Page is loading ...

PEXa PLUMBING DESIGN AND INSTALLATION GUIDE

RAUPEX

®

UV Shield Pipe and EVERLOC+

®

Compression-sleeve Fittings

1. Scope 3

2. System Overview 4

2.1 Application 4

2.2StandardsandCertications 4

2.3Specication 5

2.4Warranty 5

2.5DesignServices 5

3. RAUPEX PEXa Pipe 6

3.1 Pipe Properties 6

3.2PipeDimensionsandWeights 6

3.3PipeMarkings 7

3.4PressureandTemperatureRatings 7

3.5ExcessiveTemperatureandPressureCapability 7

3.6CorrosionResistance 8

3.7ChlorineResistance 8

3.8UltravioletResistance 8

3.9BendRadius 9

3.10ChemicalCompatibility 9

3.11FreezeBreakResistance 9

3.12 Condensation 9

3.13 Pressure Loss 9

4. EVERLOC+ Compression-sleeve Fittings 10

4.1FittingScope 10

4.2FittingAssembly 12

4.3 Installation Considerations 12

4.4EVERLOC+Compression-sleeveTools 15

CONTENTS

Forupdatestothispublicationandthemostcurrenttechnicalinstructions,safetyinformationandmanufacturer’srecommendations,visitwww.na.rehau.com/resourcecenter

5. Design Considerations 17

5.1PipeSizing 17

5.2EquivalentLengthofFittings 18

5.3PipingLayouts 19

5.4ThermalExpansionandContraction 20

5.5InstallationinFire-ratedAssemblies 22

5.6OverheadInstallations 25

5.7WaterQuality 25

5.8HotWaterRecirculation 26

5.9WaterHammer 26

6. Installation Considerations 27

6.1LocalCodeApprovals 27

6.2Packaging,Transport,HandlingandStorage 27

6.3UncoilingPipe 27

6.4BendingPipe 27

6.5DistanceBetweenFittings 28

6.6PipeProtection 28

6.7Insulation 29

6.8InstallationBelow-grade,in-slab 29

6.9FixtureConnectionCommonComponents 29

6.10WaterHeaterConnections 30

6.11SupportingRAUPEXPipe 31

6.12SupportingEVERLOC+Fittings 31

6.13CopperSoldering 31

6.14KinkRepair 32

6.15ThawingFrozenPipe 32

6.16Disinfection 32

6.17PressureTesting 33

2

This technical information applies to the REHAU PEXa

plumbing system and specically the assembly and use of the

EVERLOC+

®

compression-sleeve system with RAUPEX

®

UV shield pipe (PEXa pipe) intended for use in hot- and cold-

water potable distribution systems.

Forprofessionaluseonly.Personsusingthisguidemustbeexperi-

encedandappropriatelylicensedcontractors,whohaveanunder-

standingoftheprinciplesandpracticesfortheinstallationofhot-and

cold-waterpotabledistributionsystems.

Theinformationpresentedinthisguideisintendedtodemonstratethe

properassemblymethodandinstallationrecommendationsforthe

REHAUPEXaplumbingsystem.Itistheresponsibilityofthelicensed

contractortochecktheprevailinglocalcodesandtoverifythat

technicalinformationpresentedinthisguideisappropriatefora

particular installation.

Nothinginthisguidesupersedesnationalorlocalcoderequirements

ortherecommendationsofothermanufacturersregardingtheir

components.Observeallapplicablenational,stateandlocallaws,

regulations,standards,codesandordinances.IfyoubelieveREHAU

productinformationconictswithapplicablecoderequirements,

industrystandards,ortherecommendationsofothermanufacturers

regardingtheircomponents,contacttheREHAUdistributorinyour

areaandconsultwiththebuildingauthorityhavingjurisdictionbefore

installingtheREHAUPEXaplumbingsystem.

Beforestartingtheinstallationprocess,readtheREHAUPEXa Limited

Warranty,availableatwww.na.rehau.com/warranties.Itcanalsobe

obtainedfromyourauthorizedREHAUdistributororbywritingto

REHAUConstructionLLC,1501EdwardsFerryRoadNE,LeesburgVA

20176US.

Properinstallationistheresponsibilityoftheinstallingcontractor.

ReviewtheREHAUTechnical Guidelinespriortoinstallationofthe

REHAUPEXaplumbingsystem.REHAUTechnical Guidelines are

denedintheREHAUPEXa Limited Warranty as:Themostcurrentand

applicableversionsofallthetechnicalliteratureavailableonthe

REHAUNorthAmericawebsiteatwww.na.rehau.com/resourcecenter,

including,butnotlimitedto,technicalmanuals,instructionguides,

technicalbulletins,submittalsandREHAUAcademytrainingpresenta-

tions.ChecktheREHAUResourceCenter(www.na.rehau.com/

resourcecenter)forthelatestupdates.

ContacttheREHAUdistributorinyourareaifyoudonotunderstand

theinformationinthismanualorifyouhavequestionsaboutthe

REHAUTechnical Guidelines.

Thisguidecontainssafety-relatedinformationthatrequiresyour

specialattention.Itisindicatedwiththesafetyalertsymbolandthe

signalwordsdescribedbelow:

DANGER

Indicatesahazardoussituationwhich,ifnot

avoided,willresultindeathorseriousinjury.

WARNING

Indicatesahazardoussituationwhich,ifnot

avoided,couldresultindeathorserious

injury.

CAUTION

Indicatesahazardoussituationwhich,ifnot

avoided,couldresultinminorormoderate

injury.

NOTICE

Indicatesariskofpropertydamage.

Onlytrainedpersonnelshouldbeengagedintheinstallationprocess.

FollowtheinstructionsinthisguideandotherREHAUTechnical

Guidelinesandusecommonsensetoreducetheriskofinjuryor

propertydamage.

WARNING

ReadtheinstructionmanualfortheEVERLOC+

compression-sleevetoolsbeforeuseandfollowall

safetyprecautions-improperusecancauseserious

personalinjury

WARNING

EVERLOC+compression-sleevetoolsuseastrong

hydraulicforcetoexpandPEXapipeandcompress

componentsoftheREHAUEVERLOC+

compression-sleevesystem.

Toreducetheriskofcrushandlacerationinjury,

keepngers,handsandallpartsofyourbodyaway

fromtheexpanderhead,hydraulicslideand

compressionjawsduringoperation.Removethe

batterybeforeattemptingtochangeoradjustthe

expanderheadorcompressionjaws.

EVERLOC

®

isaregisteredtrademarkofREHAU.DEWALT

®

andthe

DEWALTlogoaretrademarksofStanleyBlack&Decker,Inc.,oran

afliatethereofandareusedunderlicense.MAKITA

®

isatrademark

ofMakitaCorporation,oranafliatethereof.

1. SCOPE

3

2.1 Application

TheREHAUPEXaplumbingsystemincludesRAUPEXUVshieldPEXa

pipe,PEXacompressionsleevesandEVERLOC+polymerand

lead-freebrassttings.Thissystemisdesignedforpotable

applications.

TheEVERLOC+compression-sleevettingsystemisacold-expan-

sionPEXattingsystemthatisavailableinpolymerandlead-free(LF)

brassandisassembledwithaspeciallydesignedPEXacompression

sleeve.ThettingisdesignedspecicallyforusewithRAUPEXpipe

andcanonlybeassembledwiththeEVERLOC+compression-sleeve

tools.

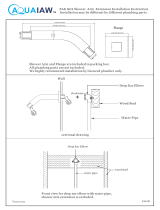

Fig. 2.1: RAUPEX UV shield crosslinked polyethylene (PEXa) pipe

Fig. 2.2: EVERLOC+ compression-sleeve fittings and sleeves

2. SYSTEM OVERVIEW

Fig. 2.3: EVERLOC+ compression-sleeve tools

2.2 Standards and Certications

ThegoverningmodelcodeswithintheUnitedStatesandCanada

denetherequiredstandardsforPEXpipingsystems.

IntheUS,themodelcodesthataretypicallyadoptedbylocal

jurisdictionsare:theInternationalCodes(Mechanical,Plumbingand

Residential)governedbytheInternationalCodeCouncil(ICC)orthe

UniformCodes(MechanicalandPlumbing)andtheNationalStandard

PlumbingCode,governedbytheInternationalAssociationofPlumbing

andMechanicalOfcials(IAPMO).

InCanada,themodelcodethatistypicallyadoptedbylocaljurisdic-

tionsistheNationalPlumbingCodeofCanada(NPCC)whichis

governedbytheNationalResearchCouncilofCanada(NRCC).

Withinthesemodelcodes,thestandardrequirementsforPEXpipe

andttingsareASTMF877orCSAB137.5.Thesestandardsdene

therequirementsandtestmethodsforPEXpipingsystems.

