Page is loading ...

O P E R A T I N G I N S T R U C T I O N S

L25

Single-beam photoelectric safety switch

Described product

L25

Manufacturer

SIC

K AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal information

T

his work is protected by copyright. Any rights derived from the copyright shall be

reserved for SICK AG. Reproduction of this document or parts of this document is only

permissible within the limits of the legal determination of Copyright Law. Any modifica‐

tion, abridgment or translation of this document is prohibited without the express writ‐

ten permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

T

his document is an original document of SICK AG.

2

O P E R A T I N G I N S T R U C T I O N S | L25 8024678/17VH/2020-06-10 | SICK

Subject to change without notice

Contents

1 About this document........................................................................ 5

1.1 Purpose of this document........................................................................ 5

1.2 Scope......................................................................................................... 5

1.3 Target groups of these operating instructions........................................ 5

1.4 Additional information.............................................................................. 5

1.5 Symbols and document conventions...................................................... 6

2 Safety information............................................................................ 7

2.1 General safety notes................................................................................ 7

2.2 Intended use............................................................................................. 7

2.3 Improper use............................................................................................. 7

2.4 Requirements for the qualification of personnel.................................... 8

3 Product description........................................................................... 9

3.1 Structure and function............................................................................. 9

3.2 Product characteristics............................................................................ 9

3.2.1 Device overview....................................................................... 9

3.2.2 Alignment aid (BluePilot)......................................................... 9

3.2.3 Test input.................................................................................. 10

3.2.4 Cascading................................................................................. 10

3.2.5 Application diagnostic output................................................. 10

3.2.6 IO-Link...................................................................................... 10

4 Project planning................................................................................ 11

4.1 Manufacturer of the machine.................................................................. 11

4.2 Operating entity of the machine.............................................................. 11

4.3 Design........................................................................................................ 11

4.3.1 Minimum distance from the hazardous point....................... 12

4.3.2 Minimum distance from reflective surfaces.......................... 14

4.3.3 Protection against interference from systems in close prox‐

imit

y to each other................................................................... 16

