Page is loading ...

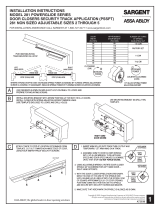

INSTALLATION INSTRUCTIONS FOR

8200 Lever with Freewheeling Escutcheon Trim FE

FOR ASSISTANCE, CALL SARGENT AT 1-800-727-5477 or www.sargentlock.com

Parts List Description

1. Inside Lever

2. Spring

3. Set screw

4. Through-bolt Screws (2)

(1/4" - 20 x 1-3/4)

5. Inside Escutcheon Plate

6. Screws & Lockwashers (2)

(#8-32 x 5/8")

7. Adapter & Plate Assy.

8. Lever spindle

9. Outside Escutcheon

Assembly

10. Cylinder

11. Screws (2) (#8-32 x 1/4")

12. Front Plate

13. Lockbody screws (2)

(#12 x 1-1/4")

14. Lockbody

25 Function Shown — For hole locations of other functions, see template page 4

Patent pending and/or patent

www.assaabloydss.com/patents

A7334G

1

Insert lockbody into mortise

cutout. Hold loosely in place

with (2) lockbody screws.

Do not tighten screws fully

at this time.

A. With outside lever

horizontal, carefully insert

the mounting posts through

the door and lockbody.

Make sure the spindle is

properly engaged in the

lock. Outside escutcheon

assembly should be flush

with door surface.

If cylinder is not included in

this function, proceed to step 3.

B. Screw cylinder into

lockbody until flush with

escutcheon face.

Install Lockbody

Outside Escutcheon Assembly

3

1

2

5

4

11

12

10

14

6

7

8

Inside

of

Door

Outside

of

Door

13

9

1

2

Copyright© 2005, 2008, 2010, 2016, Sargent Manufacturing Company, an ASSA ABLOY

Group company. All rights reserved. Reproduction in whole or in part without the

express written permission of Sargent Manufacturing Company is prohibited.

Lockbody

Screws

Inside Adapter & Plate Assembly

A7334G

2

3

A. Slide spindle (8) into lockbody hub

B. Slide adapter & plate assembly (7) over

spindle and secure with two #8-32 screws (6)

(do not tighten)

C. Tighten lockbody screws (13) on edge of

the door

D. Tighten both #8-32 (6) screws, securing

adapter & plate assembly

E. Position inside Escutcheon (5) and secure

with two 1/4-20 x 1-3/4" screws (4)

F. Place inside lever (1) horizontally onto lever

spindle (8). Hold lever firmly against the

escutcheon.

G. Use the 1/8" Allen wrench to tighten the set

screw (3) securely. Set screw should seat in

the groove of the inside adapter (7).

H. Pull on lever to verify set screw is seated

properly.

Copyright© 2005, 2008, 2010, 2016, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproduction in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.

INSIDE

INSIDE

OUTSIDE

OUTSIDE

LEFT HAND

LEFT HAND

REVERSE

BEVEL

RIGHT HAND

RIGHT HAND

REVERSE

BEVEL

DOOR HANDS DETERMINED FROM OUTSIDE

DOOR HANDING

Red color indicates locked

side of door

Locking piece

slot

Lock

front

Latch

Hub

Note: Red surface of locking piece must face secure side of door.

To rotate locking piece:

1.Position lockbody with red surface of locking piece visible

2. Insert blade type screwdriver into locking piece slot to rotate

locking piece

3. Push locking piece toward back of lock body and rotate 180°

until RED surface shows on opposite side

Note: Beveled surface of latch must face strike. The

deadlatch is self adjusting. To change hand of latch:

1. Insert screwdriver blade

into the spade shaped

slot

2. Rotate screwdriver 90º to push latchbolt out of the lock

case, until back of latchbolt clears lock front. Then

rotate latchbolt 180º allowing it re-enter the lockbody.

(Note: Latch can not be unscrewed)

How to Change Hand of Lock

Note: Functions 04, 06, 13, 17 and 31 require the following,

before the locking piece can be rotated:

(a) Remove the Green catch screw

(b) Rotate hub to make straight

(c) Rotate locking piece for required hand

(d) Red surface faces locked side of door

(e) Rotate hub to the original 45 degree position as shown

on lock case

(f) Reinstall the Green catch screw

7

4

6

13

4

5

Cylinder retainer

access hole

12

11

3

1

I. With the cylinder flush to the

escutcheon face, rotate cylinder

to make the keyway vertical. This

ensures that the cylinder retainer

fork will line up with the notch on

the side of the cylinder.

J. Secure the cylinder with a #2

Phillips screw driver, using the

cylinder retainer access hole.

K. Test key & cylinder to verify the

lock is functioning correctly.

L. Secure Outside Front (12)

with two #8-32 screws (11) to

the lockbody.

Changing Hand Of Trim

A7334G

3

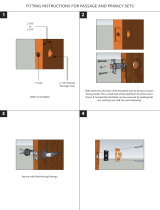

1. Loosen screw (1) and remove interlocking assembly (2).

See Figure A.