TheREHAUPEXaplumbingsystemisthird-partycertiedbyNSF

International(www.nsf.org)tothefollowingstandards:

-ASTMF876StandardSpecicationforCrosslinkedPolyethylene

(PEX)Tubing

-ASTMF877StandardSpecicationforCrosslinkedPolyethylene

(PEX)Hot-andCold-WaterDistributionSystems

-CSAB137.5CrosslinkedPolyethylene(PEX)TubingSystemsfor

Pressure Applications

-NSF/ANSI14PlasticPipingSystemComponentsandRelated

Materials

-NSF/ANSI61DrinkingWaterSystemComponentsandRelated

Materials

-NSF/ANSI372DrinkingWaterSystemComponents–LeadContent

(complieswiththelead-freerequirementsoftheU.S.SafeDrinking

Water Act)

4

2.3 Specication

REHAUprovidesarecommendedspecicationfordomesticwater

pipingandttings.Thisrecommendedspecicationisprovidedasa

guidefordevelopmentofthenalspecicationbyaarchitect,

engineer,orbuilder.Thearchitect/engineer/buildershallberespon-

sibletoconvertthisrecommendedspecicationintoanalspecica-

tionthatmeetsthefunctionalneedsoftheclient,aswellastocomply

withallapplicablebuilding,plumbing,andmechanicalcodes.

Specicationsareavailableatwww.na.rehau.com/resourcecenter.

2.4 Warranty

RAUPEXUVshieldpipeandEVERLOC+compression-sleevettings

andsleevesarebackedbya25-yearlimitedwarranty.EVERLOC+

compression-sleevetoolsarebackedbya2-yearlimitedwarranty.

REHAUoffersthiswarrantywhentheinstallationiscarriedoutin

accordancewiththerequirementsoutlinedintheREHAUPEXa

Warranty 855.018

,whichisavailableasaseparatedocumentat

www.na.rehau.com/warranties.Pleasereadwarrantypriorto

installation.

2.5 Design Services

REHAUDesignServicescanprovidecustomerswithadetailed

submittalpackagetosupporttheinstallationoftheREHAUPEXa

plumbingsystem.

REHAUPlumbingDesignServicesinclude:

-BIMlibraryofplumbingsystemcomponents

-Productsubmittals

-Projectbillofmaterials

-Supportofpipelayoutbasedontheprojectengineer’sapproved

plumbingpipingdesign

2.5.1 Building Information Modeling Library

TheREHAUBIMLibraryoffersadirectoryofdrawingsthatareeasyto

downloadintoanactivedesign.BIMlesofferefcienciestoproject

ownersthrougheaseofcollaboration.TheREHAUBIMlibraryoffers

modelsofcoreproductsincludingpipe,ttings,manifoldsand

installation accessories.

2.5.2 LoopCAD

®

Software

REHAUPlumbingCADcreatesprofessionalpipelayoutdrawingsand

billofmaterialsfortheREHAUPEXaplumbingsystem.

5

3. RAUPEX PEXa PIPE

3.1 Pipe Properties

Crosslinkedpolyethyleneispolyethylene(PE)whichhasundergonea

changeinmolecularstructurewherebythepolymerchainsare

chemicallylinked,crosslinked(X),witheachothertoformathree-

dimensionalnetwork.Theresultisaexiblethermosetpolymerwith

improvedmechanical,thermalandchemicalproperties.

TherearethreemethodsofmanufacturingPEX:

-Theperoxidemethod(PEXa),ASTMrequiresaminimumof70%

crosslinkedPEmolecules

-Thesilanemethod(PEXb),ASTMrequiresaminimumof65%

crosslinkedPEmolecules

-Theradiationmethod(PEXc),ASTMrequiresaminimumof65%

crosslinkedPEmolecules

RAUPEXpipeismanufacturedusingtheperoxidemethod(PEXa),

whichyieldsthehighest,mostconsistentlevelofcrosslinking.PEXa

technologyenhancesexibilityandthermalmemory,providingeaseof

handlingandkinkrepaircomparedtoPEXbandPEXc.

PEXahasdistinctadvantagesovermetalandotherpolymerpipes:

-Resistspittingandstresscorrosion

-Resistsscalinganddepositbuild-upwhenusedwithbothhardand

softenedwater

-Minimizesnoisethatistransmittedthroughpipes

-Resistsnotchingandabrasiondamage

RAUPEXismanufacturedbyREHAUinafacilitywhosequality

managementsystemisISO9001certied.Inaddition,RAUPEX

productionisindependentlymonitoredannuallyNSFInternational,

CSAInternationalandUnderwritersLaboratoriesInc.(UL).

Table 3.1: RAUPEX Properties

Specication English SI Standard

Minimum

Density

58lb/ft

3

926kg/m

3

ASTMF876

Minimum

Degreeof

Crosslinkling

70% 70% ASTMF876

MaxThermal

Conductivity

2.84Btuin/(ft

2

˚F•hr) 0.41W/(m˚K) DIN16892

Coefcientof

Linear

Expansion

9.33x10-4in/ft˚F

@68˚F

1.33x10-3in/ft˚F

@212˚F

0.14mm/(m˚C)

@20˚C

0.2mm/(m˚C)

@100˚C

Mean @

20-70˚CperDIN

16892

Modulusof

Elasticity

87,000-130,500psi

@68˚F

43,500-58,000psi

@176˚F

600-900N/mm

2

@20˚C

300-400N/mm

2

@80˚C

Minimum@

20˚CperDIN

16892

Specication English SI Standard

Tensile

Strength

4194-4355psi

@68˚F

2610-2900psi

@176˚F

perASTMD638

26-30N/mm

2

@20˚C

18-20N/mm

2

@80˚C

perASTMD638

--

IZODImpact

Resistance

No Break No Break --

Roughness

e=0.00028in. e=0.007mm --

Temperature

WorkingRange

-40to200˚F -40to93˚C --

Maximum

Short-term

Exposure

150psig@210˚F

(48hr)

1035kPa@99˚C

(48hr)

ASTMF876

UVResistance SeeTB218 ASTM2657

3.2 Pipe Dimensions and Weights

RAUPEXpipeisavailableinnominalsizesrangingfrom3/8to2in.

RAUPEXisinaccordancetothedimensionalstandardsdenedin

ASTMF876.RAUPEXiscoppertubesize(CTS)outsidediameter

(OD),whichmeansthattheactualODofthepipeis1/8in(3.18mm)

largerthanthenominalsize.

Wallthicknessisdenedbythestandarddimensionalratio(SDR).

RAUPEXUVshieldpipeisSDR9,whichequatestotheoutside

diameterbeingapproximatelyninetimesthewallthickness.

Table 3.2: RAUPEX Dimensions and Weights

Pipe Size Average OD

in (mm)

Min Wall Thickness

in (mm)

Weight

lb/ft (kg/m)

3/8in 0.500(12.70) 0.070(1.78) 0.04(0.07)

1/2in 0.625(15.88) 0.070(1.78) 0.06(0.08)

5/8in 0.750(19.50) 0.083(2.12) 0.08(0.11)

3/4in 0.875(22.22) 0.097(2.47) 0.10(0.15)

1 in 1.125(28.58) 0.125(3.18) 0.17(0.26)

11/4in 1.375(34.92) 0.153(3.88) 0.25(0.37)

11/2in 1.625(41.28) 0.181(4.59) 0.35(0.52)

2 in 2.125(53.98) 0.236(6.00) 0.60(0.90)

6

3.3 Pipe Markings

RAUPEXpipemarkingsarerepeatedevery3ft(0.9m),listall

certicationsandapprovals,andincludeanincrementalfootage

markingtoassistwithinstallation.

3.3.1 PEX Designation Code

RAUPEXpipeisfurtheridentiedwithaPEXMaterialDesignation

codeinaccordancetoASTMF876.ThePEXDesignationCodeisthe

abbreviationforthematerial-PEX-followedbyfournumerals.

The PEX Designation Code for RAUPEX UV shield pipe is

PEX 3306

Therstnumeral(3)referstothechlorineresistanceinoneoffour

categories,whentestedinaccordancewithASTMTestMethodF2023

andevaluatedinaccordancewithASTMF876.Thismeasurement

indicatestheallowablehoursof140°Fwaterrecirculationin1day.

0 = none

1 = 4 hours

e.g., 25% of lifetime

3 = 12 hours

e.g., 50% of lifetime

5 = 24 hours

e.g., 100% of lifetime

Thesecondnumeral(3)referstoUVresistanceinoneoffour

categories,whentestedinaccordancewithASTMTestMethodF2657

andevaluatedinaccordancewithASTMF876.Themeasurement

indicatestheallowabletimepipecanbeexposedtoUVwithoutbeing

compromised.

