Page is loading ...

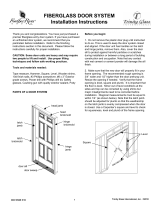

Panel Assembly, Installation, and Removal

Guía de ensamblaje, instalación y extracción del panel

for Andersen® A-Series 2-Panel, 3-Panel and 4-Panel Gliding Patio Doors

para puertas corredizas para patio de 2 paneles, 3 paneles y 4 paneles de la serie A de Andersen®

“Andersen” and all other trademarks where denoted are marks of Andersen Corporation. ©2021-2023 Andersen Corporation. All rights reserved.

“Andersen” y las demás marcas comerciales que aparezcan son marcas de Andersen Corporation. ©2021-2023 Andersen Corporation. Todos los derechos reservados. 9020095 BF Revised 01/25/23

Operating Panel

Panel operativo

Stationary Panel

Panel estacionario

or/

o bien

Tools Needed / Herramientas necesarias

• Safety glasses / Gafas de seguridad

• Phillips Screwdriver / Destornillador Phillips

• Flat Blade Screwdriver / Destornillador de punta plana

• Drill/Driver / Taladro/Destornillador

• Caulk Gun / Pistola para calafatear

• 7/32 Hex Key / 7/32 Llave hexagonal

• Stiff Blade Putty Knife or Flat Pry Bar /

Espátula de hoja rígida o palanca plana

• Tape / Cinta

Read these instructions before starting procedure. For additional information visit www.andersenwindows.com. For questions call 1-888-888-7020.

Lea estas instrucciones antes de iniciar el procedimiento. Para obtener información adicional, visite www.andersenwindows.com

Si tiene alguna pregunta, llame al 1-888-888-7020.

Astragal

Astrágalo

Parts Included / Partes incluidas

Operating Panel Carton Contains:

La caja de cartón del panel operativo

contiene lo siguiente:

(1-2) Operating Panel / Panel operativo

Stationary Panel Carton Contains:

La caja de cartón del panel estacionario

contiene lo siguiente:

(1-2) Stationary Panel / Panel estacionario

(1) Instruction Guide / Guía de instrucciones

Astragal Carton Contains (4-Panel Door Only):

La caja de cartón del Astrágalo contiene lo siguiente

(Sólo para puertas de 4 paneles ):

(1) Astragal /Astrágalo

(1) Astragal Fastener Pack /

Paquete del sujetador del astrágalo

(1) Astragal Fastener Cover Plug Pack

Paquete del tapón de la cubierta del sujetador del

astrágalo

0 0 7

2-Panel Door

Puerta de 2

paneles

3-Panel Door

Puerta de 3

paneles

4-Panel Door

Puerta de 4

paneles

#10 x 1-1/2" Pan Head Screws

( Astragal Screw Pack)

Tornillos de cabeza plana No. 10 x 1-1/2"

(Paquete de tornillos del astrágalo)

Astragal Fastener Pack

Paquete del sujetador del astrágalo

0 0 11

2-Panel Door

Puerta de 2

paneles

3-Panel Door

Puerta de 3

paneles

4-Panel Door

Puerta de 4

paneles

Astragal Fastener Plugs

Tapones del sujetador

del astrágalo

Astragal Fastener Cover Plug Pack

Paquete del tapón de la cubierta

del sujetador del astrágalo

▶Parts included may exceed quantity required for your particular installation.

Las partes que se incluyen pueden exceder la cantidad requerida para su instalación en particular.

▶Do not remove packing clips from door until instructed.

No retire los sujetadores de embalaje de la puerta hasta que se le indique.

2

9020095

Parts used for panel assembly that are included in frame carton:

Las partes que se utilizan en el ensamblaje del panel y que se

incluyen en la caja de cartón del marco son las siguientes:

(1-2) Stationary

Panel Interlock

Weatherstrip

Burlete de

enganche

del panel

estacionario

(1) Tube Silicone

Silicona en tubo

(0-2) Stationary

Jamb Trim

Contramarco

de jamba esta

cionaria

(1-2) Operating

Panel Interlock

Weatherstrip

Burlete de

enganche del

panel operativo

1 2 2

1 2 2

1 2 2

1 2 2

2 2 2

9 18 0

0 0 8

2-Panel Door

Puerta de 2

paneles

3-Panel Door

Puerta de 3

paneles

4-Panel Door

Puerta de 4

paneles

Interlock Weatherstrip

Head Dust Pad

Almohadilla antipolvo

para el cabezal del

burlete de enganche

Security Bracket

Dust Pad

Almohadilla antipolvo

para el soporte de

seguridad

Security Bracket

Soporte de seguridad

Filler Cap

Tapón de

relleno (one left-hand, one right-hand)

(una para el lado izquierdo, una

para el lado derecho)

