Danfoss ECL Comfort 310, P349 Operating instructions

- Category

- Thermostats

- Type

- Operating instructions

This manual is also suitable for

OperatingGuide

ECLComfort310,applicationP348

1.0TableofContents

1.0TableofContents...............................................1

1.1Importantsafetyandproductinformation.....................2

2.0Installation........................................................6

2.1Beforeyoustart.....................................................6

2.2Identifyingthesystemtype......................................12

2.3Mounting...........................................................13

2.4Placingthetemperaturesensors................................17

2.5Electricalconnections.............................................19

2.6InsertingtheECLApplicationKey..............................26

2.7Checklist............................................................32

2.8Navigation,ECLApplicationKeyP348.........................33

3.0Dailyuse.........................................................38

3.1Howtonavigate...................................................38

3.2Understandingthecontrollerdisplay..........................39

3.3Ageneraloverview:Whatdothesymbolsmean?...........42

3.4Monitoringtemperaturesandsystem

components........................................................43

3.5Influenceoverview................................................44

3.6Manualcontrol.....................................................45

3.7Schedule............................................................46

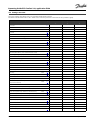

4.0Settingsoverview............................................47

5.0Settings...........................................................50

5.1IntroductiontoSettings..........................................50

5.2Flowtemperature..................................................51

5.3Roomlimit..........................................................54

5.4Returnlimit.........................................................57

5.5Flow/powerlimit.................................................63

5.6Optimization........................................................67

5.7Controlparameters................................................73

5.8Flowmeter..........................................................79

5.9Application.........................................................80

5.10Heatcut-out........................................................88

5.11Tanktemperature..................................................91

5.12Anti-bacteria........................................................94

5.13Alarm................................................................96

5.14Alarmoverview..................................................100

6.0Commoncontrollersettings............................101

6.1Introductionto‘Commoncontrollersettings’..............101

6.2Time&Date.......................................................102

6.3Inputoverview...................................................103

6.4Log.................................................................104

6.5Outputoverride..................................................105

6.6Keyfunctions.....................................................106

6.7System.............................................................108

7.0Miscellaneous................................................115

7.1ECA30/31setupprocedures.................................115

7.2Overridefunction................................................123

7.3Severalcontrollersinthesamesystem......................126

7.4Frequentlyaskedquestions....................................129

7.5Definitions........................................................131

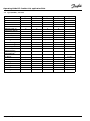

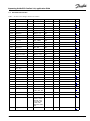

7.6Type(ID6001),overview.......................................134

7.7ParameterIDoverview..........................................135

©Danfoss|2017.04VI.LV.G2.02|1

1.1Importantsafetyandproductinformation

1.1.1Importantsafetyandproductinformation

ThisOperatingGuideisassociatedwiththeECLApplicationKey

P348(codeno.087H3843).

TheECLApplicationKeyP348containsonesubtype,P348.1,

whichisaheatingandanadvancedDomesticHotWater(DHW)

application.

SeetheInstallationGuideforelectricalconnections.

DescribedfunctionsarerealizedinECLComfort310whichalso

allowsM-bus,ModbusandEthernet(Internet)communication.

TheApplicationKeyP348complieswithECLComfort310

controllersasoffirmwareversion1.11.Thefirmware(controller

software)isvisibleatstart-upofthecontrollerandin'Common

controllersettings'in'System'.

UptotwoRemoteControlUnits,ECA30orECA31,canbe

connected.

TheapplicationP348workswithadditionalInternalI/Omodules:

•TheextensionmoduleECA32gives0-10Voltsignalforspeed

controlofDHWrelatedchargingandcirculationpump.

•TheextensionmoduleECA35gives0-10Voltsignalforspeed

controlofDHWrelatedchargingandcirculationpump.ECA35

canalsogivePWM*signalforspeedcontrolofthelistedpumps.

Acirculationpumpcanbeconsideredasacirculatortoo.

TheECLComfort310workswitheitheroneECA32oroneECA

35.TheInternalI/Omoduleinquestionisplacedinthebasepart

oftheECLComfort310.

*PWM=PulseWidthModulation

TogetherwiththeECLComfort310theadditionalInternalI/O

modulescanalsobeusedforextradatacommunicationtoSCADA:

•Temperature,Pt1000(default)

•0-10voltsignals

•Digitalinput

Theset-upofinputtypecanbedonebymeansoftheDanfoss

Software"ECLTool".

Navigation:Danfoss.com>Products&Solutions>Products>

DistrictHeatingandCooling>Documentation>Tools&Software

>ECLTool.

TheURLis:http://district-heating.danfoss.com/download/tools/

ECLComfort310isavailableas:

•ECLComfort310,230volta.c.(codeno.087H3040)

•ECLComfort310B,230volta.c.(codeno.087H3050)

•ECLComfort310,24volta.c.(codeno.087H3044)

TheB-typehasnodisplayanddial.