0 = none 1 = 1 month 2 = 3 months 3 = 6 months

Thethirdandfourthnumerals(06)refertotheHydrostaticDesign

Stressforwaterat73°Finhundredsofpsi.Thestandardpressure

ratingat73°Fisderivedfromthismeasurement.

06 = 630 psi

3.4 Pressure and Temperature Ratings

ThemaximumtemperatureandpressureratingsoftheRAUPEX

plumbingsystemareinaccordancetoASTMF876,CSAB137.5and

PPITR-3.Thedesignershalldeterminetheactualconditionsand

applytheappropriateandadditionaldesignfactorsasrequiredforany

particularproject.

AccordingtotheREHAUPEXa Limited Warranty,theRAUPEXpipe

warrantyperiodisforoperatingconditionsatorbelow180°F(82.2°C)

inpermittedapplicationswhenthehandling,use,installationand

maintenancecontinuallycomplieswithallREHAUTechnical

Guidelines.

Table 3.3: RAUPEX UV Shield Pipe Pressure and Temperature Ratings

RAUPEX UV shield Pipe

Maximum Pressures and Temperatures Design Factors

160psi@73.4°F(1055kPa@23°C) 0.50(perASTMF876,CSAB137.5)

100psi@180°F(690kPa@82.2°C) 0.50(perASTMF876,CSAB137.5)

80psi@200°F(550kPa@93.3°C) 0.50(perASTMF876,CSAB137.5)

REHAUdenesElevated Temperature Applicationsasthosewith

operatingconditionsgreaterthan180°F(82.2°C).WhenRAUPEX

pipesareplannedtobeoperatedinconditionsgreaterthan180˚F

(82.2°C),thedesignermustsufcientlyconsiderthethermaland

oxidativestabilityperformanceofthepipingmaterialtoensurethe

PEXapipedesignwillmeetprojectserviceliferequirements.

For Elevated Temperature Applications,REHAUadvisesagainsttheuse

ofastressreductiondesignfactorthatlowerstheoperatingpressure

asitmaynotsufcientlyaccountforthermaloroxidativedegradation.

REHAUappliesaservicelifemethodologyforRAUPEXpipesdrawn

fromASTMF876,CSAB137.5,ISO9080andMiner'sruleaccording

toDIN13760todeterminethewarrantyperiod.RAUPEXpipesshould

alwaysbeoperatedatorbelowtheREHAUpublishedtemperatureand

pressureratings.

Whentheoperatingconditionsarelessthanorequalto180°F

(82.2°C),thenaccordingtotheREHAU PEXa Limited Warranty the

warrantyperiodforRAUPEXpipeis25years.WhenRAUPEXpipes

are operated in Elevated Temperature Applications,wherethe

operatingconditionsaregreaterthan180°F(82.2°C),contactREHAU

Engineeringtoverifyyouroperatingconditionscomplywiththe

requirementsintheREHAU PEXa Limited Warrantyforawarranty

periodof25years.

3.5 Excessive Temperature and Pressure Capability

Temperatureandpressure(T&P)reliefvalvesaresafetymechanisms

incasethesystemoverheats(mandatoryinhotwaterdistribution

systems).Thesevalvesactquicklytorelieveexcesstemperatureor

pressureifeitheroneoftheseconditionsisreached.Intheeventofa

waterheatingsystemfailureorT&Preliefvalvefailure,RAUPEXpipe

hasbeentestedtoaccommodateshort-termexposureconditionsof

210°F(99°C)at150psi(10bar)for48hours.

NOTICE

Failuretofollowpressureandtemperaturelimitsmaydamagethepipe

resultinginleaksandoperationalfailures,andwillnegateany

warrantyprovidedbyREHAUforRAUPEXpipes.Thedesignermust

incorporatepropercontrolsintothesystemtoensurethepressureand

temperaturecapabilityofthepipeisnotexceeded.

7

3.6 Corrosion Resistance

RAUPEXpipeisnon-reactiveanddisplaysexcellentcorrosion

resistance.Corrosionisaprocessthatrequireselectricallyconductive

materialsandoccursonmetals.PEXa,beingadielectric,doesnot

corrodelikemetalpipes.PEXaalsoresiststhebuildupofscalewhich

iscommonwithcopperpipe.

3.7 Chlorine Resistance

RAUPEXpipehasbeentestedinaccordancewithASTMF2023,

Standard Test Method for Evaluating the Oxidative Resistance of

Crosslinked Polyethylene (PEX) Tubing and Systems to Hot Chlorinated

Water asrequiredinASTMF876.RAUPEXpipeexceedstheminimum

extrapolatedtestlifetimeascertiedbyNSFandPPIforcoldwater

applications,intermittenthotwaterapplicationsandtimedhotwater

applications.

Basedonthistesting,whenusingRAUPEXUVshieldpipefor

plumbingapplicationswithoutcontinuoushotwaterrecirculation,the

followingwaterqualityconditionsmustbemet:

-ThepHofwateris7.0orhigher

-Theconcentrationoffreechlorineis4.0ppmorlower

-Watertemperatureis140°F(60°C)orlower

-Waterpressureis80psig(550kPa)orlower

-Oxidativereductionpotential(ORP)of825mVorlower

ThisrecommendationappliestoRAUPEXUVshieldplumbingpipesfor

coldwaterandintermittenthotwaterapplications(25%@140°F,

75%@73°F)andfortimedhotwaterrecirculationsystemsforupto

12hoursperday(50%@140°F,50%@73°F).TheASTMF876

standardincludesdesignationcodesfortheseapplicationswhichare

includedontheprintlineofRAUPEXpipes.

WhenusingRAUPEXUVshieldpipeforplumbingapplicationswith

continuoushotwaterrecirculation,thefollowingwaterquality

conditionsmustbemet:

-ThepHofthewateris7.9orhigher

-Theconcentrationoffreechlorineis2.4ppmorlower

-Watertemperatureis140°F(60°C)orlower

-Waterpressureis80psig(550kPa)orlower

-Oxidativereductionpotential(ORP)of750mVorlower

Iftheseconditionsarenotmet,itisnecessarytoincorporateatime

controlsothesystemoperatesatamaximum50%@140°Fand

50%@73°F.

Itshouldalsobenotedthatinrareandisolatedcases,othercharac-

teristicsofthemakeupofdrinkingwatercanimpactthelong-term

performanceofplumbingsystemcomponentsevenwhenthewater

qualitylevelsarewithinthepermissiblerangesetforthbythe

EPANational Primary Drinking Water RegulationsandtheGuidelines

for Canadian Drinking Water QualitybyHealthCanada.Thelicensed

installingcontractormusthavepracticalexperiencewithintheregion

ofintendeduse.Inaddition,consultationwiththelocalplumbing

authorityandlocalwaterauthorityregardingtheperformanceof

plumbingsystemcomponentsshouldoccurbeforetheselectionand

installationofsystemswithinthatspecicgeographicregion.

Therefore,thespecicapplicationshouldalsobetakenintoconsider-

ationwhendesigningandinstallingplumbingsystems.

3.8 Ultraviolet Resistance

Allpolymersaresusceptibletodamagefromexposuretothe

ultraviolet(UV)radiationinsunlight.PEXpipescanbedesignedto

protectagainstshort-termUVdamage,butaftersometime,UV

radiationwillreducethelifetimeofthepipe.Theextentofthe

reductiondependsonfactorssuchastemperature,pressureand

chlorinationlevelsinpotablewater.

REHAUhasperformedextensivetestingofRAUPEXpipesexposedto

naturalsunlight,leadingtothemaximumUVexposuretimesex-

pressedinaccumulateddays.Oncethepipesleavethemanufacturing

plant,anyexposuretoUV,includingtransportationandstoragebythe

wholesaler,ispartoftheaccumulatedexposuretime.

AlthoughASTMF876onlycategorizesupto6monthsofUVresis-

tance(MaterialDesignationCode=3306),REHAUhastestedand

certiedRAUPEXUVshieldpipeaccordingtoASTMF2657forthe

followingmaximumUVexposureperiod:

-RAUPEXred,whiteandblueUVshieldpipe:Maximumexposure

timeofoneyearaccumulated

RAUPEXpipesmustbekeptintheoriginalpackaginguntilthetimeof

installation.RAUPEXmustnotbestoredoutdoorsandisnotdesigned

forpermanentoutdoorexposure(withtheexceptionofnon-exposed

buriedapplications).ExcessiveUVexposurewillreducethelifetimeof

PEXapipe.

