Page is loading ...

Instruction Manual

combiSENSOR 64x0

MICRO-EPSILON

MESSTECHNIK

GmbH & Co. KG

Königbacher Straße 15

94496 Ortenburg / Germany

Tel. +49 (0) 8542 / 168-0

Fax +49 (0) 8542 / 168-90

e-mail [email protected]

www.micro-epsilon.com

combiSENSOR 64x0

Contents

1. Safety ........................................................................................................................................ 7

1.1 Symbols Used ................................................................................................................................................. 7

1.2 Warnings .......................................................................................................................................................... 7

1.3 Notes on CE Marking ...................................................................................................................................... 8

1.4 Intended Use ................................................................................................................................................... 8

1.5 Proper Environment ......................................................................................................................................... 9

2. Functional Principle, Technical Data ..................................................................................... 10

2.1 Measuring Principle ....................................................................................................................................... 10

2.1.1 Capacitive Principle ...................................................................................................................... 10

2.1.2 Eddy Current Principle ................................................................................................................. 11

2.1.3 Thickness Measurement .............................................................................................................. 11

2.2 Structure ........................................................................................................................................................ 13

2.2.1 Sensor .......................................................................................................................................... 13

2.2.2 Sensor Cable ................................................................................................................................ 14

2.2.3 KSS64x0 Controller ...................................................................................................................... 14

2.3 Technical Data ............................................................................................................................................... 15

3. Delivery ................................................................................................................................... 16

3.1 Unpacking, Included in Delivery.................................................................................................................... 16

3.2 Storage .......................................................................................................................................................... 16

4. Installation and Assembly ...................................................................................................... 17

4.1 Precautionary Measures ................................................................................................................................ 17

4.2 Sensor ............................................................................................................................................................ 17

4.3 Sensor Cable ................................................................................................................................................ 19

4.4 Controller ....................................................................................................................................................... 20

4.5 Ground Connection, Earthing ....................................................................................................................... 22

4.6 Electrical Connections ................................................................................................................................... 23

4.6.1 Connectivity Options ................................................................................................................... 23

4.6.2 Pin Assignment Supply, Trigger ................................................................................................... 24

4.6.3 Analog Output .............................................................................................................................. 24

5. Operation ................................................................................................................................ 26

5.1 Starting Up ..................................................................................................................................................... 26

5.2 LED’s on the Controller ................................................................................................................................. 27

combiSENSOR 64x0

5.3 Triggering ....................................................................................................................................................... 27

5.4 Measurement Averaging ............................................................................................................................... 29

5.4.1 Introduction .................................................................................................................................. 29

5.4.2 Moving Average ............................................................................................................................ 29

5.4.3 Arithmetic Average Value ............................................................................................................. 30

5.4.4 Median .......................................................................................................................................... 30

5.4.5 Dynamic Noise Rejection ............................................................................................................. 30

6. Ethernet Interface ................................................................................................................... 31

6.1 Hardware, Interface ....................................................................................................................................... 31

6.2 Data Format of Measuring Values ................................................................................................................. 34

6.3 Settings .......................................................................................................................................................... 36

6.4 Commands .................................................................................................................................................... 36

6.4.1 Data Rate (STI) ............................................................................................................................. 37

6.4.2 Trigger Mode (TRG) ...................................................................................................................... 38

6.4.3 Get Measured Data (GMD)........................................................................................................... 38

6.4.4 Filter, Averaging Type (AVT) ......................................................................................................... 39

6.4.5 Filter, Averaging Number (AVN) ................................................................................................... 39

6.4.6 Thickness Measurement (THM) ................................................................................................... 40

6.4.7 Thickness Zeroing (THZ) .............................................................................................................. 40

6.4.8 Channel Status (CHS) .................................................................................................................. 40

6.4.9 Status (STS).................................................................................................................................. 41

6.4.10 Version (VER) ............................................................................................................................... 41

6.4.11 Ethernet Settings (IPS) ................................................................................................................. 41

6.4.12 Change between Ethernet and EtherCAT (IFC = Interface) ....................................................... 42

6.4.13 Query Data Port (GDP) ................................................................................................................. 42

6.4.14 Set Data Port (SDP) ...................................................................................................................... 42