4.4 Integration in the electrical control system............................................. 16

4.4.1 Switching outputs.................................................................... 16

4.4.2 Test input.................................................................................. 17

4.4.3 Cascading................................................................................. 18

4.4.4 Application diagnostic output................................................. 18

4.4.5 IO-Link...................................................................................... 19

4.4.6 Connection diagrams.............................................................. 20

4.5 Testing plan............................................................................................... 22

4.5.1 Test rod check.......................................................................... 23

4.5.2 Visual check of the machine and the protective device........ 24

5 Mounting............................................................................................. 25

5.1 Safety......................................................................................................... 25

CONTENTS

8024678/17VH/2020-06-10 | SICK O P E R A T I N G I N S T R U C T I O N S | L25

3

Subject to change without notice

5.2 Unpacking.................................................................................................. 25

5.3 Mounting................................................................................................... 26

6 Electrical installation........................................................................ 27

6.1 Safety......................................................................................................... 27

6.2 System connection (M12, 4-pin)............................................................. 27

7 Commissioning.................................................................................. 29

7.1 Safety......................................................................................................... 29

7.2 Overview.................................................................................................... 29

7.3 Switching on.............................................................................................. 29

7.4 Alignment of the sender and receiver..................................................... 30

7.4.1 Aligning the sender and receiver............................................ 30

7.5 Check during commissioning and modifications.................................... 31

8 Operation............................................................................................ 32

8.1 Safety......................................................................................................... 32

8.2 Regular thorough check........................................................................... 32

9 Maintenance...................................................................................... 33

9.1 Safety......................................................................................................... 33

9.2 Regular cleaning....................................................................................... 33

9.3 Regular thorough check........................................................................... 34

10 Troubleshooting................................................................................. 35

10.1 Safety......................................................................................................... 35

11 Decommissioning............................................................................. 37

11.1 Disposal..................................................................................................... 37

12 Technical data.................................................................................... 38

12.1 Data sheet................................................................................................. 38

12.2 Dimensional drawings.............................................................................. 40

13 Ordering information........................................................................ 41

13.1 Scope of delivery....................................................................................... 41

13.2 Ordering information L25......................................................................... 41

14 Accessories........................................................................................ 42

15 Annex.................................................................................................. 43

15.1 Compliance with EU directives................................................................. 43

15.2 Checklist for initial commissioning and commissioning........................ 44

16 List of figures..................................................................................... 45

17 List of tables....................................................................................... 46

CONTENTS

4

O P E R A T I N G I N S T R U C T I O N S | L25 8024678/17VH/2020-06-10 | SICK

Subject to change without notice

1 About this document

1.1 Purpose of this document

These operating instructions contain the information needed during the life cycle of the

sin

gle-beam photoelectric safety switch.

Operating instructions of the single-beam photoelectric safety switch must be made

available to all people who work with the device.

Please read these operating instructions carefully and make sure that you understand

the content fully before working with the single-beam photoelectric safety switch.

1.2 Scope

These operating instructions only apply to the L25 single-beam photoelectric safety

s

witches with the following type label entries in the “Operating Instructions” field:

•

8024676

This document is included with the following SICK part numbers (this document in all

available language versions):

8024676

1.3 Target groups of these operating instructions

Some chapters of these operating instructions are intended for certain target groups.

Ho

wever, the entire operating instructions are relevant for intended use of the product.

Table 1: Target groups and selected chapters of these operating instructions

Target group Chapters of these operating instructions

Project developers

(

planners, developers,

designers)

"Project planning", page 11

"Technical data", page 38

Installers "Mounting", page 25

Electricians "Electrical installation", page 27

Safety experts (such

a

s CE authorized rep‐

resentatives, compli‐

ance officers, people

who test and approve

the application)

"Project planning", page 11

"Commissioning", page 29

"Technical data", page 38

"Checklist for initial commissioning and commissioning", page 44

Operators "Operation", page 32

"T

roubleshooting", page 35

Maintenance person‐

ne

l

"Maintenance", page 33

"Troubleshooting", page 35

1.4 Additional information

www.sick.com

T

he following information is available on the Internet:

•

This document in other languages

•

Data sheets and application examples

•

CAD data and dimensional drawings

•

Certificates (e.g. EU declaration of conformity)

•

Guide for Safe Machinery Six steps to a safe machine

ABOUT THIS DOCUMENT 1

8024678/17VH/2020-06-10 | SICK O P E R A T I N G I N S T R U C T I O N S | L25

5

Subject to change without notice

1.5 Symbols and document conventions

The following symbols and conventions are used in this document:

Safety notes and other notes

DANGER

Indic

ates a situation presenting imminent danger, which will lead to death or serious

injuries if not prevented.

WARNING

Indic

ates a situation presenting possible danger, which may lead to death or serious

injuries if not prevented.

CAUTION

Indicates a situation presenting possible danger, which may lead to moderate or minor

injuries if not prevented.

NOTICE

Indic

ates a situation presenting possible danger, which may lead to property damage if

not prevented.

NOTE

Indic

ates useful tips and recommendations.

Instructions to action

b

T

he arrow denotes instructions to action.

1. The sequence of instructions for action is numbered.

2. Follow the order in which the numbered instructions are given.

✓

The check mark denotes the result of an instruction.

LED symbols

These symbols indicate the status of an LED:

o

The LED is off.

Ö

The LED is flashing.

O

The LED is illuminated continuously.

Sender and receiver

T

hese symbols indicate the sender and receiver of the device:

s

The symbol indicates the sender.

r

The symbol indicates the receiver.