3.8.1 UV Emitted by Fluorescent Lamps

ASTMF2657wasestablishedtotesttotheworstcasescenariofor

UVexposurebytestingindirectsunlight.UVemittedbyuorescent

lampsisinsignicantwhencomparedtoUVpresentinsunlight.GE

Lightinghasstated“SolarUVisenormouslymorephotoactiveand

damagingthantheUVfromlinearuorescentlamps.SolarUV

includesUV-A,UV-BandUV-C.UV-AisnearUV,notveryenergetic

andisthebulkofUVemittedbyorescentlamps.”Therefore,when

8

REHAUPEXapipesareinstalledinthepresenceofuorescentlamps

theUVemittedbythoselampsshouldhavenoeffectonthelifetimeof

thepipes.Forexample,thereisnoconcernofUVdamageonREHAU

PEXapipesinstalledinaboilerroomwhereuorescentlampsare

present.

NOTICE

FailuretofollowmaximumUVexposurelimitsmaydamagethepipe

resultinginleaksandoperationalfailures,andwillnegateany

warrantyprovidedbyREHAUforRAUPEXpipes.

3.9 Bend Radius

RAUPEXpipemaybebent,evenwhencold.REHAUsupportbends

canassisttocreatetightbendswithoutkinking.Thetypicalbend

radiususedbytheinstalleris8XtheOD.Theminimumbendradiusis

5XtheODforcoldbends.Foranevensmallerbendradius,thepipe

maybeheatedwithaheatgunandbenttonolessthan3XtheOD.If

atighterbendradiusisrequired,thenthedesignershouldconsider

usingasmallerdiameterpipe.

Table 3.4: RAUPEX Bend Radius

Bend Radius in (mm)

Pipe Size Typical 8X OD Min. Cold 5X OD Min. Heated 3X OD

3/8in 4.0(102) 2.500(64) 1.500(38)

1/2in 5.0(127) 3.125(79) 1.875(48)

5/8in 6.0(152) 3.750(95) 2.250(57)

3/4in 7.0(178) 4.375(111) 2.625(67)

1 in 9.0(229) 5.625(143) 3.375(86)

11/4in 11.0(279) 6.875(175) 4.125(105)

11/2in 13.0(330) -- --

2 in

17.0(432) -- --

3.10 Chemical Compatibility

WhileRAUPEXpipesareresistanttomanychemicalsthatareusedin

typicalplumbingapplications,therearesomechemicalsthatmay

damagethepipe.

Chemicalsthatmaybedamaginginclude(butarenotlimitedto):

-Adhesives

-Oilorpetroleum-basedproducts

-Paints

-Solvents

-Oxidizingagents

-Disinfectants

-PVCglues

-Solventsandcements

Manyfactors,suchasexposuretime,temperature,pressureandother

operatingparameters,caninuencetheperformanceofapipethatis

exposedtoachemical.Todeterminetheimpactofaparticular

chemical,short-andlong-termpressuretestingmayberequired.In

somecases,apipemayberesistanttoshort-termexposuretothe

chemical,butnotresistanttocontinuousexposure.Eachchemical

mustbeevaluatedindividually.Itistheresponsibilityoftheinstalling

contractortoverifychemicalcompatibilityofanychemicalswhen

comingintocontactwiththepolymermaterial.

3.11 Freeze Break Resistance

TheexibilityoftheRAUPEXpipeallowsittoexpandaswaterfreezes

inthepipeaslongasthepipehasroomtoexpand.Whenthewater

thaws,thepipereturnstoitsoriginalshape.Ifthepipeisnotallowed

toexpand(e.g.,itisencasedinconcrete),itmayburst.

NOTICE

Designersandinstallersmusttakeprecautionstoensurethatpipesdo

notfreeze.Frozenpipesmayburstresultinginleaksandoperational

failures.

3.12 Condensation

Condensationoccursonpipeswhenthesurfacetemperatureislower

thanthedewpointoftheenvironment.Thisistypicallyaproblemfor

metalliccoldwaterpiping.PEXpipehasalowerthermalconductivity

(0.41W/m°K)thancopper(401W/m°K)resultinginlessheatlossto

thesurfaceandgreaterresistancetocondensationorsweating.

Insulationshouldbeappliedtopipingtohelppreventcondensation.

3.13 Pressure Loss

ThepressurelossinthePEXasystemdependsontheowrate,water

temperaturesandthepropertiesoftheuid.UsetheREHAU

LoopCAD

®

Softwarewhichincludesabuilt-incalculatortodetermine

pipepressurelossesforthegivenconditions.RefertotheREHAU

PEXa Piping Systems Pressure Loss Tablesfortheapplicablepressure

losstablepresentedattypicalowratesandwatertemperatures.The

pressurelossinPEXacarrierpipeisbasedontheapplicationofthe

D’Arcy-WeisbachequationanduidpropertiesfromASHRAE

Fundamentals.

9

4. EVERLOC+ COMPRESSION-SLEEVE FITTINGS

4.1 Fitting Scope

TheEVERLOC+compression-sleevesystemisacold-expansionPEXa

ttingsystemthatisavailableinpolymerandlead-free(LF)brassand

isassembledwithaspeciallydesignedPEXacompressionsleeve.The

ttingisdesignedspecicallyforusewithRAUPEXpipeandmust

onlybeassembledwiththeEVERLOC+compression-sleevetools.

EVERLOC+ttingsareavailablein3/8,1/2,5/8,3/4,1,11/4,11/2

and2in.sizesandareintendedforusewithRAUPEXSDR9copper

tubesize(CTS)pipemanufacturedinaccordancewithASTMF876

ForadetaileddescriptionoftheREHAUsystemcomponents,referto

theREHAUSustainable Building Technology Product Catalog

(855.312).

4.1.1 Fitting Features

EVERLOC+polymerandlead-free(LF)brassttingshavethe

followingfeatures:

1. Foursealingedges

2. Pipe stop

3. Fittingcollar

4. Tooljawbody

Fig. 4.1: EVERLOC+ fitting features

4.1.2 Fitting and Sleeve Markings

Allpolymerttingsincludethefollowingmarksforidentication

OR

Fig. 4.2: Fitting size marking (e.g., 3/4”)

Fig. 4.3: Batch code (e.g., production date)

AllLFbrassttingsaremarked"REHAU"

Allsleevesincludethefollowing

marksforidentication

-Sleevesize(e.g.,1/2")

-Batchcodeforproductiondate

Fig. 4.4: Sleeve markings

1

2

4

3

10

4.1.3 Polymer Fittings

EVERLOC+polymerttingsareavailableincouplings,tees,elbows,

multi-portteesandplugs.Allpolymerttingsareproducedfroma

polyphenylsulfone(PPSU)materialthatmeetstherequirementsof

NSF61forhealtheffectsofdrinkingwatersystemcomponentsand

complieswiththelead-freerequirementsoftheU.S.SafeDrinking

WaterAct.SeealsoREHAUTechnical Bulletin TB265 EVERLOC+

Polymer Fitting Material - PPSU.

Fig. 4.5: EVERLOC+ polymer fittings

4.1.4 Lead Free (LF) Brass Fittings

EVERLOC+LFbrassttingsareavailableascouplings,tees,elbows,

plugsandtransitionttingstoNPTthreadandcoppersolder

connections.AllmetalttingsareproducedfromECOBRASS

®

(UNS

69300orCW724R)thatmeetstherequirementsofNSF61for

healtheffectsofdrinkingwatersystemcomponentsandcomplies

withthelead-freerequirementsoftheU.S.SafeDrinkingWaterAct.

SeealsoREHAUTechnical Bulletin TB264 EVERLOC+ Lead-free Brass

Fitting Material.

Fig. 4.6: EVERLOC+ LF brass fittings

4.1.5 Metal Manifolds

Manifoldsare1in.TypeLcopperwithEVERLOC+LFbrassttings

brazedintotheheader.

Fig. 4.7: EVERLOC+ metal manifold

4.1.6 PEXa Compression Sleeves

EVERLOC+compressionsleevesareproducedusingaspecially

formulatedPEXamaterialandaredesignedspecicallyforusewith

EVERLOC+ttingsandRAUPEXpipe.EVERLOC+compression

sleeveshavethefollowingfeatures:

-Co-extrudedplatinum-coloredPEcoating

-Squarelycutendsthatcanbeslidoverthepipeineitherdirection

-Groovedandroughenedinsidesurfaceforlockingthesleeveinto

placeonceslidoverthepipeandtting

Fig. 4.8: EVERLOC+ compression sleeves

4.1.8 Certications

TheEVERLOC+compression-sleevesystemiscertiedtothe

followingstandards:

-ASTMF877,Standard Specification for Crosslinked Polyethylene

(PEX) Hot- and Cold-Water Distribution Systems

-NSF/ANSI14,Plastic Piping System Components and Related

Materials

-NSF/ANSI61,Drinking Water System Components – Health Eects

-NSF/ANSI372,Drinking Water System Components – Lead Content

-CSAB137.5,Crosslinked polyethylene (PEX) Tubing Systems for

Pressure Applications

11

4.2 Fitting Assembly

Beforestartingtheinstallationprocess,readtheEVERLOC+

Compression-sleeve System Product Instructions (855.724).