6.4.15 Access Channel Information (CHI)............................................................................................... 43

6.4.16 Access Controller Information (COI) ............................................................................................ 43

6.4.17 Login for Web Interface (LGI) ....................................................................................................... 44

6.4.18 Logout for Web Interface (LGO) ................................................................................................... 44

6.4.19 Change Password (PWD)............................................................................................................. 44

6.4.20 Change Language for the Web Interface (LNG) .......................................................................... 45

6.4.21 Default Messages ........................................................................................................................ 45

combiSENSOR 64x0

6.5 Operation Using Ethernet .............................................................................................................................. 45

6.5.1 Requirements ............................................................................................................................... 45

6.5.2 Access via Web Interface ............................................................................................................. 47

6.5.3 Thickness Measurement .............................................................................................................. 50

6.5.4 Trigger Mode ................................................................................................................................ 52

6.5.5 Data Rate ...................................................................................................................................... 52

6.5.6 Filter, Averaging ............................................................................................................................ 52

6.5.7 Digital Interfaces ........................................................................................................................... 53

6.6 Firmware Update ........................................................................................................................................... 53

7. EtherCAT Interface ................................................................................................................. 54

7.1 Introduction .................................................................................................................................................... 54

7.2 Change Interface ........................................................................................................................................... 54

8. Operation and Maintenance .................................................................................................. 55

9. Liability for Material Defects .................................................................................................. 56

10. Decommissioning, Disposal .................................................................................................. 56

Appendix

A 1 Accessories ............................................................................................................................ 57

A 2 EtherCAT Documentation ...................................................................................................... 58

A 2.1 Preamble ........................................................................................................................................................ 58

A 2.1.1 Structure of EtherCAT®-Frames .................................................................................................. 58

A 2.1.2 EtherCAT® Services ..................................................................................................................... 59

A 2.1.3 Addressing and FMMUs ............................................................................................................... 60

A 2.1.4 Sync Manager .............................................................................................................................. 60

A 2.1.5 EtherCAT State Machine .............................................................................................................. 61

A 2.1.6 CANopen over EtherCAT.............................................................................................................. 62

A 2.1.7 Process Data PDO Mapping ........................................................................................................ 62

A 2.1.8 Service Data SDO Service ............................................................................................................ 62

A 2.2 CoE – Object Directory .................................................................................................................................. 63

A 2.2.1 Communication Specific Standard Objects (CiA DS-301) .......................................................... 63

A 2.2.2 Manufacturer Specific Objects ..................................................................................................... 65

A 2.3 Measurement Data Format ............................................................................................................................ 68

A 2.4 EtherCAT Configuration with the Beckhoff TwinCAT©-Manager .................................................................. 69

combiSENSOR 64x0

Page 7

Safety

combiSENSOR 64x0

1. Safety

Knowledge of the operating instructions is a prerequisite for equipment operation.

1.1 Symbols Used

The following symbols are used in this instruction manual:

Indicates a hazardous situation which, if not avoided, may result in minor or mode-

rate injury.

Indicates a situation which, if not avoided, may lead to property damage.

Indicates a user action.

i

Indicates a user tip.

1.2 Warnings

Disconnect the power supply before touching the sensor surface.

> Danger of injury through static discharge

Connect the power supply and the display/output device in accordance with the safety regulations for electri-

cal equipment.

> Danger of injury

> Damage to or destruction of the sensor and/or controller

Avoid shock and vibration to the sensor and controller.

> Damage to or destruction of the sensor and/or controller

The power supply may not exceed the specified limits.

> Damage to or destruction of the sensor and/or controller

Protect the sensor cable against damage

> Destruction of the sensor

> Failure of the measuring device

Page 8

Safety

combiSENSOR 64x0

1.3 Notes on CE Marking

The following apply to the combiSENSOR 64x0:

- EU Directive 2014/30/EU

- EU Directive 2011/65/EU, “RoHS“ Category 9

Products which carry the CE mark satisfy the requirements of the quoted EU directives and the European

standards (EN) listed therein. The EU declaration of conformity is kept available according to EU directive,

article 10 by the authorities responsible at

MICRO-EPSILON Messtechnik GmbH & Co. KG

Königbacher Straße 15

94496 Ortenburg / Germany

The measuring system is designed for use in industrial environments and meets the requirements.