1 A

BOUT THIS DOCUMENT

6

O P E R A T I N G I N S T R U C T I O N S | L25 8024678/17VH/2020-06-10 | SICK

Subject to change without notice

2 Safety information

2.1 General safety notes

DANGER

If t

he safety component is integrated incorrectly, the dangerous state may be ended to

late.

b

Plan the integration of the safety component in accordance with the machine

requirements, see "Project planning", page 11.

2.2 Intended use

When used in conjunction with a suitable external test device, the L25 single-beam

pho

toelectric safety switch is a Type 2 electro-sensitive protective device (ESPE) in

accordance with IEC 61496-1 and IEC 61496-2.

The external test device must satisfy the applicable requirements for a type 2 device in

accordance with IEC 61496-1 and IEC 61496-2. The external test device must provide

OSSDs (in accordance with IEC 61496-1, chapter 4.2.4), fault detection and a suitable

test rate within the target demand rate specified in the data sheet (see "Data sheet",

page 38). The response time and switching level of the sensors must be taken into

account.

Suitable test devices include, for example, all SICK safety controllers that allow a single-

beam photoelectric safety switch to be connected, e.g., Flexi Soft or Flexi Classic. A sin‐

gle-beam photoelectric safety switch in combination with an external test device can be

used in safety applications up to Category 2 according to EN ISO 13849, SILCL1

according to EN 62061 or up to PL c according to EN ISO 13849.

The single-beam photoelectric safety switch is suitable for the following applications:

•

Access protection

•

Hazardous area protection

The single-beam photoelectric safety switch does not emit any paint wetting impairment

substances or volatile silicones and does not expel any fixed parts or materials into its

surroundings.

The single-beam photoelectric safety switch must only be used within the limits of the

prescribed and specified technical data and operating conditions at all times.

Any instance of improper use, incorrect modification, or manipulation of the L25 single-

beam photoelectric safety switch shall void any warranty provided by SICK AG; further‐

more, SICK AG shall not accept any responsibility or liability for any resulting damage

and consequential damage.

2.3 Improper use

The single-beam photoelectric safety switch works as an indirect protective measure

and c

annot provide protection from pieces thrown from application nor from emitted

radiation. Transparent objects are not detected.

Among others, the single-beam photoelectric safety switch is not suitable for the follow‐

ing applications:

•

Outdoors

•

Underwater

•

In explosion-hazardous areas

•

In environments with increased levels of ionizing radiation

SAFETY INFORMATION 2

8024678/17VH/2020-06-10 | SICK O P E R A T I N G I N S T R U C T I O N S | L25

7

Subject to change without notice

2.4 Requirements for the qualification of personnel

The protective device must be configured, installed, connected, commissioned, and ser‐

v

iced by qualified safety personnel only.

Project planning

For project planning, a person is considered competent when he/she has expertise and

experience in the selection and use of protective devices on machines and is familiar

with the relevant technical rules and national work safety regulations.

Mechanical mounting, electrical installation, and commissioning

For the task, a person is considered qualified when he/she has the expertise and expe‐

rience in the relevant field and is sufficiently familiar with the application of the protec‐

tive device on the machine to be able to assess whether it is in an operationally safe

state.

Operation and maintenance

For operation and maintenance, a person is considered competent when he/she has

the expertise and experience in the relevant field and is sufficiently familiar with the

application of the protective device on the machine and has been instructed by the

machine operator in its operation.

2 S

AFETY INFORMATION

8

O P E R A T I N G I N S T R U C T I O N S | L25 8024678/17VH/2020-06-10 | SICK

Subject to change without notice

3 Product description

3.1 Structure and function

Overview

T

he L25 single-beam photoelectric safety switch is an electro-sensitive protective

device consisting of a sender and receiver.

The hazardous area is protected by means of a light beam between the sender and

receiver. As soon as the light beam is interrupted, the protective device reports the

interruption in the light path to the secure output signal switching devices.

Sensing range

T

he scanning range is the maximum dimension of the light path between sender and

receiver. This depends on the light source of the sensor.

