Page is loading ...

October

1974

FORM:

OM-1500

MODEL

STOCK

NO.

4880

CONTROL/FEEDER

.030

&

.035

hard

wire

078

026

.045

hard

wire

1/16

hard

wire

1/16

flux

cored

wire

078

029

5/64

flux

cored

wire

078

030

MODEL/STOCK

NO.

SERIAL/STYLE

NO.

DATE

PURCHASED

Effective

with

serial

No.

HE735320

078

027

078

028

OWNERS

MANUAL

AUTO

ARC

MILLER

ELECTRIC

MFG.

CO.

APPLETON,

WISCONSIN,

USA

54911

ADDITIONAL

COPY

PRICE

50

CENTS

NWSA

CODE

NO.

4579

~,s

~.

C

-

TABLE

OF

CONTENTS

Paragraph

No.

Page

No.

SECTION

1

INTRODUCTION

1

-1.

General

1

1

-

2.

Receiving-Handling

1

1

-

3.

Description

1

1:4.

Safety

1

SECTION

2

INSTALLATION

2-1.

Location

1

2-

2.

Shielding

Gas

Connections

1

2

-

3.

115

Volts

AC/Contactor

Control

Connections

1

2

-

4.

Gun

Switch

Receptacle

2

2

-

5.

Weld

Cable

Connections

2

2

-

6.

Electrode

Wire

Outlet

Connection

2

2

-

7.

Electrode

Wire

Inlet

&

Outlet

Guide

Installation

2

2

-

8.

Drive

Roll

Installation

3

2

-

9.

Upper

Drive

Roll

Alignment

3

2-10.

Hanging

Bail

Positioning

3

2-1

1.

Wire

Spool

Installation

4

2-12.

Welding

Wire

Threading

4

SECTION

3

FUNCTION

OF

CONTROLS

3

-

1.

Wire

Speed

Control

5

3

-

2.

Circuit

Breaker

5

3-3.

Purge

Switch

3

-

4.

Advance

Switch

5

3

-

5.

Burnback

Control

5

3-6.

PilotLight

5

SECTION

4

SEQUENCE

OF

OPERATION

4

-

1.

Gas

Metal-Arc

Welding

5

4

-

2.

Shutting

Down

5

SECTION

5

TROUBLESHOOTING

PARTS

LIST

SECTION

1

-

INTRODUCTION

Electrode

Wire

Dia.

Capability

Electrode

Wire

Feed

Speed

Control

Circuit

Voltage

At

Gun

Overall

Dimensions

(Inches)

Weight

(Pounds)

Net

Ship

Fraction

.030

-

5/64

50

to

700

ipm.

24

Volts

Height

-

21

Width

-

10

Depth

-

23

44

58

Figure

1-1.

Specifications

1

-1.

GENERAL

This

manual

has

been

prepared

especially

for

use

in

familiar

izing

personnel

with

the

design,

installation,

operation,

main

tenance,

and

troubleshooting

of

this

equipment.

All

informa

tion

presented

herein

should

be

given

careful

consideration

to

assure

optimum

performance

of

this

equipment.

1

-2.

RECEIVING-HANDLING

Prior

to

installing

this

equipment,

clean

all

packing

material

from

around

the

Unit

and

carefully

inspect

for

any

damage

that

may

have occurred

during

shipment.

Any

claims

for

loss

or

damage

that

may

have

occurred

in

transit

must

be

filed

by

the

purchaser

with

the

carrier.

A

copy

of

the

bill

of

lading

and

freight

bill

will

be

furnished

by

the

carrier

on

request

if

occasion

to

file

claim

arises.

When

requesting

information

concerning

this

equipment,

it is

essential

that

Model

Description

and/or

Stock

Number

and

Serial

(or

Style)

Number

of

the

equipment

be

Supplied.

1

-

3.

DESCRIPTION

This

control/feeder

is

of

the

constant

wire

feed

speed

type

and

is

designed

to

be

used

in

conjunction

with

a

constant

potential

welding

power

source.

The

control/feeder

is

a

heavy

duty

wire

feeding

unit

com

bining

both

the

wire

feeder

and

the

control

in

a

compact

assembly.

It

contains

all

the

controls

and

equipment

needed

to

supply

welding

wire

and

shielding

gas

to

the

welding

gun.

1

-4.

SAFETY

Caution

should

be

exercised

in

taking

voltage

measurements

when

troubleshooting

the

unit.

Always

avoid

contact

be

tween

any

part

of

the

human

body

and

any

current

carrying

part

of

the

control/feeder.

The

following

definitions

apply

to

CAUTION,

IMPORTANT,

and

NOTE

blocks

found

throughout

this

manual:

CAUTION

~Ilation,

operating,

and

maintenance

procedures,

practices,

etc.,

which

will

result

in

personnel

injury

or

loss

of

life

if

not

carefully

followed.

r~i

SECTION

2-

INSTALLATION

2-1.

LOCATION

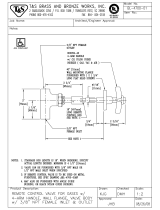

Refer

to

Figure

2-1

for

dimensional

information

on

the

con

trol/feeder.

Lead

lengths

must

be

considered

when

installing

the

control/feeder.

If

the

welding

power

source

can

be

located

near

the

work

area,

the

control/feeder

can

usually

be

installed

on

top

of

the

welding

power

source.

Suitable

space

should

be

allowed

for

making

necessary

connections.

N

Figure

2-1.

Control/Feeder

Dimensions

TC-078

027-3

2-2.

SHIELDING

GAS

CONNECTIONS

(Figure

3-1)

A

15

foot

hose

is

supplied

with

the

control/feeder

for

making

Connections

between

the

shielding

gas

source

and

the

con

trol/feeder.

Attach

the

end

of

the

gas

hose

with

the

quick

disconnect

connector

on

it

to

the

shielding

gas

connector

on

the

rear

panel

of

the

control/feeder.

Connect

the

opposite

end

of

the

gas

hose

to

the

shielding

gas

source.

The

connector

which

attaches

to

the

shielding

gas

source

has

left-hand

threading.

The

shielding

gas

hose

which

comes

from

the

gun

is

to

be

attached

to

the

shielding

gas

connector

on

the

front

panel

of

the

control/feeder.

