OPERATOR’S MANUAL

PE10X-XXX-XXX-XXXX

PE15X-XXX-XXX-XXXX

PE20X-XXX-XXX-XXXX

PE30X-XXX-XXX-XXXX

INCLUDING: OPERATION, INSTALLATION & MAINTENANCE

RELEASED: 3-26-13

(REV. B)

ELECTRONIC INTERFACE

for Diaphragm Pumps

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

INGERSOLL RAND COMPANY LTD

209 NORTH MAIN STREET – BRYAN, OHIO 43506

(800) 495-0276 FAX (800) 892-6276 © 2013 CCN 46750816

www.ingersollrandproducts.com

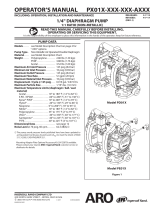

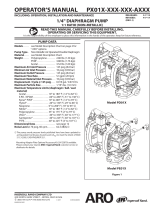

PUMP DATA

PE10X-XXX-XXX-XXXX is PE series 1” EXP Diaphragm Pumps with

electronic interface

PE15X-XXX-XXX-XXXX is PE series 1- 1/2” EXP Diaphragm Pumps

with electronic interface

PE20X-XXX-XXX-XXXX is PE series 2” EXP Diaphragm Pumps with

electronic interface

PE30X-XXX-XXX-XXXX is PE series 3” EXP Diaphragm Pumps with

electronic interface

GENERAL DESCRIPTION

This manual is supplemental information for the electronic

interface options on the PE series of pumps. For complete

pump installation, disassembly and reassembly, safety infor-

mation, and other general pump information, please refer to

the PD pump manual that was also included with the pump.

This electronic interface includes options for solenoid control,

end of stroke feedback, leak detection (diaphragm failure),

cycle counting on the major valve, and a ported motor with

no major valve for user-supplied control directly to the two

diaphragm air chambers.

Solenoid control allows the cycle rate of the pump to be con-

trolled electronically.

With Solenoid control, when the solenoid is energized, the

pump strokes and dispenses the uid in one chamber. When

the solenoid is de-energized, the pump strokes in the oppo-

site direction, dispensing the uid in the other chamber.

By providing continuous ON - OFF signals to the solenoid, the

uid transfer rate may be increased or decreased remotely.

End of stroke feedback can be used in conjunction with the

solenoid valve to cycle the pump based upon completion of

each stroke.

The leak detection option incorporates an optical uid sensor

in each air chamber to provide a signal when a diaphragm

has failed and uid is leaking through the pump.

The cycle counter option provides a closed contact output

each time the pump completes a cycle. This option is not

available combined with solenoid control.

The ported motor with no major valve is provided as an op-

tion for users who want to supply compressed air directly to

each diaphragm and control the operation of the pump with

their own external air controls

.

MODEL DESCRIPTION CHART

PEXX X

-XXX-XXX

-X

X

X

X

Pump Size

10 - 1” EXP Diaphragm Pumps

15 - 1- 1/2” EXP Diaphragm Pumps

20 - 2” EXP Diaphragm Pumps

30 - 3” EXP Diaphragm Pumps

Center Section

A - Aluminium

R - Polypropylene

S - Stainless Steel

Revision Level

Specialty Code 1 (Blank if no Speciality Code

)

B - Solenoid 12VDC

D - Solenoid 24VDC

A - Solenoid 120VAC

C - Solenoid 240VAC

G - Solenoid 12VDC ATEX

H -

Solenoid 24VDC ATEX

K - Solenoid 220VAC ATEX

N - Solenoid with no coil

P - Ported Motor (no major valve provided)

S - Cycle Sensing on Major Valve

0 -

Standard Valve Block ( No Solenoid)

Specialty Code 2 (Blank if no Speciality Code

)

F - End of stroke feedback

E - End of stroke feedback + Leak Detection

L - Leak Detection

Special Testing

Testing for special testing options, please contact your

nearest ARO Customer Service Representative or Distributor.

