Page is loading ...

INSTALLATION GUIDE

XR2400F ADDRESSABLE

FIRE ALARM CONTROL PANEL

MODEL XR2400F

Addressable Fire Alarm Control Panel

INSTALLATION GUIDE

FCC NOTICE

This equipment generates and uses radio frequency energy and, if not installed and used properly in strict accordance

with the manufacturer’s instructions, may cause interference with radio and television reception. It has been type

tested and found to comply with the limits for a Class B computing device in accordance with the speciÞ cation in

Subpart J of Part 15 of FCC Rules, which are designed to provide reasonable protection against such interference in

a residential installation. If this equipment does cause interference to radio or television reception, which can be

determined by turning the equipment off and on, the installer is encouraged to try to correct the interference by one

or more of the following measures:

Reorient the receiving antenna

Relocate the computer with respect to the receiver

Move the computer away from the receiver

Plug the compute into a different outlet so that computer and receiver are on different branch circuits

If necessary, the installer should consult the dealer or an experienced radio/television technician for additional

suggestions. The installer may Þ nd the following booklet, prepared by the Federal Communications Commission,

helpful:

“How to identify and Resolve Radio-TV Interference Problems.”

This booklet is available from the U.S. Government Printing OfÞ ce, Washington D.C. 20402

Stock No. 004-000-00345-4

Copyright © 2000 - 2003 Digital Monitoring Products, Inc.

Information furnished by DMP is believed to be accurate and reliable.

This information is subject to change without notice.

