Page is loading ...

,

This manual is intended to provide the informaon necessary for installaon, set-up, normal maintenance and service of the Hayes Radar

disc brake system. We highly recommend installaon be performed by a qualified mechanic. These instrucons can be downloaded from

the Hayes Disc Brake website at www.hayesbicycle.com.

INSTALLATION AND SET-UP INSTRUCTIONS

45-31074

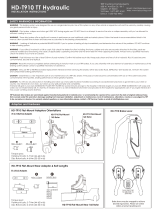

Installing the Master Cylinder

1. Remove the two mounng bolts and clamp from the master cylinder assembly.

2. Posion master cylinder on your handlebars in desired locaon. Place handlebar clamp onto master cylinder and thread the clamp bolts

into the master cylinder. Do not ghten the bolts down yet.

3. Once you have set the master cylinder in the final desired posion on your handlebars, ghten down the mount bolt that the arrow

points to on the clamp. (FIG. 1) Tighten to a torque of

30±5 in-lbs (3.37±0.55Nm). Next ghten down the other bolt to a torque of

30±5 in-lbs (3.37±0.55Nm).

4. To adjust lever reach, use a 2mm Allen to turn the lever reach adjust screw at the base of the lever. Turning it clockwise will move the lever out.

Turning it counterclockwise will move the lever in. Do not force the screw beyond its limits. (FIG. 2)

Mounng the Disc to the Hub

1. Clean the disc and hub mounng surface with isopropyl alcohol (not disc brake cleaners).

2. Place the disc on the hub mounng surface. Be sure that the arrow on the disc is poinng in the same direcon of the forward wheel rotaon.

3. Using a Torx T25 driver, install, ghten, and torque the disc screws to 50±5 in-lb (5.65±0.55Nm), in a sta

r paern sequence. (FIG. 3)

Cauon: The disc should be periodically inspected for wear and damage. The minimum disc thickness is 1.52mm

HAYES COMPONENTS - 5800 W DONGES BAY ROAD - MEQUON, WI - 53092

FAX: (262) 512-4219

techsupport@hayesbicycle.com

PHONE: (888)686-3472

www.hayesdiscbrake.com

techsupportEU@hayesbicycle.com

As a serious rider you are well aware of the need to pracce safety in all aspects of the sport. This includes service and maintenance pracces as

well as riding pracces. Before each ride, always check your brakes for proper funcon and the brake pads for wear. When you ride, always wear

a helmet.

Warning: When you need to install any of the disc brake components, that installaon work should be done by a qualified technician with the

proper tools. Improper installaon could cause severe or fatal injuries.

Warning: This brake has been designed for use on a singl

e person mountain bike. The use on any other vehicle or device will void the warranty

and can cause serious injury.

Cauon: With use, disc brake components may become very hot. Always allow components to cool before aempng to service your bike.

Warning: When following any of the procedures below, be sure to keep your hands and fingers from geng caught in the disc. Failure to do so

could result in injury.

Warning: Do not adjust the caliper while the wheel is spinning.

Warning: Do not adjust the caliper while the caliper is hot.

Warning: If your bike is involved in a fall or crash it is recommended your brakes are checked by a qualified mechanic before riding to ensure

they are funconing properly.

The following checks should be performed: Check that all components are securely mounted to the

handlebar,frame, fork, or wheel; check for proper pad installaon and retenon; check that the brake builds and holds pressure; check hose

and fings for kinks or leaks; check master cylinder body and caliper for damage. Always have a qualified bike mechanic check your brakes if

you suspect damage.

SAFETY INFORMATION

INSTALLATION

Tools Required

● Torx T25 driver

● Torque Wrench

● Allen Drivers: 2mm, 4mm, 5mm

● Safety Glasses

Mounng Caliper (Crosshair equipped calipers)

1. Verify the 2mm adjuster screws are backed out of the mount slots in the caliper feet. (FIG. 4)

2. Place the caliper feet onto the mounng surface and thread the mount bolts (with washers) into the mount leaving the caliper loose.

(FIG. 5)

3. Squeeze the lever blade a minimum of 5 mes to seat the caliper pistons.

4. Adjust the caliper on the mount so the outer pad (closest to you) is contacng the disc. (FIG. 6)

5. Snug the mount bolts using the 5mm hex tool while keeping the outer pad against the disc. (FIG. 7)

6. Using the 2mm hex tool, turn the adjuster screws clockwise unl they contact the mount bolts.

7. Turn each adjuster screw 1/4 turn clockwise then rotate the wheel and listen for pad drag. Repeat unl the pads clear the disc, looking

for a gap.

8. Torque the lower mount bolt (A) to

80±5 in-lbs (9.0±0.5 Nm).

(the upper adjuster screw keeps the caliper from rotang out of alignment).

Torque the upper mount bolt (B) to

80±5 in-lbs (9.0±0.5 Nm).

(FIG. 8)

Mounng the Caliper (For calipers without Crosshair)

1. For some installaons it will be necessary to mount a mount bracket to accept the Hayes Disc Brake caliper. Mount the mount bracket to the

frame or fork using (2) M6 x 1.0 18.4mm long mount bolts. Torque the bolts to 80±5 in-lbs (9.0±0.5 Nm).

2. Mount the caliper to the frame or fork mount bracket using (2) M6 x 1.0 18.4mm long mount bolts and (2) mount washers. Snug the bolts, but

leave them loose enough so that caliper will move on its slots.

