜

Observe the maximum and minimum values in the

following table!

Flowmeter for für injection operating water, diluting water

MIN

MAX

1a

1b

1a setting point for the maximum flow

1b setting point for the minimum flow

Flowmeter for NaClO

2

ca. 1 mm

/