2|©Danfoss|2017.04

VI.LV.G2.02

OperatingGuideECLComfort310,applicationP348

TheB-typeisoperatedbymeansoftheremotecontrolunit

ECA30/31:

•ECA30(codeno.087H3200)

•ECA31(codeno.087H3201)

InternalI/Omodules:

•ECA32(codeno.087H3202)

•ECA35(codeno.087H3205)

BasepartforECLComfort310,230voltand24volt:Codeno.

087H3230.

AdditionaldocumentationforECLComfort210and310,modules

andaccessoriesisavailableonhttp://heating.danfoss.com/.

SafetyNote

Toavoidinjuryofpersonsanddamagestothedevice,itisabsolutely

necessarytoreadandobservetheseinstructionscarefully.

Necessaryassembly,start-up,andmaintenanceworkmustbe

performedbyqualifiedandauthorizedpersonnelonly.

Locallegislationsmustberespected.Thiscomprisesalsocable

dimensionsandtypeofisolation(doubleisolatedat230V).

AfusefortheECLComfortinstallationismax.10Atypically.

TheambienttemperaturerangesforECLComfortinoperationare:

ECLComfort210/310:0-55°C

ECLComfort296:0-45°C.

Exceedingthetemperaturerangecanresultinmalfunctions.

Installationmustbeavoidedifthereisariskforcondensation(dew).

Thewarningsignisusedtoemphasizespecialconditionsthatshould

betakenintoconsideration.

Thissymbolindicatesthatthisparticularpieceofinformationshould

bereadwithspecialattention.

Applicationkeysmightbereleasedbeforealldisplaytextsare

translated.InthiscasethetextisinEnglish.

VI.LV.G2.02

©Danfoss|2017.04|3

OperatingGuideECLComfort310,applicationP348

Automaticupdateofcontrollersoftware(firmware):

Thesoftwareofthecontrollerisupdatedautomaticallywhenthekey

isinserted(asofcontrollerversion1.11(ECL210/310)andversion

1.58(ECL296)).Thefollowinganimationwillbeshownwhenthe

softwareisbeingupdated:

Progressbar

Duringupdate:

•DonotremovetheKEY

Ifthekeyisremovedbeforethehour-glassisshown,youhave

tostartafresh.

•Donotdisconnectthepower

Ifthepowerisinterruptedwhenthehour-glassisshown,the

controllerwillnotwork.

AsthisOperatingGuidecoversseveralsystemtypes,specialsystem

settingswillbemarkedwithasystemtype.Allsystemtypesareshown

inthechapter:'Identifyingyoursystemtype'.

°C(degreesCelsius)isameasuredtemperaturevaluewhereasK

(Kelvin)oftenisusedfortemperaturedifferences.

TheIDno.isuniquefortheselectedparameter.

ExampleFirstdigitSeconddigitLastthreedigits

1117411174

-

Circuit1

Parameterno.

12174

1

2

174

-

Circuit2

Parameterno.

IfanIDdescriptionismentionedmorethanonce,itmeansthatthere

arespecialsettingsforoneormoresystemtypes.Itwillbemarked

withthesystemtypeinquestion(e.g.12174-A266.9).

ParametersindicatedwithanIDno.like"1x607"meanauniversal

parameter.

xstandsforcircuit/parametergroup.

4|©Danfoss|2017.04

VI.LV.G2.02

OperatingGuideECLComfort310,applicationP348

DisposalNote

Thisproductshouldbedismantledanditscomponents

sorted,ifpossible,invariousgroupsbeforerecycling

ordisposal.

Alwaysfollowthelocaldisposalregulations.

VI.LV.G2.02

©Danfoss|2017.04|5

OperatingGuideECLComfort310,applicationP348

2.0Installation

2.1Beforeyoustart

TheECLapplicationkeyP348containsonesubtype,P348.1.

Thisapplicationforheatingtemperaturecontrolandadvanced

DHWtemperaturecontrolisveryflexible.

Theheatingcircuit:

P348.1,ex.ashowstworadiatorcircuitsinparallel,eachcircuit

withitsownreturntemperaturesensorformonitoringpurpose.

P348.1,ex.bshowsoneradiatorcircuitwithitsownreturn

temperaturesensorformonitoringpurpose.

P348.1,ex.cshowstworadiatorcircuitsinparallel,eachcircuit

withitsownreturntemperaturesensorformonitoringpurpose.

P348.1,ex.dshowsoneradiatorcircuitwithitsownreturn

temperaturesensorformonitoringpurpose.

Temperaturecontrolofheatingcircuit:

Theflowtemperatureisadjustedaccordingtoyourrequirements.

TheflowtemperaturesensorS3isthemostimportantsensorand

mustbeconnected.DesiredflowtemperatureatS3iscalculated

intheECLcontroller,basedontheoutdoortemperatureS1and

thedesiredroomtemperature.

