Page is loading ...

FormNo.3362-258RevA

ProCoreSR48,SR54,SR54–S,

SR70,SR70–S,SR72and

SR75–HDAerators

ModelNo.09920—SerialNo.290000001andUp

ModelNo.09921—SerialNo.290000001andUp

ModelNo.09922—SerialNo.290000001andUp

ModelNo.09924—SerialNo.290000001andUp

ModelNo.09925—SerialNo.290000001andUp

ModelNo.09926—SerialNo.290000001andUp

ModelNo.09927—SerialNo.290000001andUp

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.Toro.com.OriginalInstructions(EN)

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

©2009—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

2

Contactusatwww.Toro.com.

PrintedintheUSA.

AllRightsReserved

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

SafetyandInstructionalDecals.............................6

Setup............................................................................8

1ConnectingtheLowerLinkArms......................9

2ConnectingtheHydraulicTopLink

(ModelsSR48,SR54,SR70,SR72and

SR75–HD........................................................9

3ConnectingtheTractorUpperLink(Models

SR54–SandSR70–S)......................................11

4VerifyingtheTopLinkSetUp..........................11

5CheckingthePTOAngle.................................12

6FittingthePTOshaft.......................................12

7InstallingthePTOShield.................................14

8ConnectingthePTOShaft...............................15

9AdjustingtheSwayLinks.................................16

10LevelingtheAeratorSide-to-Side...................17

11InstallingtheTines.........................................17

12RemovingtheStorageStands(Models

SR54,SR54S,SR70andSR70–S).....................18

13RemovingtheStorageStands(Models

SR72).............................................................18

ProductOverview......................................................19

Specications.....................................................19

Attachments/Accessories...................................19

Operation...................................................................20

TractorControls.................................................20

PrinciplesofOperation......................................20

TractorPTOSpeed............................................20

TrainingPeriod...................................................20

BeforeAerating..................................................20

AeratingProcedures...........................................21

OperatingTips...................................................21

SubsoilCultivation.............................................22

HardGround.....................................................22

Longer/LargerTines..........................................22

MultiRowAdapterHeads..................................22

RootZoneLifting..............................................22

AdjustingtheTineAngle....................................22

TransportOperation..........................................23

InspectionandCleanupafterUse........................23

Maintenance...............................................................24

RecommendedMaintenanceSchedule(s)................24

LiftingtheMachine............................................24

GreasingtheBearings.........................................25

CheckingtheGearboxOil..................................25

ChangingtheGearboxOil..................................26

Inspecting/AdjustingtheDriveChain................26

AdjustingthePTOClutch..................................27

CheckingtheCoringHeadFastener

Torque...........................................................27

CheckingtheSprings..........................................28

AdjustingtheHoleSpacing.................................28

RemovingtheAeratorfromtheTractor...............28

TroubleShooting...............................................29

Storage.......................................................................30

3

Safety

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructions

andalwayspayattentiontothesafetyalert

symbol,whichmeansCAUTION,WARNING,or

DANGER-"personalsafetyinstruction."Failureto

complywiththeinstructionmayresultinpersonal

injuryordeath.

SafeOperatingPractices

BeforeOperating

•OwnersofthisAeratormustgiveoperatorsand

employeesfulloperationandsafetyinstructions

beforeallowingthemtooperatethismachineandat

leastannuallythereafter.Anoperatorwhohasnot

readandfullyunderstoodalloperatingandsafety

instructionsisnotqualiedtooperatethismachine.

Becomefamiliarwithallcontrolsandknowhowto

stopquickly.

•Donotallowchildrentooperatethemachine.Do

notallowadultstooperatethemachinewithout

properinstruction.

•Removealldebrisorotherobjectsthatmight

interferewithoperation.Keepallbystandersaway

fromtheworkarea.

•Locateandmarkallundergroundobstructionssuch

asirrigationcomponents,electricalortelephone

lines.

•Makesuretractorisinneutralandparkingbrake

appliedbeforestarting.RefertoTractorOperator’s

Manualforsafestartingprocedures.

•Ensurethatyourtractorissuitableforusewithan

implementofthisweightbycheckingwithyour

tractorsupplierormanufacturer.

•Mountingtheaeratortotherearofthetractor

willdecreasetheweightonthetractorfrontaxle.

Toassureadequatesteeringcontrolandstability

itmaybenecessarytoaddballasttothefrontof

thetractor.RefertoTractorOperator’sManualfor

ballastrequirements.

•Keepallshieldsandsafetydevicesinplace.Ifa

shield,safetydeviceordecalisdamaged,repairor

replaceitbeforeoperationiscommenced.Also

tightenanyloosenuts,boltsandscrewstoensure

machineisinsafeoperatingcondition.

