OPER ATOR'S MANUAL

REAR BLADES

MAN0110

(Rev. 5/19/2011)

Tested. Proven. Unbeatable.

HBL72-2

HBL84-2

HBL96-2

2 Introduction

Gen’l (Rev. 3/5/2010)

TO THE DEALER:

Assembly and proper installation of this product is the responsibility of the Woods

®

dealer. Read manual instructions

and safety rules. Make sure all items on the Dealer’s Pre-Delivery and Delivery Check Lists in the Operator’s Manual

are completed before releasing equipment to the owner.

The dealer must complete the online Product Registration form at the Woods Dealer Website which certifies that

all Dealer Check List items have been completed. Please contact your dealer to complete this form. Dealers can

register all Woods product at dealer.WoodsEquipment.com under Product Registration.

Failure to register the product does not diminish customer’s warranty rights.

TO THE OWNER:

Read this manual before operating your Woods equipment. The information presented will prepare you to do a better and

safer job. Keep this manual handy for ready reference. Require all operators to read this manual carefully and become

acquainted with all adjustment and operating procedures before attempting to operate. Replacement manuals can be

obtained from your dealer. To locate your nearest dealer, check the Dealer Locator at www.WoodsEquipment.com, or in

the United States and Canada call 1-800-319-6637.

The equipment you have purchased has been carefully engineered and manufactured to provide dependable and

satisfactory use. Like all mechanical products, it will require cleaning and upkeep. Lubricate the unit as specified.

Observe all safety information in this manual and safety decals on the equipment.

For service, your authorized Woods dealer has trained mechanics, genuine Woods service parts, and the necessary

tools and equipment to handle all your needs.

Use only genuine Woods service parts. Substitute parts will void the warranty and may not meet standards required for

safe and satisfactory operation. Record the model number and serial number of your equipment in the spaces

provided:

Model: _______________________________ Date of Purchase: _____________________

Serial Number: (see Safety Decal section for location) ____________________________________

Provide this information to your dealer to obtain correct repair parts.

Throughout this manual, the term NOTICE is used to indicate that failure to observe can cause damage to equipment.

The terms CAUTION, WARNING, and DANGER are used in conjunction with the Safety-Alert Symbol (a triangle with

an exclamation mark) to indicate the degree of hazard for items of personal safety.

Introduction 3

MAN0110 (Rev. 8/11/2006)

TABLE OF CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SAFETY RULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SAFETY DECALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

OPTIONAL EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

OWNER SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

DEALER CHECK LISTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

BOLT TORQUE CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

BOLT SIZE CHART & ABBREVIATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 23

PRODUCT WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

REPLACEMENT PARTS WARRANTY . . . . . . . . . . . . . . . . Inside back cover

Si no lee Ingles, pida ayuda a

alguien que si lo lea para que le

traduzca las medidas de seguridad.

LEA EL INSTRUCTIVO!

!

4 Introduction

MAN0110 (Rev. 8/11/2006)

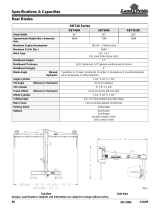

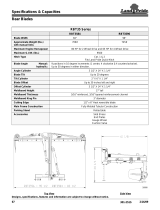

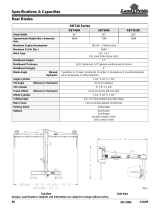

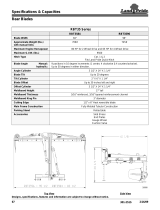

SPECIFICATIONS

GENERAL INFORMATION

The purpose of this manual is to assist you in operating

and maintaining your rear blade. Read it carefully. It

furnishes information and instructions that will help you

achieve years of dependable performance. These

instructions have been compiled from extensive field

experience and engineering data. Some information

may be general in nature due to unknown and varying

operating conditions. However, through experience

and these instructions, you should be able to develop

procedures suitable to your particular situation.

The illustrations and data used in this manual were cur-

rent at the time of printing, but due to possible inline

production changes, your machine may vary slightly in

detail. We reserve the right to redesign and change the

machines as may be necessary without notification.

Throughout this manual, references are made to right

and left directions. These are determined by standing

behind the equipment facing the direction of forward

travel.

