Page is loading ...

OPERATING INSTRUCTIONS

HISIC450

Overheight Detector

Title Page

Installation

Operation

Maintenance

2 HISIC450 · Operating Instructions · 8011735 V1.1 · © SICKAG

Document Information

Document ID

Title: Operating Instructions HISIC450

Part No.: 8011735

Version: 1.1

Release: 2013-04

Described Product

Product name: HISIC450

Manufacturer

SICK AG

Erwin-Sick-Str. 1 · 79183 Waldkirch · Germany

Phone: +49 7641 469-0

Fax: +49 7641 469-1149

E-mail: info.pa@sick.de

Trademarks

Product names used in this document may also be trademarks and

are only used for identification purposes.

Original Documents

The English edition 8011735 of this document is an original docu-

ment of SICK AG.

SICK AG assumes no liability for the correctness of an unauthor-

ized translation.

In case of doubt, contact SICK AG or your local representative.

Legal Information

Subject to change without notice.

© SICK AG. All rights reserved.

Glossary

Skilled persons: Persons who, based on their technical training

and knowledge as well as knowledge of the relevant regulations,

can assess the tasks given and recognize the dangers involved.

Competent persons: Persons who, based on their technical train-

ing on, and knowledge concerning the specific device, as well as

knowledge of the relevant regulations, can assess the tasks given

and recognize the dangers involved.

Instructed persons: Persons properly instructed on the tasks

assigned, possible risks and necessary protective measures.

HISIC450 · Operating Instructions · 8011735 V1.1 · © SICK AG 3

Warning Symbols

Signal words

DANGER

Immediate hazard which will result in severe personal injury or

death.

WARNING

Risk or hazardous situation which could result in severe personal

injury or death.

CAUTION

Hazard or unsafe practice which could result in less severe or

minor injuries and/or property damage.

Information Symbols

Hazard (general)

Hazard by voltage

Important technical information for this device

Important technical information on electrical or elec-

tronic functions

Supplementary information

Nice to know

Contents

4 HISIC450 · Operating Instructions · 8011735 V 1.1 · © SICK AG

1For your Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Basic safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Basic information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2.1 Detail level of these Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2.2 Scope of application and identification of device version . . . . . . . . . . . . . . . . . . . . . . 6

1.2.3 Designated users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2.4 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Functional principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Special features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Device variants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.5 Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Project planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1.1 Installation planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1.2 Object detection limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 Preparation of installation location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.4 Electrical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.5 Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.5.1 Manual alignment of transmitter and receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.5.2 Adjustment of light reception . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.5.3 Adjustment of delay time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.6 Completion of installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4Signal Evaluation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1 Simple AND circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.2 Direction-dependent evaluation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.3 Direction-dependent evaluation with error message . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.4 Signal level of outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.4.1 Detection of an object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.4.2 Functionality of alarm output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.1 Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.2 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.1 Maintenance work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.1 Clearing malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

8 Technical Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8.1 Operating data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8.2 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Contents

For your Safety

HISIC450 · Operating Instructions · 8011735 V1.1 · © SICK AG 5

Subject to change without notice

HISIC450

1 For your Safety

Safety information

Intended use

Responsibility of the operator

6 HISIC450 · Operating Instructions · 8011735 V 1.1 · © SICK AG

For your Safety

Subject to change without notice

1.1 Basic safety information

Read and always observe the safety and warning information in these Operating Instruc-

tions.

1.2 Basic information

1.2.1 Detail level of these Operating Instructions

These Operating Instructions contain a fundamental description of the HISIC450 over-

height detector and serve as guide for installation, operation and scheduled maintenance.

They also contain information on safe operation of the HISIC450.

Read and observe the corresponding Sections in these Operating Instructions.

1.2.2 Scope of application and identification of device version

These Operating Instructions are applicable for the HISIC450 as from date code 0807.

The date code of the HISIC450 is to be found on the type plate on the upper sides of the

transmitter and of the receiver.

1.2.3 Designated users

The HISIC450 may only be installed by skilled persons who, based on their technical

training and knowledge as well as knowledge of the relevant regulations, can assess the

tasks given and recognize the dangers involved.