AssemblingtheEVERLOC+compression-sleevesystemrequiresthe

useoftheEVERLOC+compression-sleevetools.Onlymake

EVERLOC+compression-sleevejointswiththesetools.Referto

EVERLOC+ Power Tool Product Instruction Manual (855.725),

EVERLOC+ XL Power Tool Product Instruction Manual(855.728)and

EVERLOC+ XL Expander Tool Product Instruction Manual(855.729)for

acompleteunderstandingofoperation,careanduseofthe

EVERLOC+compression-sleevetools.

WARNING

ReadtheinstructionmanualfortheEVERLOC+

compression-sleevetoolsbeforeuseandfollowall

safetyprecautions-improperusecancauseserious

personalinjury.

WARNING

Toreducetheriskofpermanenteyeinjury,always

wearclose-ttingprotectiveeyewearwithside

protection.Eyewearmustbeimpact-ratedand

markedascomplyingwithANSIZ87.

NOTICE

UseonlyEVERLOC+compression-sleevetoolsforassemblyand

installation.Useofothertoolswillresultinanimproperlyassembled

joint,whichmayresultinleakingandpropertydamage.

ThebasicprocessofassemblinganEVERLOC+compression-sleeve

jointisasfollows:

-Makeaclean,squarecutoftheRAUPEXpipeusingaRAUPEX

cutter

-SlidetheEVERLOC+compressionsleeveovertheRAUPEXpipe

ensuringthesleeveisaminimumoftwotimesthelengthofthe

sleevefromtheendofthecutpipetoallowforexpansionofthepipe

only

-ExpandtheRAUPEXpipetwice,ensuringtheexpanderheadis

rotated1/2ofoneexpanderheadsegmentbetweenexpansions,

usingtheEVERLOC+compression-sleevetools

-InserttheEVERLOC+compression-sleevettingintotheexpanded

endoftheRAUPEXpipeuntilthepipeistouchingthepipestopon

thetting

-CompresstheEVERLOC+compressionsleeveovertheRAUPEX

pipeandEVERLOC+compression-sleevettingusingthe

EVERLOC+compression-sleevetools

Requiredassemblytoolsinclude:

-RAUPEXcutter

-EVERLOC+compression-sleevetools

-EVERLOC+expanderheadsandcompressionjaws

4.3 Installation Considerations

Someprecautionsandadditionalconsiderationsthatshouldbetaken

wheninstallingthesystem.

4.3.1 EVERLOC+ Fitting Removal

-EVERLOC+LFbrassttingsCANbereused,aslongtheribarea

wasnotdamagedduringremoval.

-EVERLOC+polymerttingsCANNOTbereusedandshouldbe

discardedimmediately.

-EVERLOC+compressionsleevesCANNOTbereusedandshouldbe

discardedimmediately.

Fig. 4.9: DO NOT cut the EVERLOC+ compression sleeve from finished joint

Fig. 4.10: DO NOT cut RAUPEX pipe from fitting

4.3.1.1 Fitting Removal of Completed Joint (LF brass ONLY)

IfitisrequiredtoremovetheLFbrassttingordisassembletheLF

brasscompression-sleevejoint,usethefollowingprocedure:

Ifthettinghasbeeninsertedintothepipeandthesleevehasbeen

compressed,safelyholdthettingwhileitisheated.Becarefulnotto

damagethettingwiththetool.

1. Heatthesleevedirectlyusingaheatgun.

2. Rotatethejointseveraltimeswhileheating.

3. Removeheatanduseplierstopullthesleeveoffthetting,then

immediatelypullthettingoutofthepipe.

CAUTION

Donotuseopenamestodisassemblethejoint.Openamescan

causeinjuryorpropertydamage.

12

Fig. 4.11: Heating EVERLOC+ compression sleeve with heat gun

Fig. 4.12: Removing pipe from LF brass fitting

Forre-assemblyofajoint,thefollowingshouldbeconsidered:

-Theendofthepipewherethepreviousttinghadbeeninstalled

mustbecompletelycutoffpriortomakinganewjoint.Cuttingoffa

minimumof3in(approximately75mm)isrecommended.

Fig. 4.13: Cut o 3 in. of pipe from end prior to making new joint

4.3.1.2 Fitting Removal of Partially Completed Joint (LF Brass

ONLY)

Ifthettinghasbeeninsertedintothepipe,butthesleevehasnot

beencompressed,attempttoremoveitwithoutdamagingthetting.If

ttingcannotbeeasilyremoved,heat1to11/2in(25to38mm)of

thepipethatcoversthettingandpullthettingoutofthepipe.

4.3.2 Protecting EVERLOC+ Joints

REHAUpermitsEVERLOC+compression-sleevejoints(polymerand

LFbrass)tobeburiedorconcealed.REHAUrecommendsthreaded

connectionsneverbeburiedorconcealedastheymustbeaccessible

forperiodicinspection,perprevailinglocalcodes.

TherequirementtowrapanEVERLOC+jointcandependonmany

factorsincludinglocationandthepresenceofothermaterialsthat

contactorcancomeincontactwiththejoint.

WhenwrappinganEVERLOC+joint,thefollowingisrequired:

-Wrapthejoint,ensuringaminimumof50%overlapofthetape

-Avoidwrinklesorkinksinthetapeandensurethejointiscompletely

covered,extendingontothepipeasnecessary

-Indicatethelocationofeachjointasrequiredonthe“as-built”

drawings

Fig. 4.14: REHAU Protective Tape, Red Fig. 4.15: Linerless Rubber Tape, Black

Note:UseonlyREHAUrecommendedprotectivetapesreferencedin

REHAUTechnical Bulletin TB266 Protecting EVERLOC+ Joints.Donot

useothertypesoftapes(e.g.,ducttape,standardelectricaltape)to

wrapthejoint,aschemicalsintheadhesivemaynotbecompatible

withthePPSUttingmaterialorthePEXapipe.

Note:Neveruseheatshrinktubing(e.g.,RAUCROSS)towrapthe

joint,astheextremelyhightemperaturesproducedfromaheatgun

willsoftenthepipeandmaycauseittopullawayfromthetting.

Fig. 4.16: DO NOT use heat shrink tubing for EVERLOC+ joints

4.3.2.1 Concealed in Inaccessible Locations

WhenEVERLOC+jointsareconcealedbutarestillinopenairspace

(e.g.,behinddrywall),itisnotnecessarytowrapthejoint.However,

theinstallershouldensurethettingdoesnotcomeincontactwith

chemicals(e.g.,PVCglues,solventsandcements)thatcoulddamage

thettingmaterial.

4.3.2.2 Buried in a Concrete Slab or sub-base underneath slab

WhenburyinganEVERLOC+polymerjointdirectlyinaconcreteslab,

orinthesub-baseunderneaththeslab,itisnotnecessarytowrapthe

joint.However,therearesomeadditivesinconcreteorchemicalsused

intheinstallationthatcouldpotentiallydamagethettingmaterial,

andinthiscase,wrappingisrecommended.EVERLOC+LFbrass

jointsburieddirectlyinaconcreteslaborinthesub-baseunderneath

theslabmustbewrapped.

13

4.3.2.3 Buried in Soil:

WhenburyingEVERLOC+jointsinsoil,outsideofastructure,thejoint

mustbewrapped.

4.3.2.4 With Foaming Agents:

Foamingagentsandsolventsinclosed-cellfoaminsulationkitscan

damagethePPSUttingmaterial.Therefore,itisnecessarytowrap

polymerttingsinaprotectivetapetoprotectfrompolyurethane

foams.

4.3.3 Pressure Testing

Thecompression-sleevejointisreadyforimmediatepressuretestand

useaftercompletionoftheassemblyprocess.Thereisnowaittime

forthesystemtobeputintoservice.SeeSection6.17.2forREHAU

pressure test procedures.

4.3.4 Pressure and Temperature Ratings

ThemaximumtemperatureandpressureratingsoftheREHAUPEXa

plumbingsystemareinaccordancewithASTMF877andCSAB137.5

forSDR9PEX,asdenedinSection3.4.

4.3.5 Ultraviolet Resistance

Thettingsandsleevesmustneverbestoredindirectsunlightor

storedoutsideoftheoriginalcardboardpackaging.Inaddition,the

systemisnotintendedforpermanentoutdoorapplicationsorinareas

withcontinuousexposuretoUV.

4.3.6 Freeze Break Resistance

TheexibilityoftheRAUPEXpipeallowsittoexpandaswaterfreezes

inthepipeaslongasthepipehasroomtoexpand.However,this

exibilitydoesnotensuretheintegrityofthejoint.Therefore,installers

musttakeprecautionstoensurethatpipesandttingsdonotfreeze.

