Contents i

1 About this docum entation ...................................................................................................................................... 5

1.1 Docum ent history ................................................................................................................................... 6

1.2 Conventions u se d...................................................................................................................................... 6

1.3 Term inology used ................................................................................................................................... 6

1.4 Notes used .................................................................................................................................................. 7

2 Safety in stru ctio n s....................................................................................................................................................... 8

2.1 General safety instructions for drive c om p on en ts.................................................................. 8

2.2 Application as directed ....................................................................................................................... 9

2.3 Foreseeable m isu s e ................................................................................................................................. 10

2.4 Residual hazards ...................................................................................................................................... 10

3 Product description ....................................................................................................................................................... 12

3.1 Identification ............................................................................................................................................. 12

3.1.1 Nameplate .............................................................................................................................. 13

3.1.2 Product key ............................................................................................................................ 15

4 Technical data ................................................................................................................................................................. 19

4.1 General data and operating conditions ................................................................................... 19

4.1.1 Setting the sw itching frequency to the rated m otor data

............................ 20

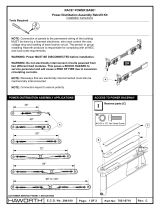

5 M echanical installation ............................................................................................................................................. 21

5.1 Im portant notes ........................................................................................................................................ 21

5.2 Preparation .................................................................................................................................................. 21

5.3 Assem bly o f built-on accessories..................................................................................................... 21

5.3.1 Installation .............................................................................................................................. 22

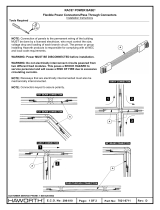

5.4 H olding brake (option) ......................................................................................................................... 22

5.4.1 Perm anent magnet holding brakes ......................................................................... 24

5.4.2 Spring-applied holding brakes ................................................................................... 26

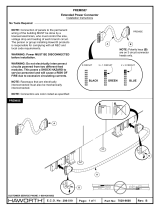

6 Electrical installation .................................................................................................................................................. 28

6.1 Im portant notes ........................................................................................................................................ 28

6.2 W iring according to EMC ....................................................................................................................... 29

6.3 Plug connectors ........................................................................................................................................ 29

6.3.1 Power connections / holding brake ............................................................................ 29

6.3.2 H olding brake ....................................................................................................................... 30

6.3.3 Fan ............................................................................................................................................. 30

6.3.4 Feedback system .................................................................................................................. 31

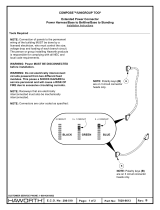

6.4 Term inal box ............................................................................................................................................. 32

6.4.1 Power connections ............................................................................................................ 33

6.4.2 H olding brake DC 205 V - connected via rectifier (optionl)

.........................

33

6.4.3 H olding brake DC 24 V (optional) .............................................................................. 33

6.4.4 Fan ............................................................................................................................................. 34

6.4.5 Feedback system .................................................................................................................. 35

Lenze • BA 33.0006 • 3.0 3