Page is loading ...

RVS-DN Digital Soft Starter

I

nstruction Manual

Power Control Systems

April 1, 2004

Pa

rt Number: 188-10036

© Copyright 2004 Magnetek

RVS-DN, Digital Soft Starter Instruction Manual— 04/01/04

Contents:

Disclaimer of Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii-iii

Chapter1: Introduction

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Starter Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Starter Selection When Operating "Inside the Delta". . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Maximum Starts Per Hour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Chapter 2: Installation

Physical Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Bypass After Acceleration Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

230/460 Volt Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Chapter 3:Terminals

Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Chapter 4: Wiring

Control Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Typical Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Inside the Delta Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Fan Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Chapter 5 : Internal Control Layout

Control Module Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Digital Operator Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Dip Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Memory System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

RVS-DN, Digital Soft Starter Instruction Manual— 04/01/04

Chapter 6: Features

Start/Stop Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Optional Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Motor Protection Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Chapter 7: Parameters

Parameter Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Chapter 8: Start-Up Procedure

Start-Up Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Start-Up Procedure with Pump Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Chapter 9: Troubleshooting

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Appendix A: Technical Data/Specifications

Technical Data/Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Appendix B: Application Drawings

Typical Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Bypass After Acceleration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Reversing with Contactors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Operation from a Generator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Brake Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Insulation Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

Appendix C: Dimensional Drawings

Dimensional Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

RVS-DN, Digital Soft Starter Instruction Manual— 04/01/04

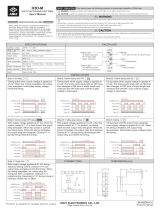

Appendix D: UL/cUL Installation Instructions

Ul/cUL Installation Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-3

Appendix E: Fuse Selection

Fuse Selection Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-3

Appendix F: Overload Trip Time Calculation

Overload Trip Time Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-3

RVS-DN, Digital Soft Starter Instruction Manual—4/01/04

i

©2004 MAGNETEK

All rights reserved. This notice applies to all copyrighted materials included with this product,

including, but not limited to, this manual and software embodied within the product. This manual is

intended for the sole use of the persons to whom it was provided, and any unauthorized distribution

of the manual or dispersal of its contents is strictly forbidden. This manual may not be reproduced in

whole or in part by any means whatsoever without the expressed written permission of Magnetek.

DANGER, WARNING, CAUTION and NOTE Statements

DANGER, WARNING, CAUTION, and Note statements are used throughout this manual to

emphasize important and critical information. You must read these statements to help ensure safety

and to prevent product damage. The statements are defined below.

DANGER

DANGER indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury. This signal word is to be limited to the most extreme situations.

WARNING

WARNING indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION

CAUTION indicates a potentially hazardous situation which, if not avoided, could result in

minor or moderate injury. It may also be used to alert against unsafe practices.

NOTE: A NOTE statement is used to notify people of installation, operation, programming,

or maintenance information that is important, but not hazard-related.

RVS-DN, Digital Soft Starter Instruction Manual—4/01/04

i

i

Disclaimer of Warranty

Magnetek hereafter referred to as Company, assumes no responsibility for improper installation of a

soft starter by untrained personnel. A soft starter should only be installed by a trained technician who

has read and understand the contents of this manual. Improper programming of a soft starter can lead

to unexpected, undesirable, or unsafe operation or performance of the soft starter. This may result in

damage to equipment or personal injury. Company shall not be liable for economic loss, property

damage, or other consequential damages or physical injury sustained by the purchaser or by any

third party as a result of such programming. Company neither assumes nor authorizes any other

person to assume for Company any other liability in connection with the sale or use of this product.

IMPORTANT

1. Read this manual carefully and follow its instructions before operating equipment.

2. Installation, operation, and maintenance should be in strict accordance with this manual,

national codes and good practice. Installation or operation not performed in strict accordance

with these instructions will void manufacturer’s warranty.

3. Disconnect all power inputs before wiring or servicing the equipment.

4. After installation, verify that no hardware (bolts, washer, etc.) have fallen into the power

section.