1.4 Intended Use

- The combiSENSOR 64x0 measuring system is designed for use in industrial and laboratory applications.

It is used for

measuring film thickness of plastics

measuring layer thickness of insulators

- The system must only be operated within the limits specified in the technical data.

- The system must be used in such a way that no persons are endangered or machines and other material

goods are damaged in the event of malfunction or total failure of the controller.

- Take additional precautions for safety and damage prevention in case of safety-related applications.

Page 9

Safety

combiSENSOR 64x0

1.5 Proper Environment

- Protection class: IP 40

- Operating temperature:

Sensor: -10 ... +85 °C (+14 to +185 °F)

Sensor cable: -10 ... +85 C (+14 to +185 °F) or 100 °C for maximum 10,000 hours

Controller: +10 ... +60 °C (+50 to +140 °F)

- Humidity: 5 - 95 % (non-condensing)

- Ambient pressure: Atmospheric pressure

- Storage temperature:

Sensor: -10 ... +100 °C (+14 to +212 °F)

Sensor cable: -10 ... +85 °C (+14 to +185 °F)

Controller: -10 ... +75 °C (+14 to +167 °F)

- The space between the sensor surface and the target must have an unvarying dielectric constant.

- The space between the sensor surface and the target may not be contaminated (for example water,

rubbed-off parts, dust, etc.)

Page 10

Functional Principle, Technical Data

combiSENSOR 64x0

2. Functional Principle, Technical Data

2.1 Measuring Principle

The construction of the measurement coil and measurement electrodes is concentric. Both therefore measure

against the same target (measuring object). The signal of the capacitive displacement sensor is a function of

the working distance, the thickness of the insulator and e

r

. At the same time the eddy current displacement

sensor measures the distance to the ground electrode (for example flat sheet or to a metal roller positioned

behind the film). The measurements are output as analog voltages of 0 to 10 VDC and digital signals through

Ethernet or EtherCAT at the following controller.

2.1.1 Capacitive Principle

The principle of capacitive distance measurement is based on the parallel plate capacitor.

If a constant AC current I

c

flows through the sensor capacitor, the amplitude of the AC voltage U

c

at the sen-

sor is proportional to the distance d between the capacitor electrodes.

Measuring object: electrical conductor

Ground

Screening electrode (guarding)

Measuring electrode

d

U

c

X

c

=

U

c

I

c

=

1

C

C =

r

A

d

U

c

= >> U

c

~ d

I

c

d

o

r

A

Fig. 1 Electric field of a capacitive sensor, no insulator material in the gap.

The measured AC voltage is demodulated, amplified and output as an analog voltage. The sensor design

with guard ring electrodes guarantees that the ideally necessary homogenous electrical field is realized for all

practical purposes.

i

A measurement object that is too small and curved (uneven) measurement surfaces also produce a

non-linear characteristic.

Page 11

Functional Principle, Technical Data

combiSENSOR 64x0

2.1.2 Eddy Current Principle

The eddy current principle is used for making measurements on targets made of either ferromagnetic or non-

ferromagnetic electrically conductive materials.

High-frequency alternating current flows through a coil in the sensor.

The electromagnetic coil field induces eddy currents in the conductive target thus changing the AC resis-

tance of the coil.

This change in impedance is interpreted by demodulation controllers which generate an electrical signal

proportional to the distance of the target from the sensor.

A compensation technique reduces temperature-dependent measuring errors to a minimum.

i

If the material of the counter electrode is changed, the measuring system must be rebalanced.

2.1.3 Thickness Measurement

The main field of application is the traversing thickness measurement of plastic film or of plastic coating on

metal plates. Arithmetical coupling of the two sensor signals provides compensation of mechanical changes,

for example thermal expansion, deflections, eccentricity in the measurement device. Through the redundancy

of this combined sensor principle, the measured thickness value remains unaffected by any changes in the

measurement setup. The target thickness T is calculated from both sensor signals.

