Page is loading ...

Instruction

Manual

Cylinder Pressure

Transmitter

Type 6613CA

ä

6613C_002-026e-02.16

Instruction

Manual

Cylinder Pressure

Transmitter

Type 6613CA

ä

6613C_002-026e-02.16

Foreword

6613C_002-026e-02.16 Page 1

Foreword

We thank you for choosing a Kistler quality product

distinguished by technical innovation, precision and long

life.

Information in this document is subject to change without

notice. Kistler reserves the right to change or improve its

products and make changes in the content without

obligation to notify any person or organization of such

changes or improvements.

© 2002 … 2016 Kistler Group. All rights reserved. Except

as expressly provided herein, no part of this manual may

be reproduced for any purpose without the express prior

written consent of Kistler Group.

Kistler Group

Eulachstrasse 22

8408 Winterthur

Switzerland

Tel. +41 52 224 11 11

Fax +41 52 224 14 14

www.kistler.com

Content

Page 2 6613C_002-026e-02.16

Content

1. Introduction ................................................................................................................................... 3

2. Description ..................................................................................................................................... 4

2.1 Introduction ......................................................................................................................... 4

2.2 Dimensions Type 6613CA .................................................................................................... 5

2.3 Working Principle ................................................................................................................. 6

3. Installation ..................................................................................................................................... 7

3.1 General ................................................................................................................................ 7

3.2 Recommended Mounting ..................................................................................................... 8

3.2.1 Sealing..................................................................................................................... 8

3.2.2 Installing the Sensor ................................................................................................ 8

3.2.3 Installing the Charge Amplifier ................................................................................ 9

3.2.4 Cable between Charge Amplifier and Data Aquisition Unit ..................................... 9

3.2.5 Measuring Functions and Pin Connections ............................................................ 10

3.2.6 Special Hints for Spark-Ignited Gas Engines ........................................................... 11

4. Operation ..................................................................................................................................... 12

5. Maintenance ................................................................................................................................ 13

6. Trouble Shooting ......................................................................................................................... 14

6.1 Repair ................................................................................................................................. 14

7. Technical Data Type 6613CA ....................................................................................................... 15

8. Declaration of Conformity ........................................................................................................... 16

Total pages 16

Introduction

6613C_002-026e-02.16 Page 3

1. Introduction

Please take the time to thoroughly read this instruction

manual. It will help you with the installation, maintenance,

and use of this product.

To the extent permitted by law Kistler does not accept any

liability if this instruction manual is not followed or

products other than those listed under Accessories are

used.

Kistler offers a wide range of products for use in measuring

technology:

Piezoelectric sensors for measuring force, torque, strain,

pressure, acceleration, shock, vibration and acoustic-

emission

Strain gage sensor systems for measuring force and

moment

Piezoresistive pressure sensors and transmitters

Signal conditioners, indicators and calibrators

Electronic control and monitoring systems as well as

software for specific measurement applications

Data transmission modules (telemetry)

Kistler also develops and produces measuring solutions for

the application fields engines, vehicles, manufacturing,

plastics and biomechanics sectors.

Our product and application brochures will provide you

with an overview of our product range. Detailed data

sheets are available for almost all products.

If you need additional help beyond what can be found

either on-line or in this manual, please contact Kistler's

extensive support organization.

Cylinder Pressure Transmitter Type 6613CA

Page 4 6613C_002-026e-02.16

2. Description

2.1 Introduction

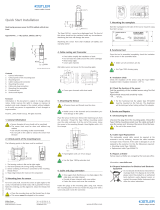

The pressure transmitter Type 6613CA contains a piezo-

electric sensor and an integrated charge amplifier. The

pressure transmitter is made for continuous cylinder

pressure monitoring of large gas engines.

Suitable for gas engines

Extremely long life due life time optimized design.

High reproducibility.

The sensor can be installed in the cylinder head, in the

indicator valve or underneath the indicator valve in a

additional adapter ring.

The integrated charge amplifier provides an uniform output

and can be connected directly to a data acquisition unit.

There are no individual sensitivity adjustments necessary,

since the output has uniform sensitivity. The sensor has a

voltage output of 0 ... 5 V with a zero line of 2 V (if

pressure is 0 bar). The output is ac – coupled, so static

pressure measurements are not possible.