WARNING

1. Internal components and printed circuit boards are at main potential when the RVS-DN is

connected to main power. This voltage is extremely dangerous, and may cause death or severe

injury if contacted.

2. The control PCB employs CMOS ICs that are easily damaged by static electricity. Use proper

electrostatic discharge (ESD) procedures when handling the control PCB.

3. When the RVS-DN is connected to main power, even if control power is not connected and the

motor is stopped, full voltage may appear on the RVS-DN’s output terminals.

4. RVS-DN must be grounded to ensure correct operation, safety, and to prevent damage.

5. Power factor capacitors must NOT be connected to the output side of the RVS-DN.

WARNING

Improper installation of a soft starter can lead to unexpected, undesirable, or unsafe operation

or performance of the soft starter.

RVS-DN, Digital Soft Starter Instruction Manual—4/01/04

i

ii

ATTENTION

1. This product was designed for compliance with IEC 947-4-2 for class A equipment.

2. RVS-DN units rated 8 to 1800 amps are listed under UL508C.

3. RVS-DN units rated 8 to 1400 amps are LR approved. RVS-DN units rated 1800 amps and

larger are designed to meet LR requirements.

RVS-DN, Digital Soft Starter Instruction Manual—4/01/04

i

v

chapter

1

Introduction

This page intentionally left blank.

RVS-DN, Digital Soft Starter Instruction Manual–4/01/04

1-3

Overview

The RVS-DN is a highly sophisticated and reliable starter designed for use with standard three-

phase, three-wire, squirrel cage induction motors. It provides the best method of reducing current

and torque during motor starting. The RVS-DN starts the motor by supplying slowly increasing

voltage to the motor, providing a soft start and smooth acceleration, while drawing the minimum

current necessary to start the motor.

The RVS-DN’s microprocessor based digital circuitry provides unique features such as pump

control, slow speed, electronic reversing and accurate motor protection with optional insulation

protection, thermistor input, etc. The optional RS-485 communication with Modbus RTU protocol

enables full control (start, stop, dual adjustment commands, etc.) and supervision. For detailed

information on RS-485/Modbus RTU serial communication, see technical manual #188-10072.

Starter Selection

When selecting a RVS-DN soft starter for your application, you need to consider the following

information:

Motor Current and Starting Conditions:

Select the RVS-DN according to the motor FLA as indicated on its nameplate (even if the motor

will not be fully loaded). The chart on the following page indicates ratings, frame sizes and

protected chassis part number for each input voltage range. The RVS-DN is designed to operate

at 400% of motor FLA for 30 seconds at 50°C allowing (4) four starts per hour at these

maximum conditions.

NOTE: See “Maximum Starts per hour” to calculate additional starts per hour. For very

frequent starts (inching applications) the inching current should be considered as the

FLA.

Supply Voltage (Line to Line)

Standard mains voltage: 220-240 Volts

460-500 Volts

575-600 Volts

Special order voltage: 380-440 Volts

660-690 Volts

1000 Volts

NOTE: All RVS-DN units are suitable for 50/60 Hz.

Control supply voltage: 110-120 Volts (+10% -15%); 50/60 Hz (standard)

220-240 Volts (+10% -15%); 50/60 Hz

Control Inputs: 110-120 Volts (+10% -15%); 50/60 Hz (standard)

220-240 Volts (+10% -15%); 50/60 Hz

24 volts DC

RVS-DN, Digital Soft Starter Instruction Manual–4/01/04

1-4

Approximate Dimensions and Weights:

