1131 VIA CALLEJON, SAN CLEMENTE, CA

R

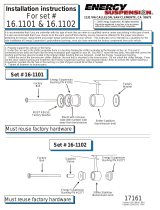

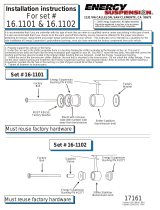

Check all hardware to be sure that it has been tightened to factory specifications

It is recommended that your vehicle be professionally aligned after this installation

17377

21303PSNJT

Updated 15/FEB/05 BRH

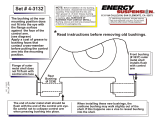

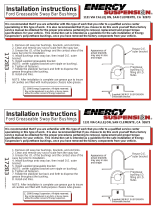

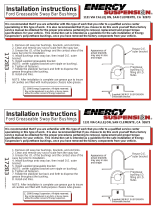

Installation Instructions 5.3128

2000-JAN/01 Mitsubishi Eclipse

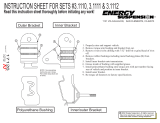

It is recommended that if you are unfamiliar with this type of work that you refer to a qualified service center specializing in this type of work. It is also recommended

that if you choose to do this work yourself that a factory service manual be obtained for the proper procedures pertaining to removal, replacement and proper torque

specifications for your vehicle. This instruction set is intended as a guideline for the safe installation of Energy Suspension’s Polyurethane.

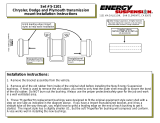

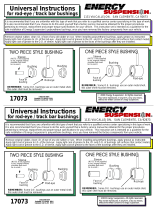

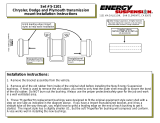

1. Starting with the trailing arm (p/n 8144 & 15.10.374.39) , remove the access

cover on the inside of the fender well (photo 1) to gain access to the pivot bolt.

Loosen and remove. At the spindle loosen and remove the bolt that secures the

trailing arm to the spindle and lower out of vehicle.

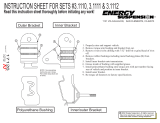

2. Using an arbor press or

hydraulic press remove the

original bushing and outer

metal sleeve from trailing arm.

(Photo 2) Be careful not to

damage the loop that the

bushing is installed. Once the bushing has been removed, clean

and de-burr all bushing surfaces. Using the supplied lubricant,

grease the ID of the trailing arm and the ID of bushing. HINT, install

a liberal amount of grease to the leading edge of the bushing

prior to insertion. Install sleeve and assemble trailing arm in

reverse order of removal.

Photo 1

Photo 2

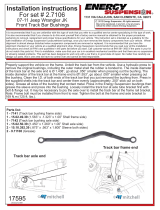

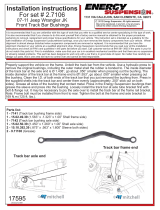

3. At the lower control arm disassemble and set aside the rear sway bar endlink

assembly. (Photo 3) Loosen and remove the pivot bolt at the rear cross member,

loosen and remove the attachment bolt at the spindle. Make certain that all

cables and or wiring which may or may not be attached to your control arm have

been removed and safely tucked out of harms way.

4. Using the same procedure as in step 2,

remove the bushing and outer shell from the

control arm making certain not to damage the

outer loop of the control arm. Grease the ID of

the loop and the ID of the bushing (p/n 3403)

and install into control arm. Insert metal sleeve

(p/n 15.10.334.39) and install control in reverse

order of removal.

5. At the upper control arm loosen and remove the bolt holding the control arm to

the top of the spindle (Photo 4). Secure the spindle out of harms way during the

remainder of this procedure making sure not to over extend or pinch the brake

lines. Loosen and remove the two pivot bolts on either side of the control arm

assembly at the body and remove arm from vehicle. Using the same procedure as

in step two, remove the two pivot bushings making sure not to damage the loop.

Grease the ID of the loop and the ID of the bushings (p/n 2475) and install into arm.

Install both sleeves (p/n 15.10.458.39) and install arm in reverse order of removal.

Photo 3

Photo 4

1

15.10.458.39 x 1

15.10.374.39 x 1

15.10.458.39 x 1

Updated 8/JAN/03 BRH

Updated 23/JAN/04 BRH

Updated 14/JAN/05 BRH

2005 Energy Suspension. All rights reserved.2005 Energy Suspension. All rights reserved.

CC

May not be reproduced, in any form, or by any means,

without the written consent of Energy Suspension.

May not be reproduced, in any form, or by any means,

without the written consent of Energy Suspension.

-

1

1

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Energy Suspension 4.3132G4.3132G Operating instructions

Energy Suspension 4.3132G4.3132G Operating instructions

-

Energy Suspension 3.1112G3.1112G Operating instructions

Energy Suspension 3.1112G3.1112G Operating instructions

-

Energy Suspension 2.7106G Installation guide

Energy Suspension 2.7106G Installation guide

-

Energy Suspension 2.7107G Installation guide

Energy Suspension 2.7107G Installation guide

-

Energy Suspension 16.7106G16.7106G Operating instructions

Energy Suspension 16.7106G16.7106G Operating instructions

-

Energy Suspension 31mm Front Sway Bar Bushings Installation guide

Energy Suspension 31mm Front Sway Bar Bushings Installation guide

-

Energy Suspension 19mm Rear Sway Bar Bushing Set Installation guide

Energy Suspension 19mm Rear Sway Bar Bushing Set Installation guide

-

Energy Suspension 4.5162G4.5162G Operating instructions

Energy Suspension 4.5162G4.5162G Operating instructions

-

Energy Suspension 5.1101G5.1101G Operating instructions

Energy Suspension 5.1101G5.1101G Operating instructions

-

Energy Suspension 16.1102G16.1102G Operating instructions

Energy Suspension 16.1102G16.1102G Operating instructions

Other documents

-

Fiat 500 Workshop Manual

-

Polaris 600 EDGE Touring 121 User manual

-

Polaris EDGE Snowmobile Owner's manual

-

Volkswagen Polo Workshop Manual

-

Snowmobiles 120 Indy Owner's manual

-

Polaris 340 / 600 / 800 EDGE Touring / Trail Touring / WideTrak LX Owner's manual

-

Polaris WideTrak User manual

-

Polaris Universal Snow Owner's manual

-

Polaris Frontier Classic / Touring Owner's manual

-

Polaris 550 Transport Trail Touring Owner's manual