Page is loading ...

Appli-Mate (RAST2.5 Power) Manual Terminator

Doc. No: TM-622030000 Release Date: 12-19-07 UNCONTROLLED COPY Page 1 of 16

Revision: D Revision Date: 10-10-16

APPLI-MATE (RAST2.5 Power)

MANUAL TERMINATOR

Operation Manual

Description

Operation

Maintenance

Appli-Mate (RAST2.5 Power) Manual Terminator

Doc. No: TM-622030000 Release Date: 12-19-07 UNCONTROLLED COPY Page 2 of 16

Revision: D Revision Date: 10-10-16

WARNING

NEVER OPERATE, SERVICE, INSTALL OR ADJUST THIS MACHINE

WITHOUT PROPER INSTRUCTION AND WITHOUT FIRST

READING AND UNDERSTANDING THE INSTRUCTIONS IN

THIS MANUAL.

WORK SAFELY AT ALL TIMES

For Service, Contact Your

Local Molex Sales Office

Molex Application Tooling Group

2200 Wellington Court

Lisle, Illinois 60532

Tel: 630-969-4550

Fax: 630-505-0049

Appli-Mate (RAST2.5 Power) Manual Terminator

Doc. No: TM-622030000 Release Date: 12-19-07 UNCONTROLLED COPY Page 3 of 16

Revision: D Revision Date: 10-10-16

Table of Contents

SECTION

1. General Description, Installation, and Operation

2. Maintenance, Perishable Parts, Spare Parts and Troubleshooting

3. Parts List and Assembly Drawings, Connector Series Chart

Appli-Mate (RAST2.5 Power) Manual Terminator

Doc. No: TM-622030000 Release Date: 12-19-07 UNCONTROLLED COPY Page 4 of 16

Revision: D Revision Date: 10-10-16

Section 1

General Description

1.1 Description

1.2 Features

1.3 Technical Specifications

1.4 Delivery Check

1.5 Installation

1.6 Setup

1.7 Operation

Appli-Mate (RAST2.5 Power) Manual Terminator

Doc. No: TM-622030000 Release Date: 12-19-07 UNCONTROLLED COPY Page 5 of 16

Revision: D Revision Date: 10-10-16

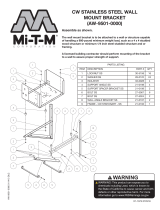

Figure 1-1

HOUSING LOAD

PLATFORM

CONNECTOR

NEST

WIRE

GUIDES

PRESS FRAME

MOUNTING HOLES

PRESS

FRAME

UPPER

TOOLING

ADAPTER

BLOCK

PRESS

LEVER

Principal Mechanical parts of the Appli-Mate (RAST2.5 Power) Terminator 62203-0000

Appli-Mate (RAST2.5 Power) Manual Terminator

Doc. No: TM-622030000 Release Date: 12-19-07 UNCONTROLLED COPY Page 6 of 16

Revision: D Revision Date: 10-10-16

General Descrition

1.1. Description

The 62203-0000 Appli-Mate (RAST2.5 Power)

Manual Terminator, complete with arbor press, is

designed to terminate the Appli-Mate (RAST2.5

Power) female connector series (91627 and 91791)

onto discrete wire (0.50mm² or 0.75mm²). The

connectors are supplied as a stack. The stack is a

series of connectors attached by tabs that are cut

apart during termination. The terminator will

accommodate circuit size 2 through 12. An operator

loads a connector into the nest, inserts the wires into

position, and cycles the press. When the cycle is

complete, the operator removes the harness. This

terminator is ideally suited for low to medium volume

production.

1.2. Features

Bench top operation.

Manual operation, no air or electricity required.

Wire tension adjustment

Quick release lever for harness removal

Adjustable press lever for operator comfort

1.3. Technical Specification

Dimensions

Width: 210mm (8.3")

Depth: 136mm (5.4") without connector support

Depth: 485mm (19.1") with connector support

Height: 525mm (20.7")

Weight

18.1kg (40lbs)

Rate

Approximately 450 discrete wires per hour

depending on operator skill.

1.4. Delivery Check

Carefully remove the Terminator from its shipping

container and determine that the following items

are included in the package.