0 - No Option

Page 2 of 16 PEXXP-XXX-XXX-XXXX (en)

Item Description

Part no

Qty

111

Spool

(

PE10A-XXX-XXX-X0XX, PE15A-XXX-

XXX-X0XX)

95835 (1)

(

PE10A-XXX-XXX-XSXX, PE15A-XXX-

XXX-XSXX)

95835-1 (1)

All PE10A, PE15A with Solenoid

95835-2 (1)

(

PE20A-XXX-XXX-X0XX, PE30A-XXX-

XXX-X0XX)

95651 (1)

(

PE20A-XXX-XXX-XSXX, PE30A-XXX-

XXX-XSXX)

95651-1 (1)

All PE20A, PE30A with Solenoid

95651-2 (1)

121

Sleeve

(PEXXA-XXX-XXX-XPXX)

96323 (2)

134

Screw

(M6 x 1 - 6g x 20 mm)

(PEXXA-XXX-XXX-XPXX)

96340 (4)

135 Valve Block

(

PE10A-XXX-XXX-XSXX, PE10A-XXX-

XXX-X0XX)

95942-3 (1)

(

PE15A-XXX-XXX-XSXX, PE15A-XXX-

XXX-X0XX)

95942-1 (1)

All PE10A with Solenoid

95942-6 (1)

All PE15A with Solenoid

95942-5 (1)

(

PE20A-XXX-XXX-XSXX, PE20A-XXX-

XXX-X0XX, PE30A-XXX-XXX-XSXX,

PE30A-XXX-XXX-X0XX)

96334-1 (1)

All PE20A, PE30A with Solenoid

96334-3 (1)

403 Valve

(AII PEXXA with SoIenoid)

114102 (1)

407 Adapter

(PEXXA-XXX-XXX-XAXX, PEXXA-XXX-

XXX-XBXX, PEXXA-XXX-XXX-XCXX,

PEXXA-XXX-XXX-XDXX, PEXXA-XXX-

XXX-XGXX, PEXXA-XXX-XXX-XHXX,

PEXXA-XXX-XXX-XKXX, PEXXA-XXX-

XXX-XNXX)

96953 (1)

PARTS LIST / PEXXA-XXX-XXX-XXXX

Item Description

Part no

Qty

410

Sensor

(for Cycle Sensing)

(PEXXA-XXX-XXX-XSXX)

95276 (1)

411

Adapter

(for Cycle Sensing)

(PEXXA-XXX-XXX-XSXX)

96583 (1)

413

Adapter Plate

(AII PEXXA with SoIenoid)

119380 (1)

414

Coil ,120 VAC (

PXXXA-XXX-XXX-

XAXX

)

116218-33 (1)

Coil ,12 VDC

(

PXXXA-XXX-XXX-XBXX

)

116218-38 (1)

Coil ,240 VAC

(

PXXXA-XXX-XXX-XCXX

)

116218-35 (1)

Coil ,24 VDC

(

PXXXA-XXX-XXX-XDXX

)

116218-39 (1)

Coil, 12 VDC ATEX

(

PXXXA-XXX-XXX-XGXX

)

117345-38 (1)

Coil, 24 VDC ATEX

(

PXXXA-XXX-XXX-XHXX

)

117345-39 (1)

Coil, 220 VAC ATEX

(

PXXXA-XXX-XXX-XKXX

)

117345-35 (1)

415 O-Ring

(AII PEXXA with Solenoid)

114103 (1)

416 O-Ring

(AII PEXXA with Solenoid)

114104 (1)

417 Screw

(AII PEXXA with Solenoid)

96728647 (2)

418 Tube

(AII PEXXA with Solenoid)

15309974 (1)

419 Seal

(AII PEXXA with Solenoid)

96957 (1)

420 Snap Ring

(AII PEXXA with Solenoid)

Y147-43 (1)

421 Retainer

(AII PEXXA with Solenoid)

96954 (1)

425

Magnet

(for Cycle Sensing)

(PEXXX-XXX-XXX-XSXX)

95275 (1)

428 O-Ring

(AII PEXXA with Solenoid)