This

connector

has

right-hand

threading.

2-3.

115

VOLTS

AC/CONTACTOR

CONTROL

CON

NECTIONS

(Figure

3-1)

The

115

volts

ac

input

power

cable

and

the

contactor

control

cable

are

both

attached

to

a

five-pole

female

plug.

This

five-

pole

plug

is

to

be

secured

into

the

five-pole

male

receptacle

on

the

rear

panel

of

the

control/feeder.

CAUTION

The

control/feeder

will

be

electrically

hot

internally

and

ready

to

operate

as

soon

as

she

115

volts

ac

plug

is

connected

to

the

115

volts

ac

source.

I

I

Installation,

operating,

and

maintenance

procedures,

practices,

etc.,

which

will

result

in

damage

to

equip

ment.

I

NOTE

Installation,

operating,

and

maintenance

procedures,

practices.

etc.,

which

it

is

essential

to

emphasize

OM-1500

Page

1

The

115

volts

ac

input

power

cable

can

be

distinguished

from

the

contactor

control

cable

(both

cables

being

10

feet

long)

by

the

three

leads

extending

from

the

115

volts

ac

cable.

The

115

volts

ac

cable

must

be

connected

to

an

outlet

which

is

capable

of

supplying

115

volts

60

hertz

electrical

power.

The

contactor

control

cable

has

two

leais

extending

from

it.

These

two

leads

are

to

be

connected

to

the

contactor

control

facility

on

the

welding

power

source.

con

jirc

jy

th

at

is

to

be

used

in

conjunction

with

this

control/feeder

must

be

of

the

type

that

operates

on

115

volts

60

Hertz

power.

This

is

necessary

because

the

control/feeder

will

supply

115

volts

ac

through

the

contactor

control

cable

whenever

the

gun

switch

is

closed.

2-4.

GUN

SWITCH

RECEPTACLE

(Figure

3-1)

A

four-prong

female

receptacle

is

provided

on

the

front

panel

of

the

control/feeder

for

connecting

the

gun

switch

plug

to

the

unit.

Ensure

that

the

securing

ring

on

the

gun

switch

plug

is

threaded

completely

onto

the

Gun

Switch

Receptacle.

2-5.

WELD

CABLE

CONNECTIONS

(Figure

3-1)

A

bolt

is

provided

on

the

front

of

the

drive

assembly

to

serve

as

a

junction

point

for

joining

together

the

weld

cables

from

the

welding

power

source

and

the

gun.

1 i

ii

Ensure

that

the

contacting

surfaces

of

the

weld

cable

terminals

are

kept

clean

at

all

times.

Also

ensure

that

the

bolt

on

this

terminal

is

secure.

If

either

one

of

the

above

conditions

is

not

met,

erratic

weld

current

could

result.

2

-

6.

ELECTRODE

WIRE

OUTLET

CONNECTION

(Fig

ure

3-1)

Proceed

as

follows

to

install

the

Electrode

Wire

Gun

Con

nector

into

the

drive

assembly

on

the

control/feeder:

1.

Rotate

the

Gun

Connector

Securing

Knob

in

a

counter

clockwise

direction

four

complete

turns.

2.

Insert

the

Electrode

Wire

Gun

Connector

fully

into

the

outlet

guide

hole

with

the

flat

side

of

the

connector

facing

the

roll

pin

inside

of

the

outlet

guide

hole.

3.

Rotate

the

Electrode

Wire

Gun

Connector

90

degrees

in

a

clockwise

direction.

4.

Rotate

the

Gun

Connector

Securing

Knob

as

far

as

it

will

turn

in

a

clockwise

direction.

J

2-7.

ELECTRODE

WIRE

INLET&

OUTLET

GUIDE

IN

STALLATION

(Figure

2-2)

1.

Loosen

the

outlet

guide

securing

screw

(item

8,

Figure

2-2).

2.

Insert

the

outlet

guide

(1)

(point

first)

into

the

outlet

guide

hole

in

the

drive

assembly.

3.

Install

the

Electrode

Wire

Gun

Connector

into

the

drive

assembly

as

instructed

in

item

2-6.

4.

Push

the

outlet

guide

(1)

into

the

drive

assembly

until

it

seats

against

the

Electrode

Wire

Gun

Connector.

5.

Tighten

the

outlet

guide

securing

screw

(8).

6.

Loosen

the

inlet

guide

securing

screw

(7).

7.

Insert

the

inlet

guide

(2)

point

first

into

the

inlet

guide

hole

until

the

flange

on

the

inlet

guide

(2)

seats

against

the

drive

assembly.

8.

Tighten

the

inlet

guide

securing

screw

(7).

Figure

2-2.

Drive

Roll

&

Wire

Guide

Installation

I I

I

Pressure

Adjustment

Knob

Pressure

Adjustment

Collar

Upper

Drive

Roll

Mounting

Bracket

2

Gun

Connector

Securing

Knob

6

TC-078

027-2

Page

2

2

-8.

DRIVE

ROLL

INSTALLATION

(Figure

2-2)

1.

Loosen

the

pressure

adjustment

knob

and

collar

and

pivot

the

pressure

adjustment

assembly

off

of

the

upper

drive

roll

mounting

bracket.

Swing

the

upper

drive

roll

mount

ing

bracket

up.

2.

Remove

the

two

thumb

screws

(6),

split

-

lock

washer

(5),

and

flat

washers

(4)

from

the

drive

roll

shafts.

NOTE

Prior

to

installing

the

lower

drive

roll,

ensure

that

the

supplied

key

is

in

the

groove

in

the

lower

drive

roll

shaft.

3.

Slide

the

keyed

drive

roll

(9)

onto

the

lower

drive

shaft.

4. Insert

a

split-lock

washer

(5)

and

flat

washer

(4)

onto

one

of

the

two

thumb

screws

(6)

and

install

the

thumb

screw

(6)

into

the

lower

drive

shaft.

5.

Slide

the

un-keyed

drive

roll

(3)

onto

the

upper

drive

roll

shaft.

6.

Insert

the

remaining

split-lock

washer

(5)

and

flat

washer

(4)

onto

thumb

screw

(6)

and

install

the

thumb

screw

(6)

into

the

upper

drive

roll

shaft.

