Page is loading ...

GM200FB, GM202FB, and

GM201UB

Corner Mantel Kit

Assembly and

Installation Instructions

Shown with optional trim kit

Firebox

Perimeter Brass

Trim included

with this

Mantel

2

For more information, visit www.desatech.com

Hardware included:

Finished Finished Oak Unfinished

• Header blocks (2) 101527-01 101527-01 101527-01

• Mounting strips (2) 101534-01 101534-01 101534-01

• Batten molding strip 103468-17 103468-19 103468-18

• Hardware package 101542-01 101542-01 101542-01

• Brass Trim Kit 102753-01 102753-01 102753-01

• Trim Kit Hardware 102865-01 102865-01 102865-01

Hardware required:

• 4 - 2

1

/

2

" Load-bearing Nails

Tools required:

• #2 Phillips screw driver (regular length)

• Electric drill

• 5/16" drill bit

• Hammer

• Pencil

• Level

• Measuring Tape

• Hand or electric saw

If any of these pieces are missing or damaged, contact the dealer where you purchased this kit or call DESA International’s Parts

Department at 1-800-972-7879 for information.

WARNING: Use care when finishing an unfin-

ished mantel. Finish pieces before assembly. Do not

finish mantel pieces near running heater or open

flame. Vapors from most finishing products are highly

flammable. Follow manufacturer’s guidelines when

using finishing products.

IMPORTANT:

If you are painting an unfinished mantel, apply an

oil base undercoat to the mantel before painting. This will seal the

wood. After undercoat dries completely, lightly sand and apply an

oil base top coat. If you do not apply an oil base undercoat and

topcoat, the wood grain will bleed through the paint.

1. Mantel must be installed flush with wall. Baseboard will pre-

vent proper installation of mantel. Baseboard can either be

altered to fit mantel or removed.

Note:

To avoid scratching mantel front pieces during assembly,

place a sheet or blanket on floor where mantel will be assembled.

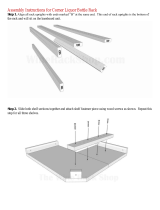

2. Remove header front panel from carton. Note position of or-

nament on front to identify top of piece. Place header front

panel face down on floor. Attach one header block to bottom

left of header approximately centered with one 1

1

/

4

" wood

screw, leaving remainder of block to overhang about one half

its length (see Figure 1). Attach one header block to the top

left of header approximately centered with one 1

1

/

4

" wood

screw, leaving remainder of block to overhang about one half

its length (see Figure 1).

Header

(Face Down)

Figure 1 - Attaching Header Blocks to Header

Header Blocks

1

1

/

4

" Wood Screw

IMPORTANT:

Read entire instruction sheet before assembling or installing mantel kit.

This mantel is only approved for use with CGFP28, VSGF28, VSGF33, VCGF30, and VYGF33 series natural gas and propane/LP

heaters, CGFB32 and (NL)FB32 series fireboxes, and 34" Direct-Vent fireplace systems. Do not use mantel with any other product.

Several optional accessories are available for this mantel kit. Contact dealer/retailer to purchase optional accessories.

WARNING: Carefully remove each mantel piece one at a time from the

shipping carton. Do not try to lift all of the parts out of the box at once. This

may damage mantel pieces.

GM200FB, GM202FB, & GM201UB CORNER MANTEL KIT

Assembly and Installation Instructions

3. Lay mounting strips on the floor. Place left and right sides

face down on mounting strips. Use the mounting strips to give

you a flat surface to work on while attaching sides to header.

Set header between right and left sides (see Figure 2, page 3).

The mounting blocks should overhang the side panels.

IMPORTANT:

To avoid damage to wood, do not kneel, lean,

or apply any pressure on the front panel in this position.

Slide header flush against left side. Align top of both pieces.

Insert 1

1

/

4

" wood screws through predrilled holes in mount-

ing block (see Figure 2, page 3). Make sure top of header and

sides are still flush and all pieces fit tightly together. Tighten

screws to fasten header to left side. Repeat to attach header to

right side (see Figure 2, page 3).

NOTE:

The mantel assembly will be loose until you attach

the top.

3

For more information, visit www.desatech.com

Mounting

Strips

2

1

/

2

" Nails

Level

Figure 3 - Installing Mounting Strips

Mantel Top

Figure 4 - Placing Top on Mantel Front Assembly.

Predrilled Holes

Top

Outside of

Mantel Front

Assembly

Inside of

Mantel Front

Assembly

Screw

Figure 5 - Placing Top on Mantel Front Assembly

Predrilled

Holes

Continued

47

1

/

4

"

Baseboard

Wall Studs

30" max

Header

Figure 2 - Connecting Header to Left and Right Legs

Legs

Wall Mounting

Strips

1

1

/

4

" Wood Screw

Header Block

Mounting Strips

Figure 6 - Attaching Top to Mounting Strips

3" Wood

Screws

4. Find studs in corner where mantel will be installed. Measure

47

1

/

4

" from floor (see Figure 3). Mark measurements parallel

to floor. Align top of mounting strip with penciled mark within

30" of the corner. Use a level to ensure mounting strips are

level (see Figure 3). Attach strip to wall with two 2

1

/

2

" nails.

