Page is loading ...

INSTALLATION INSTRUCTIONS

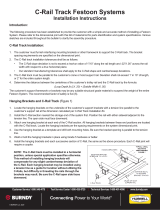

STEEL TRACK FESTOON SYSTEM for ROUND CABLE/HOSE

TRACK BRACKET –THREE PIECES

Supports track to cross arms

CROSS ARMS

Support festoon track

CROSS

ARM

TRACK SPLICE

Raised lance in rail to align

with notch in bracket to hold

track together

BEAM CLAMPS

Fasten cross arms to I-beam

Includes track nuts

TOW TROLLEY

Last trolley on moving

end of system.

FIXED CABLE

CLAMP

Secures cable and

acts as stop on

“non-moving “ end

INSTALLATION

1. Clamp cross arms to supporting I-beam. Spacing between arms must not exceed 6’ (1.8m) on center. Securely tighten clamps.

2. Hang festoon rail sections from bottom of arms using anchor brackets (one each end of system) and track brackets. Use track

splices to join track sections. NOTE: Raised lance in track mates with notch of splice.

3. Carefully level and align track. Festoon track must be parallel to crane track. Shim or adjust cross arms as required. Securely

tighten all set screws on anchor brackets and splice brackets.

4. Insert end stop into end of track opposite cable xing end. Clamp tightly in place.

5. Insert tow trolley into cable xing end of track followed by intermediate trolleys. (See illustration above).

6. Insert xed cable clamp into track with stop angle on clamping bar facing in. Securely tighten in place.

7. Install cable or hose. Number of trolleys in kit assumes 3’ loop depth (measured cable saddles to bottom of loops) when trolleys are

pushed together. NOTE: Check to make sure saddles are correct size for cable/hose to be installed. See Components, over.

8. Insert tow arm through opening in tow trolley and bolt or weld tow arm to crane. Tow arm must be centered within opening and

perpendicular to festoon rail.

TOW ARM

END STOP

Insert into track

at end of run

CABLE/HOSE SADDLE

One at each trolley or clamp. Be sure

saddle size matches cable/hose o.d.

INDIVIDUAL COMPONENTS

1.0

(25)

1.0 dia.

(25)

3.1

(79)

1.75

(44)

2.6

(70)

5.0

(127)

1.0

(25)

1.0 dia.

(25)

B

B

B

Dia.

Range ADia.

Range A

Dia.

Range A

1.80

(46)

1.8

(46)

3.6

(92)

1.6

(40)

DD

D

ROUND CABLE FIXED CLAMP

Catalog

Number

Cable O.D.

Range-A B D Wgt.

C35-RE-12

C35-RE-13

0.60”-0.94”

0.95”-1.25”

1.40”

1.65”

3.90”

5.60”

2 lbs

2 lbs

ROUND CABLE INTERMEDIATE TROLLEY

Catalog

Number

Cable O.D.

Range-A B D Wgt.

C35-RC-12

C35-RC-13

0.60”-0.94”

0.95”-1.25”

1.25”

1.50”

3.90”

5.60”

1 lbs

1 lbs

ROUND CABLE TOW TROLLEY

Catalog

Number

Cable O.D.

Range-A B D Wgt.

C35-RT-12

C35-RT-13

0.60”-0.94”

0.95”-1.25”

6.70”

6.90”

3.90”

5.60”

3 lbs

3 lbs

Bulletin No. 630379.c

Gleason Reel Corp.

600 S. Clark Street

Mayville, WI 53050

Phone: 920-387-4120

www.hubbell-gleason.com

TOW ARM

CTA-01

Wgt: 3.00 lbs

TRACK BRACKET

C35-TB

Wgt: 0.50 lbs

TRACK SPLICE

C35-TSA

Wgt: 1.00 lbs

BEAM CLAMP

C35-BCA

Wgt: 0.25 lbs

END STOP

C35-ES-Z

Wgt: 0.30 lbs

STEEL TRACK

DESCRIPTIONS LENGTH

ft

WGT.

lbs

CATALOG

NUMBER

Festoon Track

Cross Arm

10’

2.5’

10.50

3.00

C35-TR-10

C35-TR-2.5

Standard lengths shown. Sections may be cut to required

length.

Workplace Solutions

/