HBL72-2

HBL84-2 HBL96-2

Overall Height 40" 40" 40"

Moldboard Height 18" 18" 18"

Cutting Width 71" 83" 95"

Moldboard Thickness 5/16" 5/16" 5/16"

Overall Depth 50" 50" 50"

Weight 530 lbs 565 lbs 600 lbs

Cutting Edge 1/2" x 6" Reversible 1/2" x 6" Reversible 1/2" x 6" Reversible

Offset Position Left or Right 4", 10", 16" 4", 10", 16" 4", 10", 16"

No. of Forward Positions 9 9 9

No. of Backfill Positions 9 9 9

No. of Tilt Positions 5 5 5

Tractor 3-Point Cat. 1 or 2 Cat. 1 or 2 Cat. 1 or 2

(Optional) Quick Hitch Cat. 1 or 2 Cat. 1 or 2 Cat. 1 or 2

Tractor HP Rating 75 hp max 75 hp max 75 hp max

Safety 5

HBL (Rev. 8/26/2005)

TRAINING

Safety instructions are important! Read all

attachment and power unit manuals; follow all

safety rules and safety decal information. (Replace-

ment manuals and safety decals are available from

your dealer. To locate your nearest dealer, check

the Dealer Locator at www.WoodsEquipment.com,

or in the United States and Canada call 1-800-319-

6637.) Failure to follow instructions or safety rules

can result in serious injury or death.

If you do not understand any part of this manual

and need assistance, see your dealer.

Operators must be instructed in and be capable

of the safe operation of the equipment, its attach-

ments, and all controls. Do not allow anyone to

operate this equipment without proper instruc-

tions.

Never allow children or untrained persons to

operate equipment.

PREPARATION

Check that all hardware is properly installed.

Always tighten to torque chart specifications

unless instructed otherwise in this manual.

Always wear relatively tight and belted clothing

to avoid getting caught in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

Make sure attachment is properly secured,

adjusted, and in good operating condition.

Make sure all safety decals are installed.

Replace if damaged. (See Safety Decals section for

location.)

A minimum 20% of tractor and equipment

weight must be on the tractor front wheels when

attachments are in transport position. Without this

weight, front tractor wheels could raise up result-

ing in loss of steering. The weight may be attained

with front wheel weights, ballast in tires or front

tractor weights. Weigh the tractor and equipment.

Do not estimate.

OPERATION

Keep bystanders away from equipment.

Do not operate or transport equipment while

under the influence of alcohol or drugs.

Operate only in daylight or good artificial light.

Keep hands, feet, hair, and clothing away from

equipment while engine is running. Stay clear of all

moving parts.

Always comply with all state and local lighting

and marking requirements.

Never allow riders on power unit or attachment.

Power unit must be equipped with ROPS or

ROPS cab and seat belt. Keep seat belt securely

fastened. Falling off power unit can result in death

from being run over or crushed. Keep foldable

ROPS system in “locked up” position at all times.

Always sit in power unit seat when operating

controls or starting engine. Securely fasten seat

belt, place transmission in neutral, engage brake,

and ensure all other controls are disengaged

before starting power unit engine.

Look down and to the rear and make sure area

is clear before operating in reverse.

(Safety Rules continued on next page)

Safety is a primary concern in the design and

manufacture of our products. Unfortunately, our

efforts to provide safe equipment can be wiped

out by an operator’s single careless act.

In addition to the design and configuration of

equipment, hazard control and accident preven-

tion are dependent upon the awareness, con-

cern, judgement, and proper training of

personnel involved in the operation, transport,

maintenance, and storage of equipment.

It has been said, “The best safety device is an

informed, careful operator.” We ask you to be

that kind of operator.

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

6 Safety

HBL (Rev. 8/26/2005)

(Safety Rules continued from previous page)

Use extreme care when working close to fences,

ditches, other obstructions, or on hillsides.

Before transporting, pivot the unit so red reflec-

tors face the rear.

Do not operate or transport on steep slopes.

Do not stop, start, or change directions sud-

denly on slopes.

Use extreme care and reduce ground speed on

slopes and rough terrain.

Watch for hidden hazards on the terrain during

operation.

Stop power unit and equipment immediately

upon striking an obstruction. Turn off engine,

remove key, inspect, and repair any damage before

resuming operation.

MAINTENANCE

Before dismounting power unit or performing

any service or maintenance, follow these steps:

disengage power to equipment, lower the 3-point

hitch and all raised components to the ground,

operate valve levers to release any hydraulic pres-

sure, set parking brake, stop engine, remove key,

and unfasten seat belt.

NEVER GO UNDERNEATH EQUIPMENT. Never

place any part of the body underneath equipment

or between moveable parts even when the engine

has been turned off. Hydraulic system leak-down,

hydraulic system failures, mechanical failures, or

movement of control levers can cause equipment

to drop or rotate unexpectedly and cause severe

injury or death.

• Service work does not require going under-

neath implement.

• Read Operator's Manual for service instruc-

tions or have service performed by a qualified

dealer.

