Page is loading ...

FormNo.3385-390RevA

DirectDrivePowerBoxRake

CompactUtilityLoaders

ModelNo.22426—SerialNo.314000001andUp

Registeratwww.Toro.com.

OriginalInstructions(EN)

*3385-390*A

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Introduction

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1illustratesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contents

Introduction..................................................................2

Safety...........................................................................3

SafeOperatingPractices...........................................3

StabilityRatings.......................................................4

SafetyandInstructionalDecals.................................5

ProductOverview..........................................................6

Specications.........................................................6

Operation.....................................................................6

ExtendingtheCasterWheels....................................6

StartingthePowerRake............................................7

SettingtheBarrierGap.............................................7

UsingtheEndPlates................................................7

AnglingtheRoller...................................................8

TransportingthePowerRake....................................8

StoppingthePowerRake..........................................9

OperatingTips.......................................................9

Maintenance.................................................................10

RecommendedMaintenanceSchedule(s)......................10

CheckingtheTirePressure......................................10

GreasingthePowerRake.........................................10

Storage........................................................................11

Troubleshooting...........................................................12

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

2

Contactusatwww.Toro.com.

PrintedintheUSA.

AllRightsReserved

Safety

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructionsand

alwayspayattentiontothesafetyalertsymbol,which

means

Caution

,

W ar ning

,or

Danger

—personalsafety

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

SafeOperatingPractices

Thisproductiscapableofcrushingoramputatinghandsand

feet.Alwaysfollowallsafetyinstructionstoavoidserious

injuryordeath.

WARNING

Engineexhaustcontainscarbonmonoxide,and

odorless,deadlypoisonthatcankillyou

Donotruntheengineindoorsorinanenclosed

area.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadEnglish,itis

theowner'sresponsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

peopleorproperty.

Preparation

•Checkforallburiedutilitylinesbeforeoperation.

WARNING

Ifthereareburiedpower,gas,ortelephonelines

intheworkarea,youmaycontactthem,causing

ashockoranexplosion.

Havethepropertyorworkareamarkedfor

buriedlinesanddonotoperatethepowerrake

inmarkedareas.

•Evaluatetheterraintodeterminetheproperandsafe

actionstoperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Wearappropriateclothingincludinghardhat,safety

glasses,longpants,safetyshoes,andhearingprotection.

Longhair,looseclothingorjewelrymaygettangledin

movingparts.

•Inspecttheareawheretheequipmentistobeusedand

removeallobjectssuchastools,buildingmaterials,and

personalitemswhichcanbedamagedbythemachine.

•Ensurethattheshieldsareattachedandfunctioning

properly.

Operation

•Keepthecompactutilityloaderarmsandtheattachment

aslowaspossible.

•Slowdownandusecautionwhenmakingturnsandwhen

changingdirectionsonslopes.

•Donottravelorturnwiththeloaderliftarmsandthe

attachmentintheraisedposition.

WARNING

Whentheengineisoff,anattachmentinthe

raisedpositioncangraduallylower,possibly

pinningorinjuringsomeone.

Alwayslowertheattachmentlifteachtimeyou

shutoffthetractionunit.

•Goupanddownslopes,notacrossthem.

•Keeptheheavypartofthemachinefacinguphill.

•Donotoverloadthemachine.

•Neverusetheattachmenttocarryloads.

WARNING

Donotexceedtheloadcapacityofthemachine,

asthemachinecouldtiporrollover,causing

seriousinjuryordeath.

•Donotdisconnectanyhydrauliclinesuntilthewhole

systempressurehasbeenrelieved.

WARNING

Hydraulicsystemleakdown,hydraulicsystem

failures,mechanicalfailures,ormovementof

controlleverscancauseequipmenttodropor

rotateunexpectedly,andcausesevereinjuryor

death.

3

WARNING

Hydraulicuidescapingunderpressurecan

penetratetheskinandcauseinjury.Fluid

injectedintotheskinmustbesurgicallyremoved

withinafewhoursbyadoctorfamiliarwiththis

formofinjury,organgrenemayresult.

–Keepyourbodyandhandsawayfrompin

holeleaksornozzlesthatejecthigh-pressure

hydraulicuid.

–Usecardboardorpapertondhydraulic

leaks;neveruseyourhands.

•Neverdirectlydischargetowardpeople,animals,or

property.

•Donotoperatethemachinewhileundertheinuence

ofdrugsoralcohol.

•Operateonlyinthedaylight.

MaintenanceandStorage

•Parkthemachineonalevelsurface,setthethrottleto

slow,andstoptheengine.Waitforallmovementtostop

beforeadjusting,cleaning,orrepairing.