Freezingmayresultinleaksandoperationalfailures.

4.3.7 Chlorine Resistance

EVERLOC+compression-sleevejointshaveachlorineresistance

ratingbasedontheratingsofRAUPEXpipe,asdenedinSection3.7.

4.3.8 Stress Corrosion Resistance

EVERLOC+LFbrassttingshavebeentestedinaccordancewith

NSF/ANSI14andcomplywiththerequirementforstresscorrosion

resistance.However,ttingsshouldnotbeexposedtoharmful

chemicalsoraggressivewaterconditionsthatcouldresultinopera-

tionalfailures.

4.3.9 Chemical Compatibility

TherearecertainchemicalsthatcandamagetheEVERLOC+

compression-sleevesystem.Thisappliestoexternalexposureof

chemicalsandtothetransportofsuchchemicalsbythepiping

system.

Chemicalsthatmaydamagethecompression-sleevesysteminclude

(butarenotlimitedto):

-AdhesivesandtapesotherthanthoserecommendedbyREHAU

-Oil/petroleum-basedproducts

-Paints,solvents

-Oxidizingagents(e.g.,bleach)

-Disinfectants(e.g.,separatedosingunitintegratedintobuilding

distributionsystem)

-PVCglues,solventsandcements

Fig. 4.17: DO NOT use harmful chemicals near EVERLOC+ fittings

Ensurethattheemployedsealants,cleaningagents,buildingfoams,

insulation,protectivetape,adhesivetapeorthreadsealantsdonot

containanycomponentswhichcausestresscrackingorcorrosion,

suchasammonia,ammonia-bearing,aromaticandoxygenated

solvents(e.g.,ketoneandether),chlorinatedhydrocarbonsorchloride

ionswhichcanleach.

Protectsystemsagainstcontacttochemicalsanddamage.Onlyuse

leakdetectionagents(e.g.,foamingagents)approvedbythe

respectivemanufacturerforPPSUmaterials.Onlyusesealants,

threadsealants,cleaningagents,buildingfoams,insulation,protective

tape,adhesivetapeanduxapprovedbytherespectivemanufacturer

forthePPSUmaterials.Checkthecompatibilityofmaterialsforthe

correspondingareaofapplicationwiththemanufacturer.

Contactwitharomaticandoxygenatedsolvents(e.g.,ketoneand

ether)aswellashalogenatedhydrocarbons(e.g.,chlorinated

hydrocarbons)isnotpermitted.Contactwithwater-basedacrylic

paintsandadhesive/protectiveprimersisnotpermitted.

14

4.3.10 Copper Soldering

Propersolderingtechniquesmustbefollowedwhensolderingall

compression-sleevettingsaccordingtotheCopper Development

Association (CDA) Handbook:

-Thesurfaceofthettingsolderingareamustbeproperlycleanedfor

agoodsolderconnection.Applyinguxisnotconsideredsufcient

cleaningforthesolderingarea.Usingapropersandingorbrush

techniqueisnecessarytoremovethesurfaceoxides.Inorderto

preventfurtherformationofoxides,theuxshouldbeapplied

immediatelyafterthecleaningprocess.Aproperuxthatis

compatiblewiththebrassalloymustbeused.

-Caremustbetakentonotoverheatthesolderingsurfaceasthiscan

leadtotheformationofoxidespreventinggoodadhesionofthe

soldermaterial.Itisimperativethatthettingisheatedevenly

aroundtheentiresurfacesoastonotoverheatoneparticulararea.

-Allcompletedsolderjointsmustbetestedforjointintegrityfollowing

theproceduresprescribedbyprevailinglocalcodes.

4.4 EVERLOC+ Compression-sleeve Tools

AssemblingtheEVERLOC+compression-sleevesystemrequiresthe

useoftheEVERLOC+compression-sleevetools.Onlymake

EVERLOC+compression-sleevejointswiththesetools.

Beforeuse,readandunderstandthefollowingsafetysymbolswhich

arefoundontheEVERLOC+compression-sleevetools.

SafetyAlertSymbol–Toreducetheriskofinjury,follow

thespeciedsafetyinstructions.

Readandfollowallsafetyprecautionsintheinstruction

manual.Improperusecanleadtoseriouspersonalinjury

orpropertydamage.

Toreducetheriskofseriouseyeinjury,alwayswear

proper eye protection.

Riskofelectricshock.Neveroperatethepowertoolin

damporwetconditions.Neverexposetorainor

submergeinwaterorotherliquids.Neveroperatethe

powertoolnearwiresorcablescarryingelectriccurrent.

Toreducetheriskofseverepersonalinjury,including

crushandlacerationinjury,keepngers,handsandall

partsofyourbodyawayfromtheexpanderhead,

hydraulicslideandcompressionjawsduringoperation.

NOTICE

UseonlyEVERLOC+compression-sleevetoolsforassemblyand

installation.Useofothertoolswillresultinanimproperlyassembled

joint,whichmayresultinleakingandpropertydamage.

4.4.1 EVERLOC+ Power Tool 3/8 to 1 in.

ForassemblyofEVERLOC+ttingsinsizes3/8through1in.Usethe

EVERLOC+powertool.RefertoEVERLOC+ Power Tool Product

Instruction Manual (855.725)foracompleteunderstandingof

operation,careanduseofthetool

Fig. 4.18: EVERLOC+ power tool

EVERLOC+powertoolstandardkit:

-EVERLOC+powertool

-Expansionadapter

-1/2,3/4and1in.EVERLOC+expanderheads(quickchange)

-1/2,3/4and1in.EVERLOC+compressionjaws

-DEWALT

®

12VLi-ionbattery(DCB127)(2batteriesperkit)

-DEWALT12V/20VLi-ioncharger120VAC(DCB107)

-DEWALT12V/20VLi-ionBatteryChargerInstructionManual

-Pipe cutter

-Lubricant

-Cleaningbrush

-Tool case

-Product Instruction Manual

Fig. 4.19: EVERLOC+ power tool standard kit

AvailableAccessories:

-3/8in.expanderhead(quickchange)

-3/8in.compressionjaws

-5/8in.expanderhead(quickchange)

-5/8in.compressionjaws

15

4.4.2 EVERLOC+ XL Power Tool 1 1/4 to 2 in.

AssemblingtheEVERLOC+compression-sleevesystemwith

diametersof11/4through2in.requirestheuseoftheEVERLOC+

XLpowertool.Refertothe EVERLOC+ XL Power Tool Product

Instruction Manual(855.728)foracompleteunderstandingof

operation,careanduseofthetool.

Fig. 4.20: EVERLOC+ XL power tool

EVERLOC+XLpowertoolstandardkit:

-EVERLOC+XLpowertool

-Expansionadapter

-11/4,11/2and2in.EVERLOC+expanderheads(quickchange)

-11/4,11/2and2in.EVERLOC+compressionjaws

-MAKITA

®

18VLi-ionbattery(BL1840B)(2batteriesperkit)

-MAKITA18VLi-ioncharger120VAC(DC18RC)

-MAKITA18VLi-ionBatteryChargerInstructionManual

-Pipe cutter

-Lubricant

-Cleaningbrush

-Toolcase(blacklatches)

-Product Instruction Manual

Fig. 4.21: EVERLOC+ XL power tool standard kit

AvailableAccessories:

-EVERLOC+XLexpandertoolstandardkit

-EVERLOC+XLexpanderbasetool

4.4.3 EVERLOC+ XL Expander Tool 1 1/4 to 2 in.

InadditiontotheEVERLOC+XLpowertool,theEVERLOC+XL

expandertoolcanbeusedfortheexpansionstepsofthe11/4to2in.

ttingassemblyprocess.UseofthistoolinadditiontotheXLpower

toolallowsforgreaterefciencyinsomeinstallationsituations.Refer

totheEVERLOC+ XL Expander Tool Product Instruction Manual

(855.729)foracompleteunderstandingofoperation,careanduseof

thetool.

Fig. 4.22: EVERLOC+ XL expander tool Fig. 4.23: EVERLOC+ XL expander tool

standard kit

EVERLOC+XLexpandertoolstandardkit:

-EVERLOC+XLexpandertool

-MAKITA18VLi-ionbattery

-MAKITA18VLi-ionBatteryChargerInstructionManual

-Lubricant

-Cleaningbrush

-Toolcase(graylatches)

-Product Instruction Manual

AvailableAccessories:

-EVERLOC+XLpowertoolstandardkit

-EVERLOC+expanderheads(quickchange):

11/4in.,Art.105078-001;11/2in.,Art.105079-001;and

2in.,Art.105080-001

-Largeratchetcutter,Art.131558-001

16

5. DESIGN CONSIDERATIONS

5.1 Pipe Sizing

Thedesignandlayoutofthebuildinghot-andcold-waterdistribution

systemshallcomplywithacceptedplumbingengineeringpracticeand

asperprevailinglocalcodes.

