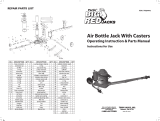

14

PARTS LIST - FULL

Ref. No. Description Ref. No. Description Kit Reference Kit Reference

1. Saddle Pad 49. Ball A I

2. Saddle Bolt 50. Release Valve Assy Contact SIP F

3. Saddle 51. ‘O’ Ring Contact SIP F / I

4. Radius Link 52. Ball Contact SIP F / I

5. Snap Ring 53. Guard Screw Contact SIP Contact SIP

6. Lifting Arm Assembly 54. ‘O’ Ring Contact SIP I

7. Retainer 55. Screw Safety Valve Contact SIP Contact SIP

8. Spring 56. Spring Contact SIP Contact SIP

9. Front Wheel 57. Valve B Contact SIP

10. Washer 58. Ball B I

11. Snap Ring 59. Bolt B Contact SIP

12. Front Axle 60. Back-Up Washer Contact SIP I

13. Lock Washer 61. ‘O’ Ring Contact SIP I

14. Cap Nut 62. Spring Contact SIP Contact SIP

15. Frame Tie Rod 63. Pump Piston Contact SIP G

16. Radius Link Stud 64. ‘O’ Ring Contact SIP G / I

17. Lock Washer 65. Pump Contact SIP G

18. Cap Nut 66. Washer Contact SIP G / I

19. Lock Washer 67. Pump Core Rest Spring C G

20. Cup-Head Bolt 68. Spring Sleeve Contact SIP G

21. Left Plate Assembly 69. Spring Stop Sheet Contact SIP G

22. Right Plate Assembly 70. Snap Ring Contact SIP G

23. Cap Nut 71. Pump Piston C H

24. Bearings 72. Back-Up Washer C / D H / I

25. Rear Caster Assembly C 73. ‘O’ Ring H / I

26. Lock Washer Contact SIP 74. Pump H

27. Nut Contact SIP 75. Back-Up Washer H

28. Lock Washer Contact SIP 76. ‘O’ Ring H / I

29. Handle Sleeve Bolt Contact SIP 77. Washer H / I

30. Frame Tie Rod Contact SIP 78. Pump Core Rest Spring H

31. Trestle Table Contact SIP 79. Spring Sleeve H

32. Magnetic Rubber Pad Contact SIP 80. Spring Stop Sheet H

33. Ram Plunger Contact SIP 81. Snap Ring H

34. Bushing Cover I 82. Filter I

35. Back-Up Washer I 83. Washer I

36. Y-Cup Seal I 84. Bolt Contact SIP

37. Snap Ring Contact SIP 85. Lock Washer Contact SIP

38. Top Nut Contact SIP 86. Washer Contact SIP

39. ‘O’ Ring I 87. Handle Base Contact SIP

40. Wedge I 88. Pin Contact SIP

41. Reservoir Contact SIP 89. Roller Contact SIP

42. Cylinder Contact SIP 90. Bolt Contact SIP

43. Back-Up Washer I 91. Environmental Protection Foam E

44. ‘O’ Ring I 92. Handle-Ⅰ E

45. Oil Seal I 93. Handle Lock Button E

46. Throttle Valve I 94. Handle-ⅡE

47. Spring I 95. Handle Grip E

48. Base Contact SIP 96. Hook E