•Cleandebrisfromthedrives,mufers,andenginetohelp

preventres.Cleanupfuelandoilspillage.

•Lettheenginecoolbeforestoringanddonotstoreneara

ame.

•Donotstorefuelnearamesordrainindoors.

•Parkthemachineonlevelground.Neverallowuntrained

personneltoservicethemachine.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

DANGER

Contactwithrotatingteethcancause

entanglement,severewounds,and/ordeath.

–Keepawayfromtherotatingteethwhile

operatingthepowerrake.

–Keepyourhands,feet,otherpartsofyour

body,andclothingawayfromrotatingparts.

–Beforeadjusting,cleaning,repairing,and

inspectingthepowerrake,lowerthepower

rakeandloaderarmstotheground,shutoff

theengine,andremovethekey.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Useextracarewhenhandlingfuels.Theyareammable

andvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Neverremovethefuelcaporaddfuelwhenthe

engineisrunning.Allowtheenginetocoolbefore

refueling.Donotsmoke.

–Neverrefuelthemachineindoors.

–Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

–Neverllafuelcontainerwhileitisinsideavehicle,

trunk,pick-upbed,oranysurfaceotherthanthe

ground.

–Keepcontainernozzleincontactwiththetankduring

lling.

•UseonlygenuineTororeplacementpartstoensurethat

originalstandardsaremaintained.

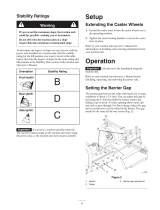

StabilityRatings

WARNING

Ifyouexceedthemaximumslope,themachine

couldtip,possiblycrushingyouorbystanders.

Donotdrivethemachineonaslopesteeperthan

themaximumrecommendedslope.

Todeterminethedegreeofslopethatyoucantraversewith

thepowerrakeinstalledonatractionunit,ndthestability

rating(Figure3)forthehillpositionthatyouwanttotravel

inthetablebelow,thenndthedegreeofslopeforthesame

ratingandhillpositionintheStabilityDatasectionofthe

tractionunitOperator’sManual.

Figure3

Important:Ifyouhaveatractionunitotherthanthe

TX,usethecounterweightonthetractionunitwhen

usingthepowerrake,orthetractionunitmaybecome

unstable.

4

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

93-9367

1.Crushinghazardofhand—keephandsaway.

100-4708

1.Thrownobjecthazard—keepbystandersawayfromthe

machine.

93-7321

1.Cutting/dismembermenthazardofhandsandfeet,rotating

knives/blades—stayawayfrommovingparts.

93-9084

1.Liftpoint

115-2903

1.Grease

5

ProductOverview

Figure4

1.Caster-armassembly

4.Tire

2.Rakeframe

5.Toothroller

3.Attachmentmount6.Rakebarrier

Specications

Height

53.1cm(20.9inches)

Weight

166kg(365lb)

Rakingwidth

122cm(48inches)

Rollertype

Carbidetoothedroller22.4cm

(8.8inches)diameter

Rollerangle

20°

Gap(tubetobarrier)3.2cm(1-1/4inches)

Maximumpressure

20,684kPa(3,000psi)

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Note:RefertoyourtractionunitOperator’sManualbefore

installing,operating,andremovingthepowerrake.

Note:RefertoyourtractionunitOperator’sManualfor

informationoninstallingandremovingattachmentsonyour

tractionunit.

ExtendingtheCasterWheels

RefertoyourtractionunitOperator’sManualforinformation

oninstallingandremovingattachmentsfromyourtraction

unit.

1.Extendthecasterarmssothatthecasterwheelarein

theoperatingposition.

2.Securethecasterarmsinplacewiththehitchpins

(5/8x3inches),clevispins(5/8x3.5inches),andthe

hairpincotters(0.094x1inch)asshowninFigure5.

Figure5

1.Casterarm3.Hitchpin(5/8x3inches)

2.Clevispin(5/8x3.5

inches)

4.Hairpincotter(0.094x1

inch)

6

StartingthePowerRake

1.Startthetractionunitengine.

2.Slowlylowerthepowerraketotheground.

3.Engagethehydraulic-controlleverforauxiliary

implements.

4.Movethetractionunitforwardorbackwardasdesired.

Note:Fortherollertooperateeffectively,rotateitin

theoppositedirectionofthetraction-unittrack.The

directionoftherollerrotationiscontrolledbythe

tractionunithydrauliccontrols;refertoFigure6below .

Figure6

SettingtheBarrierGap

Thenormalgapbetweentherollerandthebarrierforaverage

conditionsisapproximately3.2cm(1-1/4inches).