Always wear relatively tight and belted clothing

to avoid getting caught in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

Make sure attachment is properly secured,

adjusted, and in good operating condition.

Keep all persons away from operator control

area while performing adjustments, service, or

maintenance.

Tighten all bolts, nuts, and screws to torque

chart specifications. Check that all cotter pins are

installed securely to ensure equipment is in a safe

condition before putting unit into service.

Make sure all safety decals are installed.

Replace if damaged. (See Safety Decals section for

location.)

STORAGE

Block equipment securely for storage.

Keep children and bystanders away from stor-

age area.

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Safety 7

MAN0110 (Rev. 8/11/2006)

1 - 57503

4 - Serial Number Plate

MODEL NO. SERIAL NO.

Woods Equipment Company

Oregon, Illinois, U.S.A.

8 - 1002941

5 - 1002940 Yellow Reflector (Front)

6 - 57123 Red Reflector (Rear)

57503-A

WARNING

BLADE MUST BE PROPERLY

SECURED OR IT WILL FALL OFF

WHEN ANGLING OR REVERSING.

Follow all manual instructions and

safety rules.

Lower blade to ground, shut off tractor,

set park brake, and remove key.

Check under center rear of blade to

make sure pivot nut and hitch pin are

in place as shown in pictorial.

If pivot nut and pin are missing, blade

will fall off when rotated. Do not rotate

or operate blade until pivot nut and

hitch pin are replaced.

FAILURE TO FOLLOW INSTRUCTIONS

CAN RESULT IN INJURY OR DEATH.

TO AVOID SERIOUS

INJURY OR DEATH:

Read Operator's Manual

before operating, servicing,

or repairing equipment.

Follow all safety rules and

instructions. (Manuals are

available from dealer or call

1-800-319-6637.)

Operate from tractor seat

only.

Lower equipment to ground,

stop engine, remove key,

and set brake before

dismounting tractor.

Never allow children or

untrained persons to operate

equipment.

Never allow riders.

Keep bystanders away from

equipment during operation.

Keep all shields in place and

in good condition.

FAILURE TO FOLLOW THESE

INSTRUCTIONS CAN RESULT

IN INJURY OR DEATH.

1004250

WARNING

3 - 1004250

Unit must not extend

more than 4 feet left of

center of the tractor when

driving on public roads.

WARNING

1003193-A

7 - 1003193

CRUSHING AND

PINCHING HAZARD

Be extremely careful

handling various parts of the

machine. They are heavy and

hands, fingers, feet, and

other body parts could be

crushed or pinched between

tractor and implement.

Operate tractor controls from

tractor seat only.

Do not stand between tractor

and implement when tractor

is in gear.

Make sure parking brake is

engaged before going

between tractor and

implement.

Stand clear of machine while

in operation or when it is

being raised or lowered.

FAILURE TO FOLLOW THESE

INSTRUCTIONS COULD

RESULT IN SERIOUS INJURY

OR DEATH.

WARNING

1002941-A

SAFETY & INSTRUCTIONAL DECALS

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Replace Immediately If Damaged!

8 Safety

MAN0110 (Rev. 8/11/2006)

SAFETY & INSTRUCTIONAL DECALS

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Replace Immediately If Damaged!

BE CAREFUL!

Use a clean, damp cloth to clean safety decals. Avoid spraying too

close to decals when using a pressure washer; high-pressure water

can enter through very small scratches or under edges of decals

causing them to peel or come off.

Replacement safety decals can be ordered free from your Woods

dealer. To locate your nearest dealer, check the Dealer Locator at

www.WoodsEquipment.com, or in the United States and Canada call

1-800-319-6637.

WARNING

55121--C

FALLING OFF CAN RESULT IN BEING RUN OVER.

Tractor must be equipped with ROPS (or ROPS CAB) and

seat belt. Keep foldable ROPS systems in “locked up”

position at all times.

Buckle Up! Keep seat belt securely fastened.

Allow no riders.

RAISED IMPLEMENT CAN DROP AND CRUSH.

Never go underneath raised implement which can drop

from equipment or tractor 3-point hitch hydraulic leak

down, hydraulic system failures, movement of control

levers or mechanical linkage failures.

Service work does not require going underneath

implement. Read manual instructions.

FALLING OFF OR GOING UNDERNEATH IMPLEMENT

CAN RESULT IN SERIOUS INJURY OR DEATH.

2 - 55121

Operation 9

MAN0110 (Rev. 8/11/2006)

OPERATION

The operator is responsible for the safe operation of

this equipment. Operators must be instructed in and be

capable of the safe operation of the equipment, its

attachments and all controls. Do not allow anyone to

operate this equipment without proper instructions.