XR2400F Installation Guide Digital Monitoring Products

i

TABLE OF CONTENTS

Revisions to This Document

Introduction

1.1 Overview................................................1

1.2 System Components ...............................1

1.3 Power SpeciÞ cations ...............................1

1.4 Before you begin ....................................1

1.5 About this Guide .....................................1

1.6 How to use this Guide .............................1

Mounting

2.1 Mounting the Enclosure...........................2

2.2 Surface Mounting....................................2

2.3 Flush Mounting .......................................2

2.4 Fire Command Center LCD Keyboard........2

2.5 Metal Backplate ......................................2

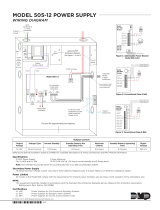

2.6 Wiring Diagram.......................................3

AC Connection

3.1 Transformers and AC Power Connection ...4

3.2 28 VAC Transformer ................................4

3.3 16 VAC Transformer ...............................4

3.4 Earth Ground from the XR2400F Panel ....4

Secondary Power Supply

4.1 Description.............................................5

4.2 Battery Connection to XR2400F

Command Processor panel ......................5

4.3 Battery Connection to the 504-24

Power Supply .........................................5

Two 866 NAC Modules

5.1 Description.............................................6

5.2 Connection.............................................6

5.3 Bell Silence/Bell Trouble ..........................6

5.4 NotiÞ cation Appliances ...........................7

462N LX-Bus™ Expansion Card

6.1 Description.............................................8

6.2 LX-Bus™ Expansion Capability .................8

6.3 Installing the 462N Module ......................8

Telephone RJ Connector

7.1 Description.............................................9

7.2 FCC registration .....................................9

7.3 NotiÞ cation.............................................9

7.4 Ground start...........................................9

893A Dual Phone Line Module

8.1 Description...........................................10

8.2 Connection...........................................10

8.3 Jumper Settings....................................10

8.4 Digital Dialer/Multiplex ..........................10

8.5 Phone Line Monitor ...............................10

8.6 Processor Fail Buzzer.............................10

Digital Monitoring Products XR2400F Installation Guide

ii

TABLE OF CONTENTS

504-24 Power Supply

9.1 Description...........................................11

9.2 LED’s ..................................................11

9.3 504-24 Condition Chart .........................11

9.4 504-24 UL Listings ................................11

9.5 24 VDC NAC Standby Battery Calculations11

9.6 Connection...........................................12

Interconnect Wiring Harness

10.1 Interconnect Harness ............................12

Fire Command Center

11.1 Description...........................................13

11.2 Connection...........................................13

11.3 Remote Fire Command Center ...............13

XR2400F Command Processor Panel

12.1 Description...........................................14

12.2 Connection ..........................................14

12.3 Relays .................................................14

12.4 Zone Reference ....................................14

XR2400F Product SpeciÞ cations

13.1 Power Supply .......................................15

13.2 Communication.....................................15

13.3 Panel Zones..........................................15

13.4 Remote Annunciator .............................15

13.5 LX-Bus™ ..............................................15

13.6 Outputs................................................15

Expansion

14.1 Expansion Zones...................................16

14.2 Output (Relay) Expansion ......................16

Accessory Devices

15.1 Wiring Diagram.....................................17

15.2 Lightning Protection ..............................17

15.3 Accessory Devices.................................18

15.4 Mounting Keypads and Zone Expanders..19

15.5 Connecting serial devices ......................19

Battery Information

16.1 Battery Only Restart..............................20

16.2 Replacement Period ..............................20

16.3 Discharge/recharge...............................20

16.4 Battery Supervision...............................20

16.5 Battery Cutoff.......................................20

16.6 XR2400F Power Requirements ...............20

16.7 XR2400F Standby Battery Calculations....21

Bell Output

17.1 Terminals 5 and 6 .................................22

XR2400F Installation Guide Digital Monitoring Products

iii

TABLE OF CONTENTS

Keypad and Zone Expander Bus

18.1 Description...........................................22

18.2 Terminal 7 - RED ..................................22

18.3 Terminal 8 - YELLOW ............................22

18.4 Terminal 9 - GREEN ..............................22

18.5 Terminal 10 - BLACK .............................22

Smoke Detector Output

19.1 Terminals 11 and 12..............................22

19.2 Current Rating......................................22

Powered Zones for 2-Wire Smoke Detectors

20.1 Terminals 25-26 and 27-28 ....................22

20.2 Compatible 2-Wire Smoke Detectors ...........23

Protection Zones

21.1 Description...........................................24

21.2 Operational Parameters .........................24

21.3 Zone Response Time.............................24

21.4 Keyswitch Arming Zone .........................24

Dry Contact Relay Outputs

22.1 Description...........................................25

22.2 Contact Rating......................................25

22.3 Output Harness Wiring ..........................25

12 VDC Voltage Outputs 3 to 10

23.1 Description...........................................25

23.2 Output Harness Wiring ..........................25

Reset and Tamper Headers

24.1 J16 Reset Header .................................26

24.2 J4 Tamper Header ................................26

Universal UL Burglary SpeciÞ cations

25.1 Introduction .........................................27

25.2 Wiring..................................................27

25.3 Control outside of protected area ...........27

25.4 Police station phone numbers ................27

25.5 Bypass reports......................................27

25.6 System maintenance.............................27

25.7 Partitions..............................................27

25.8 UL Listed Receivers ...............................27

UL 1023 SpeciÞ cations

26.1 Bell cutoff.............................................27

26.2 Entry delay...........................................27

26.3 Exit delay .............................................27

26.4 Weekly test ..........................................27

UL 1610 And 1076 SpeciÞ cations

27.1 Multiplex network capacity ....................28

27.2 Opening/Closing reports ........................28

27.3 Closing wait..........................................28

27.4 Proprietary dialer ..................................28

27.5 AA Network Communication ..................28

Digital Monitoring Products XR2400F Installation Guide

iv

TABLE OF CONTENTS

UL 1635 SpeciÞ cations

28.1 System trouble display ..........................29

28.2 Digital Dialer telephone number.............29

28.3 Entry delay...........................................29

28.4 Exit delay .............................................29

28.5 Test time..............................................29

28.6 Closing wait..........................................29

UL 365 And 609 SpeciÞ cations

29.1 System trouble display ..........................29

29.2 Grade A bell .........................................29

29.3 Bell cutoff.............................................29

29.4 Automatic bell test ................................29

29.5 Line security for Police Connect..............29

29.6 High Line Security.................................29

Universal UL And NFPA Fire Alarm SpeciÞ cations

30.1 Introduction .........................................30

30.2 Wiring..................................................30

30.3 Transformer..........................................30

30.4 End-of-Line resistor...............................30

30.5 System trouble display ..........................30

30.6 Fire display...........................................30

30.7 Police station phone number..................30

30.8 System maintenance.............................30

30.9 Audible alarm .......................................30

30.10 Fire zone programming .........................30

30.11 Style D zones .......................................30

30.12 Video Option ........................................30

30.13 UL Listed Receivers ...............................30

UL 985 NFPA 72 (Chapter 2) SpeciÞ cations

31.1 Bell output deÞ nition .............................31

UL 864 NFPA 72 (Chapter 9) SpeciÞ cations

32.1 Zone restoral reports.............................31

32.2 Power fail delay ....................................31

32.3 Sprinkler supervisory.............................31

32.4 DACT systems ......................................31

32.5 Type 2 and Type 3 Central Station

Service.................................................31

32.6 Type 1 Central Station Service ...............31

32.7 Local Protective Signaling Systems .........31

32.8 Proprietary Protective Signaling Systems 32

32.9 Remote Station Protective

Signaling Systems .................................32

32.10 Fire Protective Signaling Systems

with an iCOM™.....................................32

California State Fire Marshal SpeciÞ cations

33.1 Bell output deÞ nition .............................32

XR2400F Installation Guide Digital Monitoring Products

v

TABLE OF CONTENTS

System Wiring Diagrams

34.1 Multiple NotiÞ cation Circuit Modules .......33

34.2 Multiple NotiÞ cation Circuit Modules

for Zoned Annunciation .........................34

34.3 Dual Style D Zone Module Installation ....35

34.4 Remote Station Reversing

Relay Connection ..................................36

34.5 Supervised Remote Relay ......................37

34.6 Cellular Backup Installation for

Derived Channel Burglary ......................38

34.7 LX-Bus™ Module Connection..................39

34.8 Second LX-Bus™ with Auxiliary

Power Supply .......................................40

34.9 Multiple NotiÞ cation Circuits with

Strobes and Bells ..................................41

OPERATING INSTRUCTIONS

Digital Monitoring Products XR2400F Installation Guide

vi

REVISIONS

Revisions to This Document

This section explains the changes that were made to this document during this revision. This section lists the date

the change was made, the section number and section heading, and a quick summary of the change.