•Donotoperatemachinewhilewearingsandals,

tennisshoes,sneakersorshorts.Also,donot

wearloosettingclothingwhichcouldgetcaught

inmovingparts.Alwayswearlongpantsand

substantialshoes.Wearingsafetyglasses,safety

shoes,hearingprotectionandahelmetisadvisable

andmayberequiredbysomelocalordinancesand

insuranceregulations.

WhileOperating

•Neveroperatethetractorinreversewhentheaerator

islowered.

•Keepallbystandersandpetsawayfromthework

area.

•Usingthemachinedemandsattention,andto

preventlossofcontrol:

–Useonlyindaylightorwhenthereisadequate

articiallight.

–Watchforholesorotherhiddenhazards.

–Donotoperatethemachineclosetoasandtrap,

ditch,creekorotherhazard.

–Reducespeedonsidehillsandbeforemaking

sharpturnstopreventtippingorlossofcontrol.

–Lookbehindtheaeratorbeforebackingup.

•Ifthetinesstrikeasolidobjectorthemachine

vibratesabnormally,disengagethePTO,setthe

parkingbrakeandshuttheengineoff.Removekey

fromignitionswitch.Checkaeratorandtractionunit

fordamage.Repairanydamagebeforerestartingthe

engineandoperatingthetines.Besuretinesarein

goodconditionandallboltsaretight.

•Beforeleavingmachineunattended,disengagepower

toaerator,loweraeratorontostoragestandsandset

parkingbrake.Stopengine.

•Neverdismountwhiletractorisinmotion.Never

getonorofftractorwhileengineisrunningand

PTOdriveshaftisengaged.NeverstepoverPTO

shafttoreachothersideofaerator-walkaround

themachine.

•Whenliftingtheaerator,disengagethePTOwhen

therollerisapproximately5”fromtheground.

•Donotoperatethismachinewithouttherolleron

theground.Neveroperatewiththemachinein

theraisedposition.

•Parktheaeratoronahard,levelsurface,installthe

aeratorstoragestandsbeforedisconnectingfrom

tractor.

•Ifitisnecessarytoprobebelowthesoilsurface,use

anonconductivematerialtopreventelectricalshock

incaseelectricalwiresarepresent.

•Alwayslowertheaeratortothegroundbefore

leavingthetractorunattended.Neverleavethe

aeratorintheraisedpositionwhenitisunattended.

4

Transporting

•Theaeratorisheavy.Whenattachedtoatractor

andintheraisedposition,itsweightwillaffect

stability,brakingandsteering.Exercisecautionwhen

transportingbetweenworkingareas.

•Alwaysmaintainpropertractortirepressure.

•Besureyouareincompliancewithallregulations

beforetransportingequipmentonthepublicroads

andhighways.Makesureallrequiredreectors

andlightsareinplaceandarecleanandvisibleby

overtakingandoncomingtrafc.

•Neverallowpassengerstorideonthemachine

duringtransport.

•Reducespeedonroughroadsandsurfaces

•Independentwheelbrakesshouldalwaysbelocked

togetherwhentransporting.

PTOShaft

•ForallPTOshaftsteelparts(tubes,bearings,joints

etc.)disassemblyorrepairs,itishighlyadvisable

tocontactyourlocalTorodistributor.Removalof

componentsforrepairsandreassemblymaydamage

somepartsifnotperformedwithspecialtoolsby

trainedtechnicians.

•ThePTOshaftmustnotbeusedwithouttheguards

supplied,withpartialprotectionorwithdamaged

guards.OnCEmachines,operationisprohibited

withoutthespecialanti-rotationchainscorrectly

installed,soastopermitthemaximumangleofthe

PTOshaftwithoutbreakingthechains.

•Frictionclutchesmaybecomehotduringuse.Do

nottouch.Toavoidtheriskofre,keepthearea

aroundtheclutchfreeofammablematerialand

avoidprolongedslippingoftheclutch.

Maintenance

•Beforemakingadjustmentsorperforming

maintenanceontheaerator,switchofftheengine,

stopthePTOandapplytheparkingbrakebefore

dismountingfromthetractor.Besuretheaeratoris

onthegroundorloweredontothesafetystands.

•Supportthemachinewiththeblocks,jacksoron

storagestandswhenworkingbeneathit.Never

relyonthetractor’shydraulicstosupportthe

machine.

•Placeallcontrolsinneutral,stoptheengine,apply

parkingbrakeandwaitforallmovingpartsto

stopbeforeservicing,maintaining,adjustingor

unblockingtheaerator.

•Besurethemachineisinsafeoperatingconditionby

keepingnuts,boltsandscrewstight.Checkthetine

mountingboltsdailytobesuretheyaretightened

tospecication.

•Donotcheckoradjustthechaintensionwhenthe

tractorengineisrunning.

