Page is loading ...

FormNo.3389-753RevA

CenterlineTrencher

RT600TractionUnit

ModelNo.25431—SerialNo.313000001andUp

ModelNo.25431—SerialNo.314000001andUp

ModelNo.25431—SerialNo.315000001andUp

ModelNo.25431E—SerialNo.315000001andUp

ModelNo.25431E—SerialNo.313000001andUp

Registeratwww.Toro.com.

OriginalInstructions(EN)

*3389-753*A

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Introduction

Thisattachmentisdesignedtodigtrenchesinsoiltobury

cablingandpipingforvariousapplications.Itisnotintended

tocutrock,wood,oranyothermaterialotherthansoil.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedToroServiceDealer

orToroCustomerServiceandhavethemodelandserial

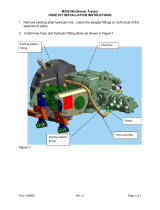

numbersofyourproductready.Figure1illustratesthe

locationofthemodelandserialnumbersontheproduct.

Writethenumbersinthespaceprovided.

1

G023157

Figure1

1.Locationofthemodelandserialnumberplate

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

2

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved

Contents

Safety...........................................................................3

SafetyandInstructionalDecals.................................4

Setup............................................................................6

1InstallingtheTrencherAttachment..........................7

2PreparingtheHydraulicMotor................................8

3InstallingtheHydraulicHoses...............................10

4InstallingtheSprocket..........................................12

5InstallingtheBoom..............................................12

6AligningtheBoom...............................................14

7InstallingtheDiggingChain..................................15

Operation....................................................................16

SelectingtheProperComponentsforthe

Trencher............................................................16

UsingtheTrencher.................................................18

OperatingTips......................................................20

Maintenance.................................................................21

GreasingtheTrencher(LeftSide).............................21

GreasingtheTrencher(RightSide)............................21

ServicingthePlanetaryDrive...................................22

ServicingtheTrencherDiggingChain.......................23

ReplacingtheDiggingChain....................................27

Storage........................................................................29

Troubleshooting...........................................................30

Safety

Improperlyusingormaintainingthetrenchercanresult

ininjury.Toreducethepotentialforinjury,comply

withthesesafetyinstructionsandthoseinthetraction

unit

Operator’ s Man ual

.Alwayspayattentiontothe

safetyalertsymbol,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failuretocomply

withtheinstructionmayresultinpersonalinjuryor

death.

DANGER

Theremaybeburiedpower,gas,and/ortelephone

linesintheworkarea.Anelectricshockoran

explosionmayoccurifyoudigintoautilityline.

Havethepropertyorworkareamarkedforburied

linesanddonotdiginmarkedareas.Contactyour

localmarkingserviceorutilitycompanytohavethe

propertymarked(forexample,intheUnitedStates,

call811forthenationwidemarkingservice).

DANGER

Themovingteethandaugerwillcutorseveryour

hands,feet,orotherbodyparts.

•Keephands,feet,andanyotherpartofyour

bodyorclothingawayfrommovingteeth,auger,

orotherparts.

•Beforeadjusting,cleaning,repairing,or

inspectingthetrencher,lowerthetrencherto

theground,stoptheengine,waitforallmoving

partstostop,andremovethekey.

WARNING

Whentheengineisoff,anattachmentintheraised

positioncangraduallylower.Someonebelow

theattachmentmaybepinnedorinjuredbythe

attachmentasitlowers.

Alwayslowertheattachmenteachtimeyoushut

offthetractionunit.

WARNING

Whengoingupordownhill,themachinecould

overturniftheheavyendistowardthedownhill

side.Someonemaybepinnedorseriouslyinjured

bythemachineifitoverturns.

Operatethemachineupanddownslopeswith

theheavyendofthemachineuphill.Anattached

trencherwillmakethebackendofthemachine

heavy.

3

WARNING

Lightningcancausesevereinjuryordeath.

Iflightningisseenorthunderisheardinthearea,

donotoperatethemachine;seekshelter.

CAUTION

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjectedinto

theskinmustbesurgicallyremovedwithinafew

hoursbyadoctorfamiliarwiththisformofinjury;

otherwise,gangrenemayresult.

•Keepyourbodyandhandsawayfrompin-hole

leaksornozzlesthatejecthigh-pressure

hydraulicuid.

•Usecardboardorpapertondhydraulicleaks;

neveruseyourhands.

CAUTION

Hydraulicttings,hydrauliclines/valves,and

hydraulicuidmaybehotandcanburnyouifyou

touchthem.

•Weargloveswhenmaintaininghydraulic

components.

•Allowthetractionunitandtrenchertocool

beforetouchinghydrauliccomponents.