Thebarriergapshouldbethesameallthewayacross.

Setthebarriergapasfollows:

•Towidenthebarriergap,loosenthe2U-bolts(3/8inch)

thatholdthebarriermount(Figure7).

Note:Awideropeningwillallowmoredirtandrock

topassthrough.

Figure7

1.Ubolts(3/8inch)

•Tonarrowthebarriergap,tightenthe2U-bolts(3/8

inch)thatholdthebarriermount(Figure7).

Important:Ensurethattherollerdoesnothitthe

barrier,asthepartscouldbedamaged.

UsingtheEndPlates

Theendplatescontainthematerialinfrontoftheroller,

whilethecleanmaterialpassesbetweentherollerandthe

barrier.Withtheendplatesmountedintheworkingposition

andtherakestraight(parallelwiththetractionunittrack),the

materialcanbemoved,llinginthelowspots.

Youcanmounttheendplatestoeitherthefrontortheback

ofthepowerrake,dependingontherakingdirection.When

youmovetheendplatesfromfronttoback,youmustmove

theleftonetotherightsideandtherightonetotheleftside.

Tomovetheendplate,performthefollowing:

1.Removethe2hairpincottersfromtheend-platepin

(Figure8).

Figure8

1.End-platepin3.Endplate

2.Hairpincotter

2.Removetheend-platepinfromtheendplate(Figure8).

3.Removetheendplate(Figure8).

7

AnglingtheRoller

Youcanangletheroller20°ineitherdirection.

Forwindrowing,removetheangle-lockingpin(Figure9),

slidetheanglemounttoanewsetofholes,andinsertthepin.

Important:Donotdropthepowerrakeontotheground

withtherollerturning.Suddenhigh-speedjoltsmultiply

thestresstothedriveline,andcancausedamage.

Figure9

1.Angle-lockingpin

TransportingthePowerRake

Transportthepowerrakebyusingtheliftpointsshownin

Figure10.

Important:Liftingthepowerrakeatotherpointscan

damagethemachine.

Note:Liftthemachinecarefullywithproperlifting

accessories.

Figure10

1.Liftpoint

8

StoppingthePowerRake

1.Stoptheengineonthetractionunit.

2.Lowertheliftarmsofthetractionunit,andlowerthe

powerraketotheground.

3.Turnofftheengine,settheparkingbrake,andremove

thekeyfromtheignitionofthetractionunit.

OperatingTips

OperatingthePowerRake

•Alwaysbeginpowerrakingattheslowestgroundspeed

possible.Increasethegroundspeedifconditionspermit.

•Alwaysusefullthrottle(maximumenginespeed).

•Ifarockorotherobstructiongetsintotheteeth,stop

thehydraulicsanddrivethetractionunitforwarduntil

theobstructionisdislodged.

•Therollershouldbelevelwiththeground.Thepower

rakeshouldalsobelevelwiththegroundfromfrontto

back.Toaccomplishthis,raiseorlowerthegaugewheels

andusethetractionunittiltcylinder.

•Toallowtherollertopenetratedeeperintotheground,

loosenthehandleandraisethegaugewheels.Toraisethe

roller,lowerthegaugewheels.

•Youcanachievefurtherdepthcontrolbytiltingtherake

forwardonitsgaugewheelstoraisetheroller,ortiltthe

rakebacktoraisethegaugewheels,andallowtheroller

topenetratemoredeeply.

•Checktheairpressureineachtireregularlytomaintain

anevenandconsistentgrade.

•Tobreakupcompactedsoil,rollbacktheattachment

platetotaketheguidewheelsofftheground,sothatonly

thetoothedrollerisincontactwiththeground.Control

thegroundspeedtoavoidstallingthetoothedroller.

Removetheendplatestoallowmaterialtomoveoutof

thewayifyouareonlytryingtobreakupthesoil.

•Toremoveloosedebris,tiltthetractionunitattachment

plateuntiltheguidewheelscontrolthedepthofthe

toothedroller.Youcanangletherakeatthistimefor

windrowingdebrisoryoucansettherakestraightwith

bothendplatesinstalledtocollectdebris.Youcan

increasethetractionunitspeedwhenyoudothis.

•Fornishgrading,tilttherakeforwarduntiltheteeth

ofthetoothedrollerarebarelytouchingthesoil.You

canincreasethetractionunitspeedtocollectthematerial

fromthehighspotsandleaveitinthelowerareas.

•Tothatchgrassyareas,tiltthetractionunitattachment

plateforwardtosupporttherakeonthefrontgauge

wheelsandthetoothedrollerraisedsothattheteethare

justgrazingthesurface.Thetravelspeedshouldbeslow.

