Page is loading ...

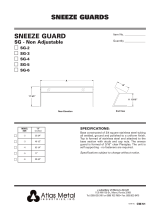

a subsidiary of Mercury Aircraft

1135 NW 159 Dr., Miami, Florida 33169

Tel: (305) 625-2451 or (800) 762-7565 • Fax: (305) 623-0475

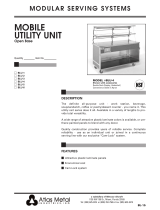

MO DU LA R SE RVING SYSTEMS

BL-1

MOBILE HOT

SERVING UNIT

Open Base, Electrically Heated,

Individual Controls

Optional Drain and Manifold

FEATURES

Attractive plastic laminate panels

Individually controlled thermostats

High wattage food wells, use wet or dry

Economical cost

Cam-Lock system

DESCRIPTION

This attractive, functional unit keeps hot foods hot - at their peak of

serving perfection. Your customers will see, taste and come back for

the difference.

A wide range of attractive plastic laminate colors is available, or ure-

thane painted panels to blend with any decor.

Quality construction provides years of reliable service. Complete re-

liability - use as an individual unit or joined in a continuous serving

line with our exclusive “Cam-Lock” system.

BLH-2

BLH-3

BLH-4

BLH-5

BLH-6

MODEL #BLH-4

Shown with accessories

Tray Slide, Work Shelf, High Shelf, Undershelf

Quantity Item No.

a subsidiary of Mercury Aircraft

1135 NW 159 Dr., Miami, Florida 33169

Tel: (305) 625-2451 or (800) 762-7565 • Fax: (305) 623-0475

BL-2

TOP: Constructed of 16 gauge, type 304 stainless

steel, die-formed, welded, ground and polished

to a uniform finish with rolled front edge.

BODY: Frame construction shall be of hi-tensile

square aluminum tubing, 1-1/4”, 1” and 3” extrud-

ed, vertical radius corners. Frame sections are all

welded construction, ground and polished to a

uniform finish. Body is complete with front panel,

end panels and 8-5/8” rear apron of plastic lami-

nate on .050 aluminum. Owner to specify laminate

finish. Cam-lock locking system included with

each unit to align and retain cart positioning,

when two or more units are joined.

HOT SERVING UNIT: The cart is complete and

includes a hot serving unit installed in the top.

Constructed of 18 gauge, type 304 stainless steel.

Individual 12” x 20” hot food wells are provided,

fabricated of 18 gauge stainless steel, one piece

construction, all welded, ground and polished to

a uniform finish. All corners are coved with a min-

imum 1/4” radius. Each well is provided with an

850 watt heating element. The wells can be used

with or without water, however, the use of water

for a more efficient operation is recommended.

ELECTRICAL: The unit is provided with a prewired

single thermostat control for each well, with a

pilot light. A 6’ long, 3-wire cord and plug is pro-

vided, extending from the control box located

under the unit, on operator’s left. Available for

single phase power only.

CASTERS: N.S.F approved, 5” diameter, non-

marking rubber tired, swivel plate caster with

grease fittings. Both casters on the operator’s

side have toe activated brakes.

Specifications subject to change without notice.

ACCESSORIES:

Tray slide, 12” wide, stainless steel, solid

ribbed, fold-down

Work shelf, 8” wide, stainless steel, flat, fold-

down.

High shelf, stainless steel, with glass sneeze

guard

SAR Plexiglass End Sneeze Guards for High

Shelf (set of 2)

Canopy, stainless steel, with SAR Plexiglass

sneeze guard on customer’s side only

Food Warmer under High Shelf or Canopy*

Fluorescent Light under High Shelf or

Canopy*

Drain Line Manifold to single drain valve

Drain Valve for each well to single drain line

Convenience Outlet (specify wattage, volt-

age & location)*

Stainless Steel Legs with adjustable feet, in

lieu of casters

Urethane painted panels (see color chart)

Undershelf (removable) bottom or middle

shelf, stainless steel

RPS - Rear Sliding Doors, stainless steel

RPS - Door Locks

RPS - Plastic Laminate Exterior

* Change in electrical required, contact factory.

SPECIFICATIONS:

MOBILE HOT SERVING UNIT

Open Base

MODEL “A”

FOOD

WELLS

ELECTRICAL

CHARACTERISTICS

NEMA

CONFIGURATION

BLH-2 36-1/4” 2 1.7 KW - 8.2 amps. 208 V 6-15P

BLH-3 50” 3 2.55 KW - 12.3 amps. 208 V L6-20P

BLH-4 63-3/4” 4 3.4 KW - 16.3 amps. 208 V L6-30P

BLH-5 77-1/2” 5 4.25 KW - 20.4 amps. 208 V L6-30P

BLH-6 91-1/4” 6 5.1 KW - 24.5 amps. 208 V 6-50P

NOTE: Electrical characteristics subject to change when electrical accessories are added.

10/08-SC

30 1/2”

Plan View

A

35”

Rear Elevation

End View

3”

/