Page is loading ...

FormNo.3377-939RevB

HydraBorer

ProSneak360VibratoryPlow

ModelNo.25418—SerialNo.313000001andUp

ModelNo.25418E—SerialNo.313000001andUp

Operator'sManual

Safety

SafetyandInstructional

Decals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

125-6671

1.Explosionhazard;electricshockhazard—calllocalutilities

beforedigging.

125–6681

1.Entanglementhazard—keepawayfrommovingparts;keep

allguardsinplace.

125–8488

1.Turnclockwise3.Turncounterclockwise

2.Stoprotation

©2013—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3377-939*B

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

Qty.

Use

Motor1

Adapter1

Retaineradapter1

Lockwasher1

Bolt(1/2x1-1/4inches)

1

90-degree,elbowtting

2

Hose,114.3cm(45inches)

2

Bracket1

Bolt(1/2x1-3/4inch)

8

Flatwasher(1/2inch)

8

Locknut(1/2inch)

8

Jointassembly1

Nut(3/8inch)

1

1

Bolt(3/8x2-1/2inch)

1

InstalltheHydraBorerMotor

Bracket1

Controlvalve

1

90-degree,elbowtting

1

45-degree,elbowtting

2

Straighttting

1

Bolt(3/8x1inch)

2

Flatwasher(3/8inch)

4

Nut(3/8inch)

2

Bolt(5/16x2-1/2inch)

1

Bolt(5/16x2-1/4inch)

1

Flatwasher(0.344inch)

2

Locknut(5/16inch)

2

Clevispin

1

Cotterpin

1

Controllever

1

Linkassembly1

2

Snapclip

1

Installthecontrolvalveandhandle.

Hose,114.3cm(45inches)

2

Hose,91.44cm(36inches)

1

Hose,37.44cm(14.74inches)

1

3

Hoseconnector1

Installthehoses.

2

1

InstallingtheHydraBorer

Motor

Partsneededforthisprocedure:

1Motor

1Adapter

1Retaineradapter

1Lockwasher

1

Bolt(1/2x1-1/4inches)

2

90-degree,elbowtting

2

Hose,114.3cm(45inches)

1Bracket

8

Bolt(1/2x1-3/4inch)

8

Flatwasher(1/2inch)

8

Locknut(1/2inch)

1Jointassembly

1

Nut(3/8inch)

1

Bolt(3/8x2-1/2inch)

Procedure

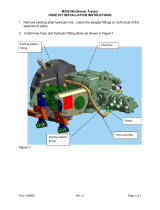

1.Greasetheshaftofthemotorandplacetheadapter

ontothemotor(Figure1).

1

2

3

4

g021919

5

Figure1

1.Bolt(1/2x1-1/4inch)

4.Adapter

2.Lockwasher5.Motor

3.Retaineradapter

2.Puttheretaineradapterontheadapter.

3.Placethewasherontheboltandapplythread-locking

adhesivetothebolt.

4.Securethebolttotheadapters;torqueto160to165

N-m(118to122ft-lb).

5.Install2ofthe90-degree,elbowttingsintotheports

onthemotor(

Figure2).

g021920

Figure2

6.Attachthe114.3cm(45inch)hosestotheelbow

ttingsonthemotor(Figure3).

g021921

Figure3

7.Securethebrackettothemotorusingthe4bolts(1/2

x13/4inch),the4atwashers(1/2inch),andthe4

locknuts(1/2inch)(Figure4);torqueto140to144

N-m(100to110ft-lb).

3

g021922

Figure4

8.Securethemotorassemblytothemachineusing2

bolts(1/2x1-3/4inch),2atwashers(1/2inch),and

2locknuts(1/2inch);torqueto142N-m(105ft-lb).