Fastener Plug

Tapón del sujetador

30 60 60

2 4 4

6 12 21

0 0 3

#7 x 5/8" White, Gray or Black Screws

Tornillos de cabeza plana No. 7 x 5/8" de color

blanco, gris o negro

#10 x 1" Stainless Steel Screws

Tornillos de acero inoxidable No. 10 x 1"

#10 x 3" Gray Screws

Tornillos No. 10 x 3" de color gris

#10 x 3" Stainless Steel Screws

Tornillos de acero inoxidable No. 10 x 3"

Black Plug

Tapón negro

Washer

Arandela

BAG

C

Panel Installation Pack

Paquete de instalación

del panel

3

9020095

(1) Receiver

Position

Template

Plantilla de

posición del

receptor

(1) Receiver

Receptor

(1) Lock

Cerrojo

(1) Bezel

Bisel

(1) Receiver

Position

Template

Plantilla de

posición del

receptor

(1) Receiver

Receptor

(1) Lock

Cerrojo

(1) Bezel

Bisel

Parts used for panel assembly that are included in frame carton: (Continued)

Las partes que se utilizan en el ensamblaje del panel y que se incluyen en la caja de cartón del

marco son las siguientes Continued:

2- and 3-Panel Door / Puerta de 2 y 3 paneles

(4) #8-32 x 7/8" Machine Screw

Tornillos para metales No. 8-32 x 7/8"

(2) #10 x 3" Security Screw

Tornillo de seguridad

n.º 10 x 3"

(1) Lock

Cerrojo (1) 2- or 3-Panel Receiver

Receptor de 2 o 3

paneles

(1) Lock

Cerrojo

(1) 4-Panel Door Receiver

Receptor para puerta

de 4 paneles

4-Panel Hardware Pack /

Paquetes de herrajes para 4 paneles

2- or 3-Panel Hardware Pack

(one pack for 2-panel doors, two packs for 3-panel doors)

Paquetes de herrajes para 2 o 3 paneles

(un paquete para puerta de 2 paneles; dos paquetes para

puerta de 3 paneles)

2- or 3-Panel Hardware Pack

(one pack for 2-panel doors, two packs for 3-panel doors)

Paquetes de herrajes para 2 o 3 paneles

(un paquete para puerta de 2 paneles; dos paquetes para

puerta de 3 paneles)

4-Panel Hardware Pack /

Paquetes de herrajes para 4 paneles

(5) #10 x 3" Stainless Steel Screw

Tornillo de acero inoxidable No. 10 x 3"

or/

o bien

or/

o bien

(1) #10 x 4" Security Screw

Tornillo de seguridad n.º 10 x 4"

(2) #10-32 x 1-1/4" Machine Screw

Tornillo para metales No. 10-32 x 1-1/4"

4-Panel Door / Puerta de 4 paneles

For Flush Mount Hardware/

Para herrajes de montaje embutido

For Reachout Lock Hardware/

Para herrajes de cerrojo de alcance

For Flush Mount Hardware/

Para herrajes de montaje embutido

For Reachout Lock Hardware/

Para herrajes de cerrojo de alcance

(2) #10 x 3" Stainless Steel Screw

Tornillo de acero inoxidable No. 10 x 3"

4

DraftDraft

1

Procedure and

Product Information

IMPORTANT

Important Safety and

Product Information

for Andersen® Windows and Doors

This is the Safety Alert Symbol used to alert you to

potential injury hazards. Obey all safety messages that

follow this symbol to avoid possible injury or death.

Signal Word and Consequence

Major Injury/Death

WARNING

COULD

Result in: Minor Injury

CAUTION

COULD

Result in:

Product or Property

Damage

NOTICE

COULD

Result in:

· Leave this installation instruction with the home/building owner.

· For additional support or help please go to: andersenwindows.com and visit our Help Center.

· To congure installation instructions go to: andersenwindows.com/installation

Handling Installation

· Use caution when working at elevated heights and

around window and door openings. Follow the

manufacturers’ instructions for ladders and scaffolding.

Failure to do so could result in injury or death.

· Support window or door in opening at all times until

fully fastened. Failure to do so could result in window or

door falling out causing injury, property or product

damage.

· Windows and doors have small parts (e.g. hole plugs,

operator spline caps, fasteners, etc.). Small parts if

swallowed could pose a choking hazard to young

children. Dispose of unused, loose, or easily removed

small parts. Failure to do so could result in injury.

· Windows and doors can be heavy. Use safe lifting

techniques and a reasonable number of people with

enough strength to lift, carry, and install window and

door products. Heavier windows and doors will require

mechanical assistance. Failure to do so could result in

injury, product or property damage.

· DO NOT lift or carry window or door by the exterior

trim or extension jambs. Doing so could result in injury,

product or property damage.

· Windows, doors, and installation components can

have sharp edges. Wear protective equipment when

handling. Failure to do so could result in injury.

· DO NOT drag, rock, cartwheel, or walk windows,

doors, sash, or panels across the floor. Doing so could

result in product or property damage.