7.

Lower

the

upper

drive

roll

mounting

bracket

until

the

teeth

in

the

upper

and

lower

drive

rolls

mesh

together.

I

NOTE~]

The

pressure

adjustment

knob

will

have

to

be

adjusted

for

proper

tension

prior

to

operation

of

the

control/

feeder.

The

amount

of

pressure

will

vary

from

one

given

set

of

welding

conditions

to

another

and

should

be

just

tight

enough

to

prevent

drive

roll

slippage

on

the

wire.

8.

Pivot

the

pressure

adjustment

assembly

upward

until

it

is

on

top

of

the

drive

roll

cover

and

then

tighten

the

collar

to

the

desired

amount

of

pressure.

Lock

the

setting

of

the

collar

by

rotating

the

knob

until

it

contacts

the

collar.

2

9.

UPPER

DRIVE

ROLL

ALIGNMENT

(Figure

2-3)

The

upper

drive

roll

mounting

bracket,

which

holds

the

upper

drive

roll,

can

be

moved

on

a

horizontal

plane

in

order

to

facilitate

alignment

of

the

groove

in

the

upper

drive

roll

with

respect

to

the

groove

in

the

lower

drive

roll.

The

upper

drive

roll

should

be

checked

for

proper

alignment

whenever

erratic

wire

feed

is

noted

or

whenever

the

drive

rolls

are

changed.

To

check

for

proper

alignment

of

the

upper

drive

roll,

remove

the

outlet

guide

and

look

into

the

outlet

guide

hole

in

the

drive

assembly.

Upon

viewing

the

groove

between

the

drive

rolls

it

should

be

noted

that

the

outer

edges

of

the

grooves

on

the

upper

and

lower

drive

rolls

should

be

precisely

aligned.

Figure

2-3

shows

examples

of

proper

and

improper

alignment.

If

the

drive

rolls

are

not

in

alignment,

proceed

as

follows

to

adjust

the

upper

drive

roll:

1.

Loosen

the

pressure

adjustment

collar

and

pivot

it

off

of

the

upper

drive

roll

mounting

bracket.

2.

Using

a

9/16

wrench,

loosen

the

outer

securing

bolt.

3.

Using

a

5/8

wrench,

rotate

the

adjustment

nut

as

required.

Rotating

the

adjustment

nut

clockwise

will

move

the

drive

roll

outward

and

counterclockwise

rota

tion

will

move

the

drive

roll

inward.

4.

When

proper

alignment

is

achieved,

tighten

the

outer

securing

bolt

to

lock

the

drive

roll

in

position.

5.

Pivot

the

pressure

adjustment

assembly

upward

until

it

is

on

top

of

the

upper

drive

roll

mounting

bracket

and

then

tighten

the

collar

to

the

desired

amount

of

pressure.

2-10.

HANGING

BAIL

POSITIONING

The

hangling

bail

supplied

with

this

control/feeder

has

two

positions

which

will

permit

the

control/feeder

to

be

sus

pended

in

either

a

horizontal

or

vertical

position.

The

hanging

bail

is

shipped

in

the

position

which

will

permit

the

control/feeder

to

be

suspended

vertically.

If

it

is

desired

to

suspend

the

control/feeder

horizontally,

procedd

as

follows:

Figure

2-3.

Upper

Drive

Roll

Alignment

Outlet

Guide

Hole

View

Counter-

Proper

Clockwise

clockwise

Alignment

Rotation

of

Rotation

of

Adjustment

Adjustment

Nut

Required

Nut

Required

TC-07g

027-2

U

U

Adjustment

Nut

Outer

Securing

Bolt

Drive

Roll

Grooves

OM~1500

Page

3

1.

Remove

the

two

9/16

bolts

from

the

rear

side

of

the

wire

spool

spindle

mounting

bracket.

2.

Tilt

the

hanging

bail

in

a

clockwise

direction

approxi

mately

60

degrees

or

until

the

two

mounting

holes

in

the

hanging

bail

come

into

view

through

the

two

holes

in

the

mounting

bracket

not

previously

used.

3.

Install

the

two

9/16

bolts

removed

in

step

1.

2-11.

WIRE

SPOOL

INSTALLATION

1.

Remove

the

retaining

ring

from

the

spindle

by

rotating

the

retaining

ring

in

a

counterclockwise

direction.

2.

Slide

the

spool

of

wire

onto

the

spindle

so

that

the

wire

will

pay

off

from

the

bottom

of

the

spool

in

a

clockwise

direction,

3.

Rotate

the

spool

until

the

hole

in

the

spool

hub

aligns

with

the

protruding

pin

in

the

flange

of

the

spindle.

Ensure

that

the

spool

is

seated

against

the

flange

of

the

spindle.

4.

Rotate

the

retaining

ring

onto

the

spindle

in

a

clockwise

direction

until

the

retaining

ring

is

seated

against

the

spool.

2-12.

WELDING

WIRE

THREADING

1.

Install

the

wire

spool

onto

the

spindle

as

instructed

in

item

2-11.

2.

Loosen

the

pressure

adjustment

collar

and

pivot

it

off

of

the

upper

drive

roll

mounting

bracket.

3.

Cut

off

any

portion

of

the

free

end

of

the

welding

wire

which

is

not

straight.

4.

Install

the

Electrode

Wire

Gun

Connector

at

explained

in

item

2-6.

5.

Check

the

upper

drive

roll

for

proper

alignment

as

instructed

in

item

2-9.

6.

Feed

the

welding

wire

into

the

inlet

guide

and

con

tinue

feeding

the

wire

into

the

outlet

guide.

Feed

approximately

four

inches

of

welding

wire

into

the

outlet

guide.

7.

Lower

the

upper

drive

roll

mounting

bracket

until

the

teeth

in

the

upper

and

lower

drive

rolls

mesh

together.

8.

Pivot

the

pressure

adjustment

assembly

upward

until

it

is

on

top

of

the

upper

drive

roIl

mounting

bracket.

Tighten

the

pressure

adjustment

collar

for

the

appro

ximate

amount

of

pressure

desired

on

the

drive

rolls.