(

Figure5).

g021923

Figure5

9.Installthejointassemblytothemotorassembly.Secure

withthebolt(3/8inch)andthenut(3/8x2-1/2inch)

(Figure6);torqueto55to63N-m(40to45ft-lb).

g021924

Figure6

2

InstallingtheControlValve

andHandle

Partsneededforthisprocedure:

1Bracket

1

Controlvalve

1

90-degree,elbowtting

2

45-degree,elbowtting

1

Straighttting

2

Bolt(3/8x1inch)

4

Flatwasher(3/8inch)

2

Nut(3/8inch)

1

Bolt(5/16x2-1/2inch)

1

Bolt(5/16x2-1/4inch)

2

Flatwasher(0.344inch)

2

Locknut(5/16inch)

1

Clevispin

1

Cotterpin

1

Controllever

1Linkassembly

1

Snapclip

4

Procedure

1.InstallthettingsasshowninFigure7.

g021925

Figure7

2.Installthebracketandsecurewiththe2nuts(3/8

inch),the2washers(3/8inch),andthe2bolts(3/8

inch)(Figure8);torqueto38to43N-m(28to32ft-lb).

1

2

3

g021926

Figure8

1.Nut(3/8inch)3.Bolt(3/8inch)

2.Flatwasher(3/8inch)

3.Installthecontrolvalveontothebracketandsecure

withthe2bolts(5/16x2-1/4inchand5/16x2-1/2

inch),the2atwashers(0.344inch)andthe2locknuts

(5/16inch)(Figure9);torqueto32to35N-m(280

to310in-lb).

5

2

3

4

g021927

1

6

Figure9

1.Bolt(2-1/4inch)

4.Bracket

2.Bolt(2-1/2inch)5.Controlvalve

3.Washer(0.344inch)6.Locknut(5/16inch)

4.Placethehydra-borer-controlleverbetweentheguide

onthebracketattachedtothemachinesothatthe

holeslineup.Securethecontrolleverwiththelink

assemblyandsnapclip(Figure10).

1

2

3

g021928

4

Figure10

1.Cotterpin

3.Linkassembly

2.Clevispin4.Snapclip

5.Securetheupperholeofthecontrolleverwiththe

clevispinandthecotterpin(Figure10).

5

3

InstallingtheHoses

Partsneededforthisprocedure:

2

Hose,114.3cm(45inches)

1

Hose,91.44cm(36inches)

1

Hose,37.44cm(14.74inches)

1Hoseconnector

InstallingtheHosesonallMachines

1

2

3

4

1

3

g021979

2

Figure11

ControlValveViews

1.45-degreetting(B

port/45-inchhosefrom

Motor)

3.45-degreetting(A

Port/45-inchhosefrom

Motor)

2.90-degreetting(HoseB

(14.74-inchhose)toPlow

Valve)

4.Straighttting(Hose

C/36-inchhose)

1.Routea114.3cm(45inch)hosefromportAonthe

motortoportAonthehydra-borer-controlvalve

(

Figure12).

Note:Routethehosesundertheframe.

g021980

1

2

3

4

Figure12

1.PortAonthemotor3.PortAonthe

hydra-borer-controlvalve

2.PortBonthemotor4.PortBonthe

hydra-borer-controlvalve

2.Routetheother114.3cm(45inch)hosefromportB

onthemotortoportBonthehydra-borer-control

valve(Figure11andFigure12).

InstallingtheHosesonaMachine

withoutaTrencherAttached

Usethisprocedureifyouhaveamachinethatdoesnothave

atrencherattached.Ifyouhaveamachinehastrencher

attached,gotoInstallingtheHosesonaMachinewitha

TrencherAttached(page7).

2

g021981

1

3

Figure13

Currenthoserouting

1.HydraulicPump3.Plow-controlvalve

2.HoseA(currentlyinstalled

onthemachine)

6

1.ConnecthoseB(14.74inches)tothe90-degreetting

onthecontrolvalve(Figure11andFigure14).

1

2

4

g021983

3

5

Figure14

1.Hoseconnector4.Plow-controlvalve

2.Hydra-borer-controlvalve

5.HoseB(14.74inches)

3.HoseA

2.DisconnecthoseAfromthehydraulicpump,addthe

hoseconnector,andconnecthoseBtotheotherend

oftheconnector(Figure13andFigure14).

