Page is loading ...

Gelcoat Shower and Tub Shower

Installation Instructions

Thank you for purchasing Praxis Bathware. For best

results, please read and follow all directions carefully.

PRE-INSTALLATION PLANNING

1. Please do not store units out of doors.- Keep out of

sunlight and exposure to weather.

2. Review

Figures 1, 2 and 3 to make sure alcove

materials. Fire rated materials must be installed prior to

unit installation.

3.

Access to drain and supply connections should be

provided so that these connections may bemade after

the unit has been installed. Inside dimensions of framing

permit installation.Framing must be solidly fastened to

4. Each manufactured unit is made with the intent of

being shimmed upon installation. This compensates for

any settling or slope that may have occured at the job

inside a plastic bag.The shims need to be placed under

the unit after it is put into place and is being leveled.

INSTALLATION PROCEDURE

1. Make certain your stud framing alcove is sized

correctly and is square and plumb. You may prefer to

complete framing of the back wall and the plumbing end

wall then frame out theopposite end wall after the unit

has been set.

2. Finish rough plumbing, but leave unstrapped at

this stage. Find drain line and trap locations as shown

in the applicable Framing Diagram. Refer to Framing

permit clearance and allow connection of the drain

assembly.

3. Locate supply lines for mixing valves, spout, and

shower. The shower head may be positioned through the

Tools you might need for proper installation

• Galvanized Nails or Screws

• Large Level

• Hammer or Screw Gun

• Shims

• Adhesive

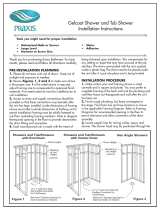

Blocking

at Unit

Height.

(optional)

Figure 1

14”

14”

7”

7”

Figure 2

Room Height.

Blocking at

Unit Height.

(optional)

14” x 7” Cutout For Drain And

Overflow Connection For

Tub/Showers.

Minimum 6” Diameter Opening For

Drain Connection on Showers

Showers and Tub/Showers

with Center Drain

Showers and Tub/Showers

with End Drain

Room Height.

Neo Angle Showers

14” x 7” Cutout For Drain

And Overflow Connection

For Tub/Showers.

Minimum 6” Diameter Opening For

Drain Connection on Showers

Figure 3

Gelcoat Shower and Tub Shower

Installation Instructions

CARE AND CLEANING

Do not use caustic or abrasive cleaners on the unit.

Avoid harsh abrasive or gritty scouring powders.To

clean the unit, simply use a household liquid detergent

with a soft sponge or cloth and warm water. More

persistent stains,tar, or paint can be removed with

mineral spirits. Remove excess plaster by scraping with

a sharpened soft wood stick. Avoid wire brushes, metal

scrapers or tools. Restore dull areas by rubbing with an

automotive type body cleaning compound.

wall of the unit or in the wall above. Measure and mark

using the appropriate size hole saw.

4.

on unit according to the manufacturers instructions. Apply

a bead of silicone caulk, or plumber’s putty around the

5. Now move unit into place. Position the unit at

the open end of the framed pocket. Align the lower edge

of the apron in approximate position and tilt back into

place.

6. Plumb and level the unit in two directions: Place

a level on top of the apron or shower dam and along

provided shims under the unit as described the Pre-

Installation Planning section.

7. Place shims under the unit after it is put into place and

as it is being leveled. Apply an adhesive to the bottom

of each shim to permanenty secure into place. To ensure

shims must be used on each unit. See Figure 4 for

additional details.

8. If there is any space between the bottom of the apron

leveling compound.

9. Mount unit to framing with 6d galvanized nails

vertically, and to all studs horizontally. Drilling holes for

fasteners is recommended.

10. Make connections to supply and drain lines. Strap all

.

11. Install wallboard along unit. Wallboard should

mounting screws or nails. See Figure 5

CAUTION

Use of a RUBBER FLOOR MAT is not recommended,

however, if you choose to do so, please remove after each

use and dry both the mat and the unit. Use of a

rubber

void your warranty.