Precise

adjustment

of

the

pressure

adjustment

assem

bly

will

have

to

be

made

when

welding

commences.

9.

Connect

the

115

Volts

AC

cable

from

the

control/

feeder

into

a

115

Volts

60

Hertz

source.

10.

Connect

the

Switch

Control

Plug

from

the

gun

into

the

Gun

Switch

Receptacle

on

the

control/feeder.

11.

Lay

the

gun

cable

out

straight.

12.

Depress

the

ADVANCE

Switch.

This

will

run

the

welding

wire

through

the

gun

without

placing

weld

current

on

the

welding

wire.

Release

the

ADVANCE

Switch

after

the

end

of

the

welding

wire

extends

approximately

one

inch

out

of

the

gun

tip.

SECTION

3

-

FUNCTION

OF

CONTROLS

Figure

3-1.

Control

Location

/

Shielding

Gas

In

Connector

Hanging

Bail

Wire

Spool

Spindle

Pressure

Adjustment

Knob

Pressure

Adjustment

Collar

Burnback

Control

weld

Cable

Bolt

Wire

Speed

Control

Circuit

Breaker

Pilot

Light

Gun

Switch

Receptacle

/5

Volts

AC/Contactor

Control

Receptacle

I-,

Gun

Connector

Securing

Knob

TC-078

027-1

Page

4

3-1.

WIRE

SPEED

CONTROL

(Figure

3-1)

The

Wire

Speed

Control

provides

a

means

of

determining

the

rate

at

which

welding

wire

will

be

fed

into

the

weld.

Rotating

the

Wire

Speed

Control

in

a

clockwise

direction

will

increase

the

rate

of

wire

feed.

When

the

Wire

Speed

Control

is

set

at

0,

wire

will

feed

at

a

rate

of

50

1PM;

when

set

at

10.

the

wire

will

feed

ata

rate

of

700

1PM.

3-2.

CIRCUIT

BREAKER

(Figure

3-1)

A

circuit

breaker,

located

on

the

rear

panel

of

the

control/

feeder,

provides

protection

to

the

control/feeder

circuitry.

In

the

event

the

motor

should

be

placed

in

an

overloaded

condi

tion,

the

breaker

would

trip

and

suspend

all

output.

Should

this

breaker

trip,

it

would

have

to

be

manually

depressed

to

reset.

3-3.

PURGE

SWITCH

(Figure

3-1)

The

PURGE

Switch,

located

on

the

front

panel

of

the

con

trol/feeder.

is

a

momentary

contact

switch.

This

switch

will

energize

the

shielding

gas

solenoid

and

purge

the

shielding

gas

line

of

the

gun.

It

also

allows

the

shielding

gas

regulator

to

be

adjusted

without

energizing

the

welding

circuit.

3

-

4.

ADVANCE

SWITCH

(Figure

3-1)

The

ADVANCE

Switch,

located

on

the

front

panel

of

the

control/feeder

is

a

spring

actuated

toggle

switch.

When

actuated

it

complates

the

circuit

to

the

motor

without

having

to

depress

the

gun

switch.

This

switch

will

permit

inching

or

threading

of

the

wire

at

whatever

setting

the

Wire

Speed

Control

is

at,

without

energizing

the

welding

power

source

contactor

or

the

gas

valve.

3-5.

BURNBACK

CONTROL

(Figure

3-1)

The

burnback

circuitry

in

this

control/feeder

provides

a

means

of

keeping

the

welding

wire

from

sticking

to

the

work-

piece

or

the

contact

tube

in

the

gun

after

the

gun

switch

is

released.

The

burnback

capability

in

this

control/feeder

will.

depending

upon

the

setting

of

the

BURNBACK

Control,

keep

weld

current

present

on

the

welding

wire

from

1/4

to

3/4

of

a

second

after

the

wire

has

stopped

feeding.

This

delay

action

will

permit

the

welding

wire

to

burn

back

to

a

point

where

it

will

neither

stick

to

the

workpiece

nor

the

contact

tube.

If

the

welding

wire

sticks

to

the

contact

tube

in

the

gun

after

the

gun

switch

is

released,

rotate

the

BURN

BACK

Con

trol

to

a

setting

closer

to

the

0

(1/4

second)

position.

If

the

welding

wire

sticks

to

the

workpiece

after

the

gun

switch

is

released,

rotate

the

BURNBACK

Control

to

a

setting

closer

to

the

10

(3/4

second)

position.

3-6.

PILOT

LIGHT

(Figure

3-1)

A

pilot

light

is

provided

on

the

front

panel

of

the

control/

feeder

to

indicate

when

the

unit

is

operational.

The

pilot

light

will

be

on

for

as

long

as

the

115

Volts

AC

plug

is

inserted

into

a

115

Volts

60

Hertz

source.

If

the

115

Volts

AC

plug

is

connected

to

a

115

volts

60

Hertz

source

and

the

pilot

light

is

not

lighted,

this

indicates

that

the

circuit

breaker

on

the

rear

panel

is

open.

SECTION

4

-

SEQUENCE

OF

OPERATION

4-

1.

GAS

METAL-ARC

WELDING

1.

Make

all

necessary

connections

as

instructed

in

Section

2

of

this

manual.

2.

Rotate

the

Wire

Speed

Control

to

the

desired

setting.

3.

Set

the

BURNBACK

Control

in

the

desired

position.

4.

Press

the

PURGE

Switch

for

10

seconds.

Prior

to

welding,

it is

imperative

that

proper

protective

clothing

(welding

coat

and

gloves)

and

eye

protection

(glasses

and/or

welding

helmet)

be

put

on.

Failure

to

comply

may

result

in

serious

or

permanent

bodily

damage.

5.

Depress

the

trigger

on

the

gun

handle.

Gas

will

start

to

flow

and

wire

will

start

to

feed

if

drive

roll

pressure

is

properly

adjusted

to

prevent

slippage.

If

wire

slippage

is

noticed,

tighten

the

pressure

adjustment

collar

1/2

turn

clockwise.

Repeat

until

slippage

stops.

Do

not

tighten

pressure

adjustment

collar

too

much.

CAUTION

The

welding

wire

and

all

metal

parts

in

contact

with

it

are

energized

while

welding.

