IOM 686 AGZ 030A through 065A 17

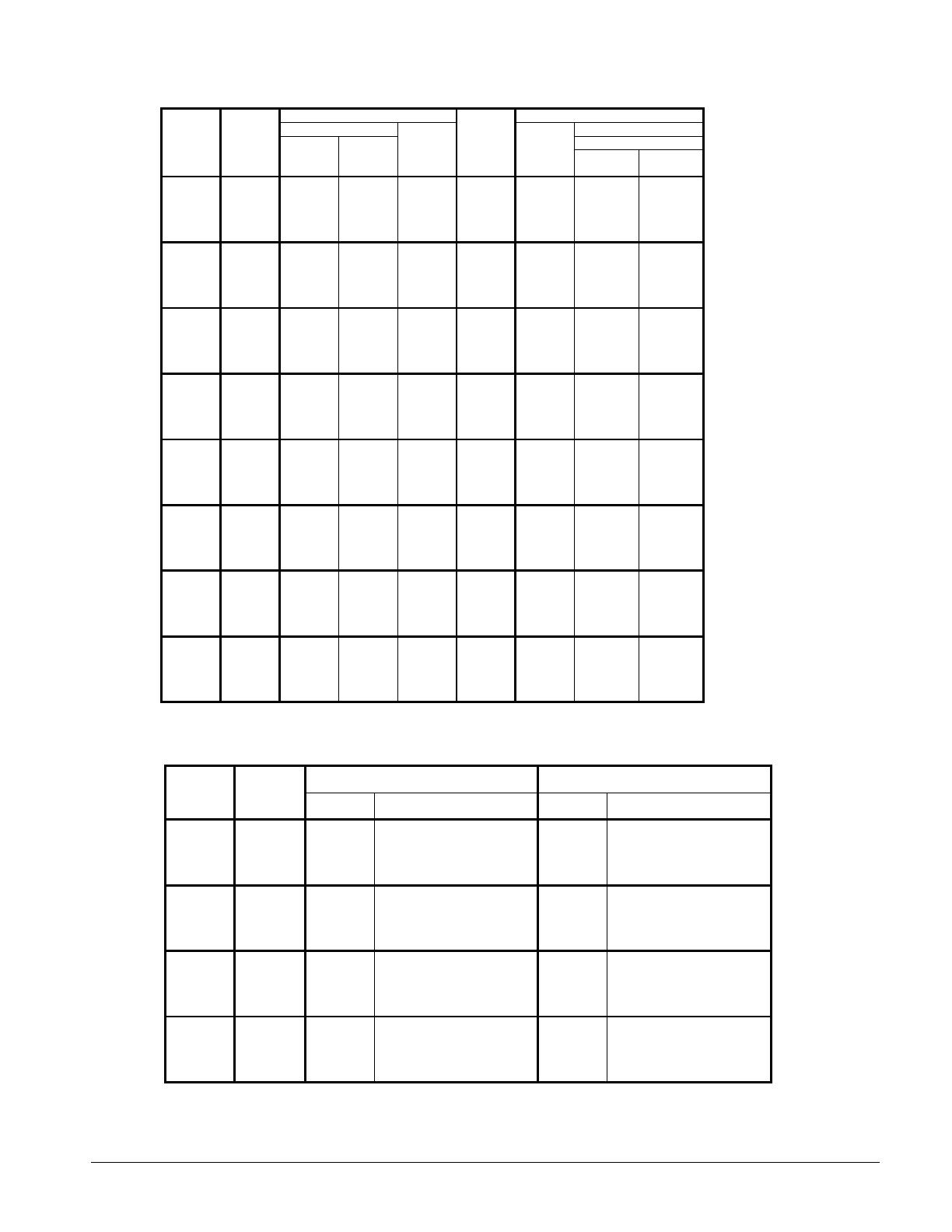

Table 11, AGZ030A - 065A, 60 Hz, Compressor and Condenser Fan Motor Amp Draw

Rated Load Amps Locked Rotor Amps

AGZ Compressors No. Of Compressors

Unit Volts No. No. Fan Fan Fan Across-The-Line

Size 1 & 3 2 & 4 Motors Motors Motors No.1 & 3 No.2 & 4

(Each) (Each) (Each) (Each) (Each) (Each)