Date Section Number and Heading Quick Explanation of Changes

4/04 5.4 NotiÞ cation Appliances Removed obsolete products and added Models 850S and 850D.

10.1 Interconnect Harness ClariÞ ed table information.

Sections 15.1, 15.3, 15.4 Added keypad models 690F and 790F.

16.7 Standby Battery Calculations Added keypad models 690F and 790F and 734 Wiegand Interface Card.

Added/revised current draw information.

5/03 FCC Statement Adjusted to properly reß ect Class A.

Entire Document Added SCS-1R references to the appropriate places.

16.7 Standby Battery Calculations Current Draw on some products adjusted.

20.1 Terminals 25-26 and 27-28 EOL information clariÞ ed.

21.3 Zone Response Time Changed from 160 milliseconds to 167.

34.9 Notif. with Strobes and Bells Wiring Diagram corrected.

10/02 1.2 System Components Updated to 16 VAC 56 VA transformer.

1.3 Power SpeciÞ cations Updated to Transformer Input of 16 VAC 56 VA and Standby battery of

12 VDC 28Ah (four Model 367 batteries) with 56 VA transformer.

2.6 Wiring Diagram Changed drawing to show 56 VA transformer.

3.1 Transformers and AC Power Updated to 16 VAC 56 VA transformer.

3.3 16.5 VAC Transformer Updated to 16 VAC 56 VA transformer.

13.1 Power Supply Updated to 16 VAC 56 VA transformer and Standby battery of 12 VDC

28Ah (four Model 367 batteries) with 56 VA transformer.

15.1 Wiring Diagram Changed drawing to show 56 VA transformer.

32.9 Remote Station Protective Added the section back to the manual.

34.4 Remote Station Reversing Added the system diagram back to the manual.

9/02 1.2 System Components Updated to Model 320 16.5 VAC 40 VA transformer.

1.3 Power SpeciÞ cations Updated to Transformer Input or 16.5 VAC 40 VA and Standby battery of

12 VDC 15.4 Ah (two Model 367 batteries) with 40 VA transformer.

2.6 Wiring Diagram Changed drawing to show 40 VA transformer.

3.1 Transformers and AC Power Updated to 16.5 VAC 40 VA transformer.

3.3 16.5 VAC Transformer Updated to 16.5 VAC 40 VA transformer.

13.1 Power Supply Updated to 16.5 VAC 40 VA transformer and Standby battery of 12 VDC

15.4 Ah (two Model 367 batteries) with 40 VA transformer.

13.5 LX-Bus™ Added 462FM.

15.1 Wiring Diagram Removed Model 321 and 322 transformers from Figure 13, and changed

drawing to show Model 320 transformer.

15.4 Mounting Keypads Added 710 and 710F.

16.6 XR2400F Power Requirements Removed Model 670 keypad.

20.1 Terminals 25-26 and 27-28 Added note about sensor reset dropping power to zones 9 and 10.

32.9 Remote Station Protective Removed section.

34.4 Remote Station Reversing Removed system diagram of remote station reversing relay.

3/02 15.5 Connecting Serial Devices LX-Bus and Keypad Bus wiring information clariÞ ed.

16.6 XR2400F Power Requirements iCOM™ Internet Alarm Router added to the Standby Battery Calculations

Chart

XR2400F Installation Guide Digital Monitoring Products

1

INTRODUCTION

Introduction

1.1 Overview

The DMP XR2400F Addressable Fire Alarm Control Panel (FACP) is an expandable 24 VDC Fire Alarm Control

with built-in DACT and LCD Fire Command Center keyboard with membrane keyswitch. A complete system

can provide a total of 494 programmable inputs and outputs for commercial and industrial Þ re alarm service.

The 24 VDC 4 Amp notiÞ cation appliance power is distributed between two class B style W NAC outputs.

Additional NAC outputs can be added with conventional supervision modules or addressable power supply/

boosters. Addressable smoke detectors and input modules round out the XR2400F to deliver a truly ß exible

and expansive Þ re detection and notiÞ cation system. The Fire Alarm Control Panel is shipped pre-wired

in a red metal enclosure housing the necessary components to monitor and control Þ re alarm notiÞ cation

appliances. The enclosure’s dimensions are as follows: 32” H x 14.5” W x 4” D. The lid adds about 0.5” to

each side.

1.2 System Components

The XR2400F FACP consists of the following components:

• One Model XR2400F Command Processor panel • One Model 893A Dual Phone Line module

• Two Model 866 Class B Style W NAC modules • One Model 630F PCB and membrane switch

• One Model 504-24 VDC Power Supply • One 28 VAC transformer, TF-0030

• One 16 VAC, 56 VA transformer • One Model 462N LX-Bus Expansion Card

• Two Model 305 Relays • One Metal Backplate

1.3 Power SpeciÞ cations

Command Processor:

Transformer Input of 16 VAC 56 VA

Standby battery of 12 VDC 28Ah (56 VA charges up to four 7.7Ah batteries)

Auxiliary power of 12 VDC at 1 Amp

NAC Output of 12 VDC at 1.5 Amp

All circuits are inherent Power Limited except red battery wires.

NAC Output:

24 VDC 4 Amps shared between NACs 1 and 2

1.4 Before you begin

Before installing the XR2400F, we recommend you read through the entire contents of this guide.