•Besureallguardsarereplacedandthehoodis

securedshutaftermaintainingoradjustingthe

machine.

•Performonlythosemaintenanceinstructions

describedinthismanual.Ifmajorrepairsare

everneededorassistanceisdesired,contactan

AuthorizedToroDistributor.Toensureoptimum

performanceandsafety,alwayspurchasegenuine

Tororeplacementpartsandaccessoriestokeepthe

ToroallToro.Neveruse"will-t"replacementparts

andaccessoriesmadebyothermanufacturers.Look

fortheTorologotoensuregenuineness.Using

unapprovedreplacementpartsandaccessoriescould

voidthewarrantyofTheToroCompany.

StorageSafety

•Storetheaeratoronthestoragestandspositionedon

armlevelsurface.

•Storetheaeratorawayfromareasofhumanactivity.

•Donotallowchildrentoplayonoraroundthe

storedmachine.

•Makesuretheaeratorispositionedonrmandsolid

groundsoitdoesnotsinkortipover.

5

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

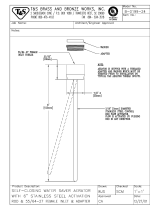

117–7052

1.ReadtheOperator’sManual,donotoilthechaindrive.

100–3612

1.Entanglementhazard—stayawayfrommovingparts,keep

allguardsandshieldsinplace.

110-4668

1.Entanglementhazard,shaft—stayawayfrommovingparts.

2.PTOspeedandinputdirection.

3.Usecliptosecurelashcablewhennotinuse.Uselash

cabletosupportthepowertake-offwhenthemachineis

disconnectedfromtractor.

117–7051

1.Crushinghazardofhandorfoot—keepbystandersasafe

distancefromthemachine.

117–7050

1.Warning—readtheOperator’sManual.

2.Warning—removetheignitionkeyandreadtheinstructionsbeforeservicingorperformingmaintenance.

3.Warning—donotoperatethismachineunlessyouaretrained.

4.Entanglementhazard,belt—stayawayfrommovingparts,keepallguardsinplace.

5.Crushinghazardofhandorfoot—keepbystandersasafedistancefromthemachine.

6.Crushinghazardofhandandbody—supportmachineonstandwhennotinuse.

7.Fallinghazard—donotcarrypassengers.

6

92–1581

92–1582

7

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

Qty.

Use

Hitchpin2

1

Lynchpin2

ConnectLowerLinkArms

Hydraulictoplink1

Hydraulichose,3–1/2feet

1

Hydraulichose,2–1/2feet

1

Extensionbracket2

Rotationalbracket1

2

Hosequickcouplings(notincluded)

2

ConnectHydraulicT opLink

Springloadedtoplink

1

Linkpin3

3

Lynchpin3

ConnectUpperLink

4

Nopartsrequired

–

Verifythetoplinksetup

5

Nopartsrequired

–

CheckingthePTOangle

6

PTOshaft

1

FittingthePTOshaft

7

PTOShield

1

InstallthePTOShield

Pin(suppliedwithPTOshaft)

1

8

Nut(suppliedwithPTOshaft)

1

ConnectPTOShaft

9

Nopartsrequired

–

AdjustingSwayLinks

10

Level(notsupplied)

1

LevelAeratorSide-to-Side

11

Tines

A/R

InstalltheTines

12

Nopartsrequired

–

RemoveStorageStands

13

Nopartsrequired

–

RemoveStorageStands

8

MediaandAdditionalParts

Description

Qty.

Use

Operator’sManual

1

Readbeforeoperatingtheaerator

PartsCatalog

1

Usetoreferencepartnumbers

SpringWires-SR54

6Replacementspringwires

SpringWires-SR70

8Replacementspringwires

SpringWires-SR72

4Replacementspringwires

SpringWires-SR72

2Replacementspringwires

Allenwrench1

TineheadboltwrenchforSR72

PTOOperatorsManual

1

Readbeforeoperatingtheaerator

1

ConnectingtheLowerLink

Arms

Partsneededforthisprocedure:

2Hitchpin

2Lynchpin

Procedure

1.Removetheboltssecuringtheaeratorstoragestands

totheshippingpalletandremovetheaeratorfrom

thepallet.

2.Theaeratormustbepositionedonaat,level

surfaceforinstallation.

3.Backthetractorsquarelyuptotheaeratoruntil

thelowerlinkarmsarealignedwiththemounting

brackets.

4.MakesurethePTOisdisengaged.

5.Engagetheparkingbrake,STOPtheengineand

removethekeyfromtheignition.Waitforthe

engineandallmovingpartstoSTOPbeforeleaving

theOperator’sseatonthetractor.

Note:Formaximumgroundclearance,thehitch

pinsshouldbesecuredintheaeratorlowermounting

bracketholes,whensoequipped.Todetermine

whentousetheuppermountingholes,referto

ConnectingthePTOShaft.