208 22.9 29.9 4.0 4 17.0 169 232

230 22.9 29.9 4.0 4 17.0 189 232

030AS 380 14.9 18.6 3.4 4 14.4 112 144

030AE 460 12.5 15.3 2.0 4 8.5 94 116

575 9.1 11.6 2.2 4 10.3 74 97

208 29.9 29.9 4.0 4 17.0 232 232

230 29.9 29.9 4.0 4 17.0 232 232

035AS 380 18.6 18.6 3.4 4 14.4 144 144

460 15.3 15.3 2.0 4 8.5 116 116

575 11.6 11.6 2.2 4 10.3 97 97

208 33.6 33.6 4.0 4 17.0 255 255

230 33.6 33.6 4.0 4 17.0 255 255

040AS 380 22.8 22.8 3.4 4 14.4 151 151

040AE 460 16.4 16.4 2.0 4 8.5 127 127

575 13.7 13.7 2.2 4 10.3 100 100

208 33.6 39.5 5.8 4 23.7 255 318

230 33.6 39.5 5.8 4 23.7 255 318

045AS 380 22.8 28.2 3.4 4 14.4 151 188

460 16.4 19.3 2.8 4 10.7 127 158

575 13.7 17.3 2.3 4 11.5 100 125

208 39.5 39.5 5.8 4 23.7 318 318

230 39.5 39.5 5.8 4 23.7 318 318

050AS 380 28.2 28.2 3.4 4 14.4 188 188

050AE 460 19.3 19.3 2.8 4 10.7 158 158

575 17.3 17.3 2.3 4 11.5 125 125

208 39.5 52.6 5.8 4 23.7 318 411

230 39.5 52.6 5.8 4 23.7 318 411

055AS 380 28.2 34.6 3.4 4 14.4 188 249

460 19.3 23.7 2.8 4 10.7 158 187

575 17.3 19.0 2.3 4 11.5 125 150

208 52.6 52.6 5.8 4 23.7 411 411

230 52.6 52.6 5.8 4 23.7 411 411

060AS 380 34.6 34.6 3.4 4 14.4 249 249

460 23.7 23.7 2.8 4 10.7 187 187

575 19.0 19.0 2.3 4 11.5 150 150