Ingeneral,thelowertheoutdoortemperature,thehigherthe

desiredflowtemperature.

Bymeansofaweekschedule,theheatingcircuitcanbein‘Comfort’

or‘Saving’mode(twovaluesforthedesiredroomtemperature).In

Savingmodetheheatingcanbereducedorswitchedofftotally.

ThemotorizedcontrolvalveM2isopenedgraduallywhenthe

flowtemperatureislowerthanthedesiredflowtemperatureand

viceversa.

ThereturntemperatureS5canbelimited,forexamplenottobe

toohigh.Ifso,thedesiredflowtemperatureatS3canbeadjusted

(typicallytoalowervalue),whichresultsinagradualclosingof

themotorizedcontrolvalve.Furthermore,thereturntemperature

limitationcanbedependentontheoutdoortemperature.

Typically,thelowertheoutdoortemperature,thehigherthe

acceptedreturntemperature.

Inboiler-basedheatingsupplythereturntemperatureshouldnot

betoolow(sameadjustmentprocedureasabove).

Ifthemeasuredroomtemperature(viaECA30/31)doesnotequal

thedesiredroomtemperature,thedesiredflowtemperaturecan

beadjusted.

Thecirculationpump,P2,isONatheatdemandoratfrost

protection.

TheheatingcanbeswitchedOFFwhentheoutdoortemperatureis

higherthanaselectablevalue.

ReturntemperaturesensorsS11andS12areusedformonitoring

purposeonly.

PressuresensorsS15andS16areusedformonitoringpurpose.

Furthermore,analarmcanbeactivatedifthepressuregetshigher

thanasetvalueorlowerthananothersetvalue.

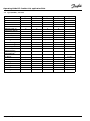

P348.1,ex.a,heating(circuitsAandB)andDHWtemperaturecontrol.

PumpsinDHWcircuitcanbe0–10Voltcontrolled.

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECLComfort310controller

ECA32

Built-inextensionmodule,0-10Voutputsfor

pumpspeedcontrol

S1

Outdoortemperaturesensor

S2

Supplytemperaturesensor

S3

(mandatory)Flowtemperaturesensor,circuit1

S4

(mandatory)DHWflowtemperaturesensor,

circuit2

S5

Returntemperaturesensor,circuit1

S6

(mandatory)Upperbuffertemperaturesensor

S7

Bufferflowtemperaturesensor

S8

Lowerbuffertemperaturesensor

S9

DHWcirculationreturntemperaturesensor

S10

Bufferreturntemperaturesensor

S11

Returntemperaturesensor,circuit1A

S12

Returntemperaturesensor,circuit1B

S15

Supplyreturnpressuresensor

S16

Supplyflowpressuresensor

F1

Flowmeter(signaltype:Pulse)

P1

DHWbufferchargingpump(ON-OFFcontrolled)

V1

SpeedcontrolofDHWbufferchargingpump(0-

10V)

P2

Circulationpump(ON-OFFcontrolled),circuit1

P3

DHWcirculationpump(ON-OFFcontrolled)

V3

SpeedcontrolofDHWcirculationpump(0-10V)

M1

Motorizedcontrolvalve(ON-OFFcontrolled)

M2

Motorizedcontrolvalve(3-pointcontrolled)

A1

Alarm

6|©Danfoss|2017.04

VI.LV.G2.02

OperatingGuideECLComfort310,applicationP348

AconnectedfloworenergymeterbasedonM-bussignalcanlimit

thefloworenergytoasetmaximumvalue.Furthermore,the

limitationcanbeinrelationtotheoutdoortemperature.Typically,

thelowertheoutdoortemperature,thehighertheacceptedflow/

power.

Thefrostprotectionmodemaintainsaselectableflowtemperature,

forexample10°C.

TheheatingcircuitcanactasmasterandviatheECL485

communicationbusfulfiltheheatdemandfromslavecircuits.

Exerciseofcirculationpumpandcontrolvalveinperiodswithout

heatingdemandcanbearranged.

TheDHW(DomesticHotWater)circuit:

P348.1,ex.aandP348.1,ex.brunwiththeextensionmodule

ECA32only.Thisallowsforspeedcontrolbymeansofvoltage

signalofchargingpumpP1/V1andcirculationpumpP3/V3.

P348.1,ex.candP348.1,ex.dcanrunwiththeextension

moduleECA32(speedcontrol(bymeansofvoltagesignal)ofthe

pumpsP1/V1andP3/V3)—orrunwiththeextensionmodule

ECA35forspeedcontrol(bymeansofvoltageorPWMsignal)of

thepumpsP1/V1andP3/V3.

Temperaturecontrolofbuffer:

ThedesiredDHWtemperatureatS4determinesthebuffer

chargingprocedure.TheDHWtemperaturesensorS4andupper

buffertemperaturesensorS6arethemostimportantsensorsand

mustbeconnected.