Do

not

touch

the

welding

wire

or

any

metal

part

making

contact

with

it.

4-2.

SHUTTING

DOWN

1

.

Turn

off

the

shielding

gas

at

the

source.

2.

Remove

the

115

Volts

AC

cable

from

the

source.

3.

Turn

off

all

associated

equipment.

1.

SECTION

5-TROUBLESHOOTING

The

data

collected

here,

discusses

some

of

the

common

problems

which

may

occur

in

this

control/feeder.

The

assumption

of

this

data

is

that

a

proper

welding

condition

has

been

achieved

and

has

been

used

until

trouble

developed.

In

all

cases

of

equipment

malfunction,

the

hianufacturers

recommendations

should

be

strictly

adhered

to

and

followed.

If

after

performing

the

following

procedures

the

trouble

is

still

not

remedied,

it

is

recommended

that

a

serviceman be

called.

It

is

recommended

that

the

circuit

diagram

be

used

for

reference

during

troubleshooting.

TROUBLE

PROBABLE

CAUSE

REMEDY

Depressing

gun

switch

will

not

energize

control/feeder.

Electrode

wire

is

not

energized

and

shielding

gas

does

not

flow.

Circuit

breaker

tripped.

Manually

reset

circuit

breaker

by

depressing.

Plug

from

gun

switch

is

not

secure

in

Gun

Switch

Receptacle

on

control/feeder.

115

volt

ac

input

cable

is

not

secure

in

recep-

tacle.

Insert

plug

fully

into

Gun

Switch

Receptacle

and

tighten.

Secure

cable

leads

to

115

vac

receptacle.

~

OM-1500

Page

5

Figure

5-1.

Circuit

Diagram

Circuit

Diagram

No.

B-002

752

.1

p

Wire

feeds,

shielding

gas

flows,

but

electrode

wire

is

not

energized.

Contactor

Control

cable

leads

not

secure

on

contactor

plug

terminals.

Secure

leads

to

plug

terminals.

Defect

in

welding

power

source.

See

troubleshooting

section

in

welding

power

source

instruction

manual.

Wire

feeds

erratically.

Pressure

on

drive

rolls

is

insufficient.

Rotate

pressure

adjustment

knob

clockwise

in

1/4

turn

increments

until

wire

slippage

stops.

Drive

rolls

are

too

large

for

wire

size

being

used.

Change

to

proper

size

drive

roll

gear.

Worn

drive

roll.

Replace

drive

roll

gear.

See

section

2-8.

Dirt

in

drive

roll

groove.

Clean

drive

roll.

Motor

is

inoperative.

Worn

brushes.

Replace

motor

brushes.

~

Motor

plug

not

secure

in

receptacle.

Tighten

motor

plug.

Page

6

October

1974

FORM:

OM-1500

Effective

with

serial

No.

HE7

35320

MODEL

STOCK

NO.

4880

CONTROL/FEEDER

.030

&

.035

hard

wire

078 026

.045

hard

wire

078

027

1/16

hard

wire

078

028

1/16

flux

cored

wire

078

029

5/64

flux

cored

wire

078

030

AUTO

ARC

MILLER

ELECTRIC

MFG.

CO.

APPLETON,

WISCONSIN,

USA

54911

4

MODEL/STOCK

NO.

SERIAL/STYLE

NO.

DATE

PURCHASED

PARTS

LIST

NWSA

CODE

NO.

4579

Figure

A

Main

Assembly

TC-078

027

OM-iSGO

Page

1

Item

Factory

No.

Part

No.

Description

Quantity

Figure

A

Main

Assembly

1

075

314

MOTOR

&

DRIVE

ASSEMBLY

(See

Fig.

B

Page

4)

1

2

602

224

WASHER,

lock

-

steel

split

3/8

5

3

604

657

SCREW,

cap

-

steel

hex

hd

3/8-16

x

1-1/4

5

4

075446

BASE

1

5

075449

BAIL,hanging

1

6

074

932

SHAFT,

support

-

hub

1

7

075 158

HUB,

with

collar

(consisting

of)

1

8

075159

.HUB

1

9

074891

.COLLAR

1

10

075

152

WASHER,

flat

-

steel

keyed

1-1/64

ID

x

1-5/8

OD

1

11

075 510

WASHER,

steel

-

lock

split

1

inch

1

12

602

246

WASHER,

flat

-

steel

1/2

1

13

073

620

SCREW,

thumb

1/2.13

x

1

inch

1

14

605

336

SCREW,

self

tapping

round

hd

10-32

x

3/8

6

15

075 150

WASHER,

shoulder

-

nylon

3

16

010

910

WASHER,

fiat

-

steel

SAE

3/8

3

17

078

368

MODULE,

control

(See

Fig.

C

Page

6)

1

18

075

056

INSULATOR,

motor

&

drive

assembly

1

BE

SURE

TO

PROVIDE

STOCK,

MODEL,

AND

SERIAL

NUMBERS

WHEN

ORDERING

REPLACEMENT

PARTS.