The HBL Series is designed for a wide range of appli-

cations. The Rear Blade may be used for scraping, lev-

eling, grading and backfilling and may be angled to

windrow debris to the side for removal.

Optional kits are also available and included in this

manual. The Single Tail Wheel Kit is useful for grading

and leveling work. The Skid Shoe Kit helps control cut-

ting height when operating on hardened surfaces.

Never allow children or untrained persons to

operate equipment.

Keep bystanders away from equipment.

Keep all persons away from operator control

area while performing adjustments, service, or

maintenance.

Never allow riders on power unit or attachment.

Always wear relatively tight and belted clothing

to avoid getting caught in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

A minimum 20% of tractor and equipment

weight must be on the tractor front wheels when

attachments are in transport position. Without this

weight, front tractor wheels could raise up result-

ing in loss of steering. The weight may be attained

with front wheel weights, ballast in tires or front

tractor weights. Weigh the tractor and equipment.

Do not estimate.

PRE-OPERATION CHECK LIST

___ Check that all hardware is properly installed and

secured.

___ Do not allow riders.

___ Review and follow all safety rules and safety

decal instructions on page 5 through page 8.

___ Check that equipment is properly and securely

attached to tractor.

___ Make sure tractor ROPS or ROPS CAB and seat

belt are in good condition. Keep seat belt

securely fastened during operation.

___ Check that all safety decals are installed and in

good condition. Replace if needed.

___ Check all lubrication points and grease as

instructed in "Owner Service, Lubrication" sec-

tion.

ATTACH REAR BLADE TO TRACTOR

HBL Series blades are shipped completely assembled

and may be installed on tractors equipped with a Cate-

gory 1 or Category 2 3-point hitch.

The tractor draw bar must be removed or installed in its

shortest position to allow the blade to rotate 180°.

Place tractor 3-point lower lift arms (1) (Figure 1) in the

correct hitch position and install mounting pins (6) as

shown. Category 1 tractor lift arms use inner hitch posi-

tion. Category 2 tractor lift arms use outer hitch position

with adapter sleeves installed over mounting pins.

Secure lower link pins with lynch pins.

Serial Number 1172641 and Before

Attach tractor top link (2) to top hole of the A-frame and

secure with clevis pin (4) and retaining pin (3), see

page 18 for details. Category 1 top link attaches to front

hole and Category 2 top link attaches to rear hole.

Adjust sway blocks or tighten tractor 3-point sway

chains to eliminate implement side-to-side movement

during operation.

Figure 1. Connecting Rear Blade to Tractor

AWARNING

ACAUTION

1. 3-Point lower lift arm

2. Tractor top link

3. Retaining pin

4. Top link clevis pin

5. 3-Point lower lift arm sway chain

6. Mounting pin

(Rev 11/9/2010)

10 Operation

MAN0110 (Rev. 8/11/2006)

ATTACH REAR BLADE TO TRACTOR

CONTINUED

Serial Number 1172642 and After

Attach tractor top link (2) to top hole of the A-frame and

secure with clevis pin (4) and retaining pin (3), see

page 18 for details.

NOTE: Category 1 tractor top link attaches to top

hole with 3/4" clevis pin (4) and retaining pin (3).

Category 2 tractor top link attaches to top hole with

3/4" clevis pin (4), sleeve (7) and retaining pin (3).

Figure 2. Connecting Rear Blade to Tractor

Figure 3. HBL Top Link Identification

Optional Quick Hitch

An optional Quick Hitch Bushing Kit is available for

Category 1 and Category 2 tractors. See page 14 for

installation instructions.

Parking Stand Placement

Operating Position

Place parking stand in the raised position during opera-

tion. This position allows the moldboard to rotate 360°.

Secure into position with 3/8 x 2-1/4 lynch pin as shown

in Figure 4.

Figure 4. Parking Stand in Raised Position

Storage Position

With rear blade raised, place parking stand in lowest

position as shown in Figure 5. Lower rear blade so cut-

ting edge and parking stand are flat on the ground. Dis-

connect 3-point arms and top link from rear blade.

Figure 5. Parking Stand in Storage Position

2

DP11

2. Tractor top link

3. Retaining pin

4. Top link clevis pin

7. Sleeve

3 4 7

(Rev 11/9/2010)

Operation 11

MAN0110 (Rev. 8/11/2006)

ADJUSTMENTS

NEVER GO UNDERNEATH EQUIPMENT. Never

place any part of the body underneath equipment

or between moveable parts even when the engine

has been turned off. Hydraulic system leak-down,

hydraulic system failures, mechanical failures, or

movement of control levers can cause equipment

to drop or rotate unexpectedly and cause severe

injury or death.