6.Securethelowerlinkarmstotheaeratormounting

bracketswitheitherlynchpins(Figure3)orhitch

pinsandlynchpins(Figure4).

Figure3

1.Lowerlink2.Lynchpin

Figure4

1.Hitchpin3.Lowerlink

2.Aeratormountingbracket

9

2

Connectingthe

HydraulicTopLink

(ModelsSR48,SR54,SR70,

SR72andSR75–HD

Partsneededforthisprocedure:

1Hydraulictoplink

1

Hydraulichose,3–1/2feet

1

Hydraulichose,2–1/2feet

2Extensionbracket

1Rotationalbracket

2

Hosequickcouplings(notincluded)

Procedure

Thetractormustbeequippedwithadoubleactingspool

valvewithanoperatorcontrolleverandtwo1/2”(12.7

mm)quick-releasecouplingsattherearofthetractor.It

isalsonecessaryforyoutoprovidetwoquickcouplings

tottothehydraulictoplinkhoses(1/2–14NPTF

hoseendthreadsize).

1.Securetheconnectinglinkendofthehydraulictop

linktothetractorwiththepinssuppliedwiththe

tractor(Figure5).Positionthehydraulictoplinkso

therodendistowardtheaerator.Thecylinderports

shouldbepositionedtowardthetractor’sauxiliary

powerhydraulics.

Note:Ifthehydrauliccylindermustbepositioned

withtheportsfacingupward,usetherotational

blockinsteadofthestandardmountingblockto

repositionthecylinder(Figure5).

Installtherotationalblockasfollows:

A.Removethecotterpinandpinsecuring

thestandardconnectinglinktothecylinder

(Figure5).Removetheconnectinglinkfromthe

cylinder.

B.Installtherotationalblocktothecylinderwith

thepinspreviouslyremoved(Figure5).

Figure5

1.Aeratorhitchpin7.Tractorlinkpin

2.Hydraulictoplink

8.Clevis&lynchpin

3.Rotationalblock

9.2–1/2foothydraulichose

4.Connectinglink10.3–1/2foothydraulichose

5.3inchextensionblock

11.Hosequickcouplings(not

included)

6.5inchextensionblock12.Tractorhydraulicports

2.Connectthe3–1/2footlonghydraulichosetothe

hydraulictoplinkportwhichisclosesttotheaerator

Figure5.ApplyTeontapeorpipethreadsealantto

thehosethreadstopreventanyleaks.

3.Connectthe2–1/2footlonghydraulichosetothe

hydraulictoplinkportwhichisclosesttothetractor

(Figure5).ApplyTeontapeorpipethreadsealant

tothehosethreadstopreventanyleaks.

4.Installquickcouplings(notincluded)tothehydraulic

hoses(1/2–14NPTFhoseendthreadsize).

5.Connectthetwohydraulichosequickcouplingsto

theportsprovidedonthetractor.

6.Startthetractorengineandoperatethetractorspool

valvetochecktheextendandretractmotionofthe

hydraulictoplink.

Note:Reversethehoseconnectionsiftheydono

agreewiththetractorcontroloperation.

7.Securetherodendofhydraulictoplinktothemost

forwardholepossibleintheaeratorbracketwithlink

pinandlynchpin(Figure6).

Important:Whensecuringtherodendof

thehydrauliclink,makesuretousethemost

forwardmountingholesinthemountingbracket

sothereisenoughclearanceforthebarrelofthe

cylinderwhenretracted.

10

Figure6

1.Rodendofcylinder4.Aeratorbracket(forward

holes)

2.Lynchpin5.Linkpin

3.Linkpin

Ifthehydrauliccylinderdoesnotreachtheaerator

mountingbracket,useanextensionblockinsteadof

thestandardmountingblocktoconnectthecylinder

tothetractor(Figure5).

Installtheextensionblocksasfollows:

A.Removethecotterpinandpinsecuring

thestandardconnectinglinktothecylinder

(Figure5).Removetheconnectinglinkfromthe

cylinder.

B.Installtherequiredlengthextensionblockto

thecylinderwiththepinspreviouslyremoved

(Figure5).

3

Connectingthe

TractorUpperLink

(ModelsSR54–SandSR70–S)

Partsneededforthisprocedure:

1

Springloadedtoplink

3Linkpin

3Lynchpin

Procedure

1.Mountthespringloadedtoplinktotheaerator

bracketwithtwolinkpinsandlynchpins(Figure7)

2.Loosenthelocknutonthetractorupperlink.Adjust

theupperlinkuntilitalignswiththeclevisonthe

springloadedtoplinkoftheaerator(Figure7).

