Page is loading ...

1 General

1.1 General product information

1.2 Cable types

1.3 Symbols in this guide

2 Tools Required

3 Parts List

3.1 Kit content

3.2 Terminal components

3.3 Configuration overview

4 Feeder cable preparation

5 Product Installation

5.1 Take out organizer with pre-connectorized

adapter drops

5.2 Secure feeder cable in the gel seal cable plugs

5.3 Store the loop (buffer tubes) in the basket

5.4 Store stripped/shaved tubes in the basket of

the base tray

5.5 Make fusion splice and store overlength in the

splice tray

5.6 Insert the gel strips

6 Close and lock the terminal closure

6.1 Place the organizer with pre-connectorized

adapter drops in the terminal housing

6.2 Close the terminal housing latches and lock

the terminal housing

6.3 Re-entry recommendations

7 Pedestal mounting

7.1 Installation on universal back plate

7.2 Installation on D-Bar

Content

1 General

1.1 General product information

The Mini-OTE 400 is a compact terminal allowing the feeder cable to be field installed in fiber-to-the-x (FTTx) architectures. Featuring pre-

connectorized hardened full-size OptiTap® or mini-size DLX® adapter ports, CommScope’s Mini-OTE 400 terminal enables FTTH deployment in

brown field and green field applications, with or without coax in place. The terminal is designed for a butt splice configuration in pedestal and hand

hole applications. The Mini-OTE 400 terminal is available with 2, 4 or 8 drops.

1.2 Cable types

The Mini-OTE 400 terminal is available with 2, 4 or 8 drops and two entry/exit ports accommodating up to 72F stranded loose tube micro cable

with cable diameter range 4.5 - 6 mm (0.18 ” - 0.24 ” ).

Feeder cable Ø 4.5 - 6 mm (0.18 ” - 0.24 ” )

Fiber types include single fiber 250micron, A2 fiber.

Mini-OTE 400

INSTALLATION INSTRUCTION

Mini-OTE 400

TC-1335-IP

Rev C, March 2017

www.commscope.com

1.3 Symbols in this guide

Note Presents useful information related to Installation Guide contents, the references and data related to the product’s use, etc.

i

Caution Describes situations where data loss and incorrect product operation may occur, and provides proper actions to take in these

situations.

!

Warning Describes a situation where product damage and user injury may occur, and provides proper actions to take in these situations.

All tools to prepare and clean cables

Socket wrench 1/4” or a flat screw driver to secure the hose clamps

Socket wrench 7/16”

Phillips screw driver

Hexagonal wrench

Pincers

2 Tools required

2

Item # Description

1 Mini-OTE 400 Terminal

2 Strength member fixation plates and screws

3 Cable ties

4 Orange rubber tubing

5 Fiber picker

6 Security bolt

7 Spiral tubing

Item # Description

8 Foam strips

9 Gel strips

10 Plastic clip

11 7/16” hex bolts

12 Color Code label

13 Cleaning tissue

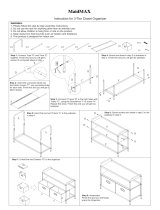

3 Part list

3.1 Kit content

1

2

3

4

5

6

7

8

9

10

13

11

12

3.2 Accessory kit for pedestal mounting

3

3.2 Terminal components

Front view Back view

Splice tray

Basket with storage for

fibers from drops and

dark fiber storage

CTU

Gel seal cable plugs

Pre-connectorized adapter drops

(2,4 or 8 drops)

Multiple hinge clamp

with latches

Basket with loop storage

3.3 Configuration overview

THIS DRAWING IS A CONTROLLED DOCUMENT

1 PLC

0 PLC

2 PLC

3 PLC

4 PLC

DIMENSIONS:

TOLERANCES UNLESS

OTHERWISE SPECIFIED:

USED ON

LTR APVDDATEREVISION RECORD DWN

DWG NO

SIZE

OF

C

1

2

3456

7

8

A

B

DRAWING NO

D

SHEET R

EV

APVD

DWN

CHK

NAME

SCALE

MATERIAL HEAT TREAT

ANGLES

SURFACE TEXTURE

A3

3306

© 2016 COMMSCOPE, INC.CONFIDENTIAL

NOTICE: THESE DRAWINGS AND SPECIFICATIONS ARE THE PROPRIATARY PROPERTY OF

COMMSCOPE, INC.AND MAY BE USED ONLY FOR THE SPECIFIC PURPOSE AUTHORIZED IN WRITING BY COMMSCOPE, INC.