Familiarize yourself with the features of the panel and the key points to remember during the installation.

Be sure to read and understand all of the caution statements printed in bold italics.

1.5 About this Guide

The information in this guide is organized into Þ ve sections: Table of Contents, Introduction, Installation,

Compliance, and System Wiring Diagrams.

• The Table of Contents at the front lists the headings and subheadings used throughout each section of

the guide.

• The Introduction section gives you an overview of the XR2400F and this document.

• The Installation section begins with mounting instructions for the enclosure. Wiring diagrams for each

component also appear in this section.

• The Compliance section lists all UL listings the XR2400F currently follows.

• The System Wiring Diagrams provide illustrations of typical XR2400F systems.

1.6 How to use this Guide

To locate information about the installation of the XR2400F, go to the Table of Contents at the front of

this guide. Find the subject heading that best describes the information you need and turn to the section

number shown to the right of the heading. If you cannot Þ nd the information you need under that heading,

scan through a few of the headings and read the text under those that sound similar.

Digital Monitoring Products XR2400F Installation Guide

2

INSTALLATION

Mounting

2.1 Mounting the Enclosure

The XR2400F must be mounted in a secure, dry

location to protect the unit from damage due

to tampering and the elements. The enclosure

can be either ß ush mounted or surface mounted

and includes a hinged door with lock. The hole

in the enclosure door allows access to the Fire

Command Center without opening the door.

Figure 1 illustrates the mounting hole locations

for the panel’s enclosure.

The enclosure’s dimensions are 32” tall, 14.5”

wide, by 4” deep. The lid adds about 0.5” to

each side.

2.2 Surface Mounting

The center hole of the enclosure should

be attached to a stud in the wall. Due to

the weight of the enclosure, especially the

batteries, it is extremely important to mount

the enclosure on the stud. Attach the two holes

beside the center hole to sheetrock to secure

enclosure. When mounting the enclosure,

be sure to leave room for the panel door to

swing open. The door’s lock should be easily

accessible.

2.3 Flush Mounting

The enclosure can also be ß ush mounted. Use

1” screws to secure the enclosure between two

studs using the two sets of holes on the sides of

the enclosure. Use the top and bottom holes to

secure to horizontal studs, if necessary.

2.4 Fire Command Center LCD Keyboard

A Fire Command Center LCD Keyboard has been

factory installed on the XR2400F enclosure.

Also, a keyswitch has been installed and pre-

wired to the left of the keyboard. The user can

turn the keyswitch to enable the four functions

keys without opening the enclosure door.

2.5 Metal Backplate

The XR2400F components are pre-wired and

installed on a metal backplate. The backplate

can easily be removed to keep components safe

during pre-wire activities.

To remove the backplate, disconnect the wires to the batteries, transformers, and the Fire Command Center

LCD keyboard. Also remove the AC wires from the 504-24 power supply. From the panel, disconnect the AC

wires from terminals 1 and 2. Disconnect the battery wires either from the batteries or the panel terminals

3 and 4. Finally, disconnect the keyboard wires from panel terminals 7, 8, 9, and 10.

Remove the screws securing the backplate to the enclosure. Then loosen the two top screws that the

backplate hangs on. After the screws are removed and loosened, lift the backplate up slightly and pull the

backplate toward you. When reinstalling the backplate, be sure all connections are secure.

Refer to Figure 2 for an illustration of the backplate and the components. The backplate is shown in light

gray.

3/4" X 1/2" Knockouts

Hole for Flush

Mounting

Holes for Surface Mounting

Holes for 1" screws for

Flush Mounting

Battery Shelf

Hole for Flush Mounting

Additional Holes for Surface Mounting

Figure 1: Mounting the XR2400F Enclosure

XR2400F Installation Guide Digital Monitoring Products

3

INSTALLATION

2.6 Wiring Diagram

The XR2400F system below shows the layout of the components. The wires shown in this guide have been

factory installed and connected. The dashed lines represent wires that run underneath a component.

Detailed wiring diagrams for each supplied component appear in following sections of this guide.

AC +B BELL GND SMK GND

RED YEL GRN BLK Z1 Z2 Z3 Z4 Z5 Z6 Z7 Z8 Z9+ Z9- Z10+ Z10-

AC -B GND GND GND

GND

XR2400F Command Processor™

Panel

See LT-0554, XR2400F Command Processor™

Panel section for complete XR2400F information.

J10

Output Header J2

462N LX-Bus Interface Card

J16

866

Module

#1

866

Module

#2

+-

+-

+

+-

Two 12 VDC batteries

connected in series with the

included Series Connecting

Strap. See Secondary

Power Supply section.

12 VDC

battery

12 VDC

battery

12 VDC battery

Two 12 VDC batteries

connected in parallel with a

Model 318 Dual Battery

Harness. See Secondary

Power Supply section.

504-24 Secondary Power Supply

1.5 Amps maximum charge current.

Use only 24 VDC rechargeable batteries

or Two DMP Model 367 12 VDC batteries

with a Series Connecting Strap.

Replace every 3 to 5 years.

XR2400F Secondary Power Supply

1.5 Amps maximum charge current.

Use only 12 VDC rechargeable batteries

DMP Model 367.