Max. FLA Frame Size 230/460 Volt 575V

8

A

RVS-DN-8-D RVS-DN-8-E

17 RVS-DN-17-D RVS-DN-17-E

31 RVS-DN-31-D RVS-DN-31-E

44 RVS-DN-44-D RVS-DN-44-E

58 RVS-DN-58-D RVS-DN-58-E

72 RVS-DN-72-D RVS-DN-72-E

85

B

RVS-DN-85-D RVS-DN-85-E

105 RVS-DN-105-D RVS-DN-105-E

145 RVS-DN-145-D RVS-DN-145-E

170 RVS-DN-170-D RVS-DN-170-E

210

C

RVS-DN-210-D RVS-DN-210-E

310 RVS-DN-310-D RVS-DN-310-E

390 RVS-DN-390-D RVS-DN-390-E

460

D

RVS-DN-460-D RVS-DN-460-E

580 RVS-DN-580-D RVS-DN-580-E

820 RVS-DN-820-D RVS-DN-820-E

1100

E

RVS-DN-1100-D RVS-DN-1100-E

1400 RVS-DN-1400-D RVS-DN-1400-E

1800 RVS-DN-1800-D RVS-DN-1800-E

2150 F RVS-DN-2150-D RVS-DN-2150-E

2400

G

RVS-DN-2400-D RVS-DN-2400-E

2700 RVS-DN-2700-D RVS-DN-2700-E

Frame Size Width (in.) Height (in.) Depth (in.) Weight (lbs.)

A 6.02 12.20 8.54 16

B 10.82 15.16 9.37 33

C 14.96 17.91 11.50 99

D 24.53 26.00 11.42 143

E 28.50 43.30 14.56 374

F 29.53 51.18 15.43 518

G 35.43 51.18 16.14 772

RVS-DN, Digital Soft Starter Instruction Manual–4/01/04

1-5

Starter Selection When Operating “Inside the Delta”

Using the RVS-DN soft starter “inside the delta” reduces the required soft starter rating by 1.73(√3)

factor. As an example, for a 150 amp, 460 volt motor, the RVS-DN-170-D is selected to operate in

standard ‘line’ mode. However, for ‘inside the delta’ mode (150 amp ÷1.73 = 87 amps), the RVS-

DN-105-D can be selected. Therefore, reducing cost and physical space in the application.

The following programming parameters are disabled, once the ‘inside the delta’ is selected:

• Pulse Start

• Pump Curve selection (only standard curve available)

• Energy Saver

• Slow Speed and Slow Speed Reverse

• Phase Sequence

The motor ratings for standard Line and Inside the Delta connections are shown here:

Model Number RVS-DN FLA

HP at 460V for

“Line”

HP at 460V for

“Inside Delta”

RVS-DN-8-D 8 5 7.5

RVS-DN-17-D171015

RVS-DN-31-D312032

RVS-DN-44-D443050

RVS-DN-58-D584068

RVS-DN-72-D725085

RVS-DN-85-D 85 60 100

RVS-DN-105-D 105 75 125

RVS-DN-145-D 145 100 170

RVS-DN-170-D 170 125 215

RVS-DN-210-D 210 150 250

RVS-DN-310-D 310 200 340

RVS-DN-390-D 390 300 515

RVS-DN-460-D 460 450 750

RVS-DN-580-D 580 600 1000

RVS-DN-820-D 820 800 1350

etc...

HP Ratings are approximate. The RVS-DN should always be sized by

the motor full load amps when using standard “line” connection; and

motor FLA/1.73= inside delta FLA for “inside delta” connection.

NOTE: See page 4-7 for “Inside the Delta” wiring

RVS-DN, Digital Soft Starter Instruction Manual–4/01/04

1-6

Maximum Starts Per Hour

For many applications it is important that the RVS-DN operate continuously even under extremely

severe load or environmental conditions. A conservative selection of the SCR’s and a superior heat-

sink cooling system has made continuous, reliable operation of the RVS-DN soft starter possible.

The RVS-DN is limited to the number of starts it can perform in an hour.

The number of starts per hour is dependant upon the following:

–Ambient temperature inside the enclosure

–Starting current (percentage of starter FLC)

–Duration of starting current (during which full starting current is flowing)

An appropriate formula for calculating the maximum starts per hour:

Where: N = the number of starts per hour

SFLC = the RVS-DN’s rated full load amps

MFLA = the rated full load amps of the motor

CL = “Current Limit” setting

T = actual starting time

EXAMPLE:

The motor is rated at 65 amps. The RVS-DN starter is rated at 72 amps with a “Current

Limit” setting of 350%. The actual measured starting time is 5 seconds.