Y325-13 (1)

429

Solenoid Muer

(AII PEXXA with Solenoid)

116464 (1)

PEXXP-XXX-XXX-XXXX (en) Page 3 of 16

Item Description

Part no

Qty

111

Spool

(

PE10S-XXX-XXX-X0XX, PE15S-XXX-

XXX-X0XX)

95835 (1)

(

PE10S-XXX-XXX-XSXX, PE15S-XXX-

XXX-XSXX)

95835-1 (1)

All PE10S, PE15S with Solenoid

95835-2 (1)

(

PE20S-XXX-XXX-X0XX, PE30S-XXX-

XXX-X0XX)

95651 (1)

(

PE20S-XXX-XXX-XSXX, PE30S-XXX-

XXX-XSXX)

95651-1 (1)

All PE20S, PE30S with Solenoid

95651-2 (1)

121

Sleeve

(PEXXS-XXX-XXX-XPXX)

96323 (2)

134

Screw

(M6 x 1 - 6g x 20 mm)

(PEXXS-XXX-XXX-XPXX)

96340 (4)

135 Valve Block

(

PE10S-XXX-XXX-XSXX, PE10S-XXX-

XXX-X0XX)

95939-3 (1)

(

PE15S-XXX-XXX-XSXX, PE15S-XXX-

XXX-X0XX)

95939-1

(1)

All PE10S with Solenoid

95939-6 (1)

All PE15S with Solenoid

95939-5 (1)

(

PE20S-XXX-XXX-XSXX, PE20S-XXX-

XXX-X0XX, PE30S-XXX-XXX-X S XX,

PE30S-XXX-XXX-X0XX)

96337-1 (1)

All PE20S, PE30S with Solenoid

96337-3 (1)

403

Valve

(AII PEXXS with SoIenoid)

114102 (1)

407 Adapter

(PEXXS-XXX-XXX-XAXX, PEXXS-XXX-

XXX-XBXX, PEXXS-XXX-XXX-XCXX,

PEXXS-XXX-XXX-XDXX, PEXXS-XXX-

XXX-XGXX, PEXXS-XXX-XXX-XHXX,

PEXXS-XXX-XXX-XKXX, PEXXS-XXX-

XXX-XNXX)

96953 (1)

PARTS LIST / PEXXS-XXX-XXX-XXXX

Item Description

Part no

Qty

410

Sensor

(for Cycle Sensing)

(PEXXS-XXX-XXX-XSXX)

95276 (1)

411

Adapter

(for Cycle Sensing)

(PEXXS-XXX-XXX-XSXX)

96583 (1)

413

Adapter Plate

(AII PEXXS with SoIenoid)

119380 (1)

414

Coil ,120 VAC (

PXXXS-XXX-XXX-

XAXX

)

116218-33 (1)

Coil ,12 VDC

(

PXXXS-XXX-XXX-XBXX

)

116218-38 (1)

Coil ,240 VAC

(

PXXXS-XXX-XXX-XCXX

)

116218-35 (1)

Coil ,24 VDC

(

PXXXS-XXX-XXX-XDXX

)

116218-39

(1)

Coil, 12 VDC ATEX

(

PXXXS-XXX-XXX-XGXX

)

117345-38 (1)

Coil, 24 VDC ATEX

(

PXXXS-XXX-XXX-XHXX

)

117345-39 (1)

Coil, 220 VAC ATEX

(

PXXXS-XXX-XXX-XKXX

)

117345-35 (1)

415 O-Ring

(AII PEXXS with Solenoid)

114103 (1)

416

O-Ring

(AII PEXXS with Solenoid)

114104

(1)

417 Screw

(AII PEXXS with Solenoid)

96728647 (2)

418 Tube

(AII PEXXS with Solenoid)

15309974 (1)

419 Seal

(AII PEXXS with Solenoid)

96957 (1)

420 Snap Ring

(AII PEXXS with Solenoid)

Y147-43 (1)

421 Retainer

(AII PEXXS with Solenoid)

