8"

Lowest position

12" Hightest position

(Sleeve extension can

also be added)

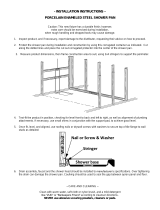

ADJUST TO DESIRED HEIGHT.

(CAN BE CUT AS SHORT AS 4-1/2")

(Fig. 1)

LOCK OUTER SLEEVE IN PLACE.

(Fig. 3)

Twist Outer Sleeve, left or right,

until locked in notches.

Push Locator Whiskers until locked in place.

(Optional, screw can be used for stronger

attachment).

RE-INSTALL CAP & INSERT WHISKERS.

(Fig. 4)

Nails, 4 places recommended

NAIL TO FORM DECK.

(Fig. 5)

Form Deck

Pour concrete to top of Sleeve.

POUR IN CONCRETE.

(Fig. 6)

Turn Wrench, counter-clock-wise.

REMOVE CAP WITH HF WRENCH,

OR BREAK-OUT WITH HAMMER.

(Fig. 7)

INSTALL PIPE FROM BELOW, INSTALL BACKING

MATERIAL & FIRE CAULKING AS REQUIRED.

(SOAPY WATER EASES PIPE INSERTION)

(Fig. 8)

Backing Material, as required.

Pipe

Fire Caulking as required.

Pull out Locator Whiskers

(optional)

CUT INNER & OUTER SLEEVE IF

DESIRED HEIGHT IS UNDER 8".

(Fig. 2)

Hydroflame PRO Series - Hollow Sleeve on Flat Form Deck. See Hydroflame Pro - "Best Practices" document and UL's online certification directory (file R25101) for more details. Rev A