3.2 Product characteristics

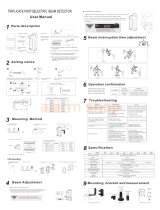

3.2.1 Device overview

1

Figure 1: Sender overview

1

green operating LED: supply voltage active

1

3

2

Figure 2: Receiver overview

1

alignment aid (BluePilot): blue alignment quality LEDs

2

yellow status LED: light received indicator

3

green operating LED: supply voltage active

3.2.2 Alignment aid (BluePilot)

An alignment aid is installed in the receiver of the single-beam photoelectric safety

s

witch. The alignment aid consists of 5 blue alignment quality LEDs.

After switching on the protective device, the alignment aid indicates the alignment qual‐

ity on the receiver.

PRODUCT DESCRIPTION 3

8024678/17VH/2020-06-10 | SICK O P E R A T I N G I N S T R U C T I O N S | L25

9

Subject to change without notice

3.2.3 Test input

The sender has a test input that can be used to switch off the light beam of the sender

and t

hereby simulate an interruption of the light beam.

The test input is provided for the purposes of checking the functioning of the sender

and receiver. When used in combination with an external test device to evaluate the

test results, the protective device is suitable for safety applications.

3.2.4 Cascading

Cascading allows up to 4 single-beam photoelectric safety switches to be connected in

ser

ies.

3.2.5 Application diagnostic output

Overview

An applic

ation diagnostic output can be configured on pin 2 of the system connection

of the receiver via IO-Link.

The application diagnostic output will signal a specific status of the protective device

depending on the configuration.

The status of the protective device is indicated via the yellow status LED.

Output signals

T

he following signals can be outputted via the application diagnostic output:

•

Alarm

When Alarm is configured on the application diagnostic output, the application

diagnostic output signals when the protective device is only partially operational,

for example if the sender or receiver is contaminated or poorly aligned.

Further topics

•

"Application diagnostic output", page 18

3.2.6 IO-Link

Overview

T

he protective device is IO-Link capable.

The IO-Link communication between the protective device and a PC can occur via an

IO-Link master. To do so, connect the IO-Link master to the system connection of the

receiver, and via a USB cable to a PC.

The connected protective device can be configured, or data exchanged or transferred

using the SOPAS ET configuration software.

Data exchange and configuration

T

he following data, for example, can be exchanged or transferred via IO-Link:

•

Device information

•

Quality of reception

The following functions, for example, can be configured via IO-Link:

•

Switching output

•

Application diagnostic output

The green operational LED on the receiver flashes during IO-Link communication.

Further topics

•

"IO

-Link", page 19

3 PRODUCT DESCRIPTION

10

O P E R A T I N G I N S T R U C T I O N S | L25 8024678/17VH/2020-06-10 | SICK

Subject to change without notice

4 Project planning

4.1 Manufacturer of the machine

DANGER

H

azard due to lack of effectiveness of the protective device

Persons and parts of the body to be protected may not be recognized in case of non-

observance.

b

Use of the single-beam photoelectric safety switch requires a risk assessment.

Check whether additional protective measures are required.

b

Comply with the applicable national regulations derived from the application (e.g.,

work safety regulations, safety rules, or other relevant safety guidelines).

b

Do not combine the components of the single-beam photoelectric safety switch

with components from other single-beam photoelectric safety switches.

b

Apart from the procedures described in this document, the components of the sin‐

gle-beam photoelectric safety switch must not be opened.

b

The components of the single-beam photoelectric safety switch must not be tam‐

pered with or changed.

b

Improper repair of the protective device can lead to a loss of the protective func‐

tion. Do not carry out any repairs on the device components.