NOTE: It is assumed that the starts will not be one immediately after another, but will be spread

out throughout the hour.

NOTE: For very frequent starts (inching/jogging), the heatsink (which has a very large mass) will

heat up more slowly than the thyristor junction. This could cause a failure in the thyristors

prior to the starter tripping on “OVERTEMPERATURE”. Therefore, the jogging current

should be considered the full load current.

N = 4 x

SFLC x 400 x 30

MFLA x CL x T

N = 4 x

72 x 400 x 30

65 x 350 x 5

N = 30 starts per hour

chapter

2

Installation

This page intentionally left blank.

RVS-DN, Digital Soft Starter Instruction Manual–4/01/04

2-3

Physical Installation

Location of the RVS-DN is important to achieve proper performance and normal operating life. The

unit should be installed in an area where it will be protected from.

• Direct sunlight, rain or moisture

• Corrosive gases or liquids

• Vibration, airborne dust or metallic particles

When preparing to mount the RVS-DN, lift it by its base, never by the front cover. For effective

cooling as well as proper maintenance, the RVS-DN must be installed on a flat, non-flammable

vertical surface (wall or panel) using four mounting screws. There must be a minimum of 4.7 in.

clearance above and below the RVS-DN for sufficient air flow. A minimum of 1.2 in. clearance is

required on each side of the RVS-DN.

The protected chassis is rated to operate over a temperature range of -14°F (-10°C) to +122°F

(50°C).

Enclosures

If the RVS-DN is to be mounted in an enclosure, the size of the enclosure should be determined by

the heat dissipation. The RVS-DN’s watts loss is approximately 3 x the FLA in watts. (Example-for

a motor of 100A, expect the watts loss of the starter to be 300 watts.)

NEMA 1 enclosure–The NEMA 1 must be properly ventilated or additional fans may be needed.

NEMA 12 enclosure–The NEMA 12 enclosure will require some means of reducing internal

enclosure heating. This can be accomplished by:

• additional ventilation (fan and filters)

• bypass after acceleration option

Bypass After Acceleration Option

The bypass after acceleration option allows the RVS-DN to control the motor during starting and

stopping for smooth, stepless acceleration and deceleration. However, once up to full voltage the

RVS-DN is bypassed to eliminate the watts loss. After the soft stop is initiated the motor switches

back from bypass to the RVS-DN.

To maintain full motor protection while in bypass:

The preparation for bypass option requires bus bar extensions for frame sizes C through E. These bus

bar extensions can be ordered from Magnetek and field installed. The current transformers (CTs) are

moved up onto the bus bar extensions, allowing the bypass to be wired after the CTs. In this manner

the CTs are always monitoring current even in bypass mode.

Frame size A must be special ordered with preparation for bypass. Frame size A (8-72 amps) will

have 3 additional terminals labeled L1b, L2b, L3b. These terminals are wired in after the CTs,

allowing current to be monitored even while in bypass. Frame size B (85-170 amps) comes standard

RVS-DN, Digital Soft Starter Instruction Manual–4/01/04

2-4

with 3 additional bus bars, labeled L1b, L2b, and L3b. These bus bars are wired in after the CT’s,

allowing current to be monitored even while in bypass. Consult Magnetek’s soft starter price book

for part numbers and pricing of the preparation for bypass option.

See appendix B, Application Drawings, for detailed wiring drawing of bypass after acceleration.

230/460 Volt Setup

All units rated for 230/460 volts will be shipped configured for 460 volt operation. If using 230 volt

supply, the under and overvoltage settings will need to be modified as follows.

Please see Chapter 7 for programming instructions.

Supply Voltage

RVS-DN Setting 575 460 230

Under Voltage 512 397 197

Over Voltage 635 521 293

chapter

3

Terminals

This page intentionally left blank.

/