• Service work does not require going under-

neath implement.

• Read Operator's Manual for service instruc-

tions or have service performed by a qualified

dealer.

Adjustments to the HBL blade require raising the blade

slightly off of the ground. Do not leave the tractor oper-

ator position with the blade raised except to make

blade adjustments during operation.

To make blade adjustments, raise the blade just high

enough to allow blade to pivot without dragging on the

ground. Shut off the tractor engine, set the park brake,

remove the key, and carefully leave the operator posi-

tion.

Never place any part of your body underneath the

blade or 3-point hitch while making adjustments.

Hydraulic leak-down or failure can cause the blade to

fall suddenly.

Angling and Reversing (Figure 6)

Ten holes are provided for angling the blade: five in the

forward position (to a maximum angle of 45 degrees)

and five in the reverse position. Lift the drop pins,

swing the blade to the desired angle or to the reverse

position, then reinsert the drop pin to lock the blade in

place.

Figure 6. Angling and Reversing

Frame Offset (Figure 7 & Figure 8)

The frame will swing to the right or left. For offsetting

the frame to the right, position the standard mechanical

linkage (1) on the left side of the frame.

Extend the linkage by pulling the center pin (2) and

swinging the frame to the desired angle. Lock the link-

age in place by inserting the pin in the desired hole.

Secure with hair pin clip. For offsetting to the left, posi-

tion the linkage on the right side of the frame and

extend the linkage.

Figure 7. Rear Blade Centered

Figure 8. Rear Blade Offset Right

Blade Pitch

The pitch of the blade can be changed by adjusting the

top link of the tractor.

AWARNING

RETAINER PLATE

DROP PIN

PIN STORAGE

DP1

1

2

CENTERED POSITION

DP2

1. Mechanical linkage

2. Centering pin

DP3

(Rev 11/9/2010)

12 Operation

MAN0110 (Rev. 8/11/2006)

Blade Tilt (Figure 9)

The blade will tilt so that one end to the moldboard is

lower than the other. Remove yoke pin (1), tilt the blade

to the desired angle, replace the pin, and secure with

the hair pin clip. Additional tilt adjustment can be made

with the tractor 3-point hitch leveling crank.

Figure 9. Blade Tilt

Blade Rotation (Figure 10)

Before transporting, pivot the unit so red reflec-

tors face the rear.

The blade can be reversed for backfilling. Remove the

drop pins and rotate the blade 180° from the forward

position. Replace and secure the drop pins.

The tractor draw bar must be removed or installed in its

shortest position to allow the blade to rotate 180°.

Adjust sway blocks or tighten tractor 3-point sway

chains to eliminate implement side-to-side movement

during operation.

Figure 10. Blade Rotated 180°

1

DP4

1.Yoke pin

ACAUTION

DP5

(Rev 11/9/2010)

Optional Equipment 13

MAN0110 (Rev. 1/28/2005)

OPTIONAL EQUIPMENT

SINGLE TAIL WHEEL KIT 1001533

Assemble Tail Wheel (Figure 11)

NOTICE

■ Floating links must be used with tail wheel to

avoid equipment damage.

■ Tail wheel kit will not function properly when

used with Quick Hitch.

Remove round retainer plate and hardware from rear of

tilt turntable of rear blade (refer to Figure 6).

NOTE: Point drop pins in tilt turntable towards center of

unit (Figure 12) before attaching tail wheel tube assem-

bly.

Attach tail wheel tube assembly (1) to rear of tilt turnta-

ble and secure with cap screws (5) and hardened flat

washers (4) from turntable. Torque cap screws to 170

lbs-ft.

Attach yoke assembly (2) to tail wheel tube and secure

into position with spirol pin (3).

Figure 11. Tail Wheel Assembly

Figure 12. Drop Pin Position

Assemble Floating Link (Figure 13)

Serial Number 1172641 and Before

Attach right and left floating link brackets (14, 15) with

offset to the inside on each side of the A-frame. Place

sleeve (16) in forward hole and secure assembly into

position using two cap screws (18) and lock nuts (19)

as shown in Figure 13.

NOTE: When attaching to tractor, install clevis pin (17)

into floating links using two 3/4 washers (20), one cot-

ter pin (21), and hair pin (22) as shown.