4.2 Operating entity of the machine

DANGER

H

azard due to lack of effectiveness of the protective device

Persons and parts of the body to be protected may not be recognized in case of non-

observance.

b

Changes to the electrical integration of the single-beam photoelectric safety switch

in the machine control and changes to the mechanical mounting of the single-

beam photoelectric safety switch necessitate a new risk assessment. The results

of this risk assessment may require the entity operating the machine to meet the

obligations of a manufacturer.

b

Apart from the procedures described in this document, the components of the sin‐

gle-beam photoelectric safety switch must not be opened.

b

The components of the single-beam photoelectric safety switch must not be tam‐

pered with or changed.

b

Improper repair of the protective device can lead to a loss of the protective func‐

tion. Do not carry out any repairs on the device components.

4.3 Design

This chapter contains important information about the design.

For information on the individual steps for mounting the device, see: see "Mounting",

page 25.

PROJECT PLANNING 4

8024678/17VH/2020-06-10 | SICK O P E R A T I N G I N S T R U C T I O N S | L25

11

Subject to change without notice

DANGER

H

azard due to lack of effectiveness of the protective device

Persons and parts of the body to be protected may not be recognized in case of non-

observance.

b

Make sure that the following design requirements are met so that the single-beam

photoelectric safety switch can fulfill its protective function.

°

Sender and receiver must be arranged such that persons or parts of the body

are reliably detected when they enter the hazardous area.

°

Ensure that nobody can pass under the light beam or pass by the side of the

protective device.

°

If people can stay between the protective device and the hazardous point

without being detected, check if additional protective measures (e.g., restart

interlock) are required.

DANGER

H

azard due to lack of effectiveness of the protective device

Certain types of light radiation can influence the protective device, e.g., light radiation

from fluorescent lamps with electronic ballast installed in the path of the beam, or

beams from laser pointers directed at the receiver.

b

If this type of light radiation is present in the environment of the protective device,

take additional measures to ensure that the protective device does not become

dangerous.

4.3.1 Minimum distance from the hazardous point

Overview

A minimum dis

tance must be maintained between the single-beam photoelectric safety

switch and the hazardous point. This distance is required to prevent a person or part of

their body from reaching the hazardous point before the end of the machine’s danger‐

ous state.

Calculating the minimum distance according to ISO 13855

The calculation of the minimum distance is based on international or national stan‐

dards and statutory requirements applicable at the place of installation of the machine.

If the minimum distance is calculated according to ISO 13855, it depends on the fol‐

lowing points:

•

Machine stopping time (time interval between triggering the sensor function and

the end of the machine’s dangerous state)

•

Response time of the protective device

•

Reach or approach speed of the person

•

Number of beams and beam separation of the single-beam photoelectric safety

switch

•

Type of approach: orthogonal (at right angles) or parallel

•

Parameters specified based on the application

For the USA (scope of OSHA and ANSI), different regulations may apply, e.g.:

a) Laws: Code of Federal Regulations, Title 29 (CFR 29), Part 1910.217

b) Standards: ANSI B11.19

Complementary information

A

dditional information is available in the ISO 13855 standard and in the Guide for Safe

Machinery.

4 P

ROJECT PLANNING

12

O P E R A T I N G I N S T R U C T I O N S | L25 8024678/17VH/2020-06-10 | SICK

Subject to change without notice

SICK offers a stopping/run-down time measurement service in many countries.

4.3.1.1 Calculating minimum distance from the hazardous point

Important information

DANGER

Minimum dis

tance from the hazardous point is too small

The dangerous state of the machine may not be stopped or not be stopped in a timely

manner due to a minimum distance that is too small.

b

Calculate the minimum distances for the machine in which the single-beam photo‐

electric safety switch is integrated.

b

When mounting the single-beam photoelectric safety switch, observe the minimum

distance.

Approach

T

he example shows the calculation of the minimum distance for an orthogonal (at right

angles) approach to the single-beam photoelectric safety switch. Depending on the

application and the ambient conditions, a different calculation may be required (e.g., at

a different angle to the direction of approach or an indirect approach).