Tools

· Follow manufacturers’ instructions for hand and power tools. Always wear safety glasses. Failure to do so could result in

injury, product or property damage.

❚ Tools

❚ Handling

❚ Installation

❚ Sealing

❚ Fastening

❚ Finishing

Safety and Product Information Index

❚ Glass

❚ Protective Film

❚ Cleaning

❚ Use/Operation

❚ Joining

❚ Product Information

Read this Important Safety and Product

Information completely before starting.

WARNING

WARNING WARNING

“Andersen” and all other marks where denoted are trademarks of Andersen Corporation. ©2021 Andersen Corporation. All rights reserved. SAFETY/PRODUCT INFORMATION 9144348 BG Revised 02/24/2021

▶Para obtener la versión en español de Información importante sobre productos y seguridad, visite: andersenwindows.com

5

DraftDraft

2

NOTICE

· Andersen head ashing and installation anges DO

NOT take the place of window and door ashing tape or

liquid ashing. Window or door must be properly ashed

and sealed with a material compatible sealant for

protection against water and air inltration.

Failure to do

so could result in product or property damage.

· DO NOT set window or door directly on installation

ange. Doing so could affect product performance, and

could result in product or property damage.

· DO NOT set window directly on sill plate. Elevate

window with shims under the side jambs. Failure to do

so could affect operation and product performance, and

could result in product damage.

· Window or door must be properly shimmed. Failure to

do so could affect operation and product performance,

and could result in product damage.

· A continuous full perimeter interior seal between

window or door frame and opening is required. Failure to

do so will affect product performance, and could result

in product or property damage.

· Protect window and door sills during installation and

throughout construction. Failure to do so could result in

product damage.

· DO NOT remove window or door packaging material until

instructed to do so. Doing so could result in product damage.

Installation (Continued)

NOTICE

· Use masonry screws when fastening directly into

masonry or through a buck into masonry. Failure to do

so could affect product performance, and could result in

product or property damage.

· DO NOT over drive screws or nails. Doing so could

result in product damage.

· Fasteners must be attached to a structural framing

member. Failure to do so will reduce the structural

performance to less than published values and could

affect product performance, and could result in product

or property damage.

Fastening

· Metal fasteners and components could corrode when

exposed to preservative-treated or fire-retardant treated

lumber. Use approved fasteners and components to

fasten window or door. Failure to do so could cause a

failure resulting in injury, product or property damage.

· Fastener must attach to a structural framing member

with a 1-1/2" minimum fastener embedment. Failure to

do so could result in injury, product or property damage.

· DO NOT remove screws that attach installation clips or

gusset plates to window or door frames. Doing so could

result in injury, product or property damage.

Sealing

NOTICE

CAUTION

· Follow instructions of foam, sealant, and flashing

manufacturers regarding safety, material application,

compatibility, and periodic maintenance for continued

weather resistance of their products. Failure to do so

could result in injury, product or property damage.

Finishing

NOTICE

· DO NOT stain or paint weatherstrip, vinyl, glass, or

hardware. Doing so could result in product damage.

· Read and follow nish manufacturer's instructions and

safety information. Failure to do so could result in

product damage.

· DO NOT over load brush with stain or paint when

nishing. Doing so could allow nish to wick between

glass stop or grille, and glass.

WARNING

· Clean and prepare surfaces receiving sealant following

sealant manufacturer's instructions. Failure to do so could

result in water inltration causing product or property damage.

· DO NOT use abrasive cleaners or solvents when

cleaning Fibrex® material. Doing so could result in

product damage. Go to andersenwindows.com for a list

of recommended cleaners.

6

DraftDraft

3

NOTICE

Glass

· Unless specifically ordered, Andersen windows are not

equipped with safety glass, and if broken, could

fragment causing injury. Many laws and building codes

require safety glass in locations adjacent to or near

doors. Andersen windows are available with safety glass

that could reduce the likelihood of injury when broken.

Information on safety glass is available from your local

Andersen dealer.

· Tempered or laminated safety glass is not standard for

windows and must be special ordered. Check local

building codes for required locations. Failure to do so

could result in injury, product or property damage.

· DO NOT place suction grips over film

seams on glass. Suction grips will not

hold if placed over lm seam to lift or

move window or door. Window or door

will fall and could result in injury,

product or property damage.

· DO NOT remove any

protective film near

flammable materials.

Static charge created

when removing film

can ignite flammable

materials or cause a

shock. Doing so could result in injury, product or

property damage. See warning label on glass.

· Dispose of protective film immediately after

removing. Failure to do so could pose a suffocation

hazard to children.

NOTICE

· DO NOT remove protective lm from glass until after

construction is completed. Doing so could allow glass to

be damaged.

· Remove protective film from non-glass components

immediately after installation. Failure to do so could

result in product damage.