96954 (1)

425

Magnet

(for Cycle Sensing)

(PEXXX-XXX-XXX-XSXX)

95275 (1)

428 O-Ring

(AII PEXXS with Solenoid)

Y325-13 (1)

429

Solenoid Muer

(AII PEXXS with Solenoid)

116464 (1)

PEXXP-XXX-XXX-XXXX (en) Page 4 of 16

Item Description

Part no

Qty

111

Spool

(

PE10R-XXX-XXX-X0XX, PE15R-XXX-

XXX-X0XX)

96293 (1)

(

PE10R-XXX-XXX-XSXX, PE15R-XXX-

XXX-XSXX)

96293-1 (1)

All PE10R, PE15R with Solenoid

96293-2 (1)

(

PE20R-XXX-XXX-X0XX, PE30R-XXX-

XXX-X0XX)

95651 (1)

(

PE20R-XXX-XXX-XSXX, PE30R-XXX-

XXX-XSXX)

95651-1 (1)

All PE20R, PE30R with Solenoid

95651-2 (1)

121

Sleeve

(PEXXR-XXX-XXX-XPXX)

96323 (2)

134

Screw

(M6 x 1 - 6g x 20 mm)

(PEXXR-XXX-XXX-XPXX)

96340 (4)

135 Valve Block

(

PE10R-XXX-XXX-XSXX, PE10R-XXX-

XXX-X0XX)

96174-1 (1)

(

PE15R-XXX-XXX-XSXX, PE15R-XXX-

XXX-X0XX)

95834-1 (1)

All PE10R with Solenoid

96174-4 (1)

All PE15R with Solenoid

95834-4 (1)

(

PE20R-XXX-XXX-XSXX, PE20R-XXX-

XXX-X0XX, PE30 R -XXX-XXX-X S XX,

PE30R-XXX-XXX-X0XX)

95789-1 (1)

All PE20R, PE30R with Solenoid

95789-3 (1)

303

Plastic Plug

(

PEXXR-XXX-XXX-XPXX)

11481-7 (1)

403 Valve

(AII PEXXR with SoIenoid)

114102 (1)

407 Adapter

(PEXXR-XXX-XXX-XAXX, PEXXR-XXX-

XXX-X BXX, PEXXR-XXX-XXX-XCXX,

PEXXR-XXX-XXX-XDXX, PEXXR-XXX-

XXX-XGXX, PEXXR-XXX-XXX-XHXX,

PEXXR-XXX-XXX-XKXX, PEXXR-XXX-

XXX-XNXX)

96953 (1)

PARTS LIST / PEXXR-XXX-XXX-XXXX

Item Description

Part no

Qty

410

Sensor

(for Cycle Sensing)

(PEXXR-XXX-XXX-XSXX)

95276 (1)

411

Adapter

(for Cycle Sensing)

(PEXXR-XXX-XXX-XSXX)

96581 (1)

413

Coil Nut

(AII PEXXR with SoIenoid)

119380 (1)

414

Coil ,120 VAC (

PXXXR-XXX-XXX-

XAXX

)

116218-33 (1)

Coil ,12 VDC

(

PXXXR-XXX-XXX-XBXX

)

116218-38 (1)

Coil ,240 VAC

(

PXXXR-XXX-XXX-XCXX

)

116218-35 (1)

Coil ,24 VDC

(

PXXXR-XXX-XXX-XDXX

)

116218-39 (1)

Coil, 12 VDC ATEX

(

PXXXR-XXX-XXX-XGXX

)

117345-38 (1)

Coil, 24 VDC ATEX

(

PXXXR-XXX-XXX-XHXX

)

117345-39 (1)

Coil, 220 VAC ATEX

(

PXXXR-XXX-XXX-XKXX

)

117345-35 (1)

415 O-Ring

(AII PEXXR with Solenoid)

114103 (1)

416

O-Ring

(AII PEXXR with Solenoid)

114104

(1)

417 Screw

(AII PEXXR with Solenoid)

96728647 (2)