1. Calculate S using the following formula:

S = K × T + C

where:

°

S = minimum dis

tance in millimeters (mm)

°

K = approach speed of 1600 mm/s

°

T = machine stopping time + response time of the protective device after

interruption in the light path in seconds (s)

°

C = adjustment factor that depends on the number of beams (1, 2, 3 or 4)

Table 2: Variables for calculating the minimum distance

Number of

be

ams

1 2 3 4

Height of the

beams above

ground in mm

750 400

900

300

700

1100

300

600

900

1200

Adjustment fac‐

t

or C in mm

1200 850 850 850

The reach or approach speed is already included in the formula.

PROJECT PLANNING 4

8024678/17VH/2020-06-10 | SICK O P E R A T I N G I N S T R U C T I O N S | L25

13

Subject to change without notice

!

"

§

S

Figure 3: Minimum distance from the hazardous point

!

Height of the light beams above ground

"

Hazardous point

§

Depending on the application and distance, persons must be prevented from standing

be

hind the protective device.

Example calculation: access protection, no danger from reaching over

Mac

hine stopping time = 290 ms

Response time after interruption of the light path = 20 ms

T = 290 ms + 20 ms = 310 ms = 0.31 s

S = 1600 mm/s × 0.31 s + 1200 mm = 1696 mm

4.3.2 Minimum distance from reflective surfaces

Overview

T

he light beam from the sender may be deflected by reflective surfaces and dispersive

media. This can prevent an object from being detected.

Therefore, all reflective surfaces and objects (e.g. material bins, machine table, etc.)

must be kept at a minimum distance (a) from the light beam. This minimum distance

(a) must be maintained on all sides of the light beam. This applies in horizontal, vertical

and diagonal directions as well as at the end of the device. The same area must be free

of dispersive media (e.g., dust, fog, or smoke).

The minimum distance (a) depends on the distance (D) between sender and receiver.

4 P

ROJECT PLANNING

14

O P E R A T I N G I N S T R U C T I O N S | L25 8024678/17VH/2020-06-10 | SICK

Subject to change without notice

rs

D

a

Figure 4: Minimum distance from reflective surfaces

Important information

DANGER

H

azard due to lack of effectiveness of the protective device

Reflective surfaces and dispersive media can prevent persons or parts of the body to

be protected from being properly reflected and therefore, they remain undetected.

b

Make sure that all reflective surfaces and objects maintain a minimum distance

from the light beam.

b

Make sure that no dispersive media (e.g., dust, fog, or smoke) are within the calcu‐

lated minimum distance from the light beam.

Determining minimum distance to reflective surfaces

1.

Determine the distance between sender and receiver D in meters (m).

2. Read the minimum distance a in millimeters (mm) in the graph or calculate it

based on the respective formula from table 3:

10 20 30 40 50 60 70 D/

m

1000

2000

4000

3000

5000

6000

7000

a/mm

262

3

Figure 5: Graph of minimum distance from reflective surfaces

T

able 3: Formula for calculating the minimum distance from reflective surfaces

Distance between sender and

r

eceiver D in m

Calculating the minimum distance from reflective sur‐

faces a in mm

D ≤ 3 m a = 262 mm

D > 3 m a = tan (5°) × 1,000 mm/m × D = 87.49 × 1 mm/m × D

PROJECT PLANNING 4

8024678/17VH/2020-06-10 | SICK O P E R A T I N G I N S T R U C T I O N S | L25

15

Subject to change without notice

4.3.3 Protection against interference from systems in close proximity to each other

Overview

s

rs

r

!

"

Figure 6: Preventing mutual interference from system

!

and system

"

The light beam of the sender of system ! can interfere with the receiver of system ".

This can disrupt the protective function of system ". This would mean that the operator

is at risk.

Avoid such installation situations or take appropriate action, e.g., install optically

opaque partitions or reverse the direction of transmission of a system.