OM-1500

Page

2

Page

3

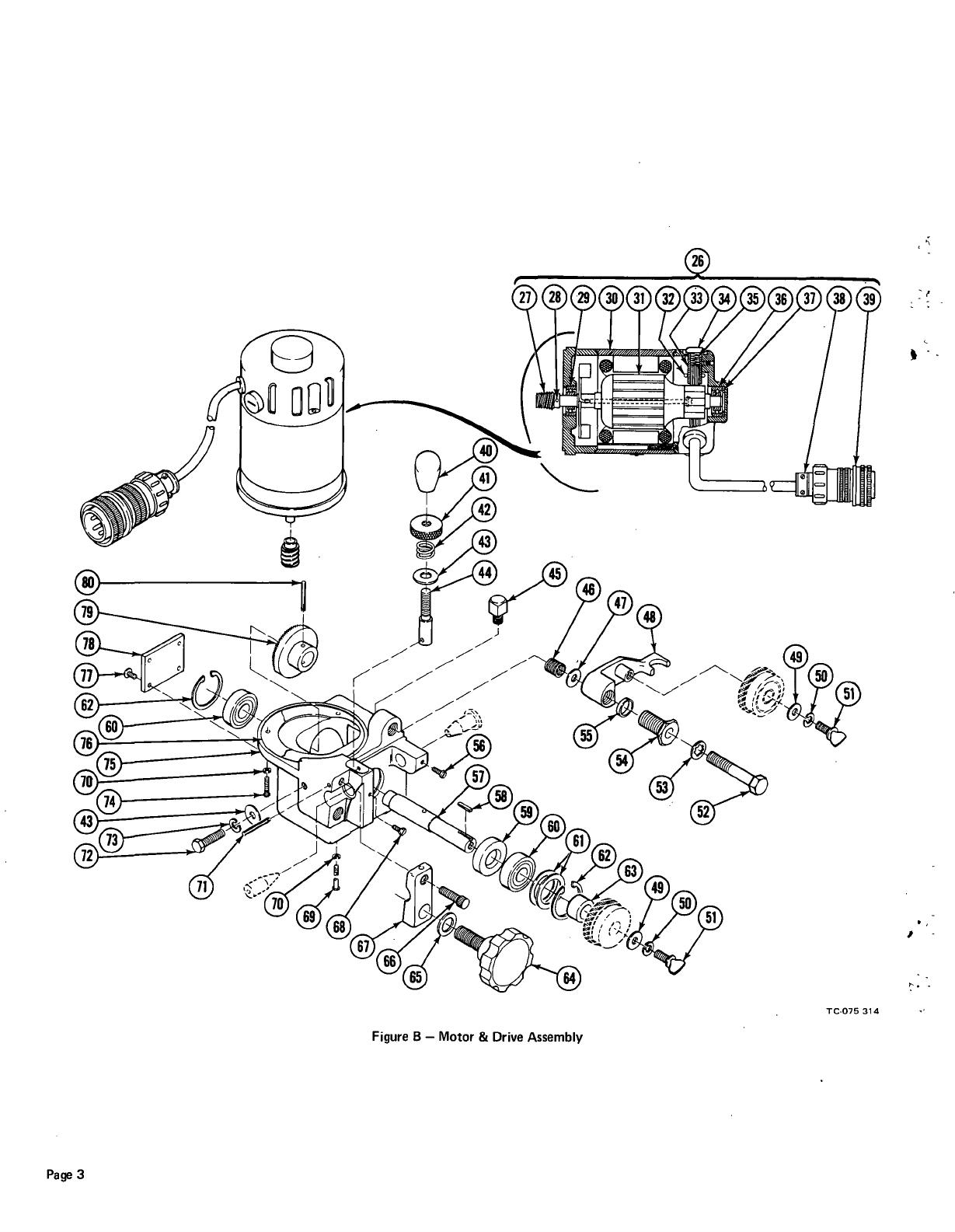

Figure

B

Motor

&

Drive

Assembly

TC-075

314

1

Item

No.

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

075

316

073 702

078

671

073

597

073

762

073

763

073

593

077

214

073

595

*073

591

073

596

075

069

073

296

073

264

073

696

074

911

073

514

602

243

075 057

077

318

073 334

010

910

074

905

604

538

602

211

073

707

605

209

602

221

074

811

074

865

075

532

075

058

056

068

073

309

073

268

073

774

073

240

074

859

073

694

075

099

602

008

079

256

075

553

078

685

078

687

078

672

601

965

602 213

078

686

075 305

073

703

078 462

074

776

073

701

010

224

*Recommended

Spare

Parts

BE

SURE

TO

PROVIDE

STOCK,

MODEL,

AND

SERIAL

NUMBERS

WHEN

ORDERING

REPLACEMENT

PARTS.

1

1

1

1

1

1

2

2

2

2

1

1

1

1

1

1

1

2

1

1

1

1

1

2

2

2

1

1

1

1

1

1

1

1

2

As

Reqd

2

1

1

1

1

1

1

2

3

1

1

1

1

1

1

4

1

1

1

Factory

Part

No.

Description

Quantity

Figure

B

075

314

Motor

&

Drive

Assembly

(See

Fig.

A

Page

2

Item

2)

MOTOR,

drive

(consisting

of)

GEAR,

miter

PIN,

spring

3/32

x

1/2

BEARING

FIELD

ASSEMBLY

ARMATURE

SPRING,

brushholder

HOLDER,

brush

CAP,

brushholder

BRUSH,

contact

BEARING

SHIM

CLAMP,

cable

amphenol

97-3057-12-6

PLUG,

amphenol

6

pin

97-3106A-20-17P

KNOB,

3/8-16

thread

COLLAR,

adjusting

-

tension

SPRING,

compression

WASHER,

flat

-

steel

3/8

FASTENER,

pin

BREATHER,

brass

-

pipe

vent

1/8

NPT

HELl

COIL,

(included

when

ordering

item

75)

WASHER,

flat

-

steel

SAE

3/8

LEVER,

mounting

-

drive

gear

WASHER,

flat

-

steel

SAE

5/16

WASHER,

lock

-

steel

split

5/16

SCREW,

thumb

5/16-18

x

1/2

SCREW,

cap

-

hex

hd

3/8-16

x

2-1/4

WASHER,

lock

-

steel

internal

tooth

3/8

BUSHING,

9/16-18

NF

x

1-5/16

lg

TUBING,

steel

5/8

OD

x

22

ga

x

7/32

SCREW,

pan

hd

1/4-20

x

1/2

SHAFT,

drive

KEY,

steel

1/8

x

1/8

x

1/2

SEAL,

oil

-

drive

shaft

BEARING,

ball

SHIM,

1-3/8

OD

xl

ID

x

.010

thick

RING,

retaining

-

external

TUBING,

steel

7/8

OD

x

9/16

ID

x

31/64

KNOB

WASHER,

steel

27/32

OD

x

17/32

ID

x

3/32

thick

SCREW,

cap

-

steel

socket

hd

1/2-20

x

1

CLAMP,

guide

(included

when

ordering

item

75)

SCREW,

pan

hd

1/4-20

x

5/8

SCREW,

round

hd

12-28

x

3

WASHER,

steel

-

lock

split

No.