Order No. Qty.

62203-0000 Appli-Mate Manual Terminator

(RAST2.5 Power) 1

62201-7414 Housing Load Platform 1

TM-622030000 Instruction Manual 1

1.5. Installation

Set the press on a bench of suitable height and

capable of supporting at least 70 kg (155 Lbs).

Using the two (2) M4 X 12 FHCS supplied with the

press, mount the Housing Load Platform to the

press as shown in Figure 1-1. (Also see the

assembly drawing in Section 3.) There are two (2)

clearance holes in the Press Frame (see Figure 1-1)

for M8 or 5/16 in. screws, if it is desired to bolt the

press to the bench. Make sure there is adequate

room around the press for the operator to load

connectors and to store wires and finished

harnesses. Make certain there is adequate lighting.

1.6. Setup

Termination Height (Figure 1-1 and 1-2)

In order to insure the connector top half is

correctly seated in the lower half and that the

wires are correctly terminated, it may necessary

to adjust the termination height. This is done as

follows:

1. To adjust the termination height, loosen the

three (3) socket head cap screws that lock the

adaptor block to the press frame.

2. To decrease the termination height (the height

of the connector after termination) turn the

height adjusting knob counterclockwise. To

increase the height, turn the knob clockwise.

3. When the desired height is set, tighten the

locking screws. The height of the terminated

connector should be 15.10mm ± 0.10 (0.594” ±

.004).

Appli-Mate (RAST2.5 Power) Manual Terminator

Doc. No: TM-622030000 Release Date: 12-19-07 UNCONTROLLED COPY Page 7 of 16

Revision: D Revision Date: 10-10-16

Figure 1

-

2

ADAPTER BLOCK AND SCREWS

ADAPTER

BLOCK

ADAPTER

BLOCK

LOCKING

SCREWS

Figure 1

-

3

SETTING THE CONNECTOR GUIDE

(MANY PARTS NOT SHOWN FOR CLARITY)

LOCKING

SCREW

FIXED GUIDE

BLOCK

CONNECTOR

STACK

CONNECTOR

SUPPORT

ADUSTUSTABLE

GUIDE BLOCK

Figure 1

-

4

WIRE TENSION ADJUSTMENT

WIRE

GUIDES (12)

STOP SCREW

RELEASE

LEVER

Adjusting for Connector Size

The Appli-Mate (RAST2.5 Power) connectors are

available in circuit sizes 2 through 12. The guides

must be adjusted to fit the desired connector circuit

size. That is done as follows:

1. Loosen or remove the locking screw for the

adjustable guide block and position the guide to fit

the desired connector stack. Place the stack on

the connector support and slide it forward until it is

between the fixed and the adjustable guide blocks.

See Figure 1-3.

2. Replace the locking screw if it was removed but do

not tighten.

3. Slide the adjustable guide block toward the fixed

guide block until the connector stack slides

between the guides with minimum clearance.

4. Tighten the adjustable guide block locking

screw.

Adjusting the Wire Tension

It is necessary to make an adjustment to the wire

stop when changing from one wire size to another.

Refer to Figure 1-4.

1. Turn the stop screw clockwise to decrease the

tension or counterclockwise to increase the

tension applied to the wire. Adjust the tension so

the wire can be pushed through the guides, into

the connector, and held firmly in place upon

release.

Appli-Mate (RAST2.5 Power) Manual Terminator

Doc. No: TM-622030000 Release Date: 12-19-07 UNCONTROLLED COPY Page 8 of 16

Revision: D Revision Date: 10-10-16

Figure 1

-

7

LOADING CONNECTOR STACKS

HOUSING

LOCATOR

F

igure 1

-

5

HOUSING (CONNECTOR) LOCATOR

HOUSING

POSITIONER

HOUSING

POSITIONER

AGAINST THE

CONNECTOR

Figure 1

-

6

CONNECTOR IN POSITION

WIRE GUIDES

(12)

MOVE

HOUSING

LOCATOR ALL

THE WAY TO

THE RIGHT

1.7. Operation

1. Load a stack of connectors between the guide

blocks as shown in Figure 1-3.

