3

1 QUICKSTART ........................................................................ 4

1.1 Denitionofterm/abbreviation .................................. 4

1.2 Symbols ....................................................................... 4

2 AUTHORIZED USE ............................................................... 5

3 BASIC SAFETY INSTRUCTIONS .......................................... 5

4 GENERAL INFORMATION .................................................... 7

4.1 Contact address .......................................................... 7

4.2 Warranty ...................................................................... 7

4.3 Informationontheinternet .......................................... 7

5 SYSTEM DESCRIPTION ....................................................... 7

5.1 Structureandfunction ................................................. 7

5.2 Modelforcontrolofthird-partydevices ...................... 8

6 TECHNICAL DATA ................................................................. 9

6.1 Conformity ................................................................... 9

6.2 Standards .................................................................... 9

6.3 Licenses ...................................................................... 9

6.4 Operating conditions ................................................... 9

6.5 Mechanical data ........................................................ 10

6.6 Typelabels ................................................................. 10

6.7 Pneumatic data ......................................................... 11

6.8 Electrical data ............................................................ 11

6.9 Factorysettingsofthepositioner .............................. 12

7 INSTALLATION .................................................................... 12

7.1 Safetyinstructions ..................................................... 12

7.2 Installationofthepositioneronprocessvalves

ofseries2103and23xx ............................................ 13

8 PNEUMATIC INSTALLATION .............................................. 14

9 ELECTRICAL INSTALLATION ............................................. 15

9.1 Safetyinstructions ..................................................... 15

9.2 Electricalinstallationwithcircularplug-inconnector 15

10 START-UP ............................................................................ 16

10.1 Safetyinstructions ..................................................... 16

10.2 Automatic adjustment X.TUNE ................................. 16

10.3 Control and display elements .................................... 18

11 SAFETY POSITIONS ........................................................... 21

12 ACCESSORIES ................................................................... 22

12.1 Communicationssoftware......................................... 22

12.2 USBinterface ............................................................ 22

12.3 Download .................................................................. 22

13 PACKAGING, TRANSPORT, STORAGE ............................. 22

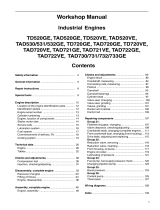

Table of Contents

english

Type 8696