Responsibility of user

● Only operate the HISIC450 according to the intended use (→ §1.2.4).

● Do not use the HISIC450 in potentially explosive atmosphere.

● Follow all specifications in these Operating Instructions and only operate the HISIC450

as described in these Operating Instructions.

● Keep these Operating Instructions for future use.

● Pass these Operating Instructions on to a new owner.

● Do not modify any components on and in the device.

● In addition to the Operating Instructions, follow local laws, regulations and operating

directives applicable at the respective installation location.

1.2.4 Intended use

The HISIC450 serves for the detection of vehicles which are too high at tunnel portals,

bridges, car parks or similar structures.

The device is not a safety component according to the EU Machinery Directive.

WARNING: Danger through defective device

The HISIC450 is likely to be unsafe when it:

● Shows visible damage on the outside.

● Has been penetrated by moisture.

● Has been stored or operated under irregular conditions.

In these cases:

▸

Put the HISIC450 out of operation, separate all connectors from the power

supply and secure against unauthorized start-up.

WARNING: Risks through electric voltages

▸

Do not interrupt protective conductor connections.

Product Description

HISIC450 · Operating Instructions · 8011735 V1.1 · © SICK AG 7

Subject to change without notice

HISIC450

2 Product Description

Functional principle

Device features

Layout

8 HISIC450 · Operating Instructions · 8011735 V 1.1 · © SICK AG

Product Description

Subject to change without notice

2.1 Functional principle

The HISIC450 overheight detector comprises two photoelectric switches that are installed

at the same height and whose beams run in opposite directions. Two photoelectric

switches are used to reduce false alarms caused by birds, leaves or other objects.

Reliability can be further increased when induction loops are used in addition to the photo-

electric switches.

Some options for the evaluation of the signals of the photoelectric switches are described

in → p. 17, §4.

2.2 Special features

● High light intensity for use in almost any weather condition.

● Resistant to snow, rain and dust.

● Aluminium housing with anticorrosive coating.

● Heated front screens against icing or condensed moisture.

● Largely insensitive to residual light.

● Integrated optical alignment aid.

● Nearly maintenance-free.

2.3 Device variants

● HISIC450-R250

– 24...240 V UC (+10% / –25%)

– Relay output, 10 ms reaction time

– Max. 10 switching operations per second

– t = approx. 0.5...12 s

● HISIC450-P250

– 10...60 V DC (limit values)

–PNP output, 500μs reaction time

– Max. 1000 switching operations per second

– Additional test input and soiling message

– t = approx. 0.015...0.3 s or approx. 0.5...12 s

● HISIC450-N250

– 10...60 V DC (limit values)

– NPN output, 500 μs reaction time

– Max. 1000 switching operations per second

– Additional test input and soiling message

– t = approx. 0.015...0.3 s or approx. 0.5...12 s

Assignment of transmitter/receiver types to the device variants

Device variant Transmitter Receiver

HISIC450-R WS45-U250 WE45-R250

HISIC450-N WS45-D250 WE45-N250

HISIC450-P WS45-D250 WE45-P250

Product Description

HISIC450 · Operating Instructions · 8011735 V1.1 · © SICK AG 9

Subject to change without notice

2.4 Scope of delivery

The scope of delivery of the HISIC450 includes:

● 2 transmitters (WS45) including fastening screws

● 2 receivers (WE45) including fastening screws

● 4 ball joint brackets made of stainless steel

● 4 hoods for weather protection made of stainless steel including fastening screws

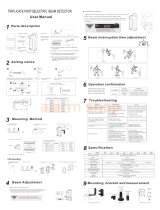

2.5 Layout

Fig. 1 Layout

1Sight slot

2 Reception indicator

3 Ocular for alignment aid (receiver only)

4Operation indicator

5 View-finder lens for alignment aid

6 Reception aperture for infrared beam

7 Attachment thread M6 - 8 mm deep

8 Connection with cable gland

1

5

6

432

87

10 HISIC450 · Operating Instructions · 8011735 V1.1 · © SICK AG

Product Description

Subject to change without notice

Installation

HISIC450 · Operating Instructions · 8011735 V1.1 · © SICK AG 11

Subject to change without notice

HISIC450

3 Installation

Project planning

Installation

Electrical installation

Adjustment

12 HISIC450 · Operating Instructions · 8011735 V1.1 · © SICK AG

Installation

Subject to change without notice

3.1 Project planning

3.1.1 Installation planning

Observe the following when planning installation:

● The distance between the two photoelectric switches (d

1

in → Fig. 2) is normally 1 m.