2. Pull the knob on the housing locator and move it

all the way to the left. See Figure 1-5.

3. Move housing positioner towards the stack of

connectors. It should snap into place.

4. Place the index and middle fingers on top of the

connector stack. Applying a slight downward

pressure, slide the connector stack forward until

the connector “snaps” into place. See Figure 1-6.

5. Push the knob on the housing locator all the way

to the right.

6. Load the wires individually by inserting them

through the wire guides into the holes of the

connector and up against the stop.

7. Move housing positioner away from the connector.

WARNING: If the positioner is not moved, the

press ram will hit the positioner and damage it.

8. When all wires are loaded, cycle the press by

pulling the press lever to the full down position.

This will press the two halves of the connector

together terminating the wires and latching the

connector halves together. This will also cut the

terminated connector from the stack.

9. Return the press lever to the full up position.

10. Remove the terminated connector assembly by

pressing down on the wire release lever and

sliding the assembly out to the right. See Figure

1-4.

NOTE: The lower housing must be removed when

loading the first stack of connectors into the press. To

attach another stack, insert the upper housing at the

end of the first stack into the lower housing of the new

stack. See Figure 1-7.

Appli-Mate (RAST2.5 Power) Manual Terminator

Doc. No: ATS-622030000 Release Date: 12-19-07 UNCONTROLLED COPY Page 9 of 16

Revision: A Revision Date: 12-19-07

Section 2

Set-Up and Operation

2.1. Maintenance

2.2. Perishable Parts

2.3. Spare Parts

2.4. Troubleshooting

Appli-Mate (RAST2.5 Power) Manual Terminator

Doc. No: TM-622030000 Release Date: 12-19-07 UNCONTROLLED COPY Page 10 of 16

Revision: D Revision Date: 10-10-16

2.1 Maintenance

(See Chart 2.1 for maintenance scheduling,)

Cleaning

The APPLI-MATE (RAST2.5 Power) Manual Terminator should be cleaned at least once a day with a soft

brush to remove dust and debris.

Lubrication

The press requires regular lubrication on a monthly basis. Place a small amount of lubricant with Teflon,

such as Permatex “Superlube”, on the sliding surfaces.

An example of a maintenance chart is shown below. Copy and use this chart to track the maintenance of your

Terminator or use this as a template to create you own schedule or use your company’s standard chart, if

applicable.

Preventive Maintenance Chart

Daily: Clean. See Section 2.1.

As Required: Lubricate. See Section 2.1.

CHECK SHEET MONTH YEAR _________

Week

Daily

Cycles

Daily

Clean

Days of the Week

Solution

MON TUE WED THU FRI SAT

SUN

1

2

3

4

Cleaning

Reapply grease

Reapply oil

Soft Brush Industrial

Degreaser

Inspect all tooling, feed

fingers etc. for wear

Replace if signs of wear.

Schedule should be adjusted up or down depending on usage. Molex recommends that a log of preventive

maintenance be kept with the press.

CAUTION:

Using compressed air to clean the Terminator is not recommended as

debris could become jammed in the tooling and/or come flying out at the operator.

Appli-Mate (RAST2.5 Power) Manual Terminator

Doc. No: TM-622030000 Release Date: 12-19-07 UNCONTROLLED COPY Page 11 of 16

Revision: D Revision Date: 10-10-16

2.2 Perishable Parts

Customers are responsible for maintaining the APPLI-MATE (RAST2.5 Power) Manual Terminator.

Perishable parts are those parts that come in contact with the product and will wear out over time. Molex

recommends that all customers keep at least one set of the perishable tool kits in stock at all times. This

will reduce the amount of production down time. These parts are identified in the Parts List in Section 3.

2.3 Spare Parts

Customers are responsible for maintaining the APPLI-MATE (RAST2.5 Power) Manual Terminator. Spare

parts are available. Moving and functioning parts can be damaged or wear out over time and will require

replacement. Molex recommends that the customer keep some or all of them in stock to reduce production

down time. These parts are identified in the Parts List. See Section 3.