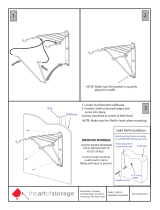

Support Wedges

Place Support Wedges

Figure 4

Place the shims under the bottom back edge of

the unit after it is put into place and leveled.

Apply an adhesive to the bottom of each shim to

permanenty secure it in place. A minimum of two

shims must be used on each unit to ensure

proper support and a solid base.

Wallboard

Small Gap

Apply Caulking

Framing

Studs

Install and Finish Wall Board

Shower Wall

Fasteners

At Studs

Figure 5

Install wallboard so it covers the mounting flanges of

the bathing unit. Leave a small gap between the

finished surface of the bathing unit and edge of the

e gap.ht llif ot gnikluac ylppA .draob llaw

Fasten wallboard to framing studs. Tape seams and

finish wall board as typical.

Praxis Companies LLC

435 Industrial Road I Savannah, Tennessee 38372 I Tel: (800) 443 7269 I Fax: (731) 925 0379

www.praxiscompanies.com

Praxis Companies, LLC Copyright 2010 PN /0410/GCG

www.ellasbubbles.com

10/12/16 Rev.1.0

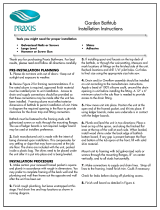

INSTALLATION INSTRUCTIONS

SU-2062-5570-11-40

SU-2062-5570-25-40

1

This product is heavy and may require two people to install.

1/4"

1/8"

5/16"

Inspect the product immediately upon receipt for transit damage, missing packs/parts or

manufacturing fault. Damage reported later will not be accepted. Handle the product with care

avoiding knocks and shock loading to all sides and edges of the glass.

Read these instructions carefully before start of installation.

Special care should be taken when drilling walls to avoid hidden pipes or electrical cables.

Note: This product is heavy and may require two people to install.

After use, your shower should be cleaned with soap and water. This is particularly important in hard

water districts where insoluble lime salts maybe deposited and allowed to build up. Cleaners of a

gritty or abrasive nature should not be used. Care should be taken to avoid contact with strong

chemicals, they can be used but with caution, if in doubt contact the manufacturer of the cleaner in

question.

Keep these instructions for aftercare and customer service details.

2

Assembly Drawing

1

2

3

1pc

2pcs

2pcs

Wall Jambs

Door Panels

Bottom Horizontal Rail

PACKING LIST

PART #

Q’TY

DESCRIPTION

PART #

Q’TY

DESCRIPTION

1pc

4sets

Screw M4x3/8"

Screws ST4x1 3/8"

9

10

2pcs

6pcs

6

8

4

5

7

6sets

1set

1pc

Top Horizontal Rail

Bumper Blocks x 6

Stopper Blocks x 6

11

15

14

16

13

12

6pcs

1pc

2pcs

2pcs

6pcs

10pcs

Wall Plugs

Knob

Screw ST4x9/16"

Screw nut

Washers

Screw Caps

Bottom Guide

Roller Bracket Assembly

Towel Bar

4

6

12

12

16

8

9

10

10

11

11

12

13

1

2

3

3

13

12

2

14

5

5

7

15

3

Installation Steps

Step 1

Step 2

B

A

A

Measure the bottom rail with a tape

measure. Cut the length according to

installer's recommendation.

B

1

4

Measure the top rail with a tape

measure. Cut the length according to

installer's recommendation.

SIDE VIEW

1/4"

A B

1

3

11

10

12

5

13

Screw

ST4x1 3/8"

B

B

A

4

Step 3

Step 4

1/8"

4

3

A

9

12

17

SIDE VIEW

A

A

A

B

8

15

7

2

2

15

C

C

C

7

5

Step 5

Step 6

A1 A2

8

4

SIDE VIEW

Screw

ST4x9/16"

A

6

12

14

A1

A2

A

6

Step 7

24

HOURS

/