NOTICE

Cleaning

Protective FilmFinishing (Continued)

· Finish all wood surfaces immediately after

installation. Unnished wood will deteriorate, discolor,

and could bow or split. Some

surfaces are hidden from view.

· Some products are shipped

unassembled, and it may be

more convenient to finish

wood surfaces for these

products prior to

assembly and

installation.

WARNING

WARNING

· Acid solutions used for cleaning masonry or concrete

will damage all components of window or doors. Protect

window or door and follow cleaning product

manufacturer's instructions. If acid contacts window or

door, wash all surfaces immediately with clean water.

· DO NOT use or apply solvents, abrasives, harsh

chemicals or cleaners to window or door components.

Doing so will result in product damage.

For a list of recommended cleaners go

to: andersenwindows.com

· DO NOT use metal razor blades to

clean glass surface. Glass damage

could result.

· DO NOT apply any type of film to insulating glass.

Doing so could cause thermal stress conditions and

result in glass damage. Shading devices (e.g. insulated

coverings, shutters, etc.) could also cause thermal

stress and condensation causing deterioration of

windows or doors.

· DO NOT use sealants on exterior or

interior glass surface.

NOTICE

7

DraftDraft

4

Joining

IMPORTANT

· Buildings constructed prior to 1978 could contain lead

paint which could be disturbed during window or door

replacement. For more information on proper management

of lead paint, go to: www.epa.gov/lead

· Instructions may not be right for all installations due to

building design, construction materials, or methods used

and/or building or site conditions. Consult a contractor or

architect for recommendations.

· Installation flanges may need to be removed for some

installations. (e.g. masonry, replacement), or where exterior

finish is already applied (e.g. siding, brick veneer, stucco).

· Installation ange on the window or door alone will not

properly ash and seal the window or door.

· DO NOT remove band, plastic ties, or packing clips from

window or door until instructed.

· DO NOT remove performance (NFRC) label until after nal

inspection. Doing so could delay nal inspection and

sign-off by the code ofcial.

· Check with your local building code ofcial to identify and

conrm compliance with local building code requirements.

· Contact local authorities or waste management company

for proper recycling and disposal instructions for removed

window or door.

· For cleaning instructions for window and door components

go to: andersenwindows.com.

· During construction protect products from construction

debris, harsh chemical such as brick wash, roof runoff, and

cement/masonry which can cause damage to window and

door products.

· Protective lm is not present on all windows or doors.

Protective lm is not a substitute for masking.

· Remove protective film from glass within six (6) months of

installation and when temperature is above 32° F.

· Remove protective lm by peeling from seam or corner.

Use a plastic scraper to start if needed.

· Extension jambs can be factory applied on some windows

or eld applied prior to installation. DO NOT apply extension

jambs prior to window or door installation that will be

fastened with installation clips. Doing so could prevent

access to installation clips for fastening.

· For extension jamb application refer to

instructions included with part(s) or go to:

andersenwindows.com

· Use painters masking tape for protecting

products during construction. Avoid using

duct or packaging tapes.

Use/Operation

· DO NOT stand in front of or near windows or doors

during a storm. Doing so could result in injury.

Accessories such as grilles, art glass, and insect

screens could dislodge and become airborne if window

or door is impacted by wind-borne debris from severe

storms or hurricane strength winds. In the event of a

storm, remove all accessories from windows or doors

and move to a safe location.

· DO NOT install air conditioner in

window. Doing so could result in

injury, product or property damage.

· Wind load brackets

must be flipped out

when not tilting or

cleaning. If wind load

brackets are not flipped

out, window could blow

in resulting in potential

injury and/or product

damage.

· DO NOT attach objects or accessories to window or

door except Andersen® products specifically designed

for the window or door. Doing so could result in injury,

product or property damage.

Product and General Information

· DO NOT join any window or door, horizontally or

vertically, to any window or door not designed for

joining. Doing so could result in injury, product or

property damage.

· Joined windows or doors must be individually

supported in the opening. Failure to do so could affect

operation and product performance, and could result in

product or property damage.

CAUTION

WARNING

WARNING

Flipped Out Flipped In

8

9020095

Right Hand

Stationary Panel

Panel estacionario

derecho

-

1

Exterior

Panel Alignment

Sticker

Etiqueta de alineación

del panel

Stationary Panel

Panel estacionario

▶For panel removal, go to page 27.

▶Para la extracción del panel, consulte la página 27.

4-Panel Door / Puerta de 4 paneles

Position stationary panel into head jamb from the exterior. Align notches on bottom of panel with sill guides and swing/push panel onto sill.

Desde el exterior, posicione el panel estacionario dentro de la jamba de cabecera. Alinee las muescas en la parte inferior del panel con las guías del

riel y gire/empuje el panel sobre el riel. Deslice los paneles tal como se muestra.

Left Hand

Stationary Panel

Panel estacionario

izquierdo

Suction grips will not hold if placed over

seam of lm to lift or move unit. Unit will

fall causing damage or injury.