Fig 1: Piezoelectric Pressure Sensor (left)

with Integrated Amplifier (right)

Description

6613C_002-026e-02.16 Page 5

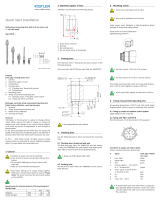

2.2 Dimensions Type 6613CA

Fig 2: Dimensions Type 6613CA and mounting bore

Cylinder Pressure Transmitter Type 6613CA

Page 6 6613C_002-026e-02.16

2.3 Working Principle

The cylinder pressure is acting on the diaphragm. The

diaphragm converts the pressure in proportional force on

the sensor element. The piezoelectric sensor element

converts the force into a charge. The charge is converted

by a charge amplifier into a voltage.

The complete measuring chain is designed for easy

operation and very long life time.

The advantage piezoelectric principle is:

Operates safe up to high temperatures and therefore

ideally suited for accurate measurements in harsh

conditions.

Very small sensitivity change over temperature range.

High stiffness, results in small diaphragm stress

High reproducibility since the piezoelectric constant of

the measuring element is a constant of nature and

does not change over time.

The zero line output signal is about 2 V if there is no

pressure on the sensor. This allows a small drift of the zero

line of the transmitter output without cutting the signal

(Fig 4). These drift is the result of temperature fluctuation

caused by a quick load change of the engine. The ac –

coupling of the amplifier forces the zero line back to 2 V.

Fig 3: Schematic cross section of sensor element

Fig. 4: Example of sensor behavior at a engine load change

Range I

250 bar = 2,5 V

4.8

2.1

1.1

0

1

2

3

4

5

time

voltage

balanced

operation

drift due to quick

load chan

g

e

recover according

time constan

t

Installation

6613C_002-026e-02.16 Page 7

3. Installation

3.1 General

The quality of the measurement and the life time depends

very much of a correct mounting.

The mounting hole must be manufactured within the

tolerances

Avoid mounting at the end of long tubes, it creates

pipe ringing and overheating of the sensor

Ideal is a mounting hole in the cylinder head with

about 20 mm distance from the combustion chamber

Also acceptable is a mounting in or below the indicator

valve. Tube between indicator valve and cylinder head

must be as short as possible

Sensor must be tightened according the mounting

torque

If there are any question regarding installation please

contact Kistler.

Fig. 5: Sensor installed underneath the indicator valve in

adapter Type 7523B…

Cylinder Pressure Transmitter Type 6613CA

Page 8 6613C_002-026e-02.16

3.2 Recommended Mounting

Fig. 6: Mounting bore for Type 6613CA

Mounting torque is 15 N·m

3.2.1 Sealing

A leakproof mounting of the sensor is essential to prevent

overheating of the sensor by leaking hot gases. Good

sealing is obtained by

fine-machined sealing face on the engine (for surface

roughness, flatness and squareness see fig 7).

all sealing faces (on engine and on sensor) must be

clean and free of any burrs.

3.2.2 Installing the Sensor

Clean all parts and apply a light film of grease to the thread

and the sealing surface. Use high-temperature paste MoS2

(e.g. Molycote P74 or 1 000) or copper grease.

Insert sensor into mounting bore an torque with 15 N·m.

Use a torque wrench for sensor mounting. After Installing

the sensor, check if there is no leakage if engine runs on

idle speed.

Installation

6613C_002-026e-02.16 Page 9

3.2.3 Installing the Charge Amplifier

Charge amplifier can be fixed with cable strips in the cable

channel. Select a location where the temperature does

certainly not exceed 110 °C. Route and fix the integrated

cable between sensor and preamplifier so it is protected

against mechanical damage. Keep it away from any source

of heat such as the exhaust or hot fuel lines.

3.2.4 Cable between Charge Amplifier and Data Aquisition Unit

This cable can be made by the user. The connector M12x1

on the charge amplifier is very common in industrial

application. Use a shielded cable, otherwise the sensor is

not conform with CE rules. The following connecting

cables are available from Kistler.

Type 1700A69

1700A69A1 1700A71 1787A5

Length in meter 10 20 10 5

Connector Side A M12x1 DIN M12x1 DIN M12x1 DIN M12x1 DIN

Connector Side B no connector no connector no connector no connector

Number of wires: 3 4 8

Function

black = GND

blue = Signal output

brown = Power supply

black = GND

blue = Signal output

brown = Power supply

white = Range selection

white = GND

grey = Signal output

red = Power supply

brown = Range selection

green = Selection of TC

only used for calibration

Remaining wires are not

used

Cylinder Pressure Transmitter Type 6613CA

Page 10 6613C_002-026e-02.16

3.2.5 Measuring Functions and Pin Connections

Fig 7: View on connector of amplifier

Pin Function Remarks

1

5

8

Ground (GND)

Signal output

Supply voltage

Must be connected

4

6

7

for manufacturer only

Not connected.