● Maximum measuring distance (d

2

in → Fig. 2) see → p. 30, §8.1.

Fig. 2 Distances and arrangement of photoelectric switches

● The installation height (upper edge of housing) is equivalent to the maximum vehicle

detection height.

● The two photoelectric switches have to be installed so that the direction of the light

beams is in the opposite direction to each other. This means that a transmitter and a

receiver must be installed on each side of the road (see → Fig. 2).

● Sunlight must not shine directly or via a reflection into the optics of the receiver.

● For photoelectric switches used outdoors, an overvoltage protector must be installed

because overvoltage caused by thunderstorms can not be discharged within the

devices.

● To increase reliability, it is recommended to use induction loops in addition to the photo-

electric switches.

1 Transmitter (WS45)

2 Receiver (WE45)

d

1

d

2

1

1

2

2

Installation

HISIC450 · Operating Instructions · 8011735 V1.1 · © SICK AG 13

Subject to change without notice

3.1.2 Object detection limits

Minimum object diameter

The prerequisite for the detection of objects is that they fully cover the receiver optical

system of the photoelectric switches for the duration of the reaction time. This implies that

moving objects must be larger the faster they move. The minimum size of an object thus

depends on the speed of the object, the reaction time of the photoelectric switches and the

size of the receiver optical system and results from the following formula:

Example:

– Width of receiver optical system: 35 mm

– Reaction time of photoelectric switch: 500 μs

– Maximum object speed: 100 km/h (

27.8 m/s)

This results in the following minimum object diameter:

If smaller objects are also to be recognized, the width of the receiver optical system can be

reduced to 20 mm by applying black paint (see → Fig. 3).

Fig. 3 Reduction of receiver optical system

Minimum object speed

To trigger an alarm, both photoelectric switches must detect the object within a predefined

time interval. This requires a certain minimum speed of the object below which no alarm is

triggered. This minimum speed depends on the distance between the two photoelectric

switches (d

1

in → Fig. 2) and the time interval.

Example:

– Minimum object speed: 5 km/h (

1.39 m/s)

– Distance between photoelectric switches: 1 m

– Time required for the distance between the two photoelectric switches:

1m/1.39m/s = 0.72 s

This means that the time interval used in signal evaluation has to be 0.72 s minimum.

D

min

= Minimum object diameter

W = Width of receiver optical system

t

R

=

Reaction time of photoelectric

switch

v = Speed of object

The application of black paint reduces the light intensity which could result in a

higher error rate when the weather conditions are bad.

D

min

Wt

R

v+=

D

min

35mm 500s27.8

m

s

------

+ 48.9mm==

35 20

14 HISIC450 · Operating Instructions · 8011735 V1.1 · © SICK AG

Installation

Subject to change without notice

3.2 Preparation of installation location

▸

Secure the place of work.

▸

Provide electricity for the tools.

▸

Provide jack lift or stable ladder.

3.3 Assembly

Installation work must be carried out only by experienced skilled personnel.

Prerequisite: Suitable masts or similar with the desired measuring height and in the

required distances (see → p. 12, Fig. 2) are available.

1 Install the four ball joint brackets at the desired measuring height.

2 Install transmitters and receivers on the ball joint brackets of the opposing masts and

perform a rough alignment. Ensure that one transmitter and receiver each are installed

on both sides of the road so that the light beams run in the opposite direction (see

→ p. 12, Fig. 2).

3.4 Electrical installation

Prerequisite: Supply line is disconnected from the mains and potential-free.

1 Open the covers of the transmitter and the receiver. Ensure that no dirt enters the

devices.

2 Loosen the cable gland and remove the sealing plug.

3 Route the supply line through the cable gland and connect it according to → Fig. 4.

Fig. 4 Connection diagram

WARNING: Danger through electrical voltage.

▸

Only allow an authorized electrician to work on the electric system.