•Donottouchhydraulicuidspills.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

Figure3

1.Decal125-66703.Decal125-6671

2.Decal125-66934.Decal125-6694

4

125–6670

1.Cutting/dismembermenthazard,trencher—keep

bystandersawayfromthetrencher;keepawayfrommoving

parts;keepallguardsandsafetiesinplace.

125-6671

1.Explosionhazard;electricshockhazard—calllocalutilities

beforedigging.

125-6693

1.Trencheroil3.Lubricatetheaugerevery

10to50operatinghours.

2.Gear-boxoil4.ReadtheOperator’s

Manualformaintenance

information.

125–6694

1.Tie-downpoint

5

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

Qty.

Use

Trencherattachment1

Bolt(3/4x2-3/4inch)

4

Bolt(3/4x2-1/2inch)

2

Flatwasher11

1

Locknut8

Installthetrencher.

Straightadaptertting(5/8inch)

1

Straightadaptertting(3/4inch)

1

Restrictortting

1

90°elbow(male/male)

1

Teetting

1

2

90°elbow(female/male)

1

Preparethehydraulicmotor.

Hose(34-1/2inch)

1

Hose(35-1/2inch)

1

Hose(40inch)

1

Bypasshose(16inch)

1

Hose(23inch)

2

Straightadaptertting(3/8inch)

2

3

Cabletie

1

Installthehydraulichoses.

Sprocketsegment

2

Bolt8

4

Locknut8

Installthesprocket.

Boom1

Bolt(3/4x6-1/2inch)

2

Washer(3/4inch)

2

Nut(3/4inch)

2

Bolt(1x2inch)

2

5

Washer(1inch)

2

Installtheboom.

6

Shim

3Aligntheboom.

7

Diggingchain1Installthediggingchain.

6

1

InstallingtheTrencher

Attachment

Partsneededforthisprocedure:

1Trencherattachment

4

Bolt(3/4x2-3/4inch)

2

Bolt(3/4x2-1/2inch)

11Flatwasher

8Locknut

Procedure

1.RaisetheattachmentofftheoorasshowninFigure4.

Important:Ensurethattheliftingequipmenthas

aliftingcapacityofatleast405kg(893lb).

Figure4

2.Locatethe2rowsofholesinthemountingplatethat

youwillusetosecuretheattachmenttothetraction

unit(Figure5).

2

3

Figure5

1.Row2mountingholes3.Row4mountingholes

2.Mountingplate

3.Insertalocknutintothenutretainerlocatedinside

thetrencherattheholeinrow2(Figure5)asshown

inFigure6.

Figure6

1.Locknut3.Washer

2.Nutretainer

4.Bolt(3/4x2-1/2inch)

4.Slipawasherontoabolt(3/4x2-1/2inch),and

partiallythreadtheboltintothenutthatyouinstalled

instep3;refertoFigure6.

7

5.Slipawasherontoeachof2bolts(3/4x2-1/4inch),

andinsertthemfrominsidethetrencher(Figure7)

throughtheremaining2holesinrow2.

Figure7

1.Bolt—3/4x2-1/4inch(2)

4.Washer

2.Washer5.Locknut

3.Hole

6.Slipawasherandpartiallythreadalocknutontothe

endofeachofthe2bolts.

7.Positionthetrenchersothatitisattherearofthe

tractionunit.

8.Aligntherowofboltsonthetrenchersothattheyare

abovetheupperslotsinthemountingplateonthe

tractionunit(Figure8).

3

Figure8

1.Upperslots3.Lowerslots

2.Mountingplate

9.Lowerthetrencherattachmentuntilitisalignedwith

themountingplateandtheboltstintheupperslots.

Note:Ensurethatthewashersontheboltsprojecting

throughthetrencherattachmentarealignedtothe

forwardsideofthemountingplateasyoulowerthe

trencherattachmentonthemachine;refertoFigure9.

Figure9

1.Trencher3.Boltsandlocknuts

2.Boltheadandwasher

4.Upperslot(3)

10.Handtightenalltheboltsandnuts.

11.Frominsidethetrencherattachment,installabolt(3/4

x2-1/2inch),2washers,andalocknutintheoutermost

leftholeinrow4(Figure8)asshowninFigure10.

Figure10

1.Locknut

4.Bolt(3/4x2-3/4inch)

2.Washer

5.Bolt(3/4x2-3/4inch)

3.Bolt(3/4x2-1/2inch)

12.Frominsidethetrencherattachment,install2bolts

(3/4x2–3/4inch),4washers,and2locknutsinthe

remainingholesinrow4asshowninFigure10.