Only for internal use of manufacturer.

2

Selection of measuring range:

Not connected (standard) or

ground connected (0 ... 0,8 V)

Range 1: 250 bar = 2,5 Volt

supply connected (3 ... 32 V)

Range 2: 100 bar = 2,5 Volt

Depending on cylinder peak pressure of engine.

3

Selection of time constant (T):

Not connected (standard) or

ground connected (0 ... 0,8 V)

T 1: 5 s

Supply connected (3 ... 32 V)

T 2: 2 500 s

At T1 a long term drift compensation is

activated.

T2 for calibration only

Calibration

In order to calibrate the Type 6613CA with a static pressure the time constant needs to be changed from

short (5 s) to long . This is done by connecting pin 3 to a voltage of 3 … 32 V.

The time for calibration must not exceed 15 s . For any questions please contact Kistler.

Installation

6613C_002-026e-02.16 Page 11

3.2.6 Special Hints for Spark-Ignited Gas Engines

Gas engines have extremely strong EMC-fields, which can

affect the transmitter signals. Please make sure that

resistance spark plugs are used, normally

the charge amplifier and the cable of the sensor, is

kept at least 150 mm away from any ignition cable or

coil.

the sensor cable and the ignition cable are not installed

in parallel if possible.

Cylinder Pressure Transmitter Type 6613CA

Page 12 6613C_002-026e-02.16

4. Operation

After starting up the engine check for any gas leakage at

once. If there is any gas leaking out, stop the engine and

rectify the mounting to achieve a complete sealing (see

chapter 4).

Warning: If the sensor is mounted in an indicator

valve: When the engine is operating do not open the

indicator valve for more than 10 seconds at a time as

otherwise the sensor may be overheated.

Maintenance

6613C_002-026e-02.16 Page 13

5. Maintenance

After installation, the transmitter needs no maintenance.

Do not use a steam or high-pressure cleaner for cleaning

purposes.

Calibration is recommended after one year of operation.

This can be done on the either with a dead weight tester,

or with the calibration equipment available from Kistler.

Please contact your Kistler representative for technical

consultation.

Never use wire brushes, screw drivers or any other sharp

pointed instrument for cleaning the diaphragm.

Cylinder Pressure Transmitter Type 6613CA

Page 14 6613C_002-026e-02.16

6. Trouble Shooting

6.1 Repair

The transmitter cannot be repaired on site. In case of

incorrect functions or broken parts the sensor must be sent

to factory.

Technical Data Type 6613CA

6613C_002-026e-02.16 Page 15

7. Technical Data Type 6613CA

Measuring range Range I bar 0 ... 250

Range II bar 0 ... 100

Sensitivity Range I (±0,5 %) mV/bar 10

Range II (±0,5 %) mV/bar 25

Measuring frequency (–3 dB) Hz 0,016 ... 20 000

Linearity °C 20 %FSO 1

Operating temperature range mounting location °C −50 ... 350

electronic °C −10 ... 110

Viton® cable connection max. °C 200

Sensitivity shift 200150 °C % 2,5

20050 °C % 1

Time constant for cylinder measuring s 5

for calibration s >2 500

Signal output (at 1mA load) max. V 4,4 ... 5

min. V >0

Signal span V 2,5

Zero line V 2 ... 2,2

Supply voltage V 7 ... 32

Supply current mA 6

Output impendance 100

Mounting torque N·m 15

Connector Lumberg M12 IP67

Accessories Included

Cr-Ni-St.seal Type 1100A3

Optional Accessories Type

Torque wrench 8 ... 40 N·m * 1300A11

Fork wrench SW 12 for 1300A11* 1300A13

Adapter M14 x 1,25 – M10x1 6582A1

Adapter BSP R 1/2”- M10x1 1/2 6582A2

Adapter for M20x1,5; for BSF 3/4”; for 6 1/2” 7523B01/B02/B03

Connecting cable 4-pin, one free cable end, 1700A71

length = 10 m, 1, 2, 5, 8

Connecting cable 3-pin, one free cable end, 1700A69

length = 10 m, 1, 5, 8

Connecting cable 3-pin, one free cable end, 1700A69A1

length = 20 m, 1, 5, 8

Tubular socket wrench 1300A6

* refer to data sheet about Special Tools and Sensor Dummies (000-068)

Viton® is a registered Trademark of DuPont Performance Elastomers

Cylinder Pressure Transmitter Type 6613CA

Page 16 6613C_002-026e-02.16

8. Declaration of Conformity

/