Figure7

1.Springloadedtoplink

4.Lynchpin

2.Upperlink5.Locknut

3.Linkpin

3.Connectthetractorupperlinktotheclevisonthe

springloadedtoplinkandsecurewithalinkpinand

lynchpin(Figure7).

4.Greasethethreadedsteelupperlinktubes.

5.Measurethelengthofthespringinthetoplink.

6.Rotatetheupperlinkuntilthespringiscompressed

byabout1/2inch(Figure7).

7.Tightenthelocknuttosecuretheupperlinkinto

position.

11

4

VerifyingtheTopLinkSetUp

NoPartsRequired

Procedure

•Extendingthehydrauliccylinderwillincreasethe

tinedepth.

•Fullyextendthehydrauliccylindertodetermine

thelocationofthetineheadsandtoverifyifthey

contacttheground.

Ifthetineheadscontacttheground,turf

damagewilloccur.

Note:Onundulatingturf,theoperatorcanadjust

thecylindertomaintaintinedepth(crestingahill)

butitwillbenecessarytohavethetineheadsset

about2inchesbelowground.

•Ifthetineheadscontacttheground,adjustthe

locationofthecylinderendstomovethetopofthe

aeratorclosertothetractor.

•Ifthetineheadsdonotcontacttheground,

extensionbrackets(includedwithaerator)canbe

installedtothetoplinktomovethetineheadscloser

totheground.

Important:WhenconnectingthePTO,besure

thattheaeratorisnotbeingliftedhigherthanis

necessary.Liftingthemachinetoohighwillcause

thePTOshaftknucklestobreak(Figure8).Never

leavethePTOturningwhentheaeratorislifted.

ThePTOcanbeoperateduptoanangleof25º,but

canneverexceeda35ºanglewhentheaeratoris

atitshighestpositionorsevereshaftdamagemay

occur.

Figure8

1.Breakagewilloccurhere

5

CheckingthePTOAngle

NoPartsRequired

Procedure

Withtheaeratorpositionedonthegroundandlowered

tothedeepestlocation,checktheanglebetweenthe

PTOandtheaerator.Makesurethetinesareremoved

beforeperformingthisoperation.

Lifttheaeratorandfullyretractthehydraulictoplink

cylinder.ChecktheanglebetweenthePTOandthe

aerator.Ifthisangleisgreaterthan35degrees,make

adjustmentstothetractorsothattheaeratorcannotbe

liftedpast35degrees.Thiscanbeaccomplishedby

usingthetractorliftstop(ifsoequipped)ormovingthe

lowerlinkstoahighermountinghole(ifsoequipped).

6

FittingthePTOshaft

Partsneededforthisprocedure:

1

PTOshaft

Procedure

1.Movethetractorandaeratortoalevelsurface.

2.Raisetheaeratorcompletelyandfullyretractthetop

linkcylinderorupperlink(Figure9).

12

Figure9

3.Measurethedistancefromthereliefontheendof

thetractorPTOshafttothereliefontheaerator

gearboxPTOshaft(Figure10).Recordthisdistance.

Example:26.5inches(67cm).

Figure10

1.Measurehere

4.Lowertheaeratortothegroundandfullyextendthe

toplinkcylinderorupperlink(Figure11).

Figure11

5.Measurethedistancefromthereliefontheendof

thetractorPTOshafttothereliefontheaerator

gearboxPTOshaft(Figure12).Recordthisdistance.

Example:27.5inches(70cm).

Figure12

1.Measurehere

6.OnthePTOshaft,measurethedistancefromthe

centeroflockingpinballononeendtothecenterof

thelockingpinbuttonontheotherend(Figure13).

Recordthisdistance.Example:32inches(81cm).

Figure13

1.Measurehere

7.Usingthesmallerofthetwomeasurementsin

Figure12andFigure10,subtractthatdistancefrom

thedistanceinFigure13.Example32(81cm)inches

minus26.5inches(67cm)equals5.5inches(14cm).

8.Theexamplemeasurementsshowthattheshaftis

5.5inchestoolong.Nowyouwillneedtoaddan

extra1/2inch(1.2cm)tobesurethatthePTOshaft

willnotbottomoutwhentheaeratorisliftedtoits

highestposition.

Example:5.50inches(14cm)plus1/2inch(1.2cm)

equals6.00inches(15cm).

9.SlidethePTOshafttubestogetheruntiltheyare

fullycollapsed.Verifythattheinsidetubedoesnot

protrudeintothecrossandbearingsectionofthe

outertube(Figure14).Ifthishappens,cutmoreoff

theinsidetube,tocorrecttheproblem.

13

Figure14

1.Insidetube

10.SeparatethetwohalvesofthePTOshaft(Figure15,

illustration1).

11.Measurethedistancefromtheendofeachtubeto

itssafetyshield(Figure15,illustration1).Record

thedistances.

