The GK1276/1296 series electric rim strikes are

surface mounted and designed to accommodate rim

exit devices with a Pullman latch. No cutting on the

frame is required for installation. These strikes are

field selectable for fail-safe or fail-secure mode and

operate on dual voltage 12/24 VDC. Available with

optional latch monitor.

Surface Installation

• For indoor use only

• The GK1276/1296 series are intended to be used with UL Listed

Exit Hardware.

• The GK1276/1296 series shall not impair the operation of panic

hardware mounted on the door.

UL Requirements

GK1276/1296 Series Electric Rim Strikes

Installation Instructions

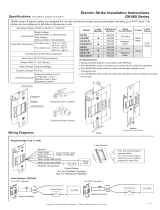

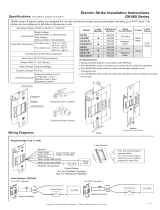

Specifications

Operating Voltage

Current Draw

Operating Temperature

Humidity

12/24VDC

0~85% non-condensing

540mA/12VDC, 270mA/24VDC

Static Strength

Lock Mode

Field selectable fail-safe

or fail-secure

1500 lbs (680Kg)

Dynamic Strength 70 ft-lbs

Endurance Rating

250,000 cycles (UL tested)

1,000,000 cycles (Factory tested)

14

°F to 120°F (-10°C~+49°C)

Model

GK1276

GK1276M

Performance Level

Destructive Attack: Level I

Line Security: Level I

Standby Power: Level I

Endurance: Level IV

Finish Brushed stainless steel (US32D)

• The GK1276/1296 series electric strikes are access control unit

accessories, intended to be controlled by an access control system. The

access control systems purpose is to provide a means for controlling the

locking and unlocking of external and internal doors of a premise.

Copyright © All rights reserved. P-MU-GK1276 Published on 2020.02.27

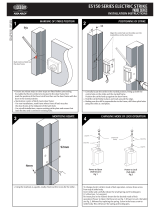

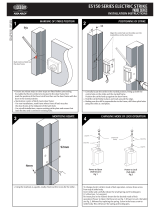

Measure 39 13/16”

(1011mm) up from

finished floor and mark

strike centerline on

door. Transfer

centerline to frame.

39

13

16

“

(1011mm)

1

2

3

Surface Installation (For Exit Device Already Installed)

Model GK1296 is used as example below.

Align strike on

centerline and mark

two slotted holes.

Drill holes and install

strike to frame.

Align template on

centerline and

against strike.

A

1

Cable

Access

Hole

3

2

A

4

5

Latch Position Line

a. Close the door and mark latch

position on the frame.

b. The latch position line will

correspond with the inside of strike

keeper as shown.

a. Position the strike on the frame

according to the marked latch

position.

b. Use the strike as a template; mark

and drill cable access hole and two

mounting holes.

c. Loosely mount the strike with

Phillips flat head screws.

a. Check latchbolt interaction and

adjust the strike horizontally until the

door latches properly.

b. Tighten the two mounting screws

and mark remaining screw holes.

Inside of

Strike Keeper

a. Remove the strike and drill holes.

b. Connect the wires.

c. Insert the blind nuts into the holes

and re-install the strike.

d. Add spacers to adjust the gap

between strike and exit device if

necessary.

e. Permanently secure the strike with

the hex socket cap screws into the

blind nuts.

a. Measure the exit device latch

position on the door.

GK1296

GK1296M

Frame Application Metal or Wood

Latch Throw

(Housing Thickness)

3/4" 1/2"

• Wiring methods shall be in accordance with NFPA 70.

Place the wire inside the connector and use pliers to press down on

the head of the connector evenly.

Latch Monitor (Option)

Contact Rating

Blue N.O.

Green COM.

Yellow N.C.

Wiring Diagrams

Control Device

Red

Black

Control Device

White

Black

(Polarity Insensitive)

(Polarity Insensitive)

Remove locking screw #1, loosen, slide and tighten sliding screw #2. Reinsert and tighten locking screw #1 to the desired fail-safe or fail-secure

setting.

Fail-Safe Fail-Secure

For 12VDC operation:

For 24VDC operation:

Copyright © All rights reserved. P-MU-GK1276 Published on 2020.02.27

Dimensions

Installing the Crimp Connectors

GK1276M: 1.5A/40VDC

GK1296M: 0.3A/6VDC

N.C. contact

for door closed

status

Changing Fail-Safe / Fail-Secure

GK1276

GK1296

Fail-Secure

Fail-Safe

GK1276 GK1276M GK1296(3) GK1296M(3)

8 1/4” (209.5mm)

6 7/16” (163mm)

1/8” (3.5mm)

(Model with Latch Monitor)

(Model with Latch Monitor)

N.O. contact for

door open status

Locking screw #1

Locking screw #1

Sliding screw #2

Sliding screw #2

9” (228.5mm)

1 1/2” (38.5mm)

(19mm)

3/4”

(44.5mm)

1 3/4”

9” (228.5mm)

1 1/2” (38.5mm)

(19mm)

3/4”

(44.5mm)

1 3/4”

(13mm)

1/2”

(44.5mm)

1

3/4”

(13mm)

1/2”

(44.5mm)

1

3/4”

9” (228.5mm)

1 1/2” (38.5mm)

9” (228.5mm)

1 1/2” (38.5mm)

GK1296M(2)GK1296(2)

9” (228.5mm)

9” (228.5mm)

1 1/2” (38.5mm)

(13mm)

1/2”

(44.5mm)

1

3/4”

(13mm)

1/2”

1 1/2” (38.5mm)

(44.5mm)

1

3/4”

-

1

1

-

2

2

Gianni Industries GK1276 Installation guide

- Type

- Installation guide

- This manual is also suitable for

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Gianni Industries GK1297 Installation guide

-

Gianni Industries GK1480 Series Installation guide

-

Gianni Industries GML880 Series User manual

-

Gianni Industries GML800 Installation guide

-

Gianni Industries GK1300 Series Installation guide

-

Gianni Industries GK1900 Installation guide

-

Gianni GK460 Series Installation guide

Gianni GK460 Series Installation guide

-

Gianni Industries GK850/GK851 Installation guide

-

Gianni Industries GK200 Installation guide

-

Gianni Industries GK236M Installation guide

Other documents

-

Cal-Royal ES1433 Grade 1 Universal Electric Strike User manual

-

Cal-Royal ES1520 Grade 1 No-Cut Electric Strike User manual

-

Lockwood ES150 Series Installation guide

Lockwood ES150 Series Installation guide

-

Von Duprin 6300 Installation guide

-

FSH FES15M Technical Manual

FSH FES15M Technical Manual

-

Cal-Royal CAL-ROYAL ES1140 Electric Strike and Accessories User manual

-

Cal-Royal LBM 185 Latch Monitor Switch User manual

-

BEA ELECTRIC STRIKES User guide

-

SECO-LARM SD-998C-D3AQ Owner's manual

-

SECO-LARM SD-998C-NUAQ Owner's manual