208 52.6 52.6 5.8 4 23.7 411 411

230 52.6 52.6 5.8 4 23.7 411 411

065AS 380 34.6 34.6 3.4 4 14.4 249 249

460 23.7 23.7 2.8 4 10.7 187 187

575 19.0 19.0 2.3 4 11.5 150 150

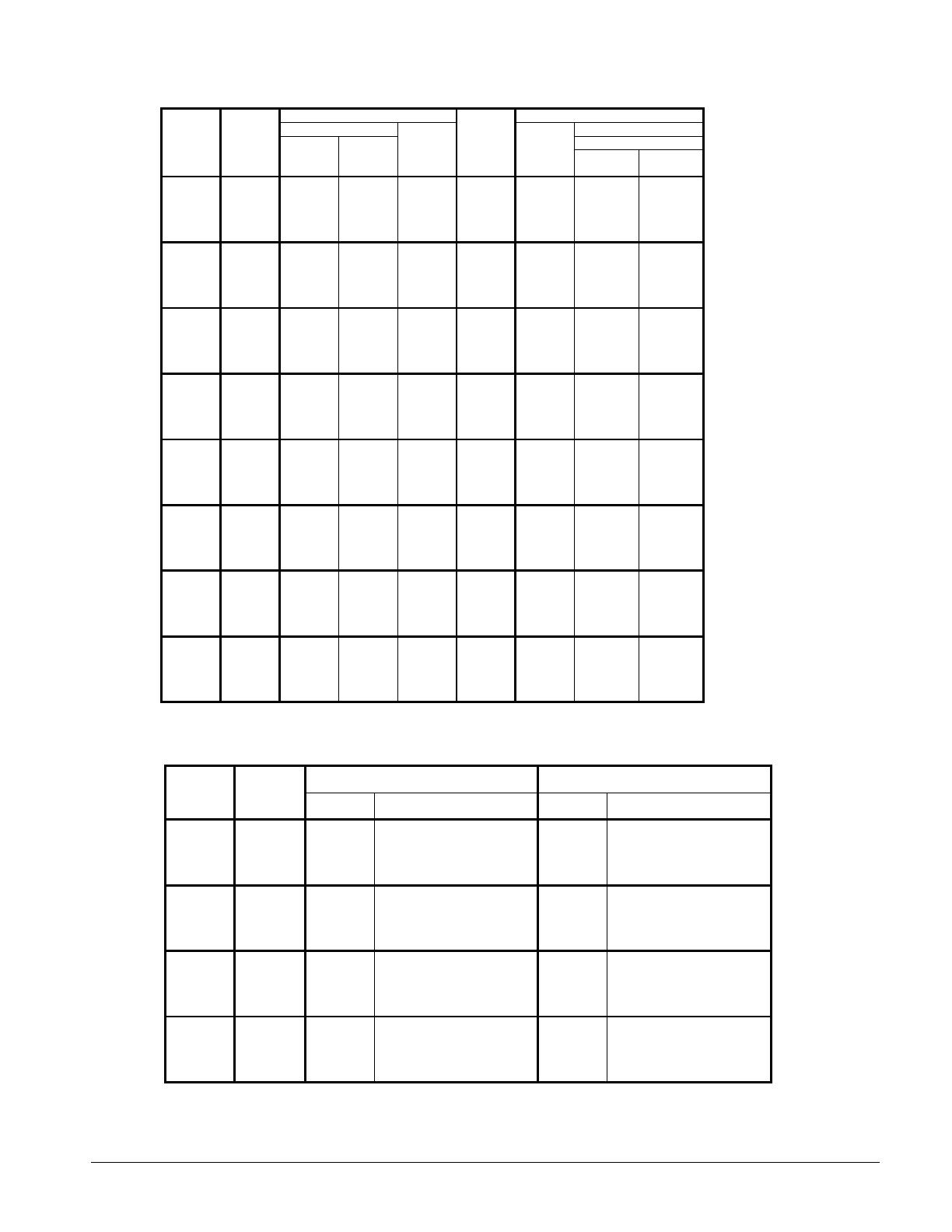

Table 12, AGZ030A - 065A, 60 Hz Single Point Power, Field Wiring Data

Wiring to Standard Wiring to Optional

AGZ Power Block Non-Fused Disconnect Switch

Unit Volts Terminal Connector Wire Range Terminal Connector Wire Range

Size Amps (Copper Wire Only) Amps (Copper Wire Only)

208 175 #12 - 2/0 225 # 3 - 300 MCM

230 175 #12 - 2/0 225 # 3 - 300 MCM

030AS 380 175 #12 - 2/0 100 #14 - 1/0

030AE 460 175 #12 - 2/0 100 #14 - 1/0

575 175 #12 - 2/0 100 #14 - 1/0

208 175 #12 - 2/0 225 # 3 - 300 MCM

230 175 #12 - 2/0 225 # 3 - 300 MCM

035AS 380 175 #12 - 2/0 100 #14 - 1/0

460 175 #12 - 2/0 100 #14 - 1/0

575 175 #12 - 2/0 100 #14 - 1/0

208 175 #12 - 2/0 225 # 3 - 300 MCM

230 175 #12 - 2/0 225 # 3 - 300 MCM

040AS 380 175 #12 - 2/0 150 #4 - 4/0

040AE 460 175 #12 - 2/0 100 #14 - 1/0

575 175 #12 - 2/0 100 #14 - 1/0

208 335 # 4 - 400 MCM 225 # 3 - 300 MCM

230 335 # 4 - 400 MCM 225 # 3 - 300 MCM

045AS 380 175 #12 - 2/0 150 #4 - 4/0

460 175 #12 - 2/0 100 #14 - 1/0

575 175 #12 - 2/0 100 #14 - 1/0

Table continued on next page