Important information

DANGER

H

azard due to lack of effectiveness of the protective device

Systems of single-beam photoelectric safety switches in close proximity to one another

can mutually interfere with each other.

b

Use suitable measures to prevent interference between systems in close proximity

to each other.

4.4 Integration in the electrical control system

This chapter contains important information about integration in the electrical control.

Inf

ormation about the individual steps for electrical installation of the device: see "Elec‐

trical installation", page 27.

Requirements for use

As the single-beam photoelectric safety switch is classified as a Type 2 device in accor‐

dance with IEC 61496, it must be monitored by an external test device. The test input

of the sender and a semiconductor switching output of the receiver are used for this

purpose.

To connect the single-beam photoelectric safety switch, refer to the corresponding oper‐

ating instructions for the test device or for the higher-order control system.

4.4.1 Switching outputs

Overview

T

wo switching outputs are provided for evaluation by an external test device:

•

Q

L1

/C

Switching output or IO-Link communication

•

MF

Switching output or configurable output

4 P

ROJECT PLANNING

16

O P E R A T I N G I N S T R U C T I O N S | L25 8024678/17VH/2020-06-10 | SICK

Subject to change without notice

The factory setting for the switching outputs is Q. The switching behavior can be found

in t

able 4.

Table 4: Push-pull

Q

Push-pull

(≤ 100 mA

)

+ (L+)

Q

‒

(M)

+ (L+)

Q

‒

(M)

Q

Push-pull

(≤ 100 mA

)

+ (L+)

Q

‒

(M)

+ (L+)

Q

‒

(M)

Important information

NOTE

If IO

-Link is used on the device, the MF switching output with the factory setting Q must

be used.

If no IO-Link is used on the device, any of the switching outputs with the factory setting

Q can be used.

The single-beam photoelectric safety switch must not be supplied with voltage via the

IO-Link master.

4.4.2 Test input

Overview

T

he sender has a test input that can be used to switch off the light beam of the sender

and thereby simulate an interruption of the light beam.

The test input is provided for the purposes of checking the functioning of the sender

and receiver. When used in combination with an external test device to evaluate the

test results, the protective device is suitable for safety applications.

Functionality

A

s soon as the test input is activated, the light beam of the sender is switched off to

simulate an object having been detected.

b

Refer to table 5 to check the function.

b

If the switching output fails to behave in accordance with table 5, check the appli‐

cation conditions.

PROJECT PLANNING 4

8024678/17VH/2020-06-10 | SICK O P E R A T I N G I N S T R U C T I O N S | L25

17

Subject to change without notice

Table 5: Test

Test → M

+ (L+)

Test

‒ (M)

+ (L+)

Test

‒

(M)

Further topics

•

"T

roubleshooting", page 35

4.4.3 Cascading

You can use cascading to connect up to 4 single-beam photoelectric safety switches in

ser

ies.

Further topics

•

"Connection diagrams", page 20

4.4.4 Application diagnostic output

Overview

An applic

ation diagnostic output can be configured on pin 2 of the system connection

of the receiver via IO-Link.

The application diagnostic output will signal a specific status of the protective device

depending on the configuration.

The status of the protective device is indicated via the yellow status LED.

Output signals

T

he following signals can be outputted via the application diagnostic output:

•

Alarm

When Alarm is configured on the application diagnostic output, the application

diagnostic output signals when the protective device is only partially operational,

for example if the sender or receiver is contaminated or poorly aligned.

In the good state: LOW (0), if excessively contaminated HIGH (1), see table 6,

page 19

4 P

ROJECT PLANNING

18

O P E R A T I N G I N S T R U C T I O N S | L25 8024678/17VH/2020-06-10 | SICK

Subject to change without notice

Table 6: Alarm

Alarm (≤ 100 mA)

+ (L+)

Alarm

‒

(M)

+ (L+)

Alarm

‒

(M)

4.4.5 IO-Link

Overview

The protective device is IO-Link capable.