▸

Observe the relevant safety regulations during all installation work.

▸

Take suitable protective measures against local risks and those arising

from the equipment.

HISIC450-N/-P HISIC450-R

WS45-D

(transmitter)

WE45-N/-P

(receiver)

WS45-U

(transmitter)

WE45-R

(receiver)

1

2

3

4

5

6

10...60 V DC

0 V

TE

1

2

3

4

5

6

10...60 V DC

0 V

Verschmutzung/

Soiling

Q

Q

1

2

3

4

5

PE

L1

N

1

2

3

4

5

PE

L1

N

Installation

HISIC450 · Operating Instructions · 8011735 V1.1 · © SICK AG 15

Subject to change without notice

The WE45-N/-P receivers have antivalent switching outputs (see also → p. 21, §4.4):

4 Apply mains voltage according to type plate.

Operation indicator on.

3.5 Adjustment

3.5.1 Manual alignment of transmitter and receiver

Alignment aids are integrated in the transmitter and the receiver. These consist of an

ocular with a crosshair through which the opposite device can be seen.

1 Look through the ocular of the transmitter and adjust it to the receiver by swiveling it

horizontally and vertically.

2 Look through the ocular of the receiver and adjust it to the transmitter by swiveling it

horizontally and vertically.

3.5.2 Adjustment of light reception

Fig. 5 Possible adjustments

1 Set the Sensitivity adjusting screw to Maximum.

The reception indicator at the receiver lights continuously.

2 If the reception indicator blinks or does not light, clean or readjust the transmitter and

the receiver.

3 Interrupt the beam path with an object.

The reception indicator must go out.

Connection WE45-N WE45-P

Q

Dark-On switched.

Output is LOW when light is inter-

rupted

Dark-On switched.

Output is HIGH when light is inter-

rupted

Q

Light-ON switched.

Output is HIGH when light is

received

Light-ON switched.

Output is LOW when light is

received

Soiling When receiving signal is too low: Output pulsating 5/s

TE Test input: Transmitter is switched off.

1 Delay mode adjusting screw

2 Sensitivity adjusting screw

3 Time fine adjustment adjusting screw

4Terminal strip

5Switch status indicator

Sensitivity

Rel. off

Rel. on

0,5 - 12s

t

0

t

0

t

1

t

1

t

2

t

2

Sensitivity

0,015 - 0,3s0,5 - 12s

HISIC450-N/-P HISIC450-R

4

3

1

3

5

2

4

1

3

5

2

4

16 HISIC450 · Operating Instructions · 8011735 V1.1 · © SICK AG

Installation

Subject to change without notice

4 If the reception indicator continues to light or blink, reduce sensitivity at the Sensitivity

adjusting screw until it goes out.

5 Remove the object from the beam path.

The reception indicator must light again.

6 If it does not light, reduce sensitivity until the switch threshold is correctly set.

3.5.3 Adjustment of delay time

Criteria for selection of the delay time → p. 17, §4.

1 Select the delay mode:

– HISIC450-R:

t

1

right: Dark-ON with switch-on delay of 0.512 s

t

2

right: Dark-ON with switch-off delay of 0.512 s

t

1

left: Light-ON with switch-on delay of 0.512 s

t

2

left: Light-ON with switch-off delay of 0.512 s

t

0

: Off

– HISIC450-N/-P:

t

1

: Switch-on delay of 0.0150.3 s

t

2

: Switch-off delay of 0.0150.3 s

t

3

: Switch-on delay of 0.312 s

t

4

: Switch-off delay of 0.312 s

t

0

: Off

2 Turn the Time fine adjustment adjusting screw clockwise/counterclockwise to

increase/reduce the delay time.

3.6 Completion of installation

1 Check the sealing surfaces, seals and threaded attachment of the cover.

2 Position and screw on the cover.

3 Install a hood for weather protection on each transmitter and receiver.

Signal Evaluation

HISIC450 · Operating Instructions · 8011735 V1.1 · © SICK AG 17

Subject to change without notice

HISIC450

4 Signal Evaluation

18 HISIC450 · Operating Instructions · 8011735 V1.1 · © SICK AG

Signal Evaluation

Subject to change without notice

The photoelectric switch signals of the HISIC450 can be evaluated via an external PLC (not

included in scope of delivery of HISIC450). This can be performed in many ways. The

description of a simple hardware wiring in → §4.1 and → §4.2 and of two signal evaluation

options by means of PLC in → §4.3 serve as examples.