2.4. Troubleshooting

Symptom Cause Solution

Terminat

ion height

not within specification

Termination tooling height not set correctly

Readjust termination height.

See Section 1.6: Termination Height.

Wire not sliding

easily

into position

Wire guide spring tension set too high

Readjust the spring tension.

See Section 1.6: Adjusting the Wire

Tension.

There is debris in the openings

Check the tooling and the connector

for debris and clean as required.

Wire not staying in

position after loaded

Wire guide spring tension set too low

Readjust the spring tension

.

See Section 1.6: Adjusting the Wire

Tension.

Appli-Mate (RAST2.5 Power) Manual Terminator

Doc. No: TM-622030000 Release Date: 12-19-07 UNCONTROLLED COPY Page 12 of 16

Revision: D Revision Date: 10-10-16

Section 3

3.1. Parts Lists and Assembly Drawings

3.2. Connector Series Chart

Appli-Mate (RAST2.5 Power) Manual Terminator

Doc. No: TM-622030000 Release Date: 12-19-07 UNCONTROLLED COPY Page 13 of 16

Revision: D Revision Date: 10-10-16

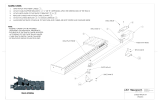

3.1 Parts List and Assembly Drawings (See Figure 3-1)

Appli

-

Mate (

RAST2.5

Power) 62203

-

0000

Item

No.

Order

No

.

Engineering No.