Replace every 3 to 5 years.

12 VDC battery

24 VDC

Circuit

Black

Red

To Fire Command Center on enclosure door

From XR2400F

panel to 12 VDC.

Black

Red

56 VA Transformer

charges 4 batteries

GREEN

WHITE

BLACK

GREEN

WHITE

BLACK

WHITE

BLACK

28 VAC

Transformer

+ DC -

+ Bat -

Red wire to positive

battery terminal. Black wire to negative

battery terminal.

AC

AC TRBL BATT TRBL

504-24

Power Supply

See LT-0554, 504-24 Power

Supply section for complete

504-24 information.

893A

P10

To Tel c o S

To Notification

Appliances

S

S

S

S

S= Supervised Wire

S

S

S

Battery

Compartment

From 504-24 Power Supply to 24 VDC.

1K EOL

1K EOL

16 VAC

Transformer

Figure 2: XR2400F System

Digital Monitoring Products XR2400F Installation Guide

4

INSTALLATION

AC Connection

3.1 Transformers and AC Power Connection

The AC connection should be completed by a licensed electrician.

Never share the Fire Alarm Control Panel circuit with any other equipment.

The XR2400F comes supplied with two transformers: the 16 VAC 56 VA transformer and the 28 VAC 175 VA

transformer. The 28 VAC and the 16 VAC transformers’ white leads and black leads must be connected

together respectively. These wires must be connected to an unswitched 120 VAC 60 Hz power source with at

least 1.85 Amps of available current.

Black wire - attach the black 120 VAC wire to the black wire of the transformers.

White wire - attach the white 120 VAC wire to the white wire of the transformers.

Green wire - attach the green wire lead to the green wire attached to the enclosure.

S

S

56 VA Transformer

charges 4 batteries.

GREEN

WHITE

BLACK

GREEN

WHITE

BLACK

WHITE

BLACK

28 VAC

Transformer

To XR2400F Panel

Violet

Terminal 1

Gray

Terminal 2

Yellow

Blue

To Model 504-24

AC Terminals

16 VAC

56 VA

Transformer

L-Bracket

Bracket

Nut

Bracket

Nut

Figure 3: Transformers and AC Power Connection

Always ground the panel before applying power to any devices! Use 18 AWG or larger for all power

connections. The XR2400F must be properly grounded before connecting any devices or applying power

to the panel. Proper grounding protects against Electrostatic Discharge (ESD) that can damage system

components.

3.2 28 VAC Transformer

The 28 VAC Transformer supplies power to the AC terminals of the 504-24 Power Supply which is factory pre-

wired to the two 866 NAC modules. The 28 VAC is located in the upper right hand corner of the enclosure

surrounded by a metal divider. See Figure 3 above and the 504-24 Power Supply section.

3.3 16 VAC Transformer

The 16 VAC 56 VA transformer supplies power to the XR2400F panel and is factory pre-wired. See Figure 3:

Transformers and AC Power Connection. Also refer to Figure 11: XR2400F Panel Wiring Diagram.

3.4 Earth Ground from the XR2400F Panel

Terminal 4 of the XR2400F panel must be connected to earth ground using 14 gauge or larger wire to provide

proper transient suppression. DMP recommends connecting to a cold water pipe or ground rod only. Do not

connect to an electrical ground or conduit, sprinkler or gas pipes, or to a telephone company ground.

XR2400F Installation Guide Digital Monitoring Products

5

INSTALLATION

Secondary Power Supply

4.1 Description

The XR2400F system includes pre-wired cables for connecting a 24 VDC battery to the 504-24 power supply

and a 12 VDC battery to the XR2400F panel. For 24 VDC battery operation to the 504-24, connect two 12

VDC sealed lead-acid batteries in series using the included series connecting strap. See Figure 4. Observe

polarity when connecting all batteries.

Use sealed lead-acid batteries only. Use the DMP Model 367, 12 VDC 7.7Ah sealed lead-acid rechargeable

battery. Batteries supplied by DMP or manufactured by Eagle Picher or Yuasa have been tested to ensure

proper charging with DMP products.

Gel cell batteries cannot be used with the XR2400F panel.

4.2 Battery Connection to XR2400F Command Processor panel

For 12 VDC battery operation to the XR2400F, connect the black battery lead to the negative terminal of the

battery. The black battery wire is connected to terminal 4 of the XR2400F panel.

Connect the red battery lead to the positive terminal of the battery. The red battery wire is connected to

terminal 3 of the XR2400F panel. See Figure 11 and Figure 2.

You can add a second battery in parallel using the DMP Model 318 Dual Battery Harness. When wiring two

batteries with the Model 318 Dual Battery Harness, plug the red male end of the Dual Battery Harness into

the red female battery lead from the panel. Plug the black male end of the Dual Battery Harness into the

black female battery lead from the panel. Attach both female leads from the Dual Wiring Harness to the

two batteries as described above. See Table 3: Battery Calculations.

4.3 Battery Connection to the 504-24 Power Supply

The 504-24 is powered by 24 VDC. After connecting two 12 VDC batteries together using the series

connecting strap (or after installing one 24 VDC battery) connect the black battery wire to the negative

terminal of the 24 VDC battery. The black battery wire is connected to the negative AC terminal of the 504-

24.