12

PIN,

spring

3/16

x

7/8

SCREW,

cap

-

steel

hex

hd

3/8-16

x

1

WASHER,

steel

-

lock

split

3/8

SCREW,

round

hd

12-28

x

3/4

HOUSING,

drive

(includes

items

46

and

67)

GASKET,

motor

SCREW,

truss

hd

-

phillips

10-24

x

1/2

COVER,

bearing

GEAR,

drive

PIN,

spring

3/16

x

1

OM-1500

Page

4

Page

5

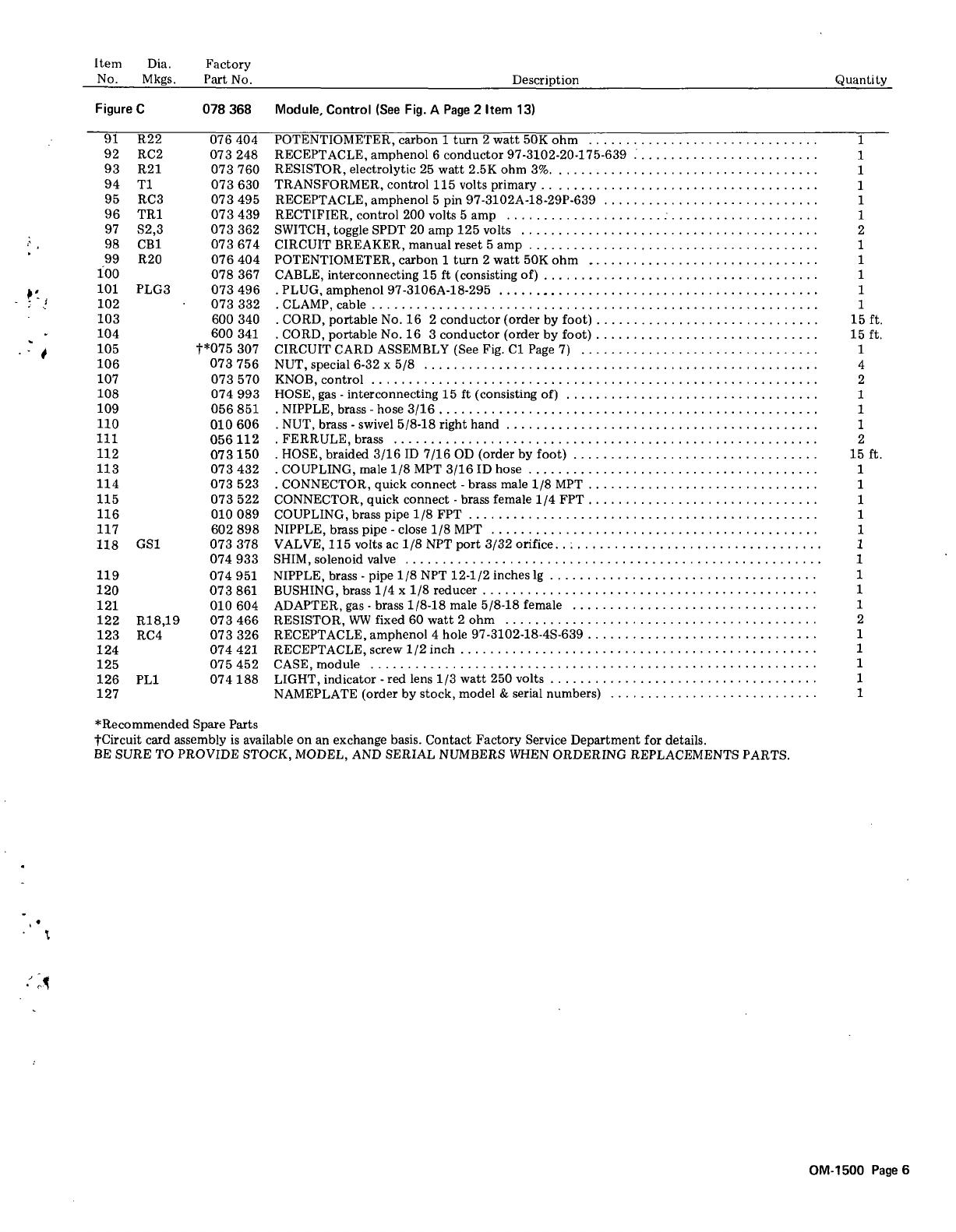

Figure

C

Module,

Control

TC-078

368

Item

Dia.

Factory

No.

Mkgs.

Part

No.

Description

Quantity

Figure

C

078

368

Module,

Control

(See

Fig.

A

Page

2 Item

13)

91

R22

076

404

POTENTIOMETER,

carbon

1

turn

2

watt

50K

ohm

1

92

RC2

073 248

RECEPTACLE,

amphenol

6

conductor

97-3102-20-175-639

1

93

R21

073

760

RESISTOR,

electrolytic

25

watt

2.5K

ohm

3%

1

94

Ti

073

630

TRANSFORMER,

control

115

volts

primary

1

95

RC3

073

495

RECEPTACLE,

amphenol

5

pin

97-3102A-18-29P-639

1

96

TR1

073

439

RECTIFIER,

control

200

volts

5

amp

1

97

S2,3

073

362

SWITCH,

toggle

SPDT

20

amp

125

volts

2

98

CB1

073

674

CIRCUIT

BREAKER,

manual

reset

5

amp

1

99

R20

076

404

POTENTIOMETER,

carbon

1

turn

2

watt

50K

ohm

1

100

078

367

CABLE,

interconnecting

15

ft

(consisting

of)

1

101

PLG3

073

496

.

PLUG,

amphenol

97-3106A-18-295

1

102

073

332

-

CLAMP,

cable

1

103

600 340

-

CORD,

portable

No.

16

2

conductor

(order

by

foot)

15

ft.

104

600

341

.

CORD,

portable

No.

16

3

conductor

(order

by

foot)

15

ft.

105

t*075

307

CIRCUIT

CARD

ASSEMBLY

(See

Fig.

Cl

Page

7)

1

106

073

756

NUT,

special

6-32

x

5/S

4

107

073

570

KNOB,

control

2

108

074

993

HOSE,

gas

-

interconnecting

15

ft

(consisting

of)

1

109

056

851

-

NIPPLE,

brass

-

hose

3/16

1

110

010

606

.

