4

6.5 Mechanicaldata .........................................................................................................................21

6.6 Pneumaticdata ..........................................................................................................................22

6.7 Typelabels .................................................................................................................................22

6.7.1 Type label ....................................................................................................................22

6.7.2 UL additional label ...................................................................................................... 22

6.8 Electricaldata ............................................................................................................................23

6.8.1 Electricaldata,withouteldbuscommunication ........................................................23

6.8.2 Electrical data, IO-Link ...............................................................................................24

6.8.3 Electrical data, büS .....................................................................................................24

6.9 Factorysettingsofthepositioner .............................................................................................25

7 CONTROL AND DISPLAY ELEMENTS ................................................................................................26

7.1 Operatingstate ............................................................................................................................. 26

7.2 Controlanddisplayelementsofthepositioner ........................................................................26

7.3 Congurationofthebuttons ........................................................................................................ 28

7.4 FunctionoftheDIPswitches ....................................................................................................... 30

7.5 DisplayoftheLEDs ...................................................................................................................... 32

7.5.1 Device status display ..................................................................................................32

7.5.2 Status LED, green ....................................................................................................... 34

7.6 Errormessages............................................................................................................................. 35

7.6.1 Messagesfordevicestatus„Outofspecication“ ....................................................35

7.6.2 Messages: Actuator moves to safety position .............................................................35

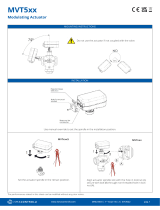

8 INSTALLATION ......................................................................................................................................37

8.1 Safetyinstructions .....................................................................................................................37

8.2 InstallationofthepositionerType8694onprocessvalvesofseries2103,2300and2301 ...37

8.3 InstallingthepositionerType8694onprocessvalvesbelongingtoseries26xxand27xx ...... 40

8.4 Rotatingtheactuatormodule....................................................................................................44

8.5 Rotatingthepositionerforprocessvalvesbelongingtoseries26xxand27xx .....................46

9 PNEUMATIC INSTALLATION ................................................................................................................47

9.1 Safetyinstructions .....................................................................................................................47

9.2 Connectingthedevicepneumatically .......................................................................................47

9.3 Manualactuationoftheactuatorviapilotvalves .....................................................................48

9.3.1 Single-acting actuators (control function A and B) .....................................................48

english

Type 8694 REV.2