ThedesiredbuffertemperatureatS6isbasedonthedesired

DHWtemperatureatS4andaset"Demandoffset"(=Charging

difference).

P4hasanON/OFFfunction.M1followsP4tobeeitherfullyopen

orfullyclosed.

Startbufferchargingprocess:

1.BuffertemperatureS6temperaturegetslowerthan('Desired

DHWtemperature'+'Demandoffset'+'Startdiff.').

Anexample:60°C+6K+(-2K)=64°C

2.P4isswitchedON;M1iscommandedtoopen

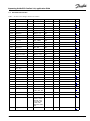

P348.1,ex.b,heating(circuitA)andDHWtemperaturecontrol.Pumpsin

DHWcircuitcanbe0–10Voltcontrolled.

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECLComfort310controller

ECA32

Built-inextensionmodule,0-10Voutputsfor

pumpspeedcontrol

S1

Outdoortemperaturesensor

S2

Supplytemperaturesensor

S3

(mandatory)Flowtemperaturesensor,circuit1

S4

(mandatory)DHWflowtemperaturesensor,

circuit2

S5

Returntemperaturesensor,circuit1

S6

(mandatory)Upperbuffertemperaturesensor

S7

Bufferflowtemperaturesensor

S8

Lowerbuffertemperaturesensor

S9

DHWcirculationreturntemperaturesensor

S10

Bufferreturntemperaturesensor

S11

Returntemperaturesensor,circuit1A

S15

Supplyreturnpressuresensor

S16

Supplyflowpressuresensor

F1

Flowmeter(signaltype:Pulse)

P1

DHWbufferchargingpump(ON-OFFcontrolled)

V1

SpeedcontrolofDHWbufferchargingpump(0-

10V)

P2

Circulationpump(ON-OFFcontrolled),circuit1

P3

DHWcirculationpump(ON-OFFcontrolled)

V3

SpeedcontrolofDHWcirculationpump(0-10V)

M1

Motorizedcontrolvalve(ON-OFFcontrolled)

M2

Motorizedcontrolvalve(3-pointcontrolled)

A1

Alarm

VI.LV.G2.02

©Danfoss|2017.04|7

OperatingGuideECLComfort310,applicationP348

Stopbufferchargingprocess:

1.a

S6connectedand'Stopdiff.'hasanegativevalue

BuffertemperatureS6temperaturegetshigherthan('Desired

DHWtemperature'+'Demandoffset').

Anexample:60°C+6K=66°C

1.b

S6connectedand'Stopdiff.'hasa

positivevalue:

BuffertemperatureS6temperaturegetshigherthan('Desired

DHWtemperature'+'Demandoffset'+'Stopdiff.').

Anexample:60°C+6K+4K=70°C

1.c

S6andS8connectedand'Stopdiff.'hasa

negativevalue:

BuffertemperatureS6temperaturegetshigherthan('Desired

DHWtemperature'+'Demandoffset')ANDS8temperature

getshigherthan('DesiredDHWtemperature'+'Demandoffset'

+'Stopdiff.').

Anexample:S6higherthan(60°C+6K=66°C)ANDS8higher

than(60°C+6K+(-8K)=58°C).

1.d

S6andS8connectedand'Stopdiff.'hasapositivevalue:

BuffertemperatureS6temperaturegetshigherthan('Desired

DHWtemperature'+'Demandoffset')ANDS8temperature

getshigherthan('DesiredDHWtemperature'+'Demandoffset'

+'Stopdiff.').

Anexample:S6higherthan(60°C+6K=66°C)ANDS8higher

than(60°C+6K+(8K)=74°C).

2.P4isswitchedOFF;M1iscommandedtoclose

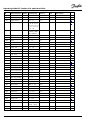

P348.1,ex.c,heating(circuitsAandB)andDHWtemperaturecontrol.

PumpsinDHWcircuitcanbe0–10VoltorPWMcontrolled.

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECLComfort310controller

ECA32

Built-inextensionmodule,0-10Voutputsfor

pumpspeedcontrol

ECA35

Built-inextensionmodule,0-10Voutputsand

PWMoutputsforpumpspeedcontrol

S1

Outdoortemperaturesensor

S2

Supplytemperaturesensor

S3

(mandatory)Flowtemperaturesensor,circuit1

S4

(mandatory)DHWflowtemperaturesensor,

circuit2

S5

Returntemperaturesensor,circuit1

S6

(mandatory)Upperbuffertemperaturesensor

S7

Bufferflowtemperaturesensor

S8

Lowerbuffertemperaturesensor

S9

DHWcirculationreturntemperaturesensor

S10

Bufferreturntemperaturesensor

S11

Returntemperaturesensor,circuit1A

S12

Returntemperaturesensor,circuit1B

F1

Flowmeter(signaltype:Pulse)

P1

DHWbufferchargingpump(ON-OFFcontrolled)

V1

SpeedcontrolofDHWbufferchargingpump(0-

10V)

P2

Circulationpump(ON-OFFcontrolled),circuit1

P3

DHWcirculationpump(ON-OFFcontrolled)

V3

SpeedcontrolofDHWcirculationpump(0-10V)

M1

Motorizedcontrolvalve(ON-OFFcontrolled)

M2

Motorizedcontrolvalve(3-pointcontrolled)

A1

Alarm

8|©Danfoss|2017.04

VI.LV.G2.02

OperatingGuideECLComfort310,applicationP348

TemperaturecontrolofDHW:

ThedesiredDHWtemperatureatS4determinesthetemperature

control.