Page 12

Functional Principle, Technical Data

combiSENSOR 64x0

T<A

Sensor

Working distance S (= eddy)

A

T

Working distance

Ground electrode

Target

Insulator (

r

)

Fig. 2 Sensor arrangement for thickness measurement

The thickness of the insulator is calculated from the following factors: max. working distance, capacitive dis-

placement signal A and the dielectric constant of the insulator:

T = S (eddy) - A (capa) *

r

r

1

* + Offset

WD

100 %

T Target thickness [µm]

S Signal eddy sensor [%]

A Signal capacitive sensor [%]

ε

r

Dielectric constant (insulator)

WD Working distance [µm]

Offset Constant [µm], standard value = 0

Page 13

Functional Principle, Technical Data

combiSENSOR 64x0

A constant dielectric constant of the target is required in order to obtain correct measuring results.

The thickness value can be calculated and output directly in the controller.

i

With measurement objects presenting a structured surface, a target thickness up to a maximum of 50

% of the working distance is recommended. If necessary, use a sensor with a larger target thickness

instead.

In contrast to the capacitive signal of the sensor, the output signal of the eddy current signal is not being

affected by the materials in the measuring gap and is therefore determined by the distance between the sen-

sor and the ground electrode.

2.2 Structure

The non-contact, single-channel measuring sys-

tem, see Fig. 3, installed in aluminium housings,

consists of:

- a KSH5 or a KSH10 sensor

with sensor cable,

- a KSS64x0 controller.

Fig. 3 Single-channel measuring system with sensor and

controller

2.2.1 Sensor

In its sensor housing the combiSENSOR combines an eddy current displacement sensor and a capacitive

displacement sensor. In order to obtain accurate measuring results, the surface of the sensor must be kept

clean and free from damage. The capacitive measuring process is area-related. The combiSENSOR requires

a minimum area of ø 45 mm (KSH5) or ø 65 mm (KSH10).

Page 14

Functional Principle, Technical Data

combiSENSOR 64x0

2.2.2 Sensor Cable

The sensor and controller are connected by a special, double screened, 1 m (3 ft) long sensor cable KC1.

Do not shorten or lengthen these special sensor cable. Do not crush the sensor cable. Do not modify

the sensor cable. This leads to a loss of functionality or of the specified technical data.

Install the sensor cable in a protected area.

A damaged cable can not be repaired. The sensor cable is not suitable for cable carriers. Minimum bending

radius: 20 mm (once), 80 mm (permanently).

i

Switch off the power supply of the controller, when plugging and removing connectors.

2.2.3 KSS64x0 Controller

The controller contains an oscillator and

a signal conditioning electronics for the

sensor. The capacitive and eddy current

part of the sensor are synchronized with

each other.

Power supply, Trigger In

Sensor

Ethernet / EtherCAT

Eddy and capa signal

differential and temperature signal

Fig. 4 Controller measuring system

Page 15

Functional Principle, Technical Data

combiSENSOR 64x0

2.3 Technical Data

Controller KSS6420 KSS6430 KSS6420(01) KSS6430(01)

Sensor KSH5(01) KSH10

Target thickness insulator 40 µm ... 3 mm 40 µm ... 6 mm

Resolution

1)

static, 104 Sa/s 0.0018 % 0.0004 % 0.0030 % 0.0006 %

dynamic, 3.9 kSa/s 0.0075 % 0.0015 % 0.0120 % 0.0025 %

Bandwidth analog: 1 kHz (3 dB)

2)

, digital: 2.6 … 3900 Sa/s (adjustable)

Linearity ± 0.05 %

Temperature stability

4)

Sensor ± 50 ppm (+10…+60 °C)

Temperature stability Controller ± 50 ppm ± 50 ppm ± 50 ppm ± 70 ppm

Temperature range controller: +10…+50 °C; sensor:+10…+50 °C; sensor cable: -10…+125 °C

Power supply 12…36 VDC (5.5 W)

Output

Analogue

capacitive, eddy current and differential signal: 0-10 V (short circuit proof);

internal sensor temperature signal (not scaled)

Ethernet capacitive, eddy current, differential and internal temperature signal: 24 Bit

EtherCAT capacitive, eddy current, differential and internal temperature signal: float

Trigger TTL, 5 V

Target geometry Straight surface or min. diameter 200 mm

3)

Working distance 2 ... 5 mm 4 ... 10 mm

Min. diameter measurement surface 45 mm 65 mm

Protection class sensor: IP 54, controller: IP 40

Weight sensor: 80 g ; controller: 750 g

Storage temperature sensor, cable: -10…+100 °C, controller: 0…75 °C

1)

Difference signal of the digital output, measured with working distance = 50 % FSO

2)

Only valid when sampling rate = 3900 Sa/s

3)

Reference material ground electrode: VA steel (1.4571) or aluminium.