TheREHAUPEXaplumbingsystemconsistsofRAUPEXUVshield

PEXapipeandtheEVERLOC+compression-sleevettingsystemand

canbedesignedandsizedperthefollowingmodelplumbingcodes:

-ICCInternationalPlumbingCode(IPC)

-ICCInternationalResidentialCode(IRC)

-IAMPONationalStandardPlumbingCode(NSPC)

-IAPMOUniformPlumbingCode(UPC)

-NRCCNationalPlumbingCodeofCanada(NPCC)

Inaddition,aproperlydesignedplumbingsystemshouldfollowthe

engineeringprinciplesaspertheAmericanSocietyofPlumbing

Engineers(ASPE)Plumbing Engineering Design Handbook Volume II

orequivalent.

Forsizingasysteminresidentialandlightcommercialbuildings,use

thewatersupplyxtureunit(WSFU)methodtodeterminethe

requiredload(GPM)andresultingpipesizeaspublishedinthemodel

plumbingcodes.Alternatively,orinlargerbuildings,theuniform

frictionheadlossmethodcanbeutilized.

5.1.1 Standard Dimension Ratio

RAUPEXpipeisinaccordancetothedimensionalstandardsinASTM

F876andCSAB137.5.RAUPEXiscoppertubesize(CTS)outside

diameter(OD)whichmeansthattheactualODofthepipeis1/8in.

(3.18mm)largerthanthenominalsize.

Wallthicknessisdenedbythestandarddimensionalratio(SDR).

RAUPEXUVshieldpipeisSDR9,whichequatestotheoutside

diameterbeingapproximatelyninetimesthewallthickness.Since

PEXpipehasathickerwallthancoppertube,theinsidediameter(ID)

isslightlysmaller.However,sincePEXpipeisnotsusceptibletothe

erosionandcorrosionissuesofcoppertube,plumbingsystemscan

bedesignedathighervelocitieswhichallowforcomparablesizingof

asystem.

5.1.2 Determining Friction Loss

ThepressurelossfortheREHAUPEXaplumbingsystemcanbe

calculatedusingtheREHAU PEXa Piping Systems Pressure Loss

Tables (855.861)availableonlineontheREHAUResourceCenteror

usingtheREHAULoopCADsoftwarepressurelosscalculatortool.

5.1.3 Velocity Considerations

Themaximumvelocityofwaterow(feet/second–fps)inthe

plumbingsystemshouldbeconsideredwhensizingaREHAUPEXa

plumbingsystem.Todeterminethepipesize,theWSFUloadcanbe

correlatedtoowrate(GPM)fromtablespublishedinthemodel

plumbingcodes.

Oncetheowrateisdetermined,thepipecanbesizedbasedonthe

allowablemaximumvelocitiesperprevailinglocalcodes.

Thedesignercanusethefollowingtablesasaguideline:

Table 5.1: Maximum Velocity of Water Flow

Cold-Water

Piping

- Typicalplumbingcodesstatemaximumvelocityof8ft/sec

- REHAUrecommendsamaximumdesignvelocityof10ft/sec

Hot-Water

Piping

- Typicalplumbingcodesstatemaximumvelocityof5ft/sec

- REHAUrecommendsamaximumdesignvelocityof8ft/sec

Hot-Water

Recirculation

Return Piping

- Maximumvelocityof2ft/sec

- Maximumoperatingtemperatureof140°F(60°C)

Table 5.2: GPM per Pipe Size

Pipe Size

GPM

@ 2 fps

GPM

@ 5 fps

GPM

@ 8 fps

GPM

@ 10 fps

3/8in 0.6 1.6 2.5 3.2

1/2in 1.1 2.9 4.6 5.8

3/4in 2.3 5.7 9.1 11.3

1 in. 3.8 9.4 15.0 18.8

11/4in 5.7 14.0 22.3 28.1

11/2in 8.0 19.7 31.3 39.1

2 in 13.7 33.4 53.8 6 7.1

17

5.2 Equivalent Length of Fittings

Itiscommonpracticefordesignerstoconvertthepressuredrop

acrossttingstoanaverageequivalentlengthofpipe.These

equivalentlengthsareaddedtothetotalpipelength.Designerscan

calculatetotalpressurelossusingthisadjustedpipingsystemlength.

Table 5.3: Equivalent Length of Fittings

Couplings

Fitting Description Equivalent Length (ft)

3/8x3/8in.EVERLOC+LFBrassCoupling 1.1

1/2x1/2in.EVERLOC+PolymerCoupling 0.4

5/8x5/8in.EVERLOC+LFBrassCoupling 1.0

3/4x1/2in.EVERLOC+PolymerCoupling 2.1

3/4x3/4in.EVERLOC+PolymerCoupling 0.8

1x3/4in.EVERLOC+PolymerCoupling 2.7

1x1in.EVERLOC+PolymerCoupling 1.1

11/4x3/4in.EVERLOC+LFBrassCoupling 3.5

11/4x1in.EVERLOC+PolymerCoupling 4.0

11/4x11/4in.EVERLOC+PolymerCoupling 2.0

11/2x1in.EVERLOC+PolymerCoupling 4.8

11/2x11/2in.EVERLOC+PolymerCoupling 2.0

2x1/2in.EVERLOC+LFBrassCoupling 3.5

2x3/4in.EVERLOC+LFBrassCoupling 3.8

2x1in.EVERLOC+LFBrassCoupling 5.2

2x11/4in.EVERLOC+LFBrassCoupling 5.3

2x11/2in.EVERLOC+LFBrassCoupling 6.1

2x2in.EVERLOC+PolymerCoupling 2.2

Elbows (PEX to PEX)

Fitting Description Equivalent Length (ft)

1/2x1/2in.EVERLOC+PolymerElbow 1.9

5/8x5/8in.EVERLOC+LFBrassElbow 5.4

3/4x3/4in.EVERLOC+PolymerElbow 7.0

1x1in.EVERLOC+PolymerElbow 10.7

11/4x11/4in.EVERLOC+PolymerElbow 14.2

11/2x11/2in.EVERLOC+PolymerElbow 16.0

11/2x11/2in.EVERLOC+LFBrass45°Elbow 3.4

2x2in.EVERLOC+PolymerElbow 24.2

Tees

Fitting Description

Equivalent

Length (ft)

RUN

Equivalent

Length (ft)