418 Tube

(AII PEXXR with Solenoid)

15309974 (1)

419 Seal

(AII PEXXR with Solenoid)

96957 (1)

420 Snap Ring

(AII PEXXR with Solenoid)

Y147-43 (1)

421 Retainer

(AII PEXXR with Solenoid)

96954 (1)

425

Magnet

(for Cycle Sensing)

(PEXXX-XXX-XXX-XSXX)

95275 (1)

428 O-Ring

(AII PEXXR with Solenoid)

Y325-13 (1)

429

Solenoid Muer

(AII PEXXR with Solenoid)

116464 (1)

Page 5 of 16 PEXXP-XXX-XXX-XXXX (en)

Item Description

Part no

Qty

74

Pipe Plug

(PEXXA-XXX-XXX-XXFX, PEXXA-XXX-

XXX-XX0X),(PEXXS -XXX-XXX-XXFX,

PEXXS-XXX-XXX-XX0X)

Y17-51-6 (2)

(PEXXR-XXX-XXX-XXFX, PEXXR-XXX-

XXX-XX0X)

93832-3 (2)

126

Plug

(PEXXA-XXX-XXX-XXLX, PEXXA-XXX-

XXX-XX0X),(PEXXS-XXX-XXX-XXLX,

PEXXS-XXX-XXX-XX0X)

59632-1 (1)

283 Diaphragm Failure Detector

(PEXXA-XXX-XXX-XXEX, PEXXA-XXX-

XXX-XXLX),(PEXXS-XXX-XXX-XXEX,

PEXXS-XXX-XXX-XXLX)

96270-1 (2)

404 Tubing

(0.417 ft)

(PEXXA-XXX-XXX-XXEX, PEXXA-XXX-

XXX-XXFX),(PEXXS-XXX-XXX-XXEX,

PEXXS-XXX-XXX-XXFX)

94981-XXX-X -

(PEXXR-XXX-XXX-XXFX, PEXXR-XXX-

XXX-XX0X)

405 Elbow

(PEXXA-XXX-XXX-XXEX, PEXXA-XXX-

XXX-XXFX),(PEXXS-XXX-XXX-XXEX,

PEXXS-XXX-XXX-XXFX)

59756-103 (1)

(PEXXR-XXX-XXX-XXFX, PEXXR-XXX-

XXX-XX0X)

408 Male Connector Fitting

(PEXXA-XXX-XXX-XXEX, PEXXA-XXX-

XXX-XXFX),(PEXXS-XXX-XXX-XXEX,

PEXXS-XXX-XXX-XXFX)

59764-4 (1)

(PEXXR-XXX-XXX-XXFX, PEXXR-XXX-

XXX-XX0X)

412 Wiring

(PEXXA-XXX-XXX-XXEX, PEXXA-XXX-

XXX-XXFX),(PEXXS-XXX-XXX-XXEX,

PEXXS-XXX-XXX-XXFX)

96965 (1)

(PEXXR-XXX-XXX-XXFX, PEXXR-XXX-

XXX-XX0X)

PARTS LIST / PEXXX-XXX-XXX-XXXX

Item Description

Part no

Qty

422 Manifold

(PEXXA-XXX-XXX-XXEX, PEXXA-XXX-

XXX-XXFX),(PEXXS-XXX-XXX-XXEX,

PEXXS-XXX-XXX-XXFX)

96969 (1)

(PEXXR-XXX-XXX-XXFX, PEXXR-XXX-

XXX-XX0X)

423 Nut

(PEXXA-XXX-XXX-XXEX, PEXXA-XXX-

XXX-XXFX),(PEXXS-XXX-XXX-XXEX,

PEXXS-XXX-XXX-XXFX)

96724182

(1)

(PEXXR-XXX-XXX-XXFX, PEXXR-XXX-

XXX-XX0X)

424 Lock Washer

(PEXXA-XXX-XXX-XXEX, PEXXA-XXX-

XXX-XXFX),(PEXXS-XXX-XXX-XXEX,

PEXXS-XXX-XXX-XXFX)