9

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Beforeeachuseordaily

•Checkthetirepressure.

Every40hours

•Greaseallofthelubricationpoints.

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Maintaintheairpressureinthetires,asuneventirepressure

cancauseunevenraking.

Checkthetireswhentheyarecoldtogetthemostaccurate

pressurereading.

Ifthetirepressureislow,inatethetire(s)to345kPa(50psi).

GreasingthePowerRake

ServiceInterval:Every40hours

GreaseType:No.2generalpurpose,lithium-basegrease

1.Turnofftheengine,settheparkingbrake,andremove

thekeyfromtheignitionofthetractionunit.

2.Placethepowerrakeonalevelsurface.

3.Cleanthegreasettingswitharag.

Note:Makesuretoscrapeanypaintoffthefrontof

thetting(s).

4.Applythenecessaryamountofgreasetothegrease

ttings(Figure11andFigure12).

Figure11

Figure12

10

Storage

1.Turnofftheengine,settheparkingbrake,andremove

thekeyfromtheignition.

2.Storethepowerrakeonahard,levelsurface.

3.Beforelongtermstorage,brushthedirtfromthe

attachment.

4.Tightenanyloosehydraulicconnections,nuts,and

capscrews.

5.Lubricateallofthegreasettings;refertoGreasing

thePowerRake(page10).

6.Sealthehydraulicsystemfromanycontaminants,and

secureallofthehydraulichosesoffthegroundto

preventdamage.

7.Storethemachineinadry,protectedplace.

8.Paintanyunpaintedareastoavoidrust.Paintis

availablefromyourAuthorizedToroServiceDealer.

9.Inatethetirestotherecommendedtirepressure;refer

toCheckingtheTirePressure(page10).

11

Troubleshooting

Problem

PossibleCauseCorrectiveAction

1.Thehydraulicvalveontheloaderis

notengaged.

1.SeetheloaderOperator’sManual.

2.Therelief-valvesettingontheloaderis

notproperlyadjusted.

2.ContactyourAuthorizedT oroService

Dealer.

3.Wornordamagedhydraulicmotor.3.Repairorreplacethehydraulicmotor.

4.Insufcientoilinthesystem.4.Servicetheloaderhydraulicreservoir.

5.Thehoseendsarenotcompletely

engaged.

5.Checkthehosecouplingsandengage

properly.

6.Thereisairinthehydrauliclines.

6.Cycletheloaderauxiliarysystem

severaltimetoremoveairfromthe

lines.

7.Thereisanobstructioninthehydraulic

lines.

7.Replacetheobstructedordamaged

line.

Therollerwillnotturn.

8.Thereisanobstructionbetweenthe

rollerandthebarrier.

8.Reversetherollertoclearthe

obstruction.

1.Wornordamagedseal.1.Replacetheleakingseal.

2.Looseordamagedhoses.2.Replacethedamagedhosesand

secureloosehoses.

Thereareoilleaks.

3.Looseordamagedconnections.3.Replacethedamagedhose

connectionsandtightentheloose

ttings.

12

Notes:

13

Notes:

14

DeclarationofIncorporation

TheT oroCompany,8111LyndaleAve.South,Bloomington,MN,USAdeclaresthatthefollowingunit(s)

conform(s)tothedirectiveslisted,wheninstalledinaccordancewiththeaccompanyinginstructionsontocertain

ToromodelsasindicatedontherelevantDeclarationsofConformity.

ModelNo.

SerialNo.

ProductDescriptionInvoiceDescription

GeneralDescription

Directive

22426314000001andUpDirectDrivePowerBoxRake

DIRECTDRIVEPOWER

BOXRAKE,CE

PowerBoxRake

2006/42/EC

RelevanttechnicaldocumentationhasbeencompiledasrequiredperPartBofAnnexVIIof2006/42/EC.

Wewillundertaketotransmit,inresponsetorequestsbynationalauthorities,relevantinformationonthispartly

completedmachinery.Themethodoftransmissionshallbeelectronictransmittal.

ThismachineryshallnotbeputintoserviceuntilincorporatedintoapprovedT oromodelsasindicatedonthe

associatedDeclarationofConformityandinaccordancewithallinstructions,wherebyitcanbedeclaredin

conformitywithallrelevantDirectives.