Note:

Do not use smaller nails. These nails will be load- bear-

ing. Repeat above steps to attach mounting strip to facing wall.

5. Place top on front assembly. Make sure molding on mantel

top fits properly over front and side panels. Locate predrilled

holes inside of mantel front assembly (see Figure 4). Attach

mantel top to front mantel assembly from the inside with 1

1

/

4

"

wood screws provided (see Figure 5).

6. Have someone help you carefully lift mantel front assembly

to its upright position. If baseboard is to be customized for

mantel, move assembly to corner where it will be installed.

Use a pencil to mark where baseboard will be altered. Re-

move sections of baseboard.

7. To attach top to wall mounting strips, drill one hole through

the bottom of each mounting strip under the top (see Figure

6). Be sure to drill hole a short distance into top to help start

wood screws. Have someone hold the mantel in place while

drilling holes.

IMPORTANT:

Do not drill through the top. Do not drill too

close to edge of top. This may damage the wood.

Use 3" wood screws to attach top to mounting strips.

8. If gas line is not installed, follow steps 9 and 10 to install gas

line.

WARNING: A qualified service person must in-

stall gas piping to heater. Follow all local codes.

3 3/16"

2701 Industrial Drive

P.O. Box 90004

Bowling Green, KY 42102-9004

Technical Service Department 1-800-323-5190

Parts Department 1-800-972-7879

www.desatech.com

107189-01

Rev. B

05/00

Figure 7 - Attaching Batten Molding Strip to Mantel Front

Batten

Molding

Strip

Header

Trim Kit

Colored Finishing Nails

Assembled

Brass Trim

Trim Hanging

Shoulder Screws

Hanging

Notches

on Trim

Shoulder Screw

Hanging

Notches

on Trim

Figure 9 - Assembling Brass Trim

Figure 8 - Assembling Brass Trim

Side Brass

Trim

Mitered Edge

Shim

Adjusting

Plate

Set Screws

Top Brass Trim

Slot

Assembling and Installing Brass Trim

1. Remove packaging from three pieces of brass trim.

2. Locate 2 adjusting plates with set screws and 2 shims in the

hardware packet.

3. Align shim under adjusting plate as shown in Figure 8.

4. Slide one end of adjusting plate/shim in slot on mitered edge of

top brass trim (see Figure 8).

5. Slide other end of adjusting plate/shim in slot on mitered edge

of side brass trim (see Figure 8).

Slot

107189 01

NOT A UPC

9. Note location of gas line. Mark floor or wall behind heater

for gas line entrance. Make sure there is enough clearance

between heater and mantel for gas lines.

IMPORTANT:

Make

sure there are no electrical lines where gas piping will go

through floor or wall.

10. From gas meter or propane tank, run hard piping to equip-

ment shutoff valve. You must install the equipment shutoff

valve within reach from heater. Install an approved flex hose

(if allowed by local or state codes) for natural or propane gas

to run from the equipment shutoff valve to heater.

WARNING: Never use an open flame to check for

a leak. Apply a mixture of liquid soap and water to all

joints. Bubbles forming show a leak. Correct all

leaks at once.

11. Connect heater to gas line according to instructions in heater

owner’s manual. Check all connections for leaks from heater

to gas meter or propane tank.

Note:

If optional trim kit is to be installed with mantel, follow in-

structions included with the accessory to attach to mantel front piece.

12. To attach batten molding to mantel assembly, measure up

3

3

/

16

" from bottom of header (see Figure 7). Place bottom

of batten molding at this measurement. If optional trim kit

is installed on mantel, make sure molding covers top edge

of trim. It may be necessary to lightly sand ends of the mold-

ing to ensure proper fit. Use masking tape to hold molding

in place. Use level to ensure proper positioning. Drill a pi-

lot hole through molding and mantel with a small drill bit.

Attach to mantel front panel with colored finishing nails.

IMPORTANT:

Keep nails centered on molding to prevent split-

ting. Fill nail holes with wood putty. Touch up paint on painted

mantels.

CAUTION: Nails will bend if pilot hole is not

drilled.

13. Break off nailing flanges using a hammer or pliers. Place

heater in front opening of mantel. Make sure all pieces fit

properly before attaching heater to floor. Follow instructions

included with heater to attach to floor.

IMPORTANT:

Do not place heavy objects on mantel.

14. After firebox is secured, replace mantel. Assemble and in-

stall brass trim.

6. While firmly holding edges of brass trim together, tighten both

screws on the adjusting plate using a slotted screwdriver.

7. Repeat steps 1 through 6 for other side.

8. Locate seven hanging shoulder screws in hardware packet.

Tighten the seven hanging shoulder screws (#10-16x.50 long with

.12 shoulder) into holes on firebox sides. Place the assembled

trim onto firebox cabinet. Align hanging notches on trim with

hanging screws on side of firebox (see Figure 9). Tap trim firmly

into place with palm of hand engaging hanging notches around

shoulder screws. Start at one end of the trim and work around

firebox until all notches are fully engaged.

/