Figure 13. Floating Link Installation

1. Tail wheel tube assembly

2. Notat yoke assembly

3. 3/8 Spirol pin

4. 5/8 Hardened flat washer (from turntable)

5. 5/8 NF x 1-1/2 Cap screw (from turntable)

14. Right float link

15. Left float link

16. Sleeve 25/32 x 1 x 2

17. 3/4 x 4-3/8 Clevis pin

18. 3/4 NC x 4-1/2 Cap screw

19. 3/4 NC Lock nut

20. 3/4 Flat washer

21. 3/16 x 1-1/2 Cotter pin

22. 5/32 Hair pin cotter

(Rev 11/9/2010)

14 Optional Equipment

MAN0110 (Rev. 1/28/2005)

Assemble Floating Link (Figure 14)

Serial Number 1172642 and After

Secure top link clevis (23) to A-Frame top hole using

cap screw (27) and hex nut (28). Install sleeves (26) in

front hole of top link clevis (23) and secure with clevis

pin (24) and linch pin (25), Figure 14.

NOTE: Item (29) may be used to make item (23)

compatible with older HBL rear blades (SN

1172641 and before).

Figure 14. Float Link Assembly

Adjust Tail Wheel Assembly

Set blade cutting edge 1/2" above the ground with the

tractor 3-point hitch. Adjust tail wheel until tire is on the

ground and the top link pin is centered in the floating

link slot. Fine tune the grading height by raising or low-

ering the 3-point hitch.

QUICK HITCH BUSHING KIT 1002011

NOTICE

■ Do not use Quick Hitch with Single Tail Wheel

Kit.

Install cap screw (5), sleeve (4), lock washer (6), and

hex nut (7) through bottom hole on of A-frame as

shown.

Install sleeves (2) for Category 2 tractors in outer pin

locations. Install sleeves (3) for Category 1 tractors in

inner pin locations as shown.

Figure 15. Quick Hitch Bushing Installation

END PLATE KIT 1001531

Install one end plate to each end of rear blade using

two carriage bolts (4) and flanged lock nuts (5) on each

end plate.

Figure 16. End Plate Installation

23. Top Link Clevis

24. Clevis Pin, 3/4 x 5.5

25. Linch Pin

26. Sleeve

27. 3/4 NC x 4-1/2 Cap Screw

28. 3/4 NC Lock Nut

29. Sleeve

1. A-Frame assembly

2. Sleeve, .94 x 1.44 x 2.75 Cat 2

3. Sleeve, .94 x 1.44 x 2.19 Cat 1

4. Sleeve, 1.0 x 1.25 x 2.06

5. 1" NC x 5.0 Cap Screw GR5

6. 1" Lock washer

7. 1" NC Hex nut

1. Moldboard assembly

2. End plate (right, not shown)

3. End plate (left)

4. 1/2 NC x 1-1/4 Carriage bolt

5. 1/2 NC Flanged lock nut

(Rev 5/19/2011)

Optional Equipment 15

MAN0110 (Rev. 1/28/2005)

SKID SHOE KIT 18300

Remove plow bolts from each end of cutting edge.

Attach right and left skid shoe brackets (3 & 4) to rear

of moldboard with plow bolts (8), washers (9), and lock

nuts (10) supplied in kit. Top of skid shoe brackets

should angle slightly toward outer edge of blade.

Adjust skid shoe to desired height using washers (7)

and spacers (5). One washer must be installed

between the shoe bracket and the spacers. Make sure

skid shoe rotates freely to prevent premature skid pad

wear.

Figure 17. Skid Shoe Installation

1. Moldboard assembly

2. Skid & Shaft assembly

3. Bracket, Right skid shoe NS

4. Bracket, Left skid shoe

5. Sleeve, 1.28 x 1.66 x .75

6. Pin, Klik 7/16 x 11/32

7. Washer, Flat 1-1/4 standard

8 Bolt, Plow 5/8 NC x 2-1/2

9. Washer, Flat 5/8 standard

10. Nut, Lock 5/8 NC

11. Grease fitting, 1/4-28 Tapered Thread

(Rev 11/9/2010)

16 Owner Service

MAN0110 (Rev. 8/11/2006)

OWNER SERVICE

The information in this section is written for operators

who possess basic mechanical skills. Should you need

help, your dealer has trained service technicians avail-

able. For your protection, read and follow all safety

information in this manual.

NEVER GO UNDERNEATH EQUIPMENT. Never

place any part of the body underneath equipment

or between moveable parts even when the engine

has been turned off. Hydraulic system leak-down,

hydraulic system failures, mechanical failures, or

movement of control levers can cause equipment

to drop or rotate unexpectedly and cause severe

injury or death.

• Service work does not require going under-

neath implement.

• Read Operator's Manual for service instruc-

tions or have service performed by a qualified

dealer.