COMMSCOPE, INC.

AA

P1

P3

P5

P7

P2

P4

P8

P6

P9

P10

EK3982-PD-00

EK3982-PD-00

P.Doultremont

12AUG2016

-

-

-

-

17:100

1 1

1

-

-

-

-

mm

-

-

-

-

-

1

-

-

FST-SPC-Inner

DRW0001

DRW0001

-

-

-

-

-

-

1:10

1 1

-

-

-

-

mm

-

-

-

-

-

1

-

drw0001.drw

-

-

A-A

Feeder cable

Feeder cable

P10 and P9 are the feeder cable positions.

Other ports are pre-connectorized adapter drops, with color code:

CONFIGURATION

Connector 1

(P1)

Connector 2

(P2)

Connector 3

(P3)

Connector 4

(P4)

Connector 5

(P5)

Connector 6

(P6)

Connector 7

(P7)

Connector 8

(P8)

BLUE ORANGE GREEN BROWN SLATE WHITE RED BLACK

2 DROPS x x

4 DROPS x x x x

8 DROPS x x x x x x x x

i

Dummy port plugs are factory-installed in ports without drops for 2 and 4 port terminals.

A A

4

4 Feeder cable preparation

4.1 Make window cut of 2.5m (100’’). Make sure oscillation point

is in the middle.

4.3 Remove the aramid yarn. 4.4 Cut the strength members to a length of 45mm (1.77”) from the

cable jacket end. Cut it in the middle of the window cut. The strength

member can be taken out now.

4.2 Use rip cord to strip jacket when available.

4.6 Cut the spiral tube in segments and place the spiral tube

segments over the non used buffer tubes. Place it over the oscillation

points of the cable.

4.5 Take out carefully the buffer tube that need to be connected

with the pre-connectorized drops.

i

Make sure no buffer tubes get damaged.

Mid cut: Cut the tube in the middle and strip the active and non-active

tube 55mm (2.17”) from the jacket end.

Shaving: Mark tube at both sides 55mm (2.17”) from jacket end. Shave

the tube between these 2 marks.

Oscillation point

Rip cord

45mm (1.77’’)

55mm (2.77’’)

4.7 Wrap the foam strips at the jacket ends. 4.8 End result.

5

5.1 Take out organizer with pre-connectorized adapter drops.

5.2 Secure the feeder cable in the gel seal cable plugs

5 Product installation

5.2.1 Open the multiple hinge clamp latches.

5.1.2 Hinge top cover open.

5.1.3 Remove foam. This foam is for packaging purpose and don’t

need to be reinstalled.

5.1.1 Open latches.

5.2.2 Remove dummy plugs in position P9 and P10 (see feeder

cable position in the configuration overview (point 3.3)).

i

Do not remove dummy plugs from ports without a factory-installed

drop for 2 and 4 port terminals.

5.1.4 Take out the organizer with pre-connectorized adapter drops.

5.2.3 Remove the hose clamps on the inside.

Don’t remove cable tie on the outside.

5.2.4 Place the cable in the free ports (P9 and P10).

i

Make sure the foam is placed in the metal part.

i

Front side

Front side

Back side

6

5.2.5 Bring shaved/stripped tube to the front side.

i

Be careful with the pre-installed pigtails.

5.2.8 Place shaved/stripped tubes in the outer tube holder channel

of the base tray. Insert orange rubber tube.

i

Align the orange rubber tube with the rib indicated by the arrow.

5.2.7 Secure the strength members.

5.2.6 Bring strength member to the CTU at the back side.

i

Wrong installation: make sure tube is not twisted around the

strength member.

i

Wrong installation: don’t bring strength member to the front side.

5.2.9 Close the latches of the multiple hinge clamp.

Front side

Back side

5.2.10 Secure the hose clamps on the inside again.

i

Be careful with the pre-installed pigtails.

