Page is loading ...

/

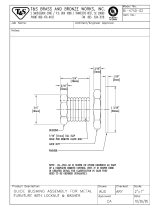

T & S Brass & Bronze Works BL-4740-02 Datasheet

T & S Brass & Bronze Works BL-4740-02 Datasheet

Kende MEWE4300 User manual

Kende MEWE4300 User manual

Toolex 597077 User manual

Toolex 597077 User manual

METAL MAN 200iDV ACDC Specification

METAL MAN 200iDV ACDC Specification

Lotos TIG200DC User manual

Lotos TIG200DC User manual

MiTEC super200P User manual

MiTEC super200P User manual