4.1 Simple AND circuit

This evaluation is advisable only for device variant HISIC450-R.

1 For the first photoelectric switch in driving direction, set a switch-off delay that matches

the minimum object speed (see → p. 13, §3.1.2; recommended are approx. 2 s) (see

→ p. 16, §3.5.3).

2 Set a switch-off delay of 0.5 s minimum for the second photoelectric switch.

3 Connect the outputs of both photoelectric switches in series on the hardware side.

With this evaluation, a reduction of false alarms by direction detection is not possible.

The wiring shown in → Fig. 6 for a light-ON photoelectric switch is a recommended solution

for wire break protection.

Fig. 6 Wiring of AND circuit

3

4

3

4

1. WE-R250

2. WE-R250

Signalspannung/

Signal voltage

Alarm

(=LOW)

Signal Evaluation

HISIC450 · Operating Instructions · 8011735 V1.1 · © SICK AG 19

Subject to change without notice

4.2 Direction-dependent evaluation

This evaluation can be performed with different PLC methods. As an example, a program is

described in the following which is similar to the contact plan of the “easy” control relay by

Moeller.

In this evaluation, the first signal has to come from the first photoelectric switch, the

second signal from the second photoelectric switch. If a signal from the second photoelec-

tric switch comes first, signals from the first photoelectric switch are suppressed until the

second photoelectric switch is uncovered again and the delay time T2 has expired.

Fig. 7 Direction-dependent evaluation

Row 1: T1 is activated when T2 is not active, i.e. when the first photoelectric switch was

first interrupted.

Row 2: T2 is activated when T1 is not active, i.e. when the second photoelectric switch was

first interrupted.

Row 3: Overheight alarm (Q1) is triggered when I2 is output while T1 is still active, i.e. when

the second photoelectric switch is interrupted before the delay time of the first photoelec-

tric switch has expired.

Rows 4a to 4c: The alarm is acknowledged when the light path of both photoelectric

switches is uncovered again.

The delay time of the photoelectric switches (see → p. 16, §3.5.3) should be set high enough

that the PLC can reliably read in the signals (depending on the PLC used and possibly its

cycle time).

I1 Signal from the first photoelectric switch in driving direction

[1]

[1]Recommendation for wire-break protection: Set the photoelectric switches to light-ON switching,

invert the inputs I1 or I2 of the PLC and connect each with Q

I2 Signal from the second photoelectric switch in driving direction

1

I3 Acknowledgment input

Q1 Alarm output

T1

Off-delay relay for the first photoelectric switch in driving direction;

minimum delay time according to → p. 13, §3.1.2

T2

Off-delay relay for the second photoelectric switch in driving direction;

delay time = some seconds

I1 T2 T1

I2 T1 T2

I2 T1 Q1

I3 Q1

T1

T2

4c

( R )

] [ ] / [ ( )

4b

( R )

] [ ] / [ ( )

] [ ( R )

1

2

3

4a

] [ ] [ ( S )

20 HISIC450 · Operating Instructions · 8011735 V1.1 · © SICK AG

Signal Evaluation

Subject to change without notice

4.3 Direction-dependent evaluation with error message

This evaluation is an extension of the program lines shown under → §4.2. It outputs an error

message when the light beam is permanently interrupted.

Fig. 8 Extension of direction-dependent evaluation

If one of the two photoelectric switches is interrupted for the duration of the reaction time

of T3/T4 without an overheight alarm, an error message is output at Q2 or Q3.

T3 On-delay relay for first photoelectric switch in driving direction

T4 On-delay relay for second photoelectric switch in driving direction

Q2 Error message for first photoelectric switch in driving direction

Q3 Error message for second photoelectric switch in driving direction

I1 Q1 T3

T3 Q2

I2 Q1 T4

T4 Q3

5

] [ ] / [ ( )

8

] [ ( )

6

] [ ( )

7

] [ ] / [ ( )

/