The IO-Link communication between the protective device and a PC can occur via an

IO-Link master. To do so, connect the IO-Link master to the system connection of the

receiver, and via a USB cable to a PC.

The connected protective device can be configured, or data exchanged or transferred

using the SOPAS ET configuration software.

Important information

DANGER

T

he output signal of the protective device that is evaluated via the external test device

is configured via IO-Link, e.g., using the logic or time delay functions.

This can slow down the response time of the protective device, or make it not possible

to evaluate it with the external test device.

b

Use the Q configuration for the switching output when using the protective device

in conjunction with an external test device.

b

Take the use of the logic and time delay functions appropriately into consideration

in the risk assessment.

Prerequisites

•

S

OPAS ET configuration software

•

SiLink2 Master IO-Link master

Data exchange and configuration

The following data, for example, can be exchanged or transferred via IO-Link:

•

Device information

•

Quality of reception

The following functions, for example, can be configured via IO-Link:

•

Switching output

•

Application diagnostic output

The green operational LED on the receiver flashes during IO-Link communication.

PROJECT PLANNING 4

8024678/17VH/2020-06-10 | SICK O P E R A T I N G I N S T R U C T I O N S | L25

19

Subject to change without notice

Complementary information

F

or more information on connecting the IO-Link master to a PC and to the protective

device, see the IOLA2US-01101 SiLink2 Master operating instructions.

For more information on IO-Link, see the IODD and the SDD for SOPAS ET.

Suitable accessories are available at www.sick.com. Enter the product part number in

the search field (part number: see the type label entry in the “Ident. no.” field). All suit‐

able accessories are listed on the Accessories tab of the product page.

4.4.6 Connection diagrams

3 x L25/L26 (cascaded) to Flexi Classic main module and input/output expansion module

0 V

+

24 V DC

FE

k1

k2

S1

2) PELV

E255351/00/2019-11-05

yx

yx

k2k1

k1

k2

1)

z

z

UE410-MM/XU

I1

I2

X1 X2 S1 S3S2A1

I3 I4

Q1

Q2

Q3

EN

Q4A2

Function

5

1

3

4

2

8

3

6

7

0

9

K1

K2

1

2

3

4

s

+24 V

n.c.

0 V

TE

L25S/

L26S

L25S/

L26S

r

1

2

3

4

+24 V

MF

0 V

Q

L1

/C

L25E/

L26E

L25E/

L26E

L25S/

L26S

L25E/

L26E

1

2

3

4

s

+24 V

n.c.

0 V

TE

r

1

2

3

4

+24 V

MF

0 V

Q

L1

/C

1

2

3

4

1

2

3

4

s

+24 V

n.c.

0 V

TE

r

+24 V

MF

0 V

Q

L1

/C

Figure 7: Connection diagram for cascaded L25/L26 to UE410-MM and input/output expansion module

1) Output circuits: These contacts must be incorporated into the control such that the dan‐

g

erous state is brought to an end if the output circuit is open. For categories 4 and 3, they

must be incorporated on dual-channels (x, y paths). Single-channel incorporation into the

control (z path) is only possible with a single-channel control and taking the risk analysis

into account.

2) PELV in accordance with the requirements of EN 60204-1 / 6.4 Optical short-circuits

must be avoided. Observe the operating instructions of the integrated devices. The safety-

related parameters (safety integrity level and response time) are dependent on the types

used.

•

T

ask

Connection of three cascaded single-beam photoelectric safety switches from the

L25 or L26 f

amily to an UE410-MU/XU safety controller on a relay control/contac‐

tor control system.

Operating mode: With restart interlock and with external device monitoring.

4 P

ROJECT PLANNING

20

O P E R A T I N G I N S T R U C T I O N S | L25 8024678/17VH/2020-06-10 | SICK

Subject to change without notice

/