Las ventosas no funcionarán si se

colocan sobre la costura de la película al

levantar o mover la unidad. La unidad se

caerá y provocará daños y lesiones.

Do not pivot panels on corners. Doing

so will result in product damage.

No gire los paneles en las esquinas.

De lo contrario, el producto se dañará.

Suction Cup

Ventosa

Film Seam

Costura de

la pelicula

Windows and doors can be heavy. Use

safe lifting techniques and a reasonable

number of people with enough strength

to lift, carry and install window and door

products to avoid injury and/or product

damage.

Las puertas y las ventanas pueden ser

pesadas. Utilice técnicas seguras de

levantamiento de peso y un número

razonable de personas con suciente

fuerza para levantar, cargar e instalar los

productos de puertas y ventanas, a n de

evitar lesiones y/o daños al producto.

3-Panel Door / Puerta de 3 paneles

2-Panel Door / Puerta de 2 paneles

View of panel

alignment sticker.

Vista de la etiqueta de

alineación del panel

CAUTION / PRECAUCIÓN

WARNING / ADVERTENCIAWARNING / ADVERTENCIA

9

9020095

2

Exterior

2-Panel Door / Puerta de 2 paneles

3-Panel Door / Puerta de 3 paneles

4-Panel Door / Puerta de 4 paneles

Correct

(in bracket)

Correcto

(en soporte)

Incorrect

(below bracket)

Incorrecto

(debajo del

soporte)

Slide panels as shown. An audible click is heard when panel retainers lock ush into bracket. Pull on panel to make sure panel retainer is engaged.

Deslice los paneles tal como se muestra. Cuando los dispositivos de retención del panel enganchan a ras en el soporte, se debe escuchar un clic.

Tire del panel para asegurarse de que el dispositivo de retención del panel esté enganchado.

Panel Retainer

Dispositivo de

retención del panel

Flush

A ras

1/2 Engaged

Acople medio

Slide toward jamb. Push

at center of panel to

prevent binding.

Deslice hacia la jamba.

Empuje desde el centro

del panel para evitar

que se atasque.

Slide toward jamb

Deslice hacia la jamba

Slide toward jamb

Deslice hacia la jamba

Slide left

(as viewed from exterior)

Lateral izquierdo

(visto desde el exterior)

Fully Engaged

Acople completo

Bracket

Soporte

3

Interior

4

Interior

10

9020095

Attach stationary panel ller cap.

Coloque el tapón de relleno del panel estacionario.

Stationary Panel Filler Cap

Tapón de relleno del panel

estacionario

Remove release liner. Position black plug on stationary panel ush with

panel edge and tight to head.

Retire el papel antiadherente Coloque el tapón negro en el panel

estacionario a ras con el borde del panel y ajuste a la cabecera.

Black Plug

Tapón negro

Release

Liner

Papel

antiadherente

Flush with

panel edge.

A ras con el

borde del

panel

Tight to head.

Ajuste a la

cabecera

Head

Cabecera

Panel

Panel

Position stationary panel interlock weatherstrip tight to stationary panel ller cap at bottom and ex into black plug at head jamb. Drill 1/16" holes,

3/8" deep using interlock weatherstrip as a guide and fasten using painted #7 x 5/8" screws.

Coloque el burlete de enganche del panel estacionario bien rme contra el tapón de relleno del panel estacionario en la parte inferior y dóblelo hacia

adentro del tapón negro en la jamba de cabecera. Taladre oricios de 3/8" de profundidad con una broca de 1/16" y utilice el burlete de enganche

como guía; ajuste con tornillos pintados n.º 7 x 5/8".

5

Interior

Stationary Panel Interlock Weatherstrip

Burlete de enganche del panel estacionario

Head Jamb / Jamba de cabecera

Sill / Riel

Black Plug

Tapón negro

1/16" Bit

Broca de 1/16"

#7 x 5/8"

Screws

Tornillos

No. 7 x 5/8"

Stationary Panel

Interlock

Weatherstrip

Burlete de

enganche del

panel

estacionario

Drill / Driver

Taladro / Destornillador

Stationary Panel

Filler Cap

Tapón de relleno

del panel

estacionario

Stationary Panel Interlock Weatherstrip

Burlete de enganche del panel estacionario

Make sure interlock

weatherstrip fits tight

to panel.

Asegúrese de que el

burlete de enganche

se ajuste bien al

panel.

11

9020095

6

78

12

9020095

Interior

Apply sealant along bottom of stationary panel interlock weatherstrip and ll security bracket rout with sealant. Slide security bracket into place and

secure using two #10 x 1" stainless steel screws.

Aplique sellador a lo largo de la parte inferior del burlete de enganche del panel estacionario y rellene la guía del soporte de seguridad con sellador.

Deslice el soporte de seguridad en su lugar y ajuste con dos tornillos n.º 10 x 1" de acero inoxidable.