13.Torquetheboltsandthelocknutsto583to624N-m

(400to460ft-lb).

8

2

PreparingtheHydraulicMotor

Partsneededforthisprocedure:

1

Straightadaptertting(5/8inch)

1

Straightadaptertting(3/4inch)

1

Restrictortting

1

90°elbow(male/male)

1

Teetting

1

90°elbow(female/male)

Procedure

1.Removeanddiscardtheplasticplugsfromtheportsof

thehydraulicmotorasshowninFigure11andFigure

12.

Figure11

1.Plasticplug

4.Port(upperoutboard)

2.Steelplug5.Steelplug—removeand

saveit

3.PortC(upperinboard)

6.PortB

Figure12

1.Port(loweroutboard)4.Steelplug(removedfrom

PortB)—insertitintothe

loweroutboardport

2.Port(lowerinboard)5.Steelplug—removeand

discardit

3.Plasticplug—removeand

discardit

2.Removethesteelplug(withtheO-ring)fromPortB

(Figure11),andinstalltheplugintotheloweroutboard

portasshowninFigure12.

3.RemoveanddiscardthesteelplugfromPortC.

4.Removeanddiscardthesteelplug(andtheO-ring)

fromthelowerinboardport(Figure12).

5.Installthestraightadaptertting(5/8inch)intoPortC

(Figure13).

9

10

Figure13

1.PortC6.Teetting

2.Straightadaptertting(5/8

inch)

7.Restrictortting

3.Straightadaptertting(3/4

inch)

8.90°elbow(female/male)

4.Port(upperoutboard)9.Port(loweroutboard)

5.PortB

10.90°elbow(male/male)

6.Installthestraightadaptertting(3/4inch)intothe

upperoutboardport(Figure13).

7.LooselythreadtheteettingintoPortBofthe

hydraulicmotor(Figure13).

Note:AligntheteettingasshowninFigure13.

8.Installtherestrictorttingintotherearportofthetee

tting(Figure13).

Note:Ensurethattheelbowisalignedtowardtherear

andupward.

9.Installthe90°elbow(female/male)totherestrictor

tting(Figure13).

10.Installthe90°elbow(male/male)ontothelower

outboardport(Figure13).

Note:Ensurethattheelbowisalignedtowardtherear

andupward.

11.Tightenallttingssecurely.

3

InstallingtheHydraulicHoses

Partsneededforthisprocedure:

1

Hose(34-1/2inch)

1

Hose(35-1/2inch)

1

Hose(40inch)

1

Bypasshose(16inch)

2

Hose(23inch)

2

Straightadaptertting(3/8inch)

1

Cabletie

Procedure

1.Installthebypasshosebetweentheelbows(Figure14).

Note:Thebypasshoseshouldforma“U”shape.

Figure14

1.Hose(34-1/2inch)4.Hose(35-1/2inch)

2.Hose(40inch)5.Bypasshose(16inch)

3.Teetting6.90°elbows

2.Removethe2caps(1-7/16inch)andthe1cap(5/8

inch)ontheleftsideofthehydraulicattachmentpanel

(Figure15).

10

3

Figure15

Hydraulicattachmentpanel

1.Cap(1-7/16inch)3.Cap(3/8inch)

2.Cap(5/8inch)

3.Removethe2caps(3/8inch)fromtherightsideofthe

hydraulicattachmentpanel(Figure15).

4.Installthe34-1/2inch,40-inch,and35-1/2inchhoses

betweenthettings(Figure14)onthehydraulicmotor

andthettingsonthehydraulicattachmentpanelas

showninFigure16.

Note:Ensurethattheangledttingsonthe

34-1/2-inchhoseandthe40-inchhoseareconnected

totheirrespectivettingsonthehydraulicattachment

panel.

7

Figure16

1.Cabletie5.Angledttings

2.Hose(35-1/2inch)6.Manifold

3.Hose(34-1/2inch)

7.Fittings

4.Hose(40inch)

5.Securethe3hydraulichoseswithacabletieasshown

inFigure16.

6.RemovetheplugsfromPortAandPortBofthe

manifold.

7.Installthestraightadapterttings(3/8inch)intothe

manifold(Figure16).

8.Connectthe2hoses(23inch)tothemanifoldandto

thehydraulicattachmentpanelttingsasshownin

Figure17.

7

Figure17

1.Retracttting5.Manifold

2.Extendtting6.Extendtting

3.Extendhose

7.Retracttting

4.Retracthose

9.Startthemachine;refertothetractionunitOperator’s

Manual.

10.Operatethetrencher-chaindirectioncontrolandthe

attachmentcontrol(locatedontherightsideofthe

operatorseat)inbothdirectionsseveraltimestobleed

theairfromthehydraulicmotorandthehydrauliclift

cylinder(Figure18).