Connect the red battery wire to the positive terminal of the 24 VDC battery. The red battery wire is

connected to the positive AC terminal of the 504-24.

12 VDC

Battery

RED

BLACK

Series

Connecting

Strap

12 VDC

Battery

Figure 4: 24 VDC Battery Wiring

See Figure 9 and Figure 2. Also see the Battery Information section.

Digital Monitoring Products XR2400F Installation Guide

6

INSTALLATION

Two 866 NAC Modules

5.1 Description

Each 866 provides one style W indicating circuit for supervising UL polarized notiÞ cation appliances, such as

bells, strobes, and horns. See Table 1: NotiÞ cation Appliances for a list of approved notiÞ cation appliances.

5.2 Connection

Each 866 module is pre-installed on the removable backplate using the standard three-hole conÞ guration.

The modules are factory pre-wired to each other, the 504-24, and the XR2400F panel. Refer to the Þ gure

below and to Figure 2: XR2400F System for wiring connections.

You can connect 24 VDC NotiÞ cation Appliances to terminals 5 and 6 of each module. Each module provides

a zone of notiÞ cation and can be activated separately.

1 AUX PWR

2 GND

3 Alarm In

4 Bell PWR In

5 Bell Out +

6 Bell Out -

7 Bell Trouble

8 Bell Trouble

866

Module #1

Normal/Silence Switch

1 AUX PWR

2 GND

3 Alarm In

4 Bell PWR In

5 Bell Out +

6 Bell Out -

7 Bell Trouble

8 Bell Trouble

866

Module #1

Normal/Silence Switch

To XR2400F Output #1 (J2 pin #2)

To XR2400F terminal 13 (Zone 1)

To XR2400F terminal 7

To 504-24 DC -

To XR2400F Output #2 (J2 pin #5)

To 504-24 DC +

To XR2400F terminal 15 (Zone 2)

To 504-24 BATT TRBL C (Common)

10K EOL

DMP Model 308

UL Listed,

Polarized

Notification

Appliances

See Table 1:

Notification

Appliances

24 VDC

10K EOL

DMP Model 308

UL Listed,

Polarized

Notification

Appliances

See Table 1:

Notification

Appliances

24 VDC

Pre-installed 1K EOL

Pre-installed 1K EOL

Figure 5: 866 Modules Wiring

5.3 Bell Silence/Bell Trouble

A bell silence switch on the 866 module is provided to prevent sounding of the indicating devices when

testing the system. When the Silence position is selected, a 15-second delay occurs before the 866 bell

trouble contacts (terminals 7 and 8) open. Select the Normal position after testing to return the 866

module to normal operation.

XR2400F Installation Guide Digital Monitoring Products

7

INSTALLATION

5.4 NotiÞ cation Appliances

The following table indicates the approved notiÞ cation appliances that can be used with the XR2400F

system.

DMP Model Description

802 12/24 VDC Multi-Tone Horn

802WP-75W 24 VDC Weatherproof Multi-Tone Horn

803 12/24 VDC Standard Horn

850S Single Action Dry Contact Pull Station

850D Dual Action Dry Contact Pull Station

806-6 12 VDC 6-Inch Bell

806-10 12 VDC 10-Inch Bell

821 12 VDC Strobe

822 12 VDC Strobe with RetroÞ t Plate

823 12 VDC Horn Strobe

831 12/24 VDC Single Circuit Sync Module

832 12/24 VDC Dual Circuit Sync Module

901 24 VDC Mini Horn

904 24 VDC Horn

904WP 24 VDC Weatherproof Horn

906-6 24 VDC 6-Inch Bell

906-10 24 VDC 10-Inch Bell

921-MCW 24 VDC Multi-Candela Strobe

922-MCW 24 VDC Multi-Candela Strobe with RetroÞ t Plate

923-MCW 24 VDC Multi-Candela Horn Strobe

924-MCW 24 VDC Multi-Candela Audible Strobe

924WP-75W 24 VDC Weatherproof Audible Strobe

Table 1: NotiÞ cation Appliances

Digital Monitoring Products XR2400F Installation Guide

8

INSTALLATION

462N LX-Bus™ Expansion Card

6.1 Description

The 462N LX-Bus™ Expansion Card provides an additional 100 zones to the XR2400F.

6.2 LX-Bus™ Expansion Capability

The 462N card provides a 4-wire LX-Bus™ that allows you to connect up to 100 Model 521LX or 521LXT

Addressable Smoke Detectors. Also the LX-Bus™ could connect up to 25 Model 714, 715, and 725 Zone

Expanders or 716 Output Expanders, up to six Model 714-16 or 715-6 Zone Expanders, and up to 100 Model

711 and 711E Zone Expanders. Power for the devices is provided through the Black and Red wires of the

expansion harness.