Bymeansofaweekschedule(upto3'Comfort'periods/day),the

DHWcircuitcanbein'Comfort'or'Saving'mode(twodifferent

temperaturevaluesforthedesiredDHWtemperatureatS4).

TheDHWflowtemperaturesensorS4andtheDHWcirculation

returntemperaturesensorS9arethemostimportantsensorsand

mustbeconnected.IfS4isnotconnected,thecontrolpumpP1/

V1willstop.IfS9isnotconnected,theDHWcirculationpumpwill

operateat100%speed.

ThecontrolpumpP1/V1isgraduallyincreasedinspeedwhenthe

DHWflowtemperatureislowerthanthedesiredDHWtemperature

andviceversa.

ThesupplytemperatureS7isusedtocompensatetheproportional

bandXpinordertoimprovethetemperaturecontrolatdifferent

supplytemperatures.

TemperaturecontroloftheDHWcirculationpipeatS9ensuresthe

desiredtemperaturebymeansofspeedcontrolofP3/V3.

Aweekschedule(upto3'Comfort'periods/day)controlsthe

DHWcirculationpumptobeONorOFF.IfinOFFmode,theDHW

temperaturecontrolwillbedisabled.

ThecoldwaterflowsignalfromF1canbeusedtooverridethe

controlvalveinordertooptimizetheDHWtemperaturecontrol.

Thispro-activefunctionalitycompensatesforthedelaybeforethe

flowtemperaturesensorS4measuresachangeintemperature.

Ananti-bacteriafunctionfortheDHWcircuitisavailablefor

activationonselecteddaysoftheweek.Theanti-bacteriafunction

canbesettoincludetheDHWcirculation.

P348.1,ex.d,heating(circuitA)andDHWtemperaturecontrol.Pumpsin

DHWcircuitcanbe0–10VoltorPWMcontrolled.

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECLComfort310controller

ECA32

Built-inextensionmodule,0-10Voutputsfor

pumpspeedcontrol

ECA35

Built-inextensionmodule,0-10Voutputsand

PWMoutputsforpumpspeedcontrol

S1

Outdoortemperaturesensor

S2

Supplytemperaturesensor

S3

(mandatory)Flowtemperaturesensor,circuit1

S4

(mandatory)DHWflowtemperaturesensor,

circuit2

S5

Returntemperaturesensor,circuit1

S6

(mandatory)Upperbuffertemperaturesensor

S7

Bufferflowtemperaturesensor

S8

Lowerbuffertemperaturesensor

S9

DHWcirculationreturntemperaturesensor

S10

Bufferreturntemperaturesensor

S11

Returntemperaturesensor,circuit1A

F1

Flowmeter(signaltype:Pulse)

P1

DHWbufferchargingpump(ON-OFFcontrolled)

V1

SpeedcontrolofDHWbufferchargingpump(0-

10V)

P2

Circulationpump(ON-OFFcontrolled),circuit1

P3

DHWcirculationpump(ON-OFFcontrolled)

V3

SpeedcontrolofDHWcirculationpump(0-10V)

M1

Motorizedcontrolvalve(ON-OFFcontrolled)

M2

Motorizedcontrolvalve(3-pointcontrolled)

A1

Alarm

VI.LV.G2.02

©Danfoss|2017.04|9

OperatingGuideECLComfort310,applicationP348

P348,ingeneral

UptotwoRemoteControlUnits,ECA30/31,canbeconnectedto

oneECLcontrollerinordertocontroltheECLcontrollerremotely.

AdditionalECLComfortcontrollerscanbeconnectedviatheECL

485businordertoutilizecommonoutdoortemperaturesignal,

timeanddatesignals.

TheECLcontrollersintheECL485systemcanworkinmaster-

slavesystem.

Whenconnectinganoverrideswitchorarelaycontacttoan

unusedinputtheECL310'sschedulecanbeoverriddento:

•Comfortmode

•Savingmode

•Frostprotectionmodeor

•Constanttemperaturemode(keepingasetdesiredflow

temperature).

ModbuscommunicationtoaSCADAsystemcanbeestablished.

Heat-meters:

Upto5heat-meterscanbeconnectedtotheM-busterminals.

M-busdatacanbetransferredtotheSCADAsystemviaModbus

andTCP/IPtotheECLPortal.