Figure15

1.Measurehere

12.Usingthedimensionsdeterminedinstep8,locate,

markandcutofftheshieldandtubefromeachPTO

half(Figure15,illustrations2&3).

Note:Morewillhavetobecutofftheinsidetube

onlyifitisprotrudingintothecrossandbearing

sectionoftheoutertube.

13.Usingthedimensionsdeterminedinstep11,locate,

markandcutoffjustthesafetyshieldstoexposethe

tubesFigure15—illustrations4&5.

14.Carefullydeburrtheendsofthetubeswithaleand

removeallthelingsfromthetubes.

15.Greasetheinsidetube.

Note:Telescopingtubesmustalwaysoverlapby

1/2oftheirlengthinnormaloperationandatleast

1/3oftheirlengthinallworkingconditions.During

transport,whenthedrivelineisnotrotating,the

telescopingtubesmusthaveasuitableoverlapto

maintainthetubesalignmentandallowthemtoslide

freely.

7

InstallingthePTOShield

Partsneededforthisprocedure:

1

PTOShield

Procedure

1.Removethe4bolts,lockwashersandatwashers

securedtotherearoftheaeratorgearbox(Figure16).

14

Figure16

1.PTOshield

4.Bolt

2.Flatwasher5.Accesspanel

3.Lockwasher

2.MountthePTOshieldtotheaeratorgearboxwith

thefastenerspreviouslyremoved(Figure16).When

mountingthePTOshield,makesuretheaccess

panel(Figure16)ispositionedtothetoporside

dependingontheaeratorframeconguration.

8

ConnectingthePTOShaft

Partsneededforthisprocedure:

1

Pin(suppliedwithPTOshaft)

1

Nut(suppliedwithPTOshaft)

Procedure

Note:Theaccesspanel(Figure16)canbeopened

toeasetheremovalandinstallationofthePTOshaft

mountingfasteners.

1.RemovethepinandnutfromthePTOshaft

(Figure17).

2.ConnecttheclutchendofthePTOshaftto

theaeratorgearboxinputshaftwithpinandnut

previouslyremoved(Figure17).Thepincanonly

beinsertedoneway.

Figure17

1.Gearboxinputshaft

3.Pin

2.PTOshaftcoupler

4.Nut

Note:MakesuretocloseandlatchthePTOshield

accesspanelifopened.

3.ConnectthePTOshafttothetractorPTOshaft

(Figure18).

Figure18

1.Tractoroutputshaft3.PTOshaft

2.PTOshaftcoupler

4.SlidethePTOshaftforwardasfarasthetractor

allows.

5.PullbackonthelockingcollartosecurethePTO

shaftinplace.SlidethePTOshaftbackandforthto

makesureitisproperlylocked.

6.ConnecttheshieldsafetychainstothePTOshield

andthetractorbracket(Figure19).Makesurethe

chainsremainslackwhentheaeratorisraisedor

lowered.

15

Figure19

1.Safetychains

Note:Toavoidexcesslift,connecttheliftarmsof

thetractorintothetopholesoftheliftbracket,if

soequipped(Figure20).Themaximumangleon

thePTOshaftis35º.

Figure20

1.Topholes

Important:WhenconnectingthePTO,be

surethattheaeratorisnotbeingliftedhigher

thanisnecessary.Liftingthemachinetoohigh

willcausethePTOshaftknucklestobreak

(Figure21).NeverleavethePTOturningwhen

theaeratorislifted.ThePTOcanbeoperated

uptoanangleof25º,butcanneverexceeda35º

anglewhentheaeratorisatitshighestposition.

7.VerifythatthePTOshielddoesnotinterferewith

theclutch.

Figure21

1.Breakagewilloccurhere

9

AdjustingtheSwayLinks

NoPartsRequired

Procedure

Theaeratorisdesignedtobecenteredwiththetractor

PTOshaftcenterline.Adjusttheswaylinksasrequired.

ThePTOshaftshouldbeasstraightaspossibletothe

tractorPTOshaft.

Adjusttheswaylinksonthelowerliftarmstominimize

side-to-sideswaytoamaximumof1inch(25mm)on

eachside(Figure22).

Figure22

1.Swaylink

16

Adjustthelowerlinksinboarduntiltheycontactthe

aeratormountingplates.Thiswillreducethestress

onthepins.Ifthetractorhasswaychainsinsteadof

swaylinks,itisrecommendedthatwashersbeinstalled

betweenthelowerlinkarmandlynchpintoreducethe

overhungloadontheliftpins.

Note:RefertothetractorOperator’sManualfor

additionalinstallationandadjustmentprocedures.

10

LevelingtheAerator

Side-to-Side

Partsneededforthisprocedure:

1

Level(notsupplied)

Procedure

1.Parkthetractorandaeratoronalevel,rmsurface.