2. Unscrew the lower through-bolt stud (11) with a 3/8" wrench.

Remove mounting plate (6) and mounting posts. Switch

mounting posts (7) so they occupy the opposite positions on

the mounting plate (6)

3. Note the original position of the extension spring (16) and

lower plate (9) in the escutcheon (14). Unhook the extension

spring from pin (13).

4. Remove spring (16), lower plate (9) and locking hub (8)

assembly together.

5. Detach extension spring (16) from lower plate (9) and locking

hub assembly (8). Flip lower plate on locking hub assembly

spindle so that the spring hole is on the opposite side.

Reattach hook end of spring to lower plate.

6. Unscrew cap screw w/spacer (12) using 5/32" Allen wrench.

Move to opposite hole and tighten firmly.

7. Rotate lever to position shown in Figure E for desired hand.

8. Tighten retaining nut (10) firmly by hand and then back off one

notch until pattern shown in Figure C appears.

9. Attach bottom of spring (16) (closed loop) to pin (13). Hold

lever horizontal while inserting locking hub assembly (8) and

lower plate (9) into retaining nut (10).

10. Refer to Figure E: Position hub (4) for required function and

hand, checking that spindle (5) is vertical. Note position of

interlocking assembly Hook when positioning hub. Reposition

spindle as shown in Figure D if necessary.

11. Place the interlocking assembly (2) into the escutcheon and

attach the bottom hook to the locking hub (8) as shown in

Figure B. Secure in place with screw (1).

Caution: Check that locking hub (4) moves freely by

rotating the hub spindle (5). If not, check that bottom

hook is engaged in locking hub (8).

12. Insert and secure mounting plate and mounting posts to

escutcheon with lower through-bolt stud (11).

Figure D

Figure A

2 Interlocking

assembly

1

7

6

7

8

9

10

3

4

5

15

14

16

13

12

Bottom

hook

Figure B

Figure C

RIGHT

HAND

SHOWN

TOOLS REQUIRED

Phillips screw driver

Wrench 3/8"

Allen wrench 5/32"

Function

05, 16, 36, 37, 38, 65

Function

24, 25, 26, 35, 39, 40, 66

11

Figure E

Note: 04, 17 & 31

function locks, the

outside lever is always

freewheel and inactive,

the key is used to

retract the latchbolt

Rotate and

press in

Pull out

Interlocking

assembly hook

Spindle

Hub

ALWAYS WEAR EYE PROTECTION WHILE WORKING

Copyright© 2005, 2008, 2010, 2016, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproduction in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.

R.H. L.H.

R.H.R. L.H.R.

R.H. L.H.

R.H.R. L.H.R.

4

A7334G

Copyright

©

2005, 2008, 2010, 2016, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproduction in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.

4X

.422

27/64"

4X

.625

5/8"

2X

2.469

2-15/32"

2X

3.875

3-7/8"

2X

1.765

1-49/64"

2X

6.688

6-11/16"

INSIDE

OF DOOR

3

5

1

7

C

L

OF BEVEL

9

9

6.500

6-1/2"

8.031

8.000

8-1/32"

8"

7.250

7-1/4"

3.625

3-5/8"

4.000

4"

DIM "B"

AA

C

L

OF LEVER

OR KNOB

MOUNTING SCREWS

2X DRILL AND TAP FOR

#12-24 x .750 [3/4"] SCREW

C

L

OF DOOR

2X

2.750

BACKSET

2-3/4"

2X

1.797

1-51/64"

DIM "C"

.375

3/8"

OUTSIDE

OF DOOR

4

6

8

2

C

L

OF STRIKE

C

L

OF

LOCKBODY

C

L

OF BEVEL

5

9

9

.219

7/32"

DIM "A"

SECTION A-A

C

L

OF BEVEL

REQUIRED HOLES

FUNCTION

123456789

1.125

[1-1/8"]

DIA.

1.125

[1-1/8"]

DIA.

1.375

[1-3/8"]

DIA.

1.375

[1-3/8"]

DIA.

.750

[3/4"]

DIA.

.750

[3/4"]

DIA.

.250

[1/4"]

DIA.

.250

[1/4"]

DIA.

.562

[9/16"]

DIA.

04, 37

05, 24, 25

17, 26, 38, 39, 40

31, 35, 36

65, 66

RELEASE DATE

TEMPLATE

NO

.

100 Sargent Drive New Haven, CT 06511

Manufacturing Company

TEMPLATE: MORTISE LOCK

8200 SERIES: (FREE WHEELING)

METAL DOOR

4500

J

NOTES:

DENOTES HOLE REQUIRED FOR FUNCTION LISTED. (CHECK TABLE BEFORE CUTTING HOLE.)

1.

REFER TO TRIM TEMPLATE FOR ADDITIONAL HOLE REQUIREMENTS.

2.

SUITABLE REINFORCEMENTS REQUIRED FOR METAL DOORS.

3.

FOR DETAILS, SEE STRIKE TEMPLATE 7063.

4.

FOR WOOD DOORS SEE TEMPLATE A7323.

5.

DETAIL OF SUGGESTED DOOR-CUT

/