Before dismounting power unit or performing

any service or maintenance, follow these steps:

disengage power to equipment, lower the 3-point

hitch and all raised components to the ground,

operate valve levers to release any hydraulic pres-

sure, set parking brake, stop engine, remove key,

and unfasten seat belt.

Keep all persons away from operator control

area while performing adjustments, service, or

maintenance.

Always wear relatively tight and belted clothing

to avoid getting caught in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

BLADE CUTTING EDGE REPLACEMENT

The moldboard blade is reversible and replaceable.

Remove the cap screws and hex nuts retaining the cut-

ting edge to the moldboard. You may either replace or

reverse the cutting edge. Secure new or reversed cut-

ting edge with cap screws and hex nuts previously

removed.

AWARNING

ACAUTION

Dealer Check Lists 17

MAN0110 (Rev. 8/11/2006)

DEALER CHECK LISTS

PRE-DELIVERY CHECK LIST

Inspect the equipment thoroughly after assembly to be

certain it is set up properly before delivering it to the

customer. The following check list is a reminder of

points to inspect. Check off each item if it is found satis-

factory or after proper adjustment is made.

___ Check that all safety decals are installed and in

good condition. Replace if damaged.

___ Check all bolts to be sure they are tight.

___ Check that all cotter pins and safety pins are

properly installed.

___ Check and grease all lubrication points as identi-

fied in the "Owner Service, Lubrication" section.

DELIVERY CHECK LIST

___ Show customer the safe and proper procedures

to be used when mounting, dismounting and stor-

ing equipment.

___ For mounted units, add wheel weights, ballast in

front tires, and/or front tractor weight to enhance

front end stability. A minimum 20% of tractor and

equipment gross weight must be on front tractor

wheels. When adding weight to attain 20% of

tractor and equipment weight on front tractor

wheels, you must not exceed the ROPS weight

certification. Weigh the tractor and equipment. Do

not estimate!

___ Show customer how to make adjustments.

___ Instruct customer how to lubricate and explain

importance of lubrication.

___ Present Operator's Manual and request that cus-

tomer and all operators read it before operating

equipment. Point out the manual safety rules,

explain their meanings, and emphasize the

increased safety hazards that exist when safety

rules are not followed.

___ Point out the safety decals. Explain their meaning

and the need to keep them in place and in good

condition. Emphasize the increased safety haz-

ards when instructions are not followed.

___ Explain to customer the potential crushing haz-

ards of going underneath raised equipment.

Instruct customer that service work does not

require going underneath unit and never to do so.

18 Parts

MAN0110 (Rev. 8/11/2006)

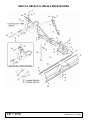

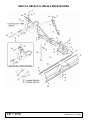

HBL72-2, HBL84-2 & HBL96-2 REAR BLADES

(Rev 11/9/2010)

Parts 19

MAN0110 (Rev. 8/11/2006)

HBL72-2, HBL84-2 & HBL96-2 REAR BLADES

REF PART HBL72-2 HBL84-2 HBL96-2 DESCRIPTION

1 1026709 1 1 1 HBL A-Frame with decals

2 HBL228 1 1 1 Clevis pin, 1 x 5 with clip

3 21624-1 1 1 1 1 NC x 7 Cap screw GR8

4 832 4 4 4 1" Flat washer

6 34279 2 2 2 1 NC Lock nut

8 27542 4 4 4 Lynch pin

9 HBL233 2 2 2 Drawbar pin

10 HBL225 3 3 3 Clevis pin, 1 x 2.6 with clip

11 18270 * 1 1 1 3/16 Hair pin clip

12 HBL222 1 1 1 Male link

13 HBL223 1 1 1 Female link

14 HBL227 1 1 1 Tilt position pin with clip

15 HBL226 2 2 2 Drop pin with clip

16 1026708 1 1 1 HBL Tilt turntable with decals

17 57817 4 4 4 5/8 Hardened flat washer

18 300461 * 4 4 4 5/8 NF x 1-1/2 Cap screw GR5

19 53500 1 1 1 Retainer plate

20 1026707 1 - - HBL72 Moldboard assembly

20 1026706 - 1 - HBL84 Moldboard assembly

20 1026705 - - 1 HBL96 Moldboard assembly

21 26920 6 7 8 5/8 NC x 1-3/4 Plow bolt GR5

22 6239 * 6 7 8 5/8 NC Lock nut

23 FA503 1 1 1 1NC x 3 Cap screw GR8

24 HBL210 1 1 1 Frame tube assembly

25 25258 1 - - HBL72 Cutting edge (12" bolt centers)