2.Placealevelontopoftheaeratorframetocheckfor

levelside-to-side(Figure23).

Figure23

1.Level

3.Turntheadjustablelinkbody(ifprovided)toraise

orlowerthelinkarmuntiltheaeratorisleveled

side-to-side.

Note:RefertotractorOperator’sManualfor

additionaladjustmentprocedures.

11

InstallingtheTines

Partsneededforthisprocedure:

A/R

Tines

Procedure

Awideselectionoftinesareavailablefortheaerator.

Choosethetinetype,sizeandspacingsrequiredforthe

job.RefertothePartsCatalogforthelistofaccessories.

1.Makecertaintheaeratorisfullysupportedonthe

ground,standsorsupportblocks.

2.Turnoffthetractorengineandremovethekey.

Avoidstandingtooclosetotherearofthe

machinewheninstallingtines.

3.Loosentheclampingboltsandremovethepreviously

usedtines(Figure24).

Figure24

1.Clampingbolt

2.Tine

4.Slidethenewtinesintotheholessizedtotthe

tinesselected.Neverusesmalldiametertinesinthe

largediameterholes-thetinesshouldtcloselyin

thehole.Besuretoslidethetineupintothehead

untilitbottomsout.

Note:Hollowcoringtinesshouldbepositioned

withtheejectionslottotherearwhilethesolidtines

shouldhavethetinetipanglefacingthemachine.

5.Tightentheclampingboltsrmlytosecurethetines.

17

6.Setthetineangleforthenewtines.Referto

AdjustingtheTineAngleintheOperationsection.

7.Beforeaeratingformalturfforthersttimeafter

installingtines,testtheaeratoronalessimportant

areasothatyoucantryalternativetractorgearsand

netunetheadjustmenttoachievetheholespacing

andturfappearancedesired.

12

RemovingtheStorageStands

(ModelsSR54,SR54S,SR70

andSR70–S)

NoPartsRequired

Procedure

1.Raisetheaeratorroller(s)3-6inchesoffground.

Placesupportblocksundertheroller(s).

2.Removethebolts,lockwashersandnutssecuringthe

storagestandstoeachendoftheaerator(Figure25).

Figure25

1.Bolts3.Nut

2.Lockwasher

4.Storagestand

3.Removethestoragestands.

4.Usethestoragestandswhenevertheaeratoris

removedfromthetractor.

13

RemovingtheStorageStands

(ModelsSR72)

NoPartsRequired

Procedure

1.Raisetheaeratorroller(s)3-6inchesoffground.

Placesupportblocksundertheroller(s).

2.Removetheboltsandnutssecuringthestorage

standstoeachendoftheaerator(Figure26).

Figure26

1.Bolts3.Nut

2.Lockwasher

4.Storagestand

3.Removethestoragestands.

4.Usethestoragestandswhenevertheaeratoris

removedfromthetractor.

Note:Whenreinstallingthestoragestands,make

suretheyaremountedtotheinsideoftheroller

platessothelowerframetubewillrestonthetopof

thestands.

18

ProductOverview

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

ProCore

SR48

ProCore

SR54

ProCore

SR54–S

ProCore

SR70

ProCore

SR70–S

ProCore

SR72

ProCore

SR75HD

Weight

withPTO&TopLink

1,450lbs.

(655kg)

990lbs.

(450kg)

1,250lbs.

(567kg)

1,500lbs.

(681kg)

1,655lbs.

(750kg)

1,985lbs.

(900kg)

3,250lbs.

(1,475kg)

WorkingWidth48”

(1.22m)

54”

(1.37m)

54”

(1.37m)

73”

(1.85m)

73”

(1.85m)

72”

(1.83m)

78”

(1.98m)

WorkingDepth

(Adjustable)

1”-14”

(25–300mm)

1”-10”

(25–250mm

1”-10”

(25–250mm

1”-10”

(25–250mm

1”-10”

(25–250mm

1”-16”

(25–400mm)

1”-16”

(25–400mm

HoleSpacing

3”-6”

(75–150mm)

2.5”-4”

(64–102mm)

2.5”-4”

(64–102mm)

2.5”-4”

(64–102mm)

2.5”-4”

(64–102mm)

3”-6”

(75–150mm)

3”-6”

(75–150mm)

Productivity25,000

sq.ft./hr.

(2,325

sq.m/hr.)

36,000

sq.ft./hr.

(3,345

sq.m/hr.)

36,000

sq.ft./hr.

(3,345

sq.m/hr.)

48,000

sq.ft./hr.

(4,460

sq.m/hr.)

48,000

sq.ft./hr.

(4,460

sq.m/hr.)

38,000

sq.ft./hr.

(3,530

sq.m/hr.)

48,000

sq.ft./hr.

(4,460

sq.m/hr.)