Interior

Remove backing and attach security bracket dust pad next to security

bracket.

Retire la lámina protectora y coloque la almohadilla antipolvo para el

soporte de seguridad al lado de este.

Backing

Lámina

protectora

Security Bracket

Dust Pad

Almohadilla

antipolvo para el

soporte de seguridad

Interior

Apply sealant to stationary panel and jamb corner at end of weatherstrip.

Aplique sellador al panel estacionario y a la esquina de la jamba en el

extremo del burlete.

2- and 4-Panel Doors Only / Sólo puertas de 2 y 4 paneles

Reverse angles shown

Se muestran los ángulos inversos

#10 x 1" Stainless

Steel Screws

Tornillos de acero

inoxidable n.º 10 x 1"

Security Bracket

Soporte de

seguridad

Security Bracket

Soporte de seguridad

Security Bracket Dust Pad

Almohadilla antipolvo para el

soporte de seguridad

Weatherstrip

Burlete

Stationary Panel Interlock Weatherstrip

Burlete de enganche del panel estacionario

11

Exterior

13

9020095

Position operating panel trim ush with bottom of panel and attach

with nishing nails.

Coloque el contramarco del panel operativo a ras con la parte inferior

del panel y una con clavos de acabado.

10

Exterior

Remove backing and attach interlock weatherstrip head dust pad above

operating panel interlock weatherstrip.

Retire la lámina protectora y coloque la almohadilla antipolvo del burlete

de enganche arriba del burlete de enganche del panel operativo.

Operating Panel

Interlock

Weatherstrip

Burlete de enganche

del panel operativo

Interlock

Weatherstrip

Head Dust Pad

Almohadilla

antipolvo para

el cabezal del

burlete de

enganche

9

Exterior

Position operating panel interlock weatherstrip tight to dust pad. Drill 1/16" holes, 3/8" deep using interlock weatherstrip as a guide and fasten using

painted #7 x 5/8" screws.

Coloque el burlete de enganche del panel operativo bien rme con la almohadilla antipolvo. Taladre oricios de 3/8" de profundidad con una broca

de 1/16" y utilice el burlete de enganche como guía; ajuste con tornillos pintados n.º 7 x 5/8".

Operating Panel Interlock

Weatherstrip

Burlete de enganche del panel

operativo

Dust Pad

Almohadilla para polvo

#7 x 5/8" Screws

Tornillos No. 7 x 5/8"

1/16" Bit

Broca de 1/16"

Operating Panel Trim

Contramarco del panel

operativo

Flush

A ras

Operating Panel

Panel operativo

Nail Gun

Pistola de clavos

12

Interior

Position panel rollers on sill track and tip into frame. Slide panel closed.

Coloque los rodillos del panel en la guía del riel e incline el panel dentro del marco. Deslice el panel cerrado.

Support panel in frame at all times until secured in next step. Failure to do so

may result in panel falling out causing injury, property, and/or product damage.

Sostenga el panel en el marco todo el tiempo, hasta que se asegure en el

siguiente paso. De no hacerlo, el panel se puede caer y provocar lesiones, daños

al producto y/o a la propiedad.

Watershed

Cuenca

Watershed

Cuenca

Do not apply panel

weight on edge of

watershed.

No aplique el peso

del panel en el borde

de la cuenca.

Do not apply panel weight

on edge of watershed.

No aplique el peso del panel

en el borde de la cuenca.

13

Interior

14

Interior

Fasten head stop and bumper(s) using screws removed previously

during frame assembly.

Ajuste el tope de cabecera y los topes con los tornillos que retiró

previamente durante el ensamblaje del marco.

Insert end of head stop into operating side jamb and rotate into position.

Verify holes in head stop align with predrilled holes in head jamb.

Coloque el extremo del tope de cabecera dentro de la jamba lateral oper-

ativa y gírela en posición. Verique que los oricios en el tope de cabecera

estén alineados con los oricios pretaladrados de la jamba de cabecera.

Panel Bumper

Tope del panel

Head Stop

Tope de cabecera

Operating Panel

Panel operativo

Head Stop

Tope de cabecera

Aluminum portion

of head stop must

contact side jamb on

the operating panel

side of unit.

La parte de aluminio

del tope de cabecera

debe estar en

contacto con la jamba

lateral en el costado

del panel operativo

dela unidad.

Fasten through holes along

ridge in head stop.

Ajuste a través de los orificios

a lo largo de la saliente en el

tope de cabecera.

Do not fasten through larger

holes located toward exterior.

No ajuste a través de los

orificios más grandes ubicados

hacia el exterior.

14

9020095

WARNING / ADVERTENCIA NOTICE / AVISO

Washer and #10 x 3"

Gray Screws

(at eight center hole

locations)

Arandela y tornillos n.º

10x 3" de color gris

(en ocho ubicaciones de

orificios centrales)

15

Interior

Open operating panel and fasten head stop on operating side using

screws removed previously during frame assembly.