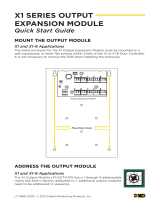

6.3 Installing the 462N Module

1. Remove AC and battery power from the XR2400F panel before installing the 462N card.

2. Align the 50 pin connector of the 462N with the J6 connector on the XR2400F panel.

3. Press the 462N onto the J6 connector while applying even pressure to both sides.

XR2400F Panel

J6 Expansion

Connector

462N Network

Interface Card

Configuration

Jumpers

B

Red - Aux. Positive Red

Y

ellow - Serial Data In Yellow

Green - Serial Data Out Green

Black - Aux. Common Black

To LX-Bus Modules

LX-Bus

Connector

Figure 6: 462N Wiring

XR2400F Installation Guide Digital Monitoring Products

9

INSTALLATION

Telephone RJ Connector

7.1 Description

Connect the XR2400F system to two lines of the public telephone network by installing two DMP 356 RJ

Cables between the RJ31X or RJ38X phone jacks, and the 893’s J4 connector (for main line) and J5 (for

backup line). Set the 3-pin headers on the XR2400F labeled J11 and J12 to DD for digital dialer, Contact ID,

or Modem IIe operation. See 893A Dual Phone Line Module.

Figure 7: Phone Jack Wiring

To Telephone

Line

RJ31X or RJ38X

Phone Block

8

7

6

54

3

2

1

Ring Tip

To Premise

Phone

Ring 1 Tip 1

7.2 FCC registration

The Model XR200/XR2400F complies with FCC part 68 and is registered with the FCC. Registration number:

CCKUSA-18660-AL-R / Ringer Equivalence: 1.1B

7.3 NotiÞ cation

Registered terminal equipment must not be repaired by the user. In case of trouble, the device must be

immediately unplugged from the telephone jack. The factory warranty provides for repairs. Registered

terminal equipment may not be used on party lines or in connection with coin telephones. No tiÞ cation must

be given to the telephone company of:

a. The particular line(s) the service is connected to (the speciÞ c phone line)

b. The FCC registration number (CCKUSA-18660-AL-R)

c. The ringer equivalence (1.1B)

d. The make, model, and serial number (see the serial # sticker on the panel) of the device

7.4 Ground start

Ground start phone service cannot be used on commercial or residential Þ re applications.

Digital Monitoring Products XR2400F Installation Guide

10

INSTALLATION

893A Dual Phone Line Module

8.1 Description

The 893A is a dual telephone line supervision module that allows the panel to indicate a phone line failure

to the premises and the central monitoring station. After the 893A senses a failure on the main line, it

switches to the backup, or secondary, phone line. The 893A is installed on the removable backplate above

the XR2400F circuit board.

8.2 Connection

The 893A connects the panel to the public telephone network by installing a DMP 356 RJ Cable between the

XR2400F panel’s J3 connector and the 893’s J3 connector labeled PANEL. The two communication jumpers

must be set to either DD or MPX.

J2 DD

MPX

J1

DD

MPX

J3

PANEL

J4

MAIN

J5

BACKUP

P10

Factory pre-wired

to XR2400F panel

Phone Jack

Connector, J3

To Primary

telephone line

To Secondary telephone line

Communication Jumpers: Both

Jumpers must be set

Processor

Stopped Buzzer

Factory pre-wired

to XR2400F panel

J10 Connector

893A Dual Telephone Line Module

Figure 8: 893A Dual Phone Line Module Wiring

8.3 Jumper Settings

There are two sets of jumpers on the 893A module. When setting the module for either DD (digital dialer) or

MPX (multiplex), both jumpers must be set.

8.4 Digital Dialer/Multiplex

You can conÞ gure the 893A to provide two lines of digital dialer or one line of multiplex with digital dialer

backup. For multiplex operation both jumpers (J1 and J2) must be set to MPX. Also, jumpers J11 and J12 on

the panel must be set to MPX. See XR2400F Command Processor Panel Connection. The XR2400F is preset

at the factory for Digital Dialer. The Main modular jack (J4) is used for the primary dialer or multiplex line.

The Backup modular jack (J5) is used for the secondary digital dialer line.

8.5 Phone Line Monitor

The 893A uses a phone line monitor for the main and backup phone lines. When sending a report, the 893A

veriÞ es the main phone line is working before sending. If the line is bad, the module tests the backup phone

line. The 893A sends the report on the Þ rst working phone line.

The phone line monitor has a 2-minute trouble delay and a 1-minute restore delay. Phone line trouble is

displayed in the Fire Command Center LCD Status List as a System Trouble. The Fire Command Center LCD is

factory programmed to display system troubles in the Status List.

8.6 Processor Fail Buzzer

The 893A module also monitors the panel’s CPU and sounds a trouble buzzer whenever either the panel’s

processor is reset using J16 or the processor stops functioning.

XR2400F Installation Guide Digital Monitoring Products

11

INSTALLATION

504-24 Power Supply

9.1 Description

The 504-24 is a power limited, switching power supply that meets UL, CSFM, NFPA, and FCC compliance

standards. Model 504-24 is rated for 24 VDC @ 4 Amps maximum and supplies power to the 866 Modules.

9.2 LED’s

The 504-24 has two status LED’s that show the current state of power. The green LED indicates low AC

input. The red LED indicates low standby battery power after AC has failed.