Changes of the ground electrode (material or geometry) require a recalibration of sensor and controller by the manufacturer.

4)

Circumferential clamping starts 5 mm behind the sensor surface, see Fig. 7.

Page 16

Delivery

combiSENSOR 64x0

3. Delivery

3.1 Unpacking, Included in Delivery

- 1 Controller KSS64x0

- 1 Sensor (KSH5 or KSH10)

- 1 Sensor cable KC1

- 1 Instruction manual

- 1 Power supply and trigger cable PC6200-3/4, 3 m long

- 1 Network cable

- 1 CD with Runtime-version/MEDAQ-LIB (Ethernet)/ EtherCAT ESI File

- 1 Conversion kit (Springs for mounting on DIN-rail, mounting plates for wall fastening)

Carefully remove the components of the measuring system from the packaging and ensure that the

goods are forwarded in such a way that no damage can occur.

Check the delivery for completeness and shipping damage immediately after unpacking.

If there is damage or parts are missing, immediately contact the manufacturer or supplier.

3.2 Storage

- Storage temperature

Sensor, sensor cable -10 °C to +100 °C (+14 to +212 °F)

Controller 10 to +75 °C (+50 to +167 °F)

- Humidity 5 - 95 % (no condensation)

Page 17

Installation and Assembly

combiSENSOR 64x0

4. Installation and Assembly

4.1 Precautionary Measures

No sharp-edged or heavy objects may come into contact with the sensor cable sheath.

In pressurised rooms the cable must be protected against pressure loads.

The minimum bending radius is 20 mm (.79 inch). Kinks must be avoided at all cost.

The connections must be checked for tight fit.

i

A damaged cable cannot be repaired.

4.2 Sensor

When assembling, make sure that the polished sensor surface is not scratched.

i

The target must not touch the sensor surface. Comply with the working distance.

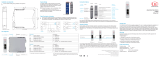

ø 30 (1.18)

KSH5

5

(.20)

26 (1.02)

37 (1.46)

5

(.20)

26 (1.02)

37 (1.46)

Mounting

area

KSH10

ø 45 (1.77)

5

5 (0.20)

Measuring

direction

Fig. 5 Sensor dimensions

Fig. 6 Free space with no metallic

conductive objects

Make sure when assembling the sensor that there are no metallic conductive objects within the gray

marked area, see Fig. 6. Else the linearity may be changed of the eddy current sensor by up to about 1

% of measuring range.

Legend

mm (inches)

Page 18

Installation and Assembly

combiSENSOR 64x0

Circumferential clamping

This sensor mounting option offers maximum reliability because the sensor is clamped around its cylindrical

housing.

It is absolutely necessary in difficult installation environments, for example on machines, production plants et

cetera.

Mounting with a

clamping ring

5

Fig. 7 Circumferential clamping

i

Pulling on the cable is inadmissible.

Page 19

Installation and Assembly

combiSENSOR 64x0

4.3 Sensor Cable

The sensor cable connects the sensor with the controller.

Connect the sensor to the controller by the sensor cable.

The connection is made by simple plugging. The connector locks automatically. The tight fit can be checked

by pulling the connector housing (cable bushing).

i

A damaged cable cannot be repaired.

appr. 38 (1.5)

14.5

(.57)

appr. 50 (2.0)

Ø 5.8

1000 (39.4) ±1 %

Fig. 8 Dimensions sensor cable

Legend

mm (inches)

Page 20

Installation and Assembly

combiSENSOR 64x0

4.4 Controller

125 (4.92)

90 (3.54)

75 (2.95)

KSS6430 DL6430

Fig. 9 Dimensional drawing controller with basic unit, demodulator module and housing cover

Dimensions in mm (inches), not to scale

Legend

mm (inches)

/