Page is loading ...

For warranty informaon please visit: hp://www.kichler.com/warranty

IS-16236-US

We’re here to help 866-558-5706

Hrs: M-F 9am to 5pm EST

Kichler 16236, 16237, 16238 Installaon Guide

LED Slim Wallpack

IMPORTANT: Read before removing xture from carton. Retain for

future reference.

SAFETY: This xture must be wired in accordance with the

NATIONAL ELECTRICAL CODE (NEC) and applicable local codes and

ordinances. A person familiar with the construcon and operaon

of the product and the hazards involved must install this product.

A qualied licensed electrician should complete all work. Proper

grounding is required for safety.

WARNING: Make certain power is OFF before installing or

maintaining xture.

RISK OF INJURY: Fixture may become damaged and/or unstable if

not installed properly.

Cauons:

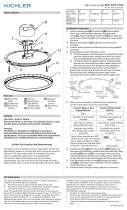

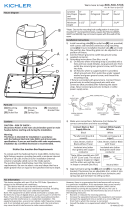

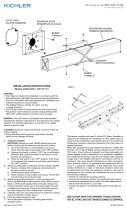

Installaon Instrucons:Fixture Diagram

NOTE: Turn o electrical supply at the breaker. Follow all local

electrical codes for wiring and grounding requirements.

Tools Required: 1/8” Allen Key, Phillips Screw Driver, Wire

Strippers & Cuers

NOTE: Unpack xture and ensure that there are no damaged parts.

FCC Informaon:

RISK OF FIRE, EXPLOSION AND ELECTRIC SHOCK

• This product should be installed, inspected, and maintained by a qualied

electrician only, in accordance with the NEC (Naonal Electric Code) and all

local codes.

• Turn o electrical power before inspecon, installaon or removal.

• Use only UL (or other NRTL) approved wire for input/output connecons.

Minimum size 18 AWG or 14 AWG for connuous runs.

• Make sure LEDs and drivers are cool to touch when performing maintenance.

Make sure the supply voltage is the same as the rated voltage of the luminaire.

• Do not install in a hazardous atmosphere, except where the ambient

temperature does not exceed the rated operang temperature of the xture.

• Keep ghtly closed when in operaon

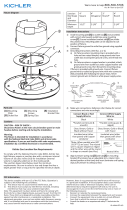

Electrical Requirements

The LED driver must be supplied with 120 to

277V, 50/60 Hz and connected to an individual,

properly grounded branch circuit protected by a

20 Ampere circuit breaker. Use min. 90°C supply.

Grounding Instrucons

The grounding and bonding of the overall

system shall be done in accordance with NEC

Arcle 600 and local codes

Black

Line

White

Neutral

Green

Ground

FIXTURE

Figure 1

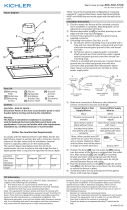

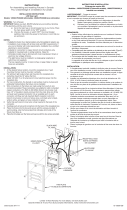

Direct mount to Juncon Box:

1) Remove the boom quick mounng plate from the xture to

install onto juncon box.

2) Apply xture to mounng surface by fastening mounng plate

to recessed juncon box. Use integral bubble level to ensure

that the plate is level.

3) Connect leads from back of xture to the power supply leads:

Green to green (ground), black to black (hot), white to white

(neutral).

4) Take care to not pinch any wires when connecng the xture to

the mounng plate.

5) Tighten Allen set screws on front of xture to secure to the

mounng plate.

6) For wet locaons, caulk between the rear housing and

mounng surface for a water ght seal.

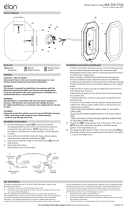

Using Oponal 16256AZT Wall Mount

Extension Juncon Box:

NOTE: Quick mounng plate not required.

1) Apply extension juncon box to mounng surface (two opons).

a. Recessed juncon box: Fasten extension juncon box

to recessed juncon box.

b. Conduit feed: Fasten extension juncon box to desired

surface and remove appropriate threaded conduit plug

and route conduit and circuit wiring into the extension

juncon box using appropriate methods.

2) Connect leads from back of xture to the power supply leads:

Green to green (ground), black to black (hot), white to white

(neutral).

3) Arrange connected wires into extension juncon box.

4) Aach xture to extension juncon box. Take care to not pinch

any wires when connecng the xture.

5) Tighten Allen set screws on front of xture to secure to the

extension juncon box.

6) For wet locaons, caulk between the rear housing and mounng

surface for a water ght seal.

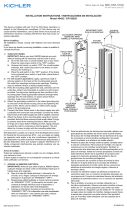

Using Oponal 16292AZT

Trunnion Mount:

NOTE: Quick mounng plate not required.

1) Connect leads from back of xture to

the power supply leads: Green to green

(ground), black to black (hot), white to

white(neutral).

2) Arrange connected wires into trunnion

juncon box.

3) Aach xture to trunnion extension

juncon box. Take care to not pinch any

wires when connecng the xture.

4) Mount the trunnion with appropriate

fasteners to selected surface. Mounng

slots are ½”.

5) Loosen pivot screws to adjust angle of

xture to desired posion. Reghten pivot

screws.

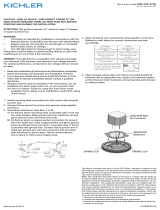

This device complies with part 15 of the FCC Rules. Operaon is subject to the following two condions:

1) This device may not cause harmful interference, and

2) This device must accept any interference received, including interference that may cause

undesired operaon.

Note: This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protecon against

harmful interference in a residenal installaon. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instrucons, may cause harmful

interference to radio communicaons.