96712666 (1)

(PEXXR-XXX-XXX-XXFX, PEXXR-XXX-

XXX-XX0X)

426 Mounting Strap

(PEXXA-XXX-XXX-XXEX, PEXXA-XXX-

XXX-XXFX),(PEXXS-XXX-XXX-XXEX,

PEXXS-XXX-XXX-XXFX)

96964

(1)

(PEXXR-XXX-XXX-XXFX, PEXXR-XXX-

XXX-XX0X)

427 Pressure Sensor

(PEXXA-XXX-XXX-XXEX, PEXXA-XXX-

XXX-XXFX),(PEXXS-XXX-XXX-XXEX,

PEXXS-XXX-XXX-XXFX)

96961

(1)

(PEXXR-XXX-XXX-XXFX, PEXXR-XXX-

XXX-XX0X)

PEXXP-XXX-XXX-XXXX (en) Page 6 of 16

SOLENOID

GENERAL DESCRIPTION

Without end of stroke feedback, solenoid control can only

be used to cycle the pump based on timing. The following

curves represent the ow rates of a pump based on timed

operation of the solenoid at a common operating point of 70

psi air pressure and 30 psi of back pressure.

80

100

120

140

Flow Rate PE10

X

0

20

40

60

80

100

120

140

0 5 10 15 20 25

Fluid Flow in U.S. Gallons Per Minute

Flow Rate

Flow Rate

140

e

Flow Rate PE10X

0

20

40

60

80

100

120

140

0 5 10 15 20 25

Fluid Flow in U.S. Gallons Per Minute

Flow Rate

Flow Rate

Flow

RateFlow

Rate

0

20

40

60

80

100

120

140

0 20 40 60 80 100

Cycle Rate in Cycles Per Minute

eCycle Rate in Cycles Per Minute

Fluid

Flow

in Liters Per Minute

Flow Rate

60

80

100

120

Cycles Per Minute

Flow

Rate PE20P

120

ute

Flow Rate PE20P

0

20

40

60

80

100

120

0 10 20 30 40 50 60

Cycle Rate in Cycles Per Minute

Fluid

Flow

in U.S. Gallons Per Minute

Flow

Rate PE20

X

Flow

Rate

0

20

40

60

80

100

120

0 50 100 150 200

Cycle Rate in Cycles Per Minute

Fluid Flow in

Liters

Per Minute

Flow Rate PE20X

Flow Rate

40

60

80

100

120

n Cycles Per Minute

Flow Rate PE30S

Flow Rate

0

20

40

60

80

100

120

0 20 40 60 80 100

Cycle Rate in Cycles Per Minute

Fluid Flow in U.S. Gallons Per Minute

Flow Rate PE30S

Flow Rate

80

100

120

Minute

Flow Rate PE30

S

0

20

40

60

80

100

120

0 20 40 60 80 100

Cycle Rate in Cycles Per Minute

Fluid Flow in U.S. Gallons Per Minute

Flow Rate PE30X

Flow Rate

0

20

40

60

80

100

120

0 50 100 150 200 250 300 350

Cycle Rate in Cycles Per Minute

Fluid Flow in Liters Per Minute

Flow Rate PE30

X

Flow

Rate

Figure 1

Figure 3

Figure 2

Page 7 of 16 PEXXP-XXX-XXX-XXXX (en)

140

141

200

233

105

107

107

236

135

�139

138�

137�

136

111

419�

421

420

134

133

429

417

403

415

418

416

407

428

414

413

Figure 4

LUBRICATION / SEALANTS

Apply Lubriplate FML-2 grease (94276) to all “O” rings,

“U” cups and mating parts.

SOLENOID PART LIST / PEXXXXXXXXXXXXX

PEXXP-XXX-XXX-XXXX (en) Page 8 of 16

END OF STROKE

GENERAL DESCRIPTION

With end of stroke feedback from a pressure switch, the

solenoid can be used to cycle the pump based on known feed-

back that the pump has fully completed each stroke.