3.ConnecthoseC(36inches)tothestraightttingon

thecontrolvalve(Figure11andFigure15).

1

g021984

3

2

Figure15

1.Hydra-borer-controlvalve

3.HoseC(36inches)

2.Hydraulicpump

4.ConnecthoseCtothehydraulicpump(wherehoseA

waspreviouslyattached).

InstallingtheHosesonaMachinewith

aTrencherAttached

Usethisprocedureifyouhaveamachinethathasatrencher

attached.Ifyouhaveamachinethatdoesnothaveatrencher

attached,gotoInstallingtheHosesonaMachinewithouta

TrencherAttached(page6).

Figure16

Currenthoseroutingonamachinewithatrencherinstalled.

1.HoseE(trencherhose)

4.Plow-controlvalve

2.Hydraulicpump

5.HoseD(trencherhose)

3.HoseA(sameashoseA

inpreviousgures)

6.Hoseconnector

1.DisconnecthoseAfromhoseD,leavingthehose

connectorattachedtohoseA(Figure16).

2.ConnecthoseBtothe90-degreettingonthe

hydra-borer-controlvalve(Figure11andFigure17).

1

2

4

g021983

3

5

Figure17

1.Hoseconnector4.Plow-controlvalve

2.Hydra-borer-controlvalve

5.HoseB(14.74inches)

3.HoseA

3.ConnecthoseBtothehoseconnectorattachedto

hoseA.

7

4.ConnecthoseCtothestraightttingonthe

hydra-borer-controlvalve(Figure11andFigure18).

1

2

3

g021985

4

5

Figure18

1.HoseC(36inches)

4.HoseD

2.Hydra-borer-controlvalve5.Trencher-controlvalve

3.Hoseconnector

5.ConnectthehoseconnectortohoseDandconnectto

hoseCtothehoseconnector(

Figure18).

Operation

BoringaHole

DiggingtheTrenches

Beforedrillingunderawalkordriveway,youmustmakean

entranceandanexittrenchoneithersideofthedrillingarea.

Bothtrenchesmustbeatleast15.24cm(6inches)wideand

45.72cm(18inchesdeep).Theentrancetrenchmustbeat

least213.36cm(7feet)longandtheexittrench91.44to

182.88cm(3to6feet)long.Theentrancetrenchshouldbe

perpendiculartothewalkordrivewayandtheexittrench

shouldbeparalleltothewalkordriveway.Theexittrench

shouldbecenteredacrossfromtheentrancetrench(Figure

19).

Figure19

1.Entrancetrench3.Exittrench

2.Sidewalk

BoringtheHole

Important:Boringisatwopersonoperation.Donot

attempttoperformthisoperationbyyourself.

1.Positionthemachinewiththedriveheadatthe

beginningofthetrenchandlowerittotheappropriate

depth.

2.Stoptheengineandwaitforallmovingpartstostop.

3.Connectarodandboringbitontothedrivehead.

4.Connecttherodguidetooltotherodjustbehindthe

boringbit(Figure20).

Figure20

1.Sidewalkordriveway

4.Rod

2.Entrancetrench5.Rodguidetool

3.Boringbit

5.Withthepersonguidingtheboringbitpositionedto

therightofthetrench(Figure20),starttheengine,

movethepumpselectorvalvetoslow ,positionthe

throttletowithinthemiddleoftheRPMrange,and

pushthehydra-borer-controlleverforwardtostartthe

forwardrotationoftheboringbit.

6.Slowlymovethemachineforward,whiletheperson

withtherodguidetoolguidestheboringbitintothe

soil(Figure20).

8

7.Oncetheentiredrillbitisinthesoil,pushthecontrol

leverintoneutral.

8.Stoptheengineandwaitforallmovingpartstostop.

9.Checkthegradeoftherod.