Note:Thetrencher-chaindirectioncontrolrotatesthe

hubforwardandrearward,andtheattachmentcontrol

raisesandlowerstheboom-mounttting.Have

anotherpersonobservethehubandtheboom-mount

ttingastheymove.Moveeachofthecontrolsinboth

directionsuntilthehubandtheboom-mounttting

movesmoothlyinbothdirections.

11

G023281

Figure18

1.Trencher-chaindirection

control

2.Attachmentcontrol

4

InstallingtheSprocket

Partsneededforthisprocedure:

2

Sprocketsegment

8Bolt

8Locknut

Procedure

1.Install1ofthe2sprocketsegmentsontothehubofthe

planetarydrivewith4boltsand4locknuts(Figure19).

1

2

3

G023225

Figure19

1.Bolt(4)3.Locknut(4)

2.Sprocketsegment

2.Startthemachineandrotatetheplanetarygearby

movingthetrencherfunctioncontroluntiltheother

halfofthehubisaccessible.

3.Repeatstep1toinstalltheothersprocketsegment.

4.Torquetheboltsandlocknutsto160to190N-m(120

to140ft-lb).

5

InstallingtheBoom

Partsneededforthisprocedure:

1Boom

2

Bolt(3/4x6-1/2inch)

2

Washer(3/4inch)

2

Nut(3/4inch)

2

Bolt(1x2inch)

2

Washer(1inch)

Procedure

1.Startthemachine;refertothetractionunitOperator’s

Manual.

2.Movetheboom-mountttingonthetrenchertothe

horizontalposition(Figure20).

12

Figure20

1.Boom-mountingttingonthetrencher

3.Attachtheliftingequipmenttotherestraintbar,and

lifttheboom(Figure21).

Important:Ensurethattheliftingequipmenthas

averticalliftcapacityofatleast313kg(690lb).

Note:Ensurethattheboomislevelwhenyouliftit.

Figure21

1.Boom-mountttingonthe

trencher

2.Mountingttingonthe

boom

4.Cleanthemountingsurfacesoftheboom-mounttting

onthetrencherandthemountingttingontheboom.

5.Aligntheholesinthemountingttingontheboom

withtheholesintheboom-mountttingonthe

trencher(Figure22).

Figure22

1.Mount-ttinghole(vertical)5.Mountttinghole

(horizontal)

2.Bolt—(3/4x6-1/2inch(2)6.Washer—1inch(2)

3.Washer—3/4inch(2)7.Bolt—1x2inch(2)

4.Nut—3/4inch(2)

6.Assemblethe2horizontalbolts(1x2inch)and2

washerstothehorizontalholesinthemountttings,

andtightenthembyhand(Figure22).

7.Assemblethe2verticalbolts(3/4x6-1/2inch),2

nuts,and2washerstotheverticalholesinthemount

ttings,andtightenthembyhand(Figure22).

8.Torquethebolts(1x2inch)263to320N-m(194to

237ft-lb).

9.Torquethebolts(3/4x6-1/2inch)189to231N-m

(140to170ft-lb).

13

6

AligningtheBoom

Partsneededforthisprocedure:

3

Shim

Procedure

1.Checkthealignmentoftheboomandrecordyour

measurementsintheAlignmentWorksheetbelow:

•Left-offsetboom:Iftheboomisalignedtothe

leftofthesprocketcenterline,placeastraight

edgeacrosstherightfaceofthedrivesprocket

andmeasurethegap(DimensionA)betweenthe

straightedgeandtheendroller(Figure23and

Figure24).

•Right-offsetboom:Iftheboomisalignedtothe

rightofthesprocketcenterline,placeastraight

edgeacrosstheleftfaceofthedrivesprocket

andmeasurethegap(dimensionA)betweenthe

straightedgeandtheendroller(Figure23and

Figure24).

•Nooffset:theboomisaligned.

Note:IfthemeasuredDimension-Agapis0to4.8

mm(0to0.1875inch),skiptostep10.

AlignmentWorksheet

YourMeasurement

(dimensionA)

Maximum-offsetGap4.8mm(0.1875inch)

Shim-correctionDimension

Figure23

Leftoffsetshown

1.DimensionAgap

3.Straightedge(211cm(83

inch)forthe48-inchrock

boom;244cm(96inch)

forthe60-inchrockboom)

2.Endroller

4.Sprocket

Figure24

1.Endroller(leftoffset)3.Endroller(rightoffset)

2.Sprocketcenterline

2.Usingthealignmentworksheet,determinethe

numberofshimsthatyouneedbysubtracting