PRESSURE SWITCH OPERATION

A calibration procedure is necessary for proper operation of

the pressure switch and accurate end of stroke feedback from

the pump. The Reset ring will always have a lower pressure

value than the Set ring.

Determine the operating air pressure of the pump.

The Reset ring should be set to approximately 25% of the

operating pressure of the pump with a minimum of 10 PSI.

The Set ring should be set to approximately 50% of the

operating pressure of the pump. This value is more vari-

able depending on the specic operating conditions. The

switch may function properly at much lower values for

the Set ring if the pump is running slowly, or at lower op-

erating pressures. In general, high operating speeds and

pressures require a higher setting value of the Set ring.

Operate the pump slowly to ensure proper operation of

the pressure switch. When the pump has shifted to one

side, the yellow LED will illuminate and remain on until

the pump shifts back to the opposite side.

If the operating pressure of the pump changes, the

Set ring may need to be adjusted accordingly.

1.

2.

3.

4.

5.

SETTING / OPERATION

9.6 to

32 V

DC

1

2

Set

Reset

3

4

7

6

5

pnp

pnp

500mA

500mA

2

1

3

4

-

+

Locking Ring

Setting Rings (manually adjustable after unlocking)

LED green: supply voltage O.K.

Process connection ¼” NPT; tightening torque 25 Nm

Setting Marks

LED yellow: Set values reached, OUT1 = ON / OUT2 = OFF

Internal Thread M5

Minimum distance between Set and Reset = 2% of the

nal value of the measuring range.

To obtain the setting accuracy: Set both rings to the mini-

mum value, then set the requested value.

1.

2.

3.

4.

5.

6.

7.

PART LIST / PEXXXXXXXXXXXEX, PEXXXXXXXXXXXFX

Figure 5

Figure 6

423

424

426

422

427

412

408

405

404

Page 9 of 16 PEXXP-XXX-XXX-XXXX (en)

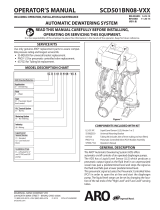

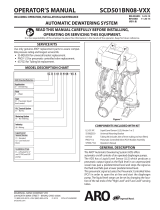

GENERAL DESCRIPTION

An AR O ® di a phragm pump equipp e d wi th the AR O

Diaphragm Failure Detector warns of a diaphragm failure by

sensing the presence of liquid in the air chamber of the pump.

This system uses a liquid sensor in each of the two air cham-

bers which will send an output signal when uid is detected.

INSTALLATION AND WARNINGS

NOTE:

ALL WIRING MUST COMPLYWITH ALL LOCAL

AND / OR NATIONAL ELECTRICAL CODES.

Electrical codes that apply must be strictly adhered to;

failure to do so may lead to shock hazard or serious injury.

Some local electrical codes may require the installation of

rigid conduit.

The diaphragm failure detector components must be

installed by a qualied electrician in compliance with all

national, state and local codes and regulations to reduce

the risk of electrical shock or other serious injury during

installation and operation.

ARO is not responsible for accidents resulting from im-

proper installation of components or hardware.

HAZARDOUS VOLTAGE. Do not attempt any service

without disconnecting all electrical supply sources.

LEAK DETECTION (DIAPHRAGM FAILURE DETECTOR)

PART LIST / PEXXX-XXX-XXX-XXEX, PEXXX-XXX-XXX-XXLX

Figure 8

LEAK DETECTION (DIAPHRAGM FAILURE DETECTOR) - PINOUT DESCRIPTIONS

96270-1 SENSOR PINOUTS

A

Pinout

Function

A +24 VDC

B Ground

C Signal

B

C

TURCK (PICOFAST) Connector PSW 3M -*/S90

Figure 7

283

PEXXP-XXX-XXX-XXXX (en) Page 10 of 16

GENERAL DESCRIPTION

The ARO diaphragm pump cycle counter provides a closed

contact output each time the pump completes a cycle.

This signal may be used to record cycles for maintenance pur-

poses or batching if the discharge volume of each complete

cycle is known.