Iftherodisnotwithinthegradetolerancesforthejob

beingperformed,starttheengine,anddrivebackward

topulltheboringbitoutofthesoil,thenrepeatsteps

5

through9,makingadjustmentstocorrectthegrade.

10.Removetherodguidetool.

11.Starttheengineandpullthecontrolleverrearwardto

starttheboringbit.

12.Slowlymovethemachineforwardastheboringbit

digsintothesoil.

Important:Donotdrivetoofast,forcingthebit

intothesoil.Allowthebittoprogressatitsown

rate.Donotpushorpullthebitthroughthesoil

whenthedriveheadisnotturning.

13.Whenabout15cm(6inches)ofrodareleftshowingin

theentrancetrenchorwhentheboringbitcompletely

entersandboresintothefarsideoftheexittrench,

stopthemachine,pushthecontrolleverintoneutral,

andstoptheengine.

14.Iftheboringbithasnotyetenteredtheexittrench,

completethefollowing:

A.Detachtherodfromthedrivehead.

B.Starttheengineandbackuptotheendofthe

entrancetrench.

C.Stopengineandwaitforallmovingpartstostop.

D.Connectanotherrodandrepeatsteps

11through

14.

ReamingtheHole

1.Withashovel,carefullydigaroundtheboringbit

clearingitofsoiluntilitcanberemoved(Figure21).

Figure21

1.Sidewalkordriveway

4.Reamer

2.Exittrench

5.Swivel

3.Shoveldugareaaround

bit

2.Removetheboringbitandattachthereamer(Figure

21).

3.Attachthecableorpipingbeinginstalledtotheswivel

ontheendofthereamer(Figure21).

4.Starttheengineandpullthecontrolleverrearwardto

startthereamer.

5.Slowlymovethemachinerearwardasthereamerdigs

intothesoil.

Important:Donotdrivetoofast,forcingthe

reamerintothesoil.Allowthereamertoprogress

atitsownrate.Neverpushorpullthereamer

throughthesoilwhenthedriveheadisnotturning.

6.Whenarodcouplingisabout15cm(6inches)intothe

entrancetrenchorwhenthereamercompletelyenters

thetrenchwithabout15cm(6inches)ofthecableor

piping,stopthemachine,pullthecontrolleverinto

neutral,andstoptheengine.

7.Ifthereamerhasnotyetenteredtheexittrench,

completethefollowing:

A.Detachtherodfromthedriveheadandrodstill

inthesoil.

B.Starttheengineandmovetothefrontofthe

entrancetrench.

C.Stoptheengineandwaitforallmovingpartsto

stop.

D.Connectthedriveheadtotherodshaftinthesoil.

E.Repeatsteps

4through7.

8.Withthereamerandcable/pipingintheentrance

trench,removethecableorpipingfromthereamer.

9

Storage

1.Beforelongtermstorage,washtheattachmentwith

milddetergentandwatertoremovedirtandgrime.

2.Checktheconditionofthehydraulichoses.Replace

anydamagedhoses.

3.Ensurethatallhydrauliccouplersareconnected

togethertopreventcontaminationofthehydraulic

system.

4.Checkandtightenallbolts,nuts,andscrews.Repairor

replaceanydamagedorwornpart.

5.Paintallscratchedorbaremetalsurfaces.Paintis

availablefromyourAuthorizedServiceDealer.

6.Storetheattachmentinaclean,drygarageorstorage

area.Coverittoprotectitandkeepitclean.

10

Troubleshooting

Problem

PossibleCauseCorrectiveAction

1.Thehydrauliccouplerisnotcompletely

connected.

1.Checkandtightenallcouplers.

2.Ahydrauliccouplerisdamaged.

2.Checkthecouplersandreplaceany

thataredamaged.

3.Thereisanobstructioninahydraulic

hose.

3.Findandremovetheobstruction.

4.Ahydraulichoseiskinked.4.Replacethekinkedhose.