BRANCH

1/2x1/2x1/2in.EVERLOC+PolymerTee 0.8 4.4

1/2x1/2x3/4in.EVERLOC+PolymerTee - 4.1

3/4x1/2x1/2in.EVERLOC+PolymerTee 2.4 4.3

3/4x1/2x3/4in.EVERLOC+PolymerTee 2.4 7.6

3/4x3/4x1/2in.EVERLOC+PolymerTee 1.3 4.0

3/4x3/4x3/4in.EVERLOC+PolymerTee 1.2 7.6

3/4x3/4x1in.EVERLOC+PolymerTee - 6.8

1x1x1/2in.EVERLOC+PolymerTee 1.6 3.9

1x3/4x3/4in.EVERLOC+PolymerTee 2.8 6.5

1x3/4x1in.EVERLOC+PolymerTee 3.1 10.9

1x1x3/4in.EVERLOC+PolymerTee 1.2 6.7

1x1x1in.EVERLOC+PolymerTee 1.6 10.6

11/4x1x3/4in.EVERLOC+LFBrassTee 3.7 5.4

11/4x1x1in.EVERLOC+PolymerTee 3.8 9.7

11/4x1x11/4in.EVERLOC+LFBrassTee 4.3 9.6

11/4x11/4x1/2in.EVERLOC+LFBrassTee 0.8 5.0

11/4x11/4x3/4in.EVERLOC+LFBrassTee 1.3 5.5

11/4x11/4x1in.EVERLOC+PolymerTee 2.3 10.1

11/4x11/4x11/4in.EVERLOC+PolymerTee 2.2 14.4

11/2x1x3/4in.EVERLOC+LFBrassTee 6.8 6.8

11/2x1x1in.EVERLOC+LFBrassTee 5.5 7. 9

11/2x1x11/2in.EVERLOC+LFBrassTee 5.6 12.4

11/2x11/4x3/4in.EVERLOC+LFBrassTee 4.5 5.5

11/2x11/4x1in.EVERLOC+LFBrassTee 4.4 8.1

11/2x11/4x11/4in.EVERLOC+LFBrassTee 4.5 9.5

11/2x11/4x11/2in.EVERLOC+LFBrassTee 4.3 10.9

11/2x11/2x1/2in.EVERLOC+LFBrassTee 1.0 4.9

11/2x11/2x3/4in.EVERLOC+LFBrassTee 1.0 5.4

11/2x11/2x1in.EVERLOC+PolymerTee 2.2 9.1

11/2x11/2x11/4in.EVERLOC+LFBrassTee 1.7 9.6

11/2x11/2x11/2in.EVERLOC+PolymerTee 2.6 17.0

2x11/4x2in.EVERLOC+LFBrassTee 6.7 14.9

2x11/2x3/4in.EVERLOC+LFBrassTee 5.8 5.7

2x11/2x1in.EVERLOC+LFBrassTee 6.2 7.7

2x11/2x11/4in.EVERLOC+LFBrassTee 6.3 9.5

2x11/2x11/2in.EVERLOC+LFBrassTee 6.4 11.2

2x11/2x2in.EVERLOC+LFBrassTee 6.5 14.6

2x2x1/2in.EVERLOC+LFBrassTee 1.1 5.0

2x2x3/4in.EVERLOC+LFBrassTee 1.0 5.9

2x2x1in.EVERLOC+PolymerTee 3.2 9.0

2x2x11/4in.EVERLOC+LFBrassTee 1.9 9.7

2x2x11/2in.EVERLOC+LFBrassTee 1.9 10.9

2x2x2in.EVERLOC+PolymerTee 4.0 25.3

18

Elbows (PEX to transition)

Fitting Description

Equivalent

Length (ft)

1/2x1/2in.CMaleor3/8in.CFemaleEVERLOC+LFBrassElbow 7.4

1/2x1/2in.CFemaleEVERLOC+LFBrassElbow 7.2

3/4x3/4in.CFemaleEVERLOC+LFBrassElbow 7.1

3/4x3/4in.CMaleEVERLOC+LFBrassElbow 7.4

1/2x1/2in.MPTEVERLOC+LFBrassDropEarElbow 7.6

1/2x1/2in.FPTEVERLOC+LFBrassDropEarElbow 4.9

3/4x3/4in.MPTEVERLOC+LFBrassElbow 7.5

3/4x3/4in.MPTEVERLOC+LFBrassDropEarElbow 7.7

3/4x3/4in.FPTEVERLOC+LFBrassDropEarElbow 9.0

1x1in.FPTEVERLOC+LFBrassDropEarElbow 13.6

Adapters (PEX to copper)

Fitting Description

Equivalent

Length (ft)

1/2x1/2in.CFemaleEVERLOC+LFBrassAdapter 2.3

1/2x1/2in.CMaleor3/8in.CFemaleEVERLOC+LFBrassAdptr 2.4

1/2x3/4in.CFemaleEVERLOC+LFBrassAdapter 4.0

3/4x1/2in.CMaleEVERLOC+LFBrassAdapter 0.3

3/4x1/2in.CFemaleEVERLOC+LFBrassAdapter 0.5

3/4x1in.CFemaleEVERLOC+LFBrassAdapter 3.9

3/4x3/4in.CFemaleEVERLOC+LFBrassAdapter 2.7

3/4x3/4in.CMaleEVERLOC+LFBrassAdapter 2.6

1x1in.CFemaleEVERLOC+LFBrassAdapter 3.5

1x1in.CMaleEVERLOC+LFBrassAdapter 3.3

11/4x11/4in.CFemaleEVERLOC+LFBrassAdapter 4.1

11/4x11/4in.CMaleEVERLOC+LFBrassAdapter 4.3

11/2x11/2in.CFemaleEVERLOC+LFBrassAdapter 5.3

11/2x11/2in.CMaleEVERLOC+LFBrassAdapter 5.4

2x2in.CFemaleEVERLOC+LFBrassAdapter 7.0

2x2in.CMaleEVERLOC+LFBrassAdapter 6.9

Adapters (PEX to MPT/FPT)

Fitting Description

Equivalent

Length (ft)

3/8x1/2in.MPTEVERLOC+LFBrassAdapter 2.4

1/2x1/2in.FPTEVERLOC+LFBrassAdapter 2.8

1/2x1/2in.MPTEVERLOC+LFBrassAdapter 3.3

5/8x1/2in.MPTEVERLOC+LFBrassAdapter 2.9

5/8x3/4in.MPTor1/2in.CFemaleEVERLOC+LFBrassAdptr 3.6

3/4x3/4in.FPTEVERLOC+LFBrassAdapter 2.8

3/4x3/4in.MPTEVERLOC+LFBrassAdapter 3.4

3/4x1in.MPTEVERLOC+LFBrassAdapter 4.3

1x3/4in.FPTEVERLOC+LFBrassAdapter 0.1

1x1in.FPTEVERLOC+LFBrassAdapter 3.6

1x1in.MPTEVERLOC+LFBrassAdapter 3.8

11/4x11/4in.MPTEVERLOC+LFBrassAdapter 4.9

11/2x11/2in.MPTEVERLOC+LFBrassAdapter 5.9

2x2in.MPTEVERLOC+LFBrassAdapter 7.3

5.3 Piping Layouts

Mostpipinglayoutdesignsutilizesomeformofreducingteeinorder

tobranchfromamaintrunklinetosmallerpipediametersthatroute

toxturesandappliances.TheexibilityofRAUPEXpipeallowsyou

toeasilyroutearoundobstaclesandreducethenumberofttings

needed.Multi-portteesfunctionlikereducingtees,butreducethe

numberofconnectionpoints.Ingeneral,thebestsystemdesigns

utilizetheexibilityoftheRAUPEXpipeandminimizeconnections.

5.3.1 Tee and Branch

-Increasesinstallationspeedbytakingadvantageoftheexibilityof

PEXapipe

-Reducespressureatthefurthestxture

-Similartotraditionalrigidpipeinstallationlayouts

-Reduceshotwaterwaittime,comparedtoahome-runsystem

Parts list:

-Reducingtees

-Straighttees

-Straightorcoiledpipe

Fig. 5.1: Tee and branch piping layout

19

5.4 Thermal Expansion and Contraction

Whenthermalexpansionisanticipated,pipemovementshouldbe

controlledtoavoidchangesthatcoulddamagethepipingsystem.

Anchoringanduseofexpansionloopsmaybeusedtoaccomplish

this.Allowingforcontrolledexpansionandcontractioninmultiple

partsofapipingsystemisanacceptedmeansofpreventingadded

stressesinotherpartsofthesystem.

RAUPEXpipingsystemsexhibitahigherexpansionandcontraction

ratewhensubjectedtochangesintemperatureascomparedto

metallicpipingsystems.Becauseofitslowermodulusofelasticity,

RAUPEXpipeislessrigidthanmetallicpipinganddevelopslessforce

thanmetallicpipewhenexposedtotemperaturechanges.

5.4.1 Calculating Thermal Expansion of RAUPEX Pipe

Whenapipeisanchoredatoneendbutcanotherwisefreelymovein

theaxialdirection,anincreaseintemperaturecausesthepipeto

increaseinoveralllength.Adecreaseintemperaturecausesa

decreaseinlength.

Thefollowingequationpredictsthenetexpansion/contractioninthe

lengthofafullyunrestrainedpipethatoccursinconsequenceofa

givenchangeintemperature:

(1)

where,

ΔL=changeinpipelength,in.

α=coefcientoflinearexpansion/contraction,in/ft°F

L=initialpipelength,in.

ΔT=changeinpipetemperature,°F

Note:SeeTable3.1forcoefcientoflinearexpansion

5.4.2 Calculating L-bend and U-bend for RAUPEX Pipe

RAUPEXpipewillexpandandcontractwhenheatedorcooleddueto

achangeinwatertemperatureorambienttemperature.Thermal

expansionofRAUPEXpipemustbeconsideredinthedesignand

installationofthepipingsystem.Fixedanchorpoints,guidesand

expansionloopsshouldbeutilizedtoaccountfortheexpansionand

contractionofthepipetopreventanydamagetothepipingsystem.

5.3.2 Multi-port Tee

-Minimizesnumberofconnections

-Combinesteeandbranchandhome-runconcepts

-Systemsarepressure-balancedateachmanifold

-Reduceshotwaterwaittime,comparedtoahome-runsystem

Parts list:

-Flow-throughmulti-porttees

-Closed-endmulti-porttees

-Straightorcoiledpipe

Fig. 5.2: Multi-port tee piping layout

5.3.3 Home-run

-Generallyforresidentialinstallations

-Eliminatesmostttings

-Balancespressuretoallxtures

-Increaseshotwaterwaittime,comparedtoteeandbranchand

remotemulti-portdesigns

-Usesmorepipe

-Mayrequiremoreholestobedrilledinjoistspaces

Parts list:

-Multi-porttees

-Straightorcoiledpipe

Fig. 5.3: Home-run piping layout

20

/