3. Squeeze and hold the brake lever. While squeezing the lever, ghten the mounng bolts. Tor

que the bolts to 80±5 in-lbs (9.0±0.5 Nm).

4. Release the lever, spin the wheel. Check that it spins freely and that the gaps, between the pad and the disc, are equal. If gaps are unequal, or if

there is drag, readjust the caliper posion by loosening the mounng bolts and adjusng the caliper needed.

Hint: A white piece of paper can be used as a background to help sight down the disc looking for equal clearance between the pads and disc.

5. When the gaps are equal and the wheel spins freely (without drag), torque the mounng bolts to 80±5 in-lbs (9.0±0.5 Nm).

Brake Pad Change

Due to wear, contaminaon, or damage, the brake pads will, on occasion, need to be replaced. The following procedure is to be followed for a

change of brake pads:

1. Removing the pads.

A. Remove the wheel.

B. Remove the pad retaining pin from the caliper using a pliers.

C. Remove pads and sandwich spring through the window on the boom of the caliper.

D. Using the boxed end of a 10mm wrench, push the caliper pistons back in their bores unl they are flush with the edge of the caliper. This will

give you more room to insert the new pads.

2. Installing the pads.

A. Assemble the pads and sandwich spring. (FIG. 9)

B. Compress the pads together on the sandwich spring and insert through the

boom of the caliper.

C. Insert pad retaining pin through the hole in the caliper and through the tab on both pads.

D. Insert the pad retaining coer pin, bend down the ends so the pin cannot be removed.

E. Install the wheel.

3. Burnish brake pads.

Performing the proper burnish process is essenal to ensure that your new brakes have consistent, high power braking

in all riding condions. Hard braking before proper burnish can result in a reducon in brake performance. A proper burnish, or break in

process of 50+ stops under 15 mph or 24 Km/h is required in order to reach full braking power.

Piston(s) Pumped Out

If the brake lever is stroked without the disc between the pads (this is possible when brake pads are being changed), the self-adjusng feature will

allow the pads to push out. The caliper pistons will be pumped out of their bore. This can cause excessive drag on the disc when the wheel and disc

are reinstalled, or even make it impossible to inst

all the wheel and disc. To fix this problem:

1. Remove the brake pads from the caliper if they are not already removed.

2. With the pads removed, push back the pistons unl they are flush with the edge of the caliper using the box end of a 10mm wrench.

Hint: If the pads are pushed together ght, slide the travel spacer, or Hayes Feel ‘R Gauge between the pads and enlarge the gap unl it is large

enough to pull the pads out.

3. When the pistons are back into their bores, replace the pads.

Cleaning and Care

The Hayes Radar brake system uses mineral oil. Any spilled on the brake assembly , bike or otherwise can be cleaned up with mild soap and water.

The brake rotor and pads should only be cleaned with isopropyl alcohol (not disc brake cleaner).

MAINTENANCE & TROUBLESHOOTING

● Pliers

WARRANTY INFORMATION

Any Hayes Bicycle Group component found by the factory to be defecve in materials and/or workmanship

within two years from the date of purchase will be repaired or replaced at the opon of the manufacturer,

free of charge, when received at the factory with proof of purchase, freight prepaid. Any other warranty

claims not included in this statement are void. This includes assembly costs (for instance by the dealer),

which shall not be covered by Hayes Bicycle Group. This warranty does not co

ver breakage, bending, or

damage that may result from crashes or falls. This warranty does not cover any defects or damage caused

by alteraons or modificaons of new Hayes Bicycle Group parts or by normal wear, accidents, improper

maintenance, damages caused by the use of parts of different manufactures, improper use or abuse of the

product, or failure to follow the instrucons contained in an instrucon manual for the specific component.

Any modificaons made by the user will render the warranty null and void. The cost of normal maintenance

or replacement of service items, which are not defecve, shall be paid for by the original purchaser. This

warranty is expressly in lieu of all other warranes, and any implied are limited in duraon to the same

duraon as the expressed warranty herein. Hayes Bicycle Group shall not be liable for any incidental or

consequenal damages. If for any reason warranty work is necessary, return the component to the place of

purchase. In the USA, contact Hayes Bicycle Group for a return authorizaon number (RA#) at (888)

686-3472. At that me, instrucons for repair, return, or replacement shall be given. Customers in

countries other than USA should contact their dealer or local Hayes Bicycle Group distributor.

L

I

F

E

T

I

M

E

L

E

A

K

P

R

O

O

F

W

A

R

R

A

N

T

Y

Limited Lifeme Leakproof Warranty: hp://www.hayesdiscbrake.com/support/lifeme/

INSTALLATION AND ASSEMBLY TORQUE VALUES

Part Torque (in-lb) Torque (Nm)

Disc Screw 50±5 5.6±0.5

Mount Bolt 80±5 9.0±0.5

Master Cylinder Clamp Screw 30±5 3.4±0.5

Caliper Bridge Bolt 170±5 19.2±0.5

Bleed Screw 12±2 1.4±0.2

Compression Nut 70±5 7.9±0.5

FIG. 2

FIG. 1

1

2

FIG. 3

1

3

2

4

5

6

FIG. 4

FIG. 5

FIG. 6

FIG. 7

5mm

FIG. 8

A

5mm

FIG. 9

/