5.Theauxiliaryvalveonthemachineis

notopening.

5.Repairthevalve.

Theboredriveheadwillnotrotate.

6.Ahydraulicmotorisdamagedorworn.6.Replaceorrepairthemotor.

11

TheToroUndergroundWarranty

AstecBrandProduct

Soldafter

November1,2012

ALimitedWarranty

ConditionsandProductsCovered

TheToroCompanyanditsafliate,T oroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroUnderground

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship.

Whereawarrantableconditionexists,wewillrepairtheProduct

atnocosttoyouincludingdiagnostics,labor,andparts.

ThefollowingwarrantyappliesfromthedatetheProductisdeliveredto

theoriginalretailpurchaserorrentalowner.

ProductsWarrantyPeriod

RT600,RT800,RT1000,RT1200,

DD2024,andDD4045

2yearsor1500operatinghours,

whicheveroccursrst

AllOtherEnginePoweredBase

UnitsandFluidMixers

1yearor1000operatinghours,

whicheveroccursrst

AllSerializedAttachments

1year

RockHammer6months

Engines

Throughenginemanufacturers:

2yearsor2000operatinghours,

whicheveroccursrst

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheUndergroundDealerfromwhomyou

purchasedtheProductassoonasyoubelieveawarrantablecondition

exists.IfyouneedhelplocatingaUndergroundDealer,orifyouhave

questionsregardingyourwarrantyrightsorresponsibilities,youmay

contactusat:

ToroCustomerCare

ToroWarrantyCompany

8111LyndaleAvenueSouth

Bloomington,MN55420-1196

TollFreeat855-493-0088(U.S.Customers)

1-952-948-4318(InternationalCustomers)

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenance

andadjustmentsstatedinyourOperator'sManual.Failuretoperform

requiredmaintenanceandadjustmentscanbegroundsfordisallowinga

warrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-Toro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinan

abusive,negligent,orrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobe

defective.Examplesofpartswhichareconsumed,orusedup,during

normalProductoperationinclude,butarenotlimitedto:brakes,

lters,lights,bulbs,belts,tracksortires,diggingteeth,diggingbooms,

digging,drive,ortrackchains,trackpads,drivesprockets,idlers,

rollers,blades,cuttingedges,orothergroundengagingcomponents.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather,storage

practices,contamination,useofunapprovedfuels,coolants,

lubricants,additives,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damagetoseats

duetowearorabrasion,wornpaintedsurfaces,scratcheddecals,etc.

•Haulingexpenses,traveltime,mileage,orovertimeassociatedwith

transportingproducttotheauthorizedTorodealer.

Parts

Partsscheduledforreplacementasrequiredmaintenanceinthe

Operator’sManual,arewarrantedfortheperiodoftimeuptothescheduled

replacementtimeforthatpart.Partsreplacedunderthiswarrantyare

coveredforthedurationoftheoriginalproductwarrantyandbecomethe

propertyofToro.T orowillmakethenaldecisionwhethertorepairany

existingpartorassemblyorreplaceit.T oromayuseremanufactured

partsforwarrantyrepairs.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesT oroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedT oroUndergroundDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.

Allimpliedwarrantiesofmerchantabilityandtnessforuseare

limitedtothedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sothe

aboveexclusionsandlimitationsmaynotapplytoyou.Thiswarranty

givesyouspeciclegalrights,andyoumayalsohaveotherrightswhich

varyfromstatetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EPA)and/ortheCaliforniaAir

ResourcesBoard(CARB).Thehourlimitationssetforthabovedonot

applytotheEmissionsControlSystemWarranty.RefertotheEngine

EmissionControlWarrantyStatementsuppliedwithyourproductor

containedintheenginemanufacturer’sdocumentationfordetails.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirToroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourUndergroundDealer’sserviceorhavedifculty

obtainingguaranteeinformation,contacttheT oroimporter.

AustralianConsumerLaw:AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalToro

Dealer.

374-0291RevA

/