CYCLE COUNTER

PART LIST PEXXAXXXXXXXSXX / PEXXSXXXXXXXSXX

Figure 9

134

135

133

126

166k

132k

141k

140

200k

233

176k 101 181 103

k 139

111

k 138

136

128

105

k 137

411

410

LUBRICATION / SEALANTS

Apply Lubriplate FML-2 grease (94276) to all “O” rings,

“U” cups and mating parts.

Page 11 of 16 PEXXP-XXX-XXX-XXXX (en)

PART LIST PEXXRXXXXXXXSXX

166k

132k

141k

140

200k

233

176k 101 181 103

134

135

133

136

107

105

107

236

k 137

k 139

k 138

111

411

410

126

Figure 10

LUBRICATION / SEALANTS

Apply Lubriplate FML-2 grease (94276) to all “O” rings,

“U” cups and mating parts.

Page 12 of 16 PEXXP-XXX-XXX-XXXX (en)

OPERATION

Maximum Operating Voltage . . . . . . . . . 200 V DC

Switching Current . . . . . . . . . . . . . . . . . . . . 0.5 Amps

The pump may be interfaced with a control device in the

following ways:

As a SOURCING switch (see gure 1) for use with PLC’s.

As a SINKING switch (see gure 2) for use with PLC’s.

As a closed contact switch (see gure 3) for use with meters.

Sourcing Switch

Sinking Switch

Closed Contact Switch

INPUT

INPUTS

INPUT

+V

Figure 1

Figure 2

Figure 3

Figure 11

PEXXP-XXX-XXX-XXXX (en) Page 13 of 16

PORTED NO MOTOR OPTIONS

134

160

133

121

173 k

132 k 176 k

101

181 103

173 k121166 k

43

Figure 12

PART LIST PEXXAXXXXXXXPXX / PEXXSXXXXXXXPXX

PART LIST PEXXRXXXXXXXPXX

132 k 176 k 101 181 103

121

173 k

173 k121166 k

134

160

133

LUBRICATION / SEALANTS

Apply Lubriplate FML-2 grease (94276) to all “O” rings,

“U” cups and mating parts.

Figure 13

Page 14 of 16 PEXXP-XXX-XXX-XXXX (en)

PEXXP-XXX-XXX-XXXX (en) Page 15 of 16

Page 16 of 16 PEXXP-XXX-XXX-XXXX (en)

PN 97999-1652

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

Ingersoll-Rand PE20X-XXX-XXX-XXXX User manual

- Type

- User manual

- This manual is also suitable for

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Ingersoll-Rand 637412 User manual

-

Ingersoll-Rand 95087 User manual

-

Ingersoll-Rand 67072 User manual

-

Ingersoll-Rand ARO 651763-AP-1 User manual

-

Ingersoll-Rand Marine Radio H2XXXX-XXX-X User manual

-

Ingersoll-Rand PD15X-XXX-XXX User manual

-

Ingersoll-Rand 6744X User manual

-

Ingersoll-Rand ARO PD05 Series User manual

-

ARO PX10R-XAX series User manual

ARO PX10R-XAX series User manual

-

Ingersoll-Rand PM10X-X-X-A02 User manual

Other documents

-

ARO Ingersoll Rand PD07P-APS-PAA Owner's manual

ARO Ingersoll Rand PD07P-APS-PAA Owner's manual

-

Panasonic 6276 User manual

-

HP G6E88AA Datasheet

-

ARO SCD501BN08-V Series User manual

ARO SCD501BN08-V Series User manual

-

Rockwell Automation Allen-Bradley Kinetix 2090-CTPW-MEDF Installation Instructions Manual

Rockwell Automation Allen-Bradley Kinetix 2090-CTPW-MEDF Installation Instructions Manual

-

Murphy EMS447 Installation guide

-

Electro-Voice SE15 User manual

-

Magnetrol Thermatel TD1/TD2 Operating instructions

-

Audi A4 Avant 95-01 Service & Repair Manual

-

Gaggia DECO Tecnichal Service Manual