AlarmA1(=relay6)canbeactivatedif:

•Theactualflowtemperaturediffersfromthedesiredflow

temperature.

•Ifatemperaturesensororitsconnectiondisconnects/short

circuits.(See:Commoncontrollersettings>System>Raw

inputoverview).

Ameasuredtemperaturecanbeoffsetadjusted,ifneeded.

10|©Danfoss|2017.04

VI.LV.G2.02

OperatingGuideECLComfort310,applicationP348

PWM(PulseWidthModulation)

A200HzfrequencyisappliedtothePWMcontrolledpump.The

dutycycle(thepercentageoftheperiodtime)determinesthe

pumpspeed.

Pumpspeed,PWMor0–10Voltcontrolled

Sometypesofspeedcontrolledpumpsarelimitedtoaminimum

speed,forexample30%(PWMor3.0Volt).Eveniftheapplied

control%getslowerthan30%,thepumpspeedremainsonthe

minimumlevel*.

Furthermore,whentheappliedcontrol%getsbelow,forexample,

10%,thepumpswitchesOFF.Inordertogetthepumpswitched

ONagain,theappliedcontrol%mustexceed20%.

Thisbehaviorcan,atlowloadoratoobigpump,causeunstable

temperatureregulation.Toavoidthis,theP348hasafunction

wheretheappliedcontrolsignalisconvertedintoapulsedsignal.

Thepumpisshortlystoppedandthenstartedagain.Theresultisa

pumpspeedcontrolalsobelowtheminimumspeedlevel.

Theparameters"PWMperiod"(ID12565)and"Adapttime"(ID

12065)areusedforthisfunctionality.

*)Seethepumpmanufacturer'sdatasheet

Commissioning

WhentheP348applicationhasbeenuploadedtheECLComfort

310controllerstartsinManualmode.Thiscanbeusedtoverify

correctconnectionsoftemperature,pressureandflowsensors.

Alsoverifyingthecontrolledcomponentsforcorrectfunctionality

canbedone.

Dependingonsystemtype,itmightbenecessarytochangesome

factorysettingsindividuallyinordertooptimizethefunctionality.

Theapplicationkeymustbeinsertedinordertochangesettings.

Important:

•Setthecorrectrunningtime"Mrun"oftheMotorizedControl

ValveM2.(Circuit1>MENU>Settings>Controlparameters

>Mrun).

•SetaminimumspeedofP1/V1andensurethatthepumpruns

constantly.(Circuit2>MENU>Settings>Controlpar.1>Vout

min.).Seepumpmanufacturer'smanual.

•Verifyifthespeedcontrolledpumpsshouldbereversed

controlled.(Circuit2/3>MENU>Settings>Controlpar.>

Reverseout).Seepumpmanufacturer'smanual.

Thecontrollerispre-programmedwithfactorysettingsthatareshown

inthe‘ParameterIDoverview’appendix.

VI.LV.G2.02

©Danfoss|2017.04|11

OperatingGuideECLComfort310,applicationP348

2.2Identifyingthesystemtype

Sketchyourapplication

TheECLComfortcontrollerseriesisdesignedforawiderange

ofheating,domestichot-water(DHW)andcoolingsystemswith

differentconfigurationsandcapacities.Ifyoursystemdiffers

fromthediagramsshownhere,youmaywanttomakeasketch

ofthesystemabouttobeinstalled.Thismakesiteasiertouse

theOperatingGuide,whichwillguideyoustep-by-stepfrom

installationtofinaladjustmentsbeforetheend-usertakesover.

TheECLComfortcontrollerisauniversalcontrollerthatcanbe

usedforvarioussystems.Basedontheshownstandardsystems,

itispossibletoconfigureadditionalsystems.Inthischapteryou

findthemostfrequentlyusedsystems.Ifyoursystemisnotquite

asshownbelow,findthediagramwhichhasthebestresemblance

withyoursystemandmakeyourowncombinations.

SeetheInstallationGuide(deliveredwiththeapplicationkey)for

applicationtypes/sub-types.

12|©Danfoss|2017.04

VI.LV.G2.02

OperatingGuideECLComfort310,applicationP348

2.3Mounting

2.3.1MountingtheECLComfortcontroller

SeetheInstallationGuidewhichisdeliveredtogetherwiththe

ECLComfortcontroller.

Foreasyaccess,youshouldmounttheECLComfortcontrollernear

thesystem.

ECLComfort210/296/310canbemounted

•onawall

•onaDINrail(35mm)

ECLComfort296canbemounted

•inapanelcut-out

ECLComfort210canbemountedinanECLComfort310basepart

(forfutureupgrade).

Screws,PGcableglandsandrawlplugsarenotsupplied.

LockingtheECLComfort210/310controller

InordertofastentheECLComfortcontrollertoitsbasepart,secure

thecontrollerwiththelockingpin.