25 46440 - 1 - HBL84 Cutting edge (12" bolt centers)

25 25270 1 - - HBL96 Cutting edge (12" bolt centers)

26 56598 2 2 2 Category 2 adapter sleeve

27 54465 1 1 1 Complete safety decal set

28 55011 1 1 1 Parking stand

29 33000 1 1 1 3/8 x 2-1/4 Lynch pin

30 1002927 1 1 1 Complete decal set

31 1031222 1 1 1 Angle shim kit (weld-in)

32 43627 1 1 1 7/16 Linch Pin

33 43645 1 1 1 Clevis Pin, 3/4 x 5.5

34 7372 2 2 2 Sleeve, 25/32 x 1 x 2 (CAT2)

* Standard hardware, obtain locally

(Rev 11/9/2010)

20 Parts

MAN0110 (Rev. 8/11/2006)

TAILWHEEL KIT 1001533

REF PART QTY DESCRIPTION

1 1001530 1 Tail wheel retainer plate

2 57817 5 5/8 Hardened flat washer

3 6239 * 5 5/8 NC Lock nut

4 1001534 2 Tail wheel mast bar

5 902 * 4 5/8 NC x 2 Cap screw GR5

6 1001535 1 M4 Tail wheel tube assembly

7 3097 * 1 5/8 NC x 4-1/2 Cap screw GR5

8 13853 * † 1 3/8 x 1-3/4 Spirol pin

8 40775 • 1 Spirol pin, 10 mm x 65 mm

9 15314 † 1 Notat wheel yoke 4 x 16

9 1013220 • 1 Caster fork

10 23638 † 1 5/8 NC x 7 Cap screw GR5

10 1013878 • 1 M24 x 2.0P x 192 mm Spindle bolt

11 19025 † 1 5/8 NC Flange lock nut

11 20892 • 1 M24 x 2.0P Castle nut

12 57182 † 1 Sleeve, .656 x .997 x 5.39

12 1013219 • 1 Sleeve, .656 x .985 x 5.24

13 20879 † 1 Notat tire 4 x 16

13 1013222 • 1 Wheel assembly, 4 x 15

13A 1009091 † 1 Wheel hub Assembly

13A 1013879 • 1 ITG Wheel hub

REF PART QTY DESCRIPTION

13B 1009090 † 2 Bushing, flange 1.00 x 1.37 x 1.00

13B 1013880 • 2 Bushing, flange .984 x 1.378 x .984

14 29652 1 Right floating link

15 29653 1 Left floating link

16 7372 1 Sleeve 25/32 x 1 x 2

(CAT2 only)

17 1591 1 Clevis pin, 3/4 x 4-3/8

18 12558 2 3/4 NC x 4-1/2 Cap screw

19 2371 2 3/4 NC Lock nut

20 1257 2 3/4 Flat washer

21 1266 * 1 3/16 x 1-1/2 Cotter pin

22 2688 * 1 5/32 Hair pin cotter

23 HBL234 1 Top Link Clevis

24 43645 1 Clevis Pin, 3/4 x 5.5

25 43627 1 7/16 Linch Pin

26 19369 2 Sleeve .76 x 1 x 1.5

(CAT2 only)

27 12558 * 1 3/4 NC x 4-1/2 HHCS

28 2371 1 3/4 NC Lock Nut

29 1033970 1 Sleeve .782 x 1.000 x 3.13

* Standard hardware, obtain locally

† Burnt orange yoke

• Black yoke

(Rev 5/19/2011)

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

Woods HBL96-2 User manual

- Category

- Lawnmowers

- Type

- User manual

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Woods Equipment LRC60 User manual

-

Woods RD8400-2 User manual

-

Woods Equipment RB750-4 User manual

-

Woods DBH5.31 User manual

-

Woods DBH5.30 User manual

-

Woods Equipment MD80-2 User manual

-

Woods Equipment TS1680 User manual

-

Woods HSS72 User manual

-

Woods M208-2 User manual

-

Woods Equipment BB7200X User manual

Other documents

-

Land Pride RBT4096 User manual

Land Pride RBT4096 User manual

-

Land Pride RBT3596 User manual

Land Pride RBT3596 User manual

-

Hansen 5300 Operating instructions

Hansen 5300 Operating instructions

-

Land Pride RBT40 Series Quick start guide

-

Land Pride RBT40 User manual

Land Pride RBT40 User manual

-

HDX 21656CPS User guide

-

Land Pride RBT35 Series User manual

Land Pride RBT35 Series User manual

-

Woods Equipment DS96 User manual

-

Land Pride RBT40 User manual

-

Polaris 105475 Operating instructions