Description

Quantity

Perishable Tooling

1

62

300

-

5913

62

300

-

5913

Termination Blade

1

-

PP

2

6220

3

-

0016

6220

3

-

0016

Carrier Cutoff Blade

1

-

PP

Other Components

3

62201

-

7412

62201

-

7412

Mounting Base

1

4

62201

-

7414

62201

-

7414

Housing Load P

latform

1

5

62201

-

7420

62201

-

7420

Shaft

-

Ram

1

6

62201

-

7423

62201

-

7423

Adapter

-

Front Head

1

7

6220

3

-

00

25

62

203

-

00

25

Ram Guard

1

8

62201

-

7426

62201

-

7426

Molex Nameplate

1

9

62201

-

7428

62201

-

7428

Locator Spacer

1

10

62201

-

7523

62201

-

7523

Guard Angle

1

11

62203

-

0001

62203

-

0001

Locator

-

Housing

1

12

62203

-

0002

62203

-

0002

Ramp

-

Housing

1

13

62203

-

0003

62203

-

0003

Guide

-

Left Housing

1

14

62203

-

0004

62203

-

0004

Guide

-

Right Housing

1

15

62203

-

0005

62203

-

0005

Holder

-

Wire Guide

1

16

62203

-

0006

62203

-

0006

Guide

-

Wire

12

-

RSP

17

62203

-

0007

62203

-

0007

Cover

-

Guide Front

1

18

62203

-

0008

62203

-

0008

Shaft

-

Pivot

1

19

62203

-

0009

62203

-

0009

Release Lever

1

20

62203

-

0011

62203

-

0011

Base

-

Tool

1

21

62203

-

0013

62203

-

0013

Hold

-

Down Spring

1

22

62203

-

0015

62203

-

0015

Positioner

-

Housing

1

23

62203

-

0

017

62203

-

0017

Blade

-

Front Locator

1

24

62203

-

0018

62203

-

0018

Blade

-

Cutoff Support

1

25

62203

-

0019

62203

-

0019

Block

-

Ram

1

26

62203

-

0021

62203

-

0021

Guide

-

Top Wire

1

27

63600

-

0937

63600

-

0937

Slide Knob

1

28

63600

-

0939

63600

-

0939

Wire Guide Spring

12

-

RSP

29

63600

-

1263

63600

-

1263

M5 Ball Plunger

1

30

63600

-

1533

63600

-

1533

M5 Hex Nut

1

31

63600

-

1937

63600

-

1937

Shoulder Screw

2

32

69808

-

1204

69808

-

1204

M8

Fender Washer

2

Frame

33

63600

-

0942

63600

-

0942

Press

-

Toggle

1

Hardware

34

N/A

N/A

M

3

by

6

Long SHCS

3**

35

N/A

N/A

M

3

by

8

Long SHCS

2**

36

N/A

N/A

M

3

by

12

Long

F

HCS

1**

37

N/A

N/A

M

3

by

12

Long SHCS

2**

38

N/A

N/A

M

3

by

14

Long SHCS

2**

Appli-Mate (RAST2.5 Power) Manual Terminator

Doc. No: TM-622030000 Release Date: 12-19-07 UNCONTROLLED COPY Page 14 of 16

Revision: D Revision Date: 10-10-16

Appli

-

Mate (

RAST2.5

Power) 62203

-

0000

39

N/A

N/A

M

3

by

16

Long SHCS

6**

40

N/A

N/A

M

4

by

12

Long

F

HCS

4**

41

N/A

N/A

M

4

by

25

Long

S

HCS

4**

42

N/A

N/A

M5 by

6

Long S

SS

1

**

43

N/A

N

/A

M5 by

12

Long S

SS

1**

44

N/A

N/A

M5 by 20 Long SHCS

4

**

45

N/A

N/A

M8 by

16

Long

F

HCS

1**

46

N/A

N/A

M8 by

30

Long SHCS

3

**

47

N/A

N/A

M8 by

40

Long

F

HCS

1

**

48

N/A

N/A

M8 by 4

0

Long SHCS

3

**

49

N/A

N/A

M8 by 45 Long SHCS

1**

50

N/A

N/A

M3 Flat Washer

1**

51

N/

A

N/A

M

4

Flat Washer

1**

52

N/A

N/A

M

8

Hex Nut Full

1**

53

N/A

N/A

3mm by 10 Long Dowel Pin

4**

54

N/A

N/A

3mm by 12 Long Dowel Pin

4**

55

N/A

N/A

5mm by 12 Long Dowel Pin

1**

56

N/A

N/A

5mm by 16 Long Dowel Pin

2**

** Available from an industrial supply compa

ny such as MSC (1

-

800

-

645

-

7270).

The following pages contain the APPLI-MATE (RAST2.5 Power) Manual Terminator Parts Lists and

Assembly Drawings. The following definitons may help the reader better understand and use this material.

1. The “RSP” appearing at the end of the description column means this item is a Recommended Spare

Part. See Section 2.3 for description of “recommended spare part”.

2. The “PP” appearing at the end of the description column means this item is a Perishable Part. See

Section 2.2 for description of “perishable part”.

3. The termination blade supplied with the Manual Terminator will terminate all circuit sizes of RAST2.5

Power connectors with open end walls and any combination of inner ribs and/or latches. For

connectors with closed end wall(s) the specific circuit size blade must be ordered:

Closed

-

End Wall Termination Blades

Item No.

Order No.

Engineering No.

Description

Quantity

1

62300

-

5923

62300

-

5923

Termination Blade

–

2 circuit

1

-

PP

1

62300

-

5924

62300

-

5924

Termination Blade

–

3 c

ircuit

1

-

PP

1

62300

-

5925

62300

-

5925

Termination Blade

–

4 circuit

1

-

PP

1

62300

-

5926

62300

-

5926

Termination Blade

–

5 circuit

1

-

PP

1

62300

-

5927

62300

-

5927

Termination Blade

–

6 circuit

1

-

PP

1

62300

-

5928

62300

-

5928

Termination Blade

–

7 circuit

1

-

PP

1

6

2300

-

5929

62300

-

5929

Termination Blade

–

8 circuit

1

-

PP

1

62300

-

5930

62300

-

5930

Termination Blade

–

9 circuit

1

-

PP

1

62300

-

5931

62300

-

5931

Termination Blade

–

10 circuit

1

-

PP

1

62300

-

5932

62300

-

5932

Termination Blade

–

11 circuit

1

-

PP

1

62300

-

5933

6230

0

-

5933

Termination Blade

–

12 circuit

1

-

PP

Appli-Mate (RAST2.5 Power) Manual Terminator

Doc. No: TM-622030000 Release Date: 12-19-07 UNCONTROLLED COPY Page 15 of 16

Revision: D Revision Date: 10-10-16

21

17

26

30

50

36

28

54

13

38

43

14

53

12

54

34

11

27

19

53

(2)