Topreventinjuriestopersonsorthecontroller,thecontrollerhasto

besecurelylockedintothebase.Forthispurpose,pressthelocking

pinintothebaseuntilaclickisheardandthecontrollernolonger

canberemovedfromthebase.

Ifthecontrollerisnotsecurelylockedintothebasepart,thereisarisk

thatthecontrollerduringoperationcanunlockfromthebaseandthe

basewithterminals(andalsothe230Va.c.connections)areexposed.

Topreventinjuriestopersons,alwaysmakesurethatthecontroller

issecurelylockedintoitsbase.Ifthisisnotthecase,thecontroller

shouldnotbeoperated!

VI.LV.G2.02

©Danfoss|2017.04|13

OperatingGuideECLComfort310,applicationP348

Theeasywaytolockthecontrollertoitsbaseorunlockitistousea

screwdriveraslever.

Mountingonawall

Mountthebasepartonawallwithasmoothsurface.Establishthe

electricalconnectionsandpositionthecontrollerinthebasepart.

Securethecontrollerwiththelockingpin.

MountingonaDINrail(35mm)

MountthebasepartonaDINrail.Establishtheelectrical

connectionsandpositionthecontrollerinthebasepart.Secure

thecontrollerwiththelockingpin.

DismountingtheECLComfortcontroller

Inordertoremovethecontrollerfromthebasepart,pulloutthe

lockingpinbymeansofascrewdriver.Thecontrollercannowbe

removedfromthebasepart.

Theeasywaytolockthecontrollertoitsbaseorunlockitistousea

screwdriveraslever.

14|©Danfoss|2017.04

VI.LV.G2.02

OperatingGuideECLComfort310,applicationP348

BeforeremovingtheECLComfortcontrollerfromthebasepart,ensure

thatthesupplyvoltageisdisconnected.

2.3.2MountingtheRemoteControlUnitsECA30/31

Selectoneofthefollowingmethods:

•Mountingonawall,ECA30/31

•Mountinginapanel,ECA30

Screwsandrawlplugsarenotsupplied.

Mountingonawall

MountthebasepartoftheECA30/31onawallwithasmooth

surface.Establishtheelectricalconnections.PlacetheECA30/

31inthebasepart.

Mountinginapanel

MounttheECA30inapanelusingtheECA30framekit(ordercode

no.087H3236).Establishtheelectricalconnections.Securethe

framewiththeclamp.PlacetheECA30inthebasepart.TheECA

30canbeconnectedtoanexternalroomtemperaturesensor.

TheECA31mustnotbemountedinapanelifthehumidity

functionistobeused.

VI.LV.G2.02

©Danfoss|2017.04|15

OperatingGuideECLComfort310,applicationP348

2.3.3MountingtheinternalI/OmoduleECA32orECA35

TheECA32module(ordercodeno.087H3202)orECA35module

(ordercodeno.087H3205)canbeinsertedintotheECLComfort

310/310Bbasepartforadditionalinputandoutputsignalsin

relevantapplications.

ECA32

ECA35

16|©Danfoss|2017.04

VI.LV.G2.02

OperatingGuideECLComfort310,applicationP348

2.4Placingthetemperaturesensors

2.4.1Placingthetemperaturesensors

Itisimportantthatthesensorsaremountedinthecorrectposition

inyoursystem.

Thetemperaturesensormentionedbelowaresensorsusedforthe

ECLComfort210/296/310serieswhichnotallwillbeneeded

foryourapplication!

Outdoortemperaturesensor(ESMT)

Theoutdoorsensorshouldbemountedonthatsideofthebuilding

whereitislesslikelytobeexposedtodirectsunshine.Itshouldnot

beplacedclosetodoors,windowsorairoutlets.

Flowtemperaturesensor(ESMU,ESM-11orESMC)

Placethesensormax.15cmfromthemixingpoint.Insystems

withheatexchanger,DanfossrecommendsthattheESMU-typeto

beinsertedintotheexchangerflowoutlet.

Makesurethatthesurfaceofthepipeiscleanandevenwhere

thesensorismounted.

Returntemperaturesensor(ESMU,ESM-11orESMC)

Thereturntemperaturesensorshouldalwaysbeplacedsothatit

measuresarepresentativereturntemperature.

Roomtemperaturesensor

(ESM-10,ECA30/31RemoteControlUnit)

Placetheroomsensorintheroomwherethetemperatureistobe

controlled.Donotplaceitonoutsidewallsorclosetoradiators,

windowsordoors.

Boilertemperaturesensor(ESMU,ESM-11orESMC)

Placethesensoraccordingtotheboilermanufacturer’s

specification.

Airducttemperaturesensor(ESMB-12orESMUtypes)

Placethesensorsothatitmeasuresarepresentativetemperature.

DHWtemperaturesensor(ESMUorESMB-12)

PlacetheDHWtemperaturesensoraccordingtothemanufacturer’s

specification.