NUT,

brass

-

swivel

5/8-18

right

hand

1

111

056

112

.

FERRULE,

brass

2

112

073

150

-

HOSE,

braided

3/16

ID

7/16

OD

(order

by

foot)

15

ft.

113

073

432

-

COUPLING,

male

1/8

MPT

3/16

ID

hose

1

114

073

523

-

CONNECTOR,

quick

connect

-

brass

male

1/8

MPT

1

115

073

522

CONNECTOR,

quick

connect

-

brass

female

1/4

FPT

1

116

010

089

COUPLING,

brass

pipe

1/8

FPT

1

117

602

898

NIPPLE,

brass

pipe

-

close

1/8

MPT

1

118

GS1

073

378

VALVE,

115

volts

ac

1/8

NPT

port

3/32

orifice

1

074

933

SHIM,

solenoid

valve

1

119

074

951

NIPPLE,

brass

-

pipe

1/8

NPT

12-1/2

inches

lg

1

120

073

861

BUSHING,

brass

1/4

x

1/8

reducer

1

121

010

604

ADAPTER,

gas

-

brass

1/8-18

male

5/8-18

female

1

122

R18,19

073

466

RESISTOR,

WW

fixed

60

watt

2

ohm

2

123

RC4

073

326

RECEPTACLE,

amphenol

4

hole

97-3102-18-4S-639

1

124 074

421

RECEPTACLE,

screw

1/2

inch

1

125

075452

CASE,module

1

126

PL1

074

188

LIGHT,

indicator

-

red

lens

1/3

watt

250

volts

1

127

NAMEPLATE

(order

by

stock,

model

&

serial

numbers)

1

*Recommended

Spare

Parts

tCircuit

card

assembly

is

available

on

an

exchange

basis.

Contact

Factory

Service

Department

for

details.

BE

SURE

TO

PROVIDE

STOCK,

MODEL,

AND

SERIAL

NUMBERS

WHEN

ORDERING

REPLACEMENTS

PARTS.

OM-1500

Page

6

Cl

C2

C3,6

C4

C5

C7

C8

C9

CAL

Q1

Q2

Q3

Q4

Q5

Q6

Q7

R1,8,i0

R3

R4

R5

,1

2

R6,9

R7,i1

Ri

4

R15

Ri

6

REC1,16

REC2,11

REC3

REC4

REC5,6,12,13

REC7,9

REC8

REC1O

REC14

REC15

T2,4

T3

074

201

074

197

073

549

073

460

073

453

073

547

073 714

073

740

See

Note+

073

710

073

789

605

841

077

190

073

712

073

529

073

791

605

918

074

041

605

912

605

911

074

039

074

110

074

026

074

043

074 042

073 539

037

250

073

560

074

246

073

551

073 555

074

453

022 073

037 243

037

095

073

684

073

683

073 946

074

509

Figure

Cl

Circuit

Card

Assembly

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

3

1

1

2

2

2

1

1

1

2

2

1

1

4

2

1

1

1

1

2

1

1

1

TA.075

307

/

+Resistors

labeled

CAL

on

the

circuit

card

assembly

are

used

to

compensate

for

variations

in

other

circuit

card

component

tolerances.

The

value

of

these

resistors

may

vary

from

circuit

card

to

circuit

card.

If

replacement

is

necessary,

be

sure

a

resistor

of

identical

value

is

used.

If

the

resistor

value

is

indistinguishable,

contact

the

Factory

Service

Department.

BE

SURE

TO

PROVIDE

STOCK,

MODEL,

AND

SERIAL

NUMBERS

WHEN

ORDERING

REPLACEMENT

PARTS.

Dia.

Factory

Mkgs.

Part

No.

Description

Quantity

Figure

Cl

075

307

Circuit

Card

Assembly

(See

Fig.

C

Page

6

Item

105)

CAPACITOR,

mylar

0.1

Ut

4(30

volts

dc

CAPACITOR,

mylar

0.047

uf

100

volts

dc

CAPACITOR,

mylar

0.015

uf

200

volts

dc

CAPACITOR,

electrolytic

2

uf

50

volts

dc

CAPACITOR,

electrolytic

10

uf

150

volts

dc

CAPACITOR,

mylar

0.33

uf

200

volts

dc

CAPACITOR,

tantalum

0.22

uf

35

volts

dc

CAPACITOR,

ceramic

.01

uf

50

volts

TRANSISTOR,

6

amp

200

volts

DIODE,

10

amp

10

volts

THYRISTOR,

6

amp

500

volts

THYRISTOR,

7

amp

200

volts

THYRISTOR,

ac

TRANSISTOR,

unijunction

THYRISTOR,

35

amp

200

volts

RESISTOR,

carbon

0.25

watt

100

ohm

RESISTOR,

carbon

0.25

watt

47K

ohm

RESISTOR,

carbon

0.25

watt

4700

ohm

RESISTOR,

carbon

0.25

watt

10K

ohm

RESISTOR,

carbon

0.25

watt

27K

ohm

RESISTOR,

carbon

1

watt

10K

ohm

RESISTOR,

carbon

0.25

watt

150

ohm

RESISTOR,

carbon

0.25

watt

lOOK

ohm

RESISTOR,

carbon

0.25

watt

82K

ohm

DIODE,

diac

DIODE,

zener

25

volts

1

watt

DIODE,

1

amp

400

volts

DIODE,

zener

75

volts

1

watt

DIODE,

1

amp

600

volts

DIODE,

1

amp

400

volts

RECTIFIER,

integrated

1

amp

600

volts

RECTIFIER,

integrated

18.5

amp

600

volts

DIODE,

zener

18

volts

1

watt

DIODE,

15

amp

200

volts

straight

polarity

TRANSFORMER,

pulse

1

to

1

TRANSFORMER

BLOCK,

terminal

15

amp

16

pole

PRINTED

WIRING

BOARD

Page

7

I

Figure

D

Wire

Guide

and

Drive

Gear

Assembly

TC-076

195

WIRE

GUIDE

INLET

UPPER

DRIVE

GEAR

LOWER

WIRE

GUIDE

GEAR,

DRIVE

OUTLET

OM-1500

Page

8

/