However, there is no guarantee that interference will not occur in a parcular installaon. If this

equipment does cause harmful interference to radio or television recepon, which can be determined

by turning the equipment o and on, the user is encouraged to try to correct the interference by one or

more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separaon between the equipment and receiver.

• Connect the equipment into an outlet on a circuit dierent from that to which the receiver is

connected.

• Consult the dealer or an experienced radio/TV technician for help.

IS-16236-CB

For warranty informaon please visit: hp://www.kichler.com/warranty

We’re here to help 866-558-5706

Hrs: M-F 9am to 5pm EST

Kichler 16236, 16237, 16238 Installaon Guide

LED Slim Wallpack

IMPORTANT: Read before removing xture from carton. Retain for

future reference.

SAFETY: This xture must be wired in accordance with the

NATIONAL ELECTRICAL CODE (NEC) and applicable local codes and

ordinances. A person familiar with the construcon and operaon

of the product and the hazards involved must install this product.

A qualied licensed electrician should complete all work. Proper

grounding is required for safety.

WARNING: Make certain power is OFF before installing or

maintaining xture.

RISK OF INJURY: Fixture may become damaged and/or unstable if

not installed properly.

Cauons:

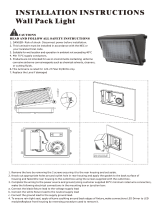

Installaon Instrucons:Fixture Diagram

NOTE: Turn o electrical supply at the breaker. Follow all local

electrical codes for wiring and grounding requirements.

Tools Required: 1/8” Allen Key, Phillips Screw Driver, Wire

Strippers & Cuers

NOTE: Unpack xture and ensure that there are no damaged parts.

FCC Informaon:

RISK OF FIRE, EXPLOSION AND ELECTRIC SHOCK

• This product should be installed, inspected, and maintained by a qualied

electrician only, in accordance with the NEC (Naonal Electric Code) and all

local codes.

• Turn o electrical power before inspecon, installaon or removal.

• Use only UL (or other NRTL) approved wire for input/output connecons.

Minimum size 18 AWG or 14 AWG for connuous runs.

• Make sure LEDs and drivers are cool to touch when performing maintenance.

Make sure the supply voltage is the same as the rated voltage of the luminaire.

• Do not install in a hazardous atmosphere, except where the ambient

temperature does not exceed the rated operang temperature of the xture.

• Keep ghtly closed when in operaon

Electrical Requirements

The LED driver must be supplied with 120 to

277V, 50/60 Hz and connected to an individual,

properly grounded branch circuit protected by a

20 Ampere circuit breaker. Use min. 90°C supply.

Grounding Instrucons

The grounding and bonding of the overall

system shall be done in accordance with NEC

Arcle 600 and local codes

Black

Line

White

Neutral

Green

Ground

FIXTURE

Figure 1

Direct mount to Juncon Box:

1) Remove the boom quick mounng plate from the xture to

install onto juncon box.

2) Apply xture to mounng surface by fastening mounng plate

to recessed juncon box. Use integral bubble level to ensure

that the plate is level.

3) Connect leads from back of xture to the power supply leads:

Green to green (ground), black to black (hot), white to white

(neutral).

4) Take care to not pinch any wires when connecng the xture to

the mounng plate.

5) Tighten Allen set screws on front of xture to secure to the

mounng plate.

6) For wet locaons, caulk between the rear housing and

mounng surface for a water ght seal.

Using Oponal 16256AZT Wall Mount

Extension Juncon Box:

NOTE: Quick mounng plate not required.

1) Apply extension juncon box to mounng surface (two opons).

a. Recessed juncon box: Fasten extension juncon box

to recessed juncon box.

b. Conduit feed: Fasten extension juncon box to desired

surface and remove appropriate threaded conduit plug

and route conduit and circuit wiring into the extension

juncon box using appropriate methods.

2) Connect leads from back of xture to the power supply leads:

Green to green (ground), black to black (hot), white to white

(neutral).

3) Arrange connected wires into extension juncon box.

4) Aach xture to extension juncon box. Take care to not pinch

any wires when connecng the xture.

5) Tighten Allen set screws on front of xture to secure to the

extension juncon box.

6) For wet locaons, caulk between the rear housing and mounng

surface for a water ght seal.

Using Oponal 16292AZT

Trunnion Mount:

NOTE: Quick mounng plate not required.

1) Connect leads from back of xture to

the power supply leads: Green to green

(ground), black to black (hot), white to

white(neutral).

2) Arrange connected wires into trunnion

juncon box.

3) Aach xture to trunnion extension

juncon box. Take care to not pinch any

wires when connecng the xture.

4) Mount the trunnion with appropriate

fasteners to selected surface. Mounng

slots are ½”.

5) Loosen pivot screws to adjust angle of

xture to desired posion. Reghten pivot

screws.

This device complies with part 15 of the FCC Rules. Operaon is subject to the following two condions:

1) This device may not cause harmful interference, and

2) This device must accept any interference received, including interference that may cause

undesired operaon.

Note: This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protecon against

harmful interference in a residenal installaon. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instrucons, may cause harmful

interference to radio communicaons.

However, there is no guarantee that interference will not occur in a parcular installaon. If this

equipment does cause harmful interference to radio or television recepon, which can be determined

by turning the equipment o and on, the user is encouraged to try to correct the interference by one or

more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separaon between the equipment and receiver.

• Connect the equipment into an outlet on a circuit dierent from that to which the receiver is

connected.

• Consult the dealer or an experienced radio/TV technician for help.

/