Abra el panel operativo y ajuste el tope de cabecera en el lado operativo

con los tornillos que retiró previamente durante el ensamblaje del marco.

Fasten through holes along

ridge in head stop.

Ajuste a través de los orificios

a lo largo de la saliente en el

tope de cabecera.

Do not fasten through larger

holes located toward exterior.

No ajuste a través de los

orificios más grandes

ubicados hacia el exterior.

2- and 3-Panel Doors Only

Sólo puertas de 2 y 3 paneles

18

16

Interior

2- and 3-Panel Doors / Puerta de 2 o 3 paneles 4-Panel Door / Puerta de 4 paneles

Shim near screw locations at head jamb and secure.

Coloque las cuñas cerca de las ubicaciones de la jamba de cabecera y asegure.

#10 x 3" Gray Screws

Tornillos No. 10 x 3"

de color gris

#10 x 3" Gray Screws

Tornillos No. 10 x 3"

de color gris

Shim

Cuña Shim

Cuña

Head stop screws fastened

in previous steps.

Los tornillos de tope de

cabecera se ajustaron en

los pasos anteriores.

15

9020095

17

Interior

Secure through head support bracket.

Asegure a través del soporte de apoyo de cabecera.

4-Panel Doors Only / Sólo para puertas de 4 paneles

#10 x 3" Stainless Steel Screws

Tornillos de acero inoxidable No. 10 x 3"

Head Support Bracket

Soporte de apoyo de cabecera

(shown from exterior)

(vista desde el exterior)

16

9020095

18

Exterior

Operating Door Panel

Panel operativo de la

puerta

Panel Astragal

Astrágalo del panel

Position astragal on edge of operating door panel, as shown, with veneer to the interior. Align astragal ush with top and bottom of panel, with exterior

side tight to door panel. Drill 1/8 holes, 1-1/2" deep, using astragal as a guide and fasten using #10x1-1/2" pan head screws.

Apply astragal fastener plugs at screw locations.

Coloque el astrágalo en el borde del panel operativo de la puerta, tal como se muestra, con la chapa hacia el interior. Alinee el astrágalo al ras con la

parte superior e inferior del panel, con el lateral exterior rme contra el panel de la puerta. Taladre oricios de 1-1/2" de profundidad con una broca

de 1/8" y utilice el astrágalo como guía; ajuste con tornillos de cabeza plana n.º 10 x 1-1/2". Coloque los tapones del sujetador del astrágalo en

las ubicaciones de los tornillos.

Astragal fastener plugs are small parts and,

if swallowed, could pose a choking hazard

to young children. Remove and dispose

of any loose or easily removed astragal

fastener plugs.

Los tapones del sujetador del astrágalo son

partes pequeñas que, en caso de ingesta,

pueden representar un riesgo de asxia

para niños pequeños. Retire y deseche

todos los tapones del sujetador del

astrágalo sueltos o que se puedan quitar

fácilmente.

Left Operating Door Panel

(as viewed from exterior)

Panel de puerta operativo

izquierdo

(visto desde el exterior)

4-Panel Door Only / Sólo para puerta de 4 paneles

1/8" Drill Bit

Broca para taladro

de 1/8"

#10 x 1-1/2"

Pan Head Screws

Tornillos de

cabeza plana

No. 10 x 1-1/2"

Astragal Fastener

Plugs

Tapones del

sujetador del

astrágalo

(shown not installed

for clarity)

(Se muestra no

instalado para

mayor claridad)

Astragal flush with top of panel.

Astrágalo al ras con la parte

superior del panel.

(as viewed from exterior)

(visto desde el exterior)

17

9020095

WARNING / ADVERTENCIA

15

19

Interior

Equal gap between

panel and side jamb

Igual espacio entre el

panel y la jamba lateral

Open operating panel slightly. Remove adjustment hole caps. Insert at blade screwdriver into sockets and turn clockwise to raise panel or counter-

clockwise to lower panel until gap is equal full length. Replace adjustment hole caps.

Abra ligeramente el panel operativo. Retire los tapones de oricios de ajuste. Coloque un destornillador de punta plana dentro del adaptador y gire

hacia la derecha para levantar el panel o hacia la izquierda para bajar el panel hasta que el espacio sea igual en todo el largo. Retire las tapas para

oricios de ajuste.

Adjustment hole caps are small parts. And if swallowed, could pose a choking hazard to young children. Remove and dispose of

any loose or easily removed adjustment hole caps. Replace adjustment hole caps after making adjustments.

Las tapas para oricios de ajuste son partes pequeñas que, en caso de ingesta, pueden representar un riesgo de asxia para

niños pequeños. Retire y deseche todas las tapas sueltas o que se puedan quitar fácilmente. Vuelva a colocar los tapones

después de realizar los ajustes.

Adjustment Hole Cap

Replace when

adjustment is

complete.