Slabtemperaturesensor(ESMB-12)

Placethesensorinaprotectiontubeintheslab.

ESM-11:Donotmovethesensorafterithasbeenfastenedinorderto

avoiddamagetothesensorelement.

ESM-11,ESMCandESMB-12:Useheatconductingpasteforquick

measurementofthetemperature.

ESMUandESMB-12:Usingasensorpockettoprotectthesensorwill,

however,resultinaslowertemperaturemeasurement.

VI.LV.G2.02

©Danfoss|2017.04|17

OperatingGuideECLComfort310,applicationP348

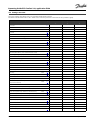

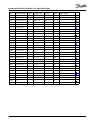

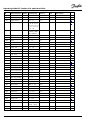

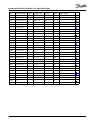

Pt1000temperaturesensor(IEC751B,1000Ω/0°C)

Relationshipbetweentemperatureandohmicvalue:

18|©Danfoss|2017.04

VI.LV.G2.02

OperatingGuideECLComfort310,applicationP348

2.5Electricalconnections

2.5.1Electricalconnections230Va.c.

SafetyNote

Necessaryassembly,start-up,andmaintenanceworkmustbe

performedbyqualifiedandauthorizedpersonnelonly.

Locallegislationsmustberespected.Thiscomprisesalsocablesize

andisolation(reinforcedtype).

AfusefortheECLComfortinstallationismax.10Atypically.

TheambienttemperaturerangefortheECLComfortinoperationis

0-55°C.Exceedingthistemperaturerangecanresultinmalfunctions.

Installationmustbeavoidedifthereisariskforcondensation(dew).

Thecommongroundterminalisusedforconnectionofrelevant

components(pumps,motorizedcontrolvalves).

ECL210/310

SeealsotheInstallationGuide(deliveredwiththeapplicationkey)

forapplicationspecificconnections.

Wirecrosssection:0.5-1.5mm²

Incorrectconnectioncandamagetheelectronicoutputs.

Max.2x1.5mm²wirescanbeinsertedintoeachscrewterminal.

Maximumloadratings:

Relayterminals

4(2)A/230Va.c.

(4Aforohmicload,2Afor

inductiveload)

Triac(=electronic

relay)terminals

0,2A/230Va.c.

VI.LV.G2.02

©Danfoss|2017.04|19

OperatingGuideECLComfort310,applicationP348

Electricalconnections,ECA32/ECA35

Connections,ingeneral.

SeealsotheInstallationGuide(deliveredwiththeapplicationkey)forapplicationspecificconnections.

Maximumloadratings:

Terminals

ECA32ECA35

PWMOut1(52)

5kΩ*

PWMOut2(53)

5kΩ*

PWMOut3(54)

5kΩ*

PWMOut4(55)

5kΩ*

AnalogOut1(59)AnalogOut1(59)47kΩ*

AnalogOut2(60)AnalogOut2(60)47kΩ*

AnalogOut3(61)AnalogOut3(61)47kΩ*

*Thevalueisaminimum.

20|©Danfoss|2017.04

VI.LV.G2.02

OperatingGuideECLComfort310,applicationP348

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

-

105

105

-

106

106

-

107

107

-

108

108

-

109

109

-

110

110

-

111

111

-

112

112

-

113

113

-

114

114

-

115

115

-

116

116

-

117

117

-

118

118

-

119

119

-

120

120

-

121

121

-

122

122

-

123

123

-

124

124

-

125

125

-

126

126

-

127

127

-

128

128

-

129

129

-

130

130

-

131

131

-

132

132

-

133

133

-

134

134

-

135

135

-

136

136

-

137

137

-

138

138

-

139

139

Danfoss ECL Comfort 310, P349 Operating instructions

- Category

- Thermostats

- Type

- Operating instructions

- This manual is also suitable for

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Danfoss ECA 30 Installation guide

-

Danfoss ECL 9304 Operating instructions

-

Danfoss ECA 86 Operating instructions

-

Danfoss ECA 86 Temperature Alarm Module for ECL Comfort Operating instructions

-

Danfoss ECL Portal - 5-step Installation guide

-

Danfoss Extended heat cut-out Operating instructions

-

Danfoss ECA 30 / 31 Operating instructions

-

Danfoss ECL 310 to ECL Portal Operating instructions

-

Danfoss PC cable Operating instructions

-

Danfoss M-BUS MODULE Operating instructions

Other documents

-

OP/TECH USA 1301322 User manual

OP/TECH USA 1301322 User manual

-

Boston HEC-658 hygrometer user Owner's manual

-

Raypak PS270VSP User guide

-

OUMAN S203 User manual

-

OUMAN H23 User manual

-

OUMAN A203 User manual

-

OUMAN EH-800 User manual

-

Shure SW6000-ECA User guide

-

Daikin EGSQH10S18AA9W Operating instructions

-

Daikin EHYHBH08AA Operating instructions