7

5.2.11 Secure the tie wraps at the outside.

5.3.3 Secure the loop with 3 cable ties.

5.4.1 The basket in the base tray is designed to store dark fiber or

unused shaved fibers.

5.3.1 Carefully make a loop of Ø 11 cm (4.33’’). 5.3.2 Fit the loop in the basket at the back side.

5.4 Store stripped/shaved tubes in the basket of the base tray

5.3 Store the loop (buffer tubes) in the basket at the backside

8

5.5.1 Route the fibers from the basket in the base tray to the splice

tray via channel as indicated in above photo.

5.6.1 Bend plastic clip.

5.5.2 Make fusion splice and store fiber overlength and SMOUV(s)

as standard practice.

5.5.3 If the fibers (feeder and drop) come from the same side on

the tray, one of the 2 fibers need to make a cross on the tray (see white

dotted line on the picture).

5.6.2 Place folded plastic clip over gel strip.

5.5 Make fusion splice and store overlength in the splice tray

5.6 Insert the gel strips

5.6.3 Push gel strip covered with plastic clip through opening

near gel seal cable plug from the back side (loop storage) to the

front side.

5.6.4 Pull gel strip covered with plastic clip at the front side until

plastic clip is completely pushed through.

Back side

Front side

9

5.6.7 Press on gel strip end to ensure gel adhesion.

6.1.2 Face back side of organizer towards the bottom cover. Make

sure the pen located in the bottom cover is inserted in the organizer.

6.1.1 Paste the color code label in the bottom cover. Fill in color

code info before placing the organizer in the terminal housing.

5.6.8 Install second gel strip in the same way.

6.1 Place the organizer with pre-connectorized adapter drops into the terminal housing

6 Close and lock the terminal housing

Front side

5.6.5 First flip gel strip end coming from the middle part to the

outside.

i

Take care gel strip is flipped to the correct side. There needs to be

an opening left to push through the second gel strip.

5.6.6 Then flip other end of the gel strip to the inside.

6.1.3 Installation of organizer in the terminal housing complete.

10

6.2.1 Hinge top cover to close terminal housing.

i

Make sure top cover is well positioned.

6.3.1 The terminal housing can be re-entered 10x, without

opening the gel donut.

6.3.2 The gel donut can be re-entered 4x. Re-entry of the gel

donut is: open both ends of the donut completely, but keep the donut

fixed in the clamp, and close again as described on pg 9.

6.2.3 Insert the locking bolt and tighten the locking bolt with a

hexagonal wrench.

6.2.2 Close all the latches, starting with top latch towards the gel

seal area. Close the latches left and right side alternating: 1 left,

1right, 1 left,...

6.3.3 After every gel donut re-entry a break off tap should be

removed from the terminal housing.

6.3.4 Initial installation is not a re-entry.

6.3.5 Replacing a gel donut by a new one is allowed.

6.2.4 Installation complete.

6.2 Close the terminal housing latches and lock the terminal housing

6.3 Re-entry recommendations

Top

11

7.2.2 Secure pre-assembly in the inserts on the back side of the

terminal housing.

7.2.1 Pre-assemble the aerial hardware kit as shown.

7.2.3 Mount the mounting plates around the D-bar.

7.2 Installation on D-Bar

7.1.1 Push the 2 bolts through the openings of the grid structure

of the back plate. Secure them in the inserts on the back side of the

terminal housing.

7.1 Installation on universal back plate

7 Pedestal Mounting

7.1.2 Installation complete.

© 2017 CommScope, Inc. All rights reserved.

OptiTap® is a registered trademark by Corning. All other trademarks used in this publication are CommScope registered trademarks.

This document is for planning purposes only and is not intended to modify or supplement any specifications or warranties relating to

CommScope products or services.

This product is covered by one or more U.S. patents or their foreign equivalents. For patents, see:

www.commscope.com/ProductPatent/ProductPatent.aspx.

7.2.4 Secure the mounting plates around the D-bar with a 7/16’’

wrench.

7.2.6 Installation complete.

7.2.5 If necessary, terminal housing can be repositioned/centered

in the pedestal.

To find out more about CommScope® products, visit us on the

web at www.commscope.com

For technical assistance, customer service, or to report any

missing/damaged parts, visit us at:

http://www.commscope.com/SupportCenter

/