Tapón para

oricio de ajuste

Vuelva a colocarlo

cuando el ajuste esté

completo.

Raise

Para levantar

Lower

Para bajar

Flat Blade Screwdriver

Destornillador de punta

plana

20

Interior

Insert lock in operating panel with lock button on top.

Introduzca el cerrojo en el panel operativo con el botón del cerrojo en

la parte superior.

Operating Panel

Panel operativo

Lock Button on top

Botón del cerrojo

Lock

Cerrojo

Insert lock in operating panel with lock button on top and fasten

using two (2) #10 x 3" stainless steel screws.

Introduzca el cerrojo en el panel operativo con el botón del cerrojo

en la parte superior y fíjelo con dos (2) tornillo de acero inoxidable

No. 10 x 3"

Lock Button on top

Botón del cerrojo

18

9020095

WARNING / ADVERTENCIA

or/

o bien

#10 x 3"

Stainless

Steel Screws

Tornillo de

acero

inoxidable

No. 10 x 3"

Lock

Cerrojo

For Flush Mount Hardware/

Para herrajes de montaje embutido

For Reachout Lock Hardware/

Para herrajes de cerrojo de alcance

21 2- and 3-Panel Door / Puerta de 2 y 3 paneles

Apply panel receiver as shown for your specic door panel and hardware type.

Aplique el receptor de paneles tal como se muestra para su tipo especíco de herrajes y panel de la puerta.

Exterior View

Vista exterior

Interior View

Vista interior

#10-32 x 1-1/4"

Machine Screws

Tornillos para

metales

No. 10-32 x 1-1/4"

19

9020095

Bezel

Bisel

Receiver

Receptor

4-Panel Door / Puerta de 4 paneles

Insert receiver as shown.

Inserte el receptor como se muestra.

Assemble ush mount receiver

and bezel. Insert receiver/bezel

assembly and secure as shown.

Do not fully tighten screws.

Ensamble el receptor de montaje

embutido y el bisel. Inserte el

ensamble del receptor y bisel y

fíjelo como se muestra. No ajuste

completamente los tornillos.

For Flush Mount Hardware/

Para herrajes de montaje embutido

For Reachout Lock Hardware/

Para herrajes de cerrojo de alcance

#8-32 x 7/8"

Machine Screw

Tornillo para metales

No. 8-32 x 7/8"

Reverse Angle

Ángulo trasero

>TARGET< Area

(on top)

Área destinada

(en la parte

superior)

Jamb

Jamba

2 or 3-Panel

Reachout Lock Receiver

Receptor de bloqueo

de alcance de 2 o

3-paneles

Bezel

Bisel

Receiver

Receptor

Open edge

toward exterior

Borde abierto

hacia el

exterior

Astragal

Astrágalo

#10 x 3" Stainless

Steel Screws

Tornillo de acero

inoxidable

No. 10 x 3"

4-Panel

Flush Mount Receiver

Receptor de montaje

embutido de 4-panel

>TARGET< Area

(on top)

Área destinada

(en la parte

superior)

Astragal

Astrágalo

4-Panel

Reachout Lock Receiver

Receptor de bloqueo de

alcance de 4-panel

For Flush Mount Hardware/

Para herrajes de montaje embutido

For Reachout Lock Hardware/

Para herrajes de cerrojo de alcance

Jamb

Jamba

Reverse Angle

Ángulo trasero

2 or 3-Panel

Flush Mount Receiver

Receptor de montaje

embutido de 2 o

3-paneles

Insert receiver and secure

as shown. Do not fully

tighten screws.

Inserte el receptor y fíjelo

como se muestra. No

ajuste completamente los

tornillos.

Assemble ush mount receiver

and bezel. Insert receiver/bezel

assembly and secure as shown. Do

not fully tighten screws.

Ensamble el receptor de montaje

embutido y el bisel. Inserte el

ensamble del receptor y bisel y

fíjelo como se muestra. No ajuste

completamente los tornillos.

Retract lock hooks by turning lock adjustment screw counterclockwise 2 turns, then apply receiver position template into ush mount lock.

Retraiga los ganchos del cerrojo girando 2 vueltas en sentido contrario a las agujas del reloj el tornillo de ajuste del cerrojo y, a continuación,

aplique el Plantilla de posición del receptor en el cerrojo de montaje embutido.

20

9020095

vv

22

Interior

1 2

Receiver

Position

Template

Plantilla de

posición del

receptor

Flush Mount Lock

(with lock hooks

retracted)

Cerrojo de montaje

embutido

(con los ganchos de

cierre retraídos)

For Flush Mount Hardware ONLY

SOLO para herrajes de montaje embutido

Turn lock adjustment screw

counterclockwise 2 turns.

Gire 2 vueltas en sentido

contrario a las agujas del reloj el

tornillo de ajuste del bloqueo.

Insert receiver position

template into lock.

Inserte el plantilla de

posición del receptor en el

cerrojo.

/