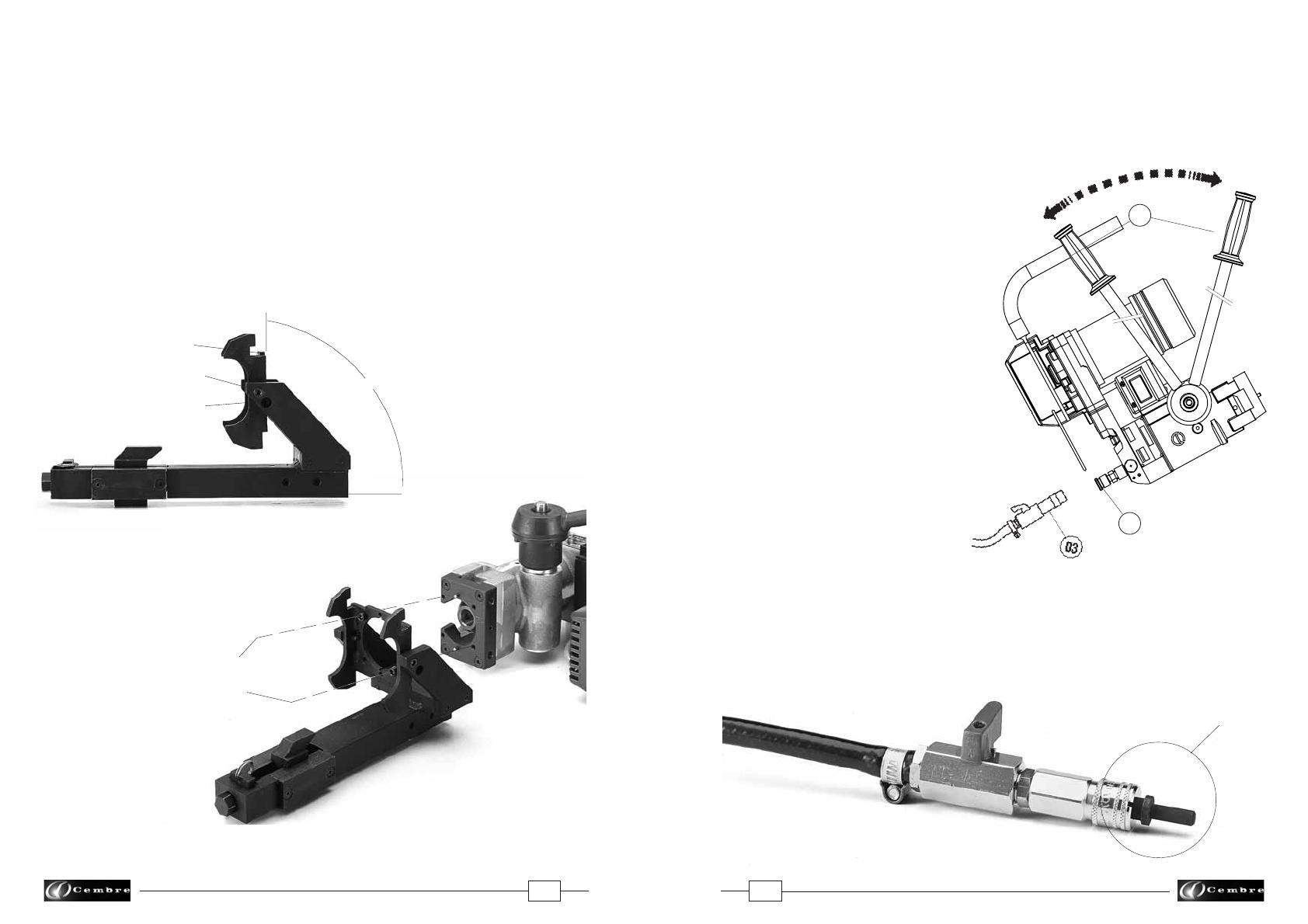

Cembre LD-2EY is a powerful electric shear designed for cutting copper and aluminum cables and conductors. It features a compact and lightweight design, making it easy to handle and transport. The LD-2EY has a cutting capacity of up to 70 mm² for copper cables and 50 mm² for aluminum cables, making it suitable for a wide range of applications.

Cembre LD-2EY is a powerful electric shear designed for cutting copper and aluminum cables and conductors. It features a compact and lightweight design, making it easy to handle and transport. The LD-2EY has a cutting capacity of up to 70 mm² for copper cables and 50 mm² for aluminum cables, making it suitable for a wide range of applications.

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

Cembre LD-2EY is a powerful electric shear designed for cutting copper and aluminum cables and conductors. It features a compact and lightweight design, making it easy to handle and transport. The LD-2EY has a cutting capacity of up to 70 mm² for copper cables and 50 mm² for aluminum cables, making it suitable for a wide range of applications.

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Cembre LD-1P-ECO User manual

-

Cembre LD-41P User manual

-

Cembre LD-41P User manual

-

Cembre LD-2E User manual

-

Cembre LD-16B User manual

-

Cembre BTEPE2.DET10 User manual

-

Cembre ANE-U User manual

-

Cembre CP1120-W-1000-KV User manual

-

Cembre BTEPE2.DET12 User manual

-

Cembre A-M Fine stranded Operating instructions

Other documents

-

AUKEY 2021 Upgraded AUKEY Phone Car Holder User guide

-

Erbauer EBC18-Li Original Instructions Manual

Erbauer EBC18-Li Original Instructions Manual

-

Full Boar FBMD-1242 User manual

-

Santec 3429AT91-TM User manual

Santec 3429AT91-TM User manual

-

Euroboor RAIL.40S User manual

-

Atdec AW-FB Installation guide

-

Croydex AD116541YW Installation guide

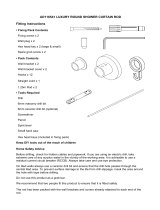

Croydex AD116541YW Installation guide

-

Milltronics VM4325xp (8200 Control) Instruction Handbook

-

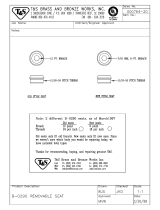

T & S Brass & Bronze Works 000764-20 Datasheet

T & S Brass & Bronze Works 000764-20 Datasheet

-

Croydex AD116441YW Installation guide

Croydex AD116441YW Installation guide