Recommended

TractorSize

25HP16–18HP18HP25–35HP25–35HP45HP55+HP

Recommended

LiftCapacity

1,800lbs.

(817kg)

1,200lbs.

(544kg)

1,500lbs.

(680kg)

1,700lbs.

(771kg)

1,800lbs.

(817kg)

2,800lbs.

(1,270kg)

4,000lbs.

(1,815kg)

Recommended

CounterWeight

300lbs.

(135kg)

150lbs.

(70kg)

150lbs.

(70kg)

250lbs.

(115kg)

250lbs.

(115kg)

300–500lbs.

(135–225kg)

700–900

(315–410kg)

Recommended

PTOSpeed

400–500rpm400–500rpm400–500rpm400–500rpm400–500rpm400–460rpm400–500rpm

ActualWorking

Speed@400

PTORPM

(Varieswithhole

spacing)

.8–1.3mph1.5–2.5mph1.5–2.5mph1.5–2.5mph1.5–2.5mph.8–1.5mph.8–1.5mph

LiftSystemStd.3–pointStd.3–pointStd.3–pointStd.3–pointStd.3–pointStd.3–pointStd.3–point

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

19

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

TractorControls

Itisnecessarytofamiliarizeyourselfwiththeoperation

ofthefollowingtractorcontrolsbeforeyouareableto

operatetheaerator:

•PTOEngagement

•Engine/PTORpm

•3PointHitch(Raise/Lower)

•AuxiliaryValveOperation

•Clutch

•Throttle

•GearSelection

•Parkingbrake

Note:RefertotractorOperator’sManualfor

operatinginstructions.

PrinciplesofOperation

Thetractor’sthreepointhitchlinkage/hydraulictop

linkliftstheaeratorfortransportandlowersitfor

operation.

Thetractor’spowertakeoff(PTO)poweristransmitted

viashafts,gearboxandO-ringdrivechainstoa

crankshaftwhichdrivesthetineholdingarmsintothe

turfsurface.

AsthetractortravelsforwardwiththePTOengaged

andthemachinelowered,aseriesofholesarecreated

intheturfsurface.

Thedepthofthetine’spenetrationisdeterminedby

extendingthehydraulictoplinkorsettingthexedtop

linktothedesiredposition.

Note:Donotattempttoadjustaxedtoplinkwhile

themachineisrunning.

Thedistancebetweentheholescreatedisdetermined

bythetractor’sgearratio(orhydrostatictractionpedal

position)andthenumberoftinesineachtinehead.

Simplychangingenginerpmdoesnotchangehole

spacing.

TractorPTOSpeed

TheaeratorisdesignedtooperatewithaPTOspeed

ofupto500rpmdependingonthesize/weightofthe

tines.Mosttractorsindicatea540PTOrpmposition

ontherevcounters.SincetheengineandPTOrpms

aredirectlyproportional,youcandeterminetheengine

rpmrequiredfora400rpmPTObycalculatingas

follows:

(Enginerpmat540PTOspeed)x(400÷540)=requiredengine

rpm

Forexample,iftheenginerpmwere2700foraPTO

speedof540rpm,youwouldget:

2700x(400÷540)=2000rpm

Inthisexample,runningyourtractorat2000rpmnow

providesyouwitha400rpmPTOspeed.

Ifyourtractorindicatessomeotherenginerpmat540

PTOrpm,substitutethatnumberforthe2700thatwas

usedabove.

TrainingPeriod

Beforeusingtheaerator,ndaclearareaandpractice

usingthemachine.Operatethetractoratrecommended

gearsettingsandPTOdrivespeedsandbecome

thoroughlyfamiliarwithmachinehandling.Practice

stoppingandstarting,raisingandloweringtheaerator,

disengagingthePTOdriveandaligningthemachine

withpreviouspasses.Apracticesessionassures

condenceintheperformanceoftheaeratorandhelps

ensureuseofproperoperatingtechniqueswherever

themachineisoperated.

Iftherearesprinklerheads,electricalorcommunication

linesorotherobstructionsintheareatobeaerated,

marktheseitemstoensuretheyarenotdamagedduring

operation.

Toavoidpersonalinjury,neverleavethetractor

seatwithoutrstdisengagingthePTOdrive,

settingtheparkingbrakeandstoppingthe

engine.Neverperformaeratorrepairswithout

rstloweringtheaeratorontothestorage

standorappropriateblockingorjacks.Besure

allsafetydevicesaresecuredinproperplace

beforeresumingoperation.

BeforeAerating

Inspecttheareaofoperationforhazardsthatcould

damagethemachineandremovethem,ifpossible,

orplanhowtoavoidthem.Carryreplacementtines,

springwires,springsandtoolsincasetinesaredamaged

duetocontactwithforeignmaterials.

20

/