2-3.2 Installing Optional ANVIS

Dual Visor Assemblies

(Quick-Disconnect or

Direct-Mount)

Both types of ANVIS dual visor

assemblies (quick-disconnect and

direct mount, Figure 2-6) are

installed in the same manner (after

the existing dual visor assembly is

removed).

Tools and Materials Required

• ANVIS dual visor assembly,

quick-disconnect (95B9246)

or

• ANVIS dual visor assembly,

direct mount (88D7611-1)

Procedure

Install the ANVIS dual visor

assembly (quick-disconnect or

direct-mount) as follows:

1. Loosen (do not remove) the four

thumb screws (Figure 2-7) on

the existing dual visor assembly

on the helmet.

2. Lift the entire existing dual visor

assembly away from the helmet

and set aside.

3. Align the thumbscrews of the

ANVIS dual visor assembly over

the four posts protruding upward

through the helmet (Figure 2-8).

4. Tighten the four thumb screws

on the ANVIS dual visor

assembly into the posts.

Ensure that the ANVIS dual visor

assembly is securely attached to

the helmet.

5. Install the ANVIS attachment kit

per Paragraph 2-3.3 (for

quick-disconnect) or Paragraph

2-3.4 (for direct-mount).

9

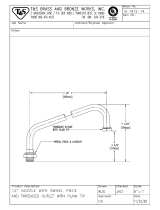

Figure 2-6. ANVIS Dual Visor Assemblies

Figure 2-7. Existing Dual Visor Assembly

Figure 2-8. Installing ANVIS Dual Visor Assembly

(Quick-Disconnect Shown)

Quick-disconnect

Direct-mount

Thumb screw

(four places)

Thumb screw

(four places)

Post

(four places)