9.3 504-24 Condition Chart

Condition Voltage Levels LED Status Condition

AC Trouble Approx. 102 VAC AC LED (Green) On AC Good

Battery Trouble Below 23.6 VDC AC LED (Green) Off AC Bad

Battery Restoral Above 25.0 VDC DC LED (Red) On Battery Good

Battery Cutoff Below 20.4 VDC DC LED (Red) Off Battery Bad

Table 2: 504-24 Condition and LED Indicators

9.4 504-24 UL Listings

For UL 603 Power Supplies for Burglary Alarm Systems and UL 294 Power Supplies for Access Control System

applications: Voltage Range of 22.9 to 25.5 VDC.

For UL 1481 Power Supplies for Fire Protective Signaling the following maximum battery standby Ampere

hours apply for 24 hours of battery backup:

Battery Standby Maximum: 49.2Ah

Output Voltage: 24 VDC

Output Current: 1.5A standby, 4 Amp alarm

9.5 24 VDC NAC Standby Battery Calculations

The following calculation deÞ nes the total number of standby battery Amp-hours required to support

operation of the NACs and any other devices attached to the 504-24 power supply. From this calculation,

assemble the appropriate number of batteries that will just exceed the calculated total Amp-hour

requirement. The 866 NACs receive power for internal operation from the XR2400F panel and do not enter

in this calculation themselves.

1. Add all standby current values including the power supply operating current.

2. Multiply the total standby current by the number of standby hours needed.

3. Add all alarm current values from the notiÞ cation appliances attached to the 866 NACs and multiply by

0.25.

4. Add the total alarm mA-hour with the total standby mA-hour and then multiply this number by 0.001.

Power Supply Operating Current 200 mA

Other Standby Current + ______ mA

1. Total Standby Current + ______ mA

Number of Standby Hours Required X ______ hr

2. Total Standby (mA-hr) Required = ______ mA-hr

3. Total Alarm Current = ______ mA

Total Alarm Current X 0.25 = ______ mA-hr

(0.25 = 5 minutes in alarm)

Total Standby (Required) + ______ mA-hr

Total = ______ mA-hr

X 0.001

4. Total Required Amp-hours = ______

Table 3: Battery Calculations

Digital Monitoring Products XR2400F Installation Guide

12

INSTALLATION

9.6 Connection

The 24 VDC power supply is completely pre-wired. Refer to the following 504-24 wiring diagram for speciÞ c

wire connections.

+ DC -

+ Bat -

Red wire to positive

battery terminal.

Black wire to negative

battery terminal.

AC

AC TRBL BATT TRBL

504-24 Power Supply To XR2400F Panel

terminal 10 (BLK)

To 866 Module #2

terminal 2 (GND)

To 866 Module #2

terminal 4 (Bell PWR In)

NC C NO NC C NO

To 866 Module #2

terminal 8 (BELL TRBL)

To XR2400F Panel

terminal 18 (Zone 4)

To XR2400F Panel

terminal 16 (Zone 3)

Both wires to

28 VAC

Transformer

AC

Green

LED

DC

Red

LED

Yellow

Blue

Green

Green

Black

Black

Red

Black

Black

White/Red

Figure 9: 504-24 Wiring

Interconnect Wiring Harness

10.1 Interconnect Harness

This chart explains the colors of the wires on the Interconnect Wiring Harnesses. It also explains what each

wire connects.

Wire Color Connection From Connection To

Red Panel Terminal 7 (DC Power) 866 Module #2 Terminal 1 (Auxiliary Power)

Black Panel Terminal 10 (Common) 504-24 DC - Negative DC Terminal (Ground)

Brown Panel Terminal 13 (Zone 1) 866 Module #1 Terminal 7 (Bell Trouble)

Violet Panel Terminal 15 (Zone 2) 866 Module #2 Terminal 7 (Bell Trouble)

Green Panel Terminal 16 (Zone 3) 504-24 Battery Trouble Terminal N/O

White Panel Terminal 18 (Zone 4) 504-24 AC Trouble Terminal N/C

Blue Panel J2 Pin 2 (Common) 866 Module #1 Terminal 3 (Alarm In)

Orange Panel J2 Pin 3 (Output 1 N/O) Panel Terminal 5 (Bell Output)

Yellow Panel J2 Pin 5 (Common) 866 Module #2 Terminal 3 (Alarm In)

Orange Panel J2 Pin 6 (Output 2 N/O) Panel Terminal 5 (Bell Output)

White/Red 504-24 DC + (Positive DC Terminal) 866 Module #2 Terminal 4 (Bell Power In)

Black 504-24 DC - (Negative DC Terminal) 866 Module #2 Terminal 2 (Ground)

Red 866 Module #2 Terminal 1 (Auxiliary Power) 866 Module #1 Terminal 1 (Auxiliary Power)

Black 866 Module #2 Terminal 2 (Ground) 866 Module #1 Terminal 2 (Ground)

Black 866 Module #2 Terminal 2 (Ground) 866 Module #1 Terminal 8 (Bell Trouble)

White/Red 866 Module #2 Terminal 4 (Bell Power In) 866 Module #1 Terminal 4 (Bell Power In)

Black 866 Module #2 Terminal 8 (Bell Trouble) 504-24 Battery Trouble Common Terminal

Black 866 Module #2 Terminal 8 (Bell Trouble) 866 Module #1 Terminal 8 (Bell Trouble)

Table 4: Interconnect Wiring Harness

/