Certied:EUT echnicalContact:

PeterTetteroo

ToroEuropeNV

B-2260Oevel-Westerloo

Belgium

JoeHagerTel.003214562960

Sr.EngineeringManager

Fax003214581911

8111LyndaleAve.South

Bloomington,MN55420,USA

May30,2014

15

ToroCompactUtilityEquipmentWarranty

AOne-YearLimitedWarranty

CompactUtilityEquipment

(CUE)Products

ConditionsandProductsCovered

TheT oroCompanyanditsafliate,T oroWarrantyCompany,pursuantto

anagreementbetweenthem,jointlywarrantyourToroCompactUtility

Equipment(“Product”)tobefreefromdefectsinmaterialsorworkmanship.

Thefollowingtimeperiodsapplyfromthedateofpurchase:

ProductsWarrantyPeriod

ProSneak

CompactUtilityLoaders,

Trenchers,StumpGrinders,

andAttachments

1yearor1000operatinghours,

whicheveroccursrst

KohlerEngines3years

*

AllotherEngines2years

*

Whereawarrantableconditionexists,wewillrepairtheProductatnocost

toyouincludingdiagnosis,labor,andparts.

*

SomeenginesusedonToroProductsarewarrantedbytheenginemanufacturer.

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure:

1.ContactanyAuthorizedT oroCompactUtilityEquipment(CUE)

ServiceDealertoarrangeserviceattheirdealership.Tolocatea

dealerconvenienttoyou,accessourwebsiteatwww.Toro.com.You

mayalsocallourToroCustomerCareDepartmenttollfreeatthe

numberbelow.

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothe

ServiceDealer.

3.IfforanyreasonyouaredissatisedwiththeServiceDealer’s

analysisorwiththeassistanceprovided,contactusat:

SWSCustomerCareDepartment

ToroWarrantyCompany

8111LyndaleAvenueSouth

Bloomington,MN55420-1196

TollFree:888-384-9940

OwnerResponsibilities

YoumustmaintainyourT oroProductbyfollowingthemaintenance

proceduresdescribedintheOperator’sManual.Suchroutinemaintenance,

whetherperformedbyadealerorbyyou,isatyourexpense.Parts

scheduledforreplacementasrequiredmaintenance(“MaintenanceParts”),

arewarrantedfortheperiodoftimeuptothescheduledreplacementtime

forthatpart.Failuretoperformrequiredmaintenanceandadjustmentscan

begroundsfordisallowingawarrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarrantyperiod

aredefectsinmaterialsorworkmanship.Thisexpresswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,modied,orunapproved

accessories

•Productfailureswhichresultfromfailuretoperformrequired

maintenanceand/oradjustments

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligentorrecklessmanner

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

productoperationinclude,butarenotlimitedto,belts,wipers,spark

plugs,tires,lters,gaskets,wearplates,seals,O-rings,drivechains,

clutches.

•Failurescausedbyoutsideinuence.Itemsconsideredtobeoutside

inuenceinclude,butarenotlimitedto,weather,storagepractices,

contamination,useofunapprovedcoolants,lubricants,additives,or

chemicals,etc.

•Normal“wearandtear”items.Normal“wearandtear”includes,butis

notlimitedto,wornpaintedsurfaces,scratcheddecals,etc.

•Repairsnecessaryduetofailuretofollowrecommendedfuel

procedure(consultOperator'sManualformoredetails)

–Removingcontaminantsfromthefuelsystemisnotcovered

–Useofoldfuel(morethanonemonthold)orfuelwhichcontains

morethan10%ethanolormorethat15%MTBE

–Failuretodrainthefuelsystempriortoanyperiodofnon-use

overonemonth

•Anycomponentcoveredbyaseparatemanufacturer’swarranty

•Pickupanddeliverycharges

GeneralConditions

RepairbyanAuthorizedT oroCompactUtilityEquipment(CUE)Service

Dealerisyoursoleremedyunderthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletionof

repairsunderthiswarranty.Allimpliedwarrantiesofmerchantability

andtnessforusearelimitedtothedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sothe

aboveexclusionsandlimitationsmaynotapplytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

ExceptfortheenginewarrantycoverageandtheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.The

EmissionsControlSystemonyourProductmaybecoveredbyaseparate

warrantymeetingrequirementsestablishedbytheU.S.Environmental

ProtectionAgency(EPA)ortheCaliforniaAirResourcesBoard(CARB).

ThehourlimitationssetforthabovedonotapplytotheEmissions

ControlSystemWarranty.RefertotheCaliforniaEmissionControl

WarrantyStatementsuppliedwithyourProductorcontainedintheengine

manufacturer’sdocumentationfordetails.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedToroproductsoutsidetheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtainguarantee

policiesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtainingguarantee

information,contacttheToroimporter.Ifallotherremediesfail,youmaycontactusatT oroWarrantyCompany.

AustralianConsumerLaw:AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalToro

Dealer.

374-0261RevE

/