51

(2)

34

40

37

41

29

31

41

16

18

22

15

Figure 3-1

35

32

33

32

49

46

40

4

20

55

52

3

56

44

44

9

42

45

10

47

7

24

2

1

53

5

25

23

39

48

(2)

(2)

(2)

(12)

(12)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(3)

(6)

(3)

9

6

(2)

Appli-Mate (RAST2.5 Power) Manual Terminator Assembly

Appli-Mate (RAST2.5 Power) Manual Terminator

Doc. No: TM-622030000 Release Date: 12-19-07 UNCONTROLLED COPY Page 16 of 16

Revision: D Revision Date: 10-10-16

3.2 Connector Series Chart

Products: 5.00mm (.197") Pitch Appli-Mate RAST2.5 Power IDT Connector Assemblies 2 to 12 Circuits.

Connector

Series No.

Circuit Size

Connector Assembly Order No.

91627

2

91627

-

0001

91627

-

0002

91627

-

0003

91627

-

0004

91627

-

0005

91627

-

0006

91627

-

0008

91627

-

0009

91627

-

0010

91627

-

0011

91627

-

0012

91627

-

0013

91627

-

0014

91627

-

0015

91627

-

0016

91627

-

0501

91627

-

0502

91627

-

0503

91627

-

0504

91627

-

0505

91627

-

0506

91627

-

0507

91627

-

0508

3

91627

-

1001

91627

-

1002

91627

-

1004

91627

-

1005

91627

-

1006

91627

-

1007

91627

-

1008

91627

-

1009

91627

-

1010

91627

-

1011

91627

-

1012

91627

-

1013

91627

-

1014

9162

7

-

1015

91627

-

1016

91627

-

1017

91627

-

1501

91627

-

1502

91627

-

1503

91627

-

1504

91627

-

1506

91627

-

1507

91627

-

1508

4

91627

-

2001

91627

-

2002

91627

-

2003

91627

-

2004

91627

-

2005

91627

-

2006

91627

-

2007

91627

-

2008

91627

-

2009

91627

-

2010

91627

-

2011

91627

-

2501

91627

-

2503

5

91627

-

3001

91627

-

3002

91627

-

3003

91627

-

3004

91627

-

3005

91627

-

3006

91627

-

3501

91627

-

3502

91627

-

3503

91627

-

3504

6

91627

-

4001

91627

-

4002

91627

-

4003

91627

-

4004

91627

-

4005

91627

-

4006

91627

-

4007

91627

-

4501

91627

-

4502

91627

-

4503

7

91627

-

5001

91627

-

5002

91627

-

5003

91627

-

5004

91627

-

5005

91627

-

5006

91627

-

5501

91627

-

5502

91627

-

5503

91627

-

5504

91627

-

5505

8

91627

-

6001

91627

-

6002

91627

-

6501

91627

-

6502

9

91627

-

7001

91627

-

7002

91627

-

7003

91627

-

7501

91627

-

7502

91627

-

7503

91627

-

7504

10

91627

-

8001

91627

-

8501

11

91627

-

9001

91627

-

9251

12

91627

-

9501

91627

-

9751

91791

2

91791

-

0001

3

91791

-

1001

91791

-

1002

91791

-

1003

91791

-

1004

91791

-

1504

4

91791

-

2001

91791

-

2004

5

91791

-

3001

6

91791

-

4001

7

91791

-

5001

8

91791

-

6001

9

91791

-

7001

10

91791

-

8001

11

91791

-

9001

12

91791

-

9501

Note: Connectors with closed end wall(s) require different termination blade. See chart on page 14.

Americas Headq

uarters

Lisle, Illinois 60532 U.S.A.

1-800-78MOLEX

Far East North Headquarters

Yamato, Kanagawa, Japan

81-462-65-2324

Far East South Headquarters

Jurong, Singapore

65-6-268-6868

European Headquarter

s

Munich, Germany

49-89-413092-0

Corporate Headquarters

2222 Wellington Ct.

Lisle, IL 60532 U.S.A.

630-969-4550

Fax: 630-969-1352

Visit our Web site at http://www.molex.com

/