Carlisle Smart Pumps EV2-30 Owner's manual

- Type

- Owner's manual

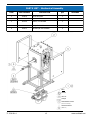

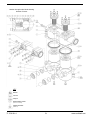

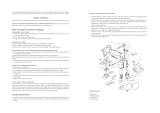

Carlisle Smart Pumps EV2-30 are great for use with solvent and water-based materials in hazardous areas such as Zone 1, with a protection level of Ex h IIB T4 Gb X (pump), II 2 G Exd/Exde IIB T4 IP55 (motor), and II 2 GD ck T4 (gearbox). They have a nominal pump stroke of 50mm, a maximum fluid pressure of 20bar, and a nominal flow volume per cycle of 0.75 l/m. Fluid output at 20 Hz is 7.5 l/m, and at 80 Hz is 30 l/m.

Carlisle Smart Pumps EV2-30 are great for use with solvent and water-based materials in hazardous areas such as Zone 1, with a protection level of Ex h IIB T4 Gb X (pump), II 2 G Exd/Exde IIB T4 IP55 (motor), and II 2 GD ck T4 (gearbox). They have a nominal pump stroke of 50mm, a maximum fluid pressure of 20bar, and a nominal flow volume per cycle of 0.75 l/m. Fluid output at 20 Hz is 7.5 l/m, and at 80 Hz is 30 l/m.

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

Carlisle Smart Pumps EV2-30 Owner's manual

- Type

- Owner's manual

Carlisle Smart Pumps EV2-30 are great for use with solvent and water-based materials in hazardous areas such as Zone 1, with a protection level of Ex h IIB T4 Gb X (pump), II 2 G Exd/Exde IIB T4 IP55 (motor), and II 2 GD ck T4 (gearbox). They have a nominal pump stroke of 50mm, a maximum fluid pressure of 20bar, and a nominal flow volume per cycle of 0.75 l/m. Fluid output at 20 Hz is 7.5 l/m, and at 80 Hz is 30 l/m.

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Carlisle IntelliSpray IS40 Owner's manual

-

Carlisle BINKS - Smart Pumps EV2-30 User manual

-

Carlisle Ransburg BINKS - CCV Valves User manual

-

Carlisle High Pressure Color Change Valve Owner's manual

-

Carlisle Maple 8/25 Pump Owner's manual

-

Carlisle 104019 User manual

-

Carlisle BINKS - Smart Pumps E2-60 User manual

-

Carlisle BINKS - Maple 7/15 PSP Pump User manual

-

Carlisle Gemini 2 55gal Drum Owner's manual

-

Carlisle BINKS - Smart Pump E2-15 User manual

Other documents

-

Global Industrial 293224 User manual

-

Macnaught L-BG18V User manual

Macnaught L-BG18V User manual

-

Binks Smart Pumps User manual

Binks Smart Pumps User manual

-

Binks Smart Pumps User manual

Binks Smart Pumps User manual

-

Northern Industrial Tools Please see replacement Item# 58082. 50:1 Grease Pump Owner's manual

Northern Industrial Tools Please see replacement Item# 58082. 50:1 Grease Pump Owner's manual

-

DESTACO CAMCO RNG Series User manual

DESTACO CAMCO RNG Series User manual

-

Binks E4-60 User manual

Binks E4-60 User manual

-

Macnaught K4-01 User manual

Macnaught K4-01 User manual

-

Binks DX200 3:1 Ratio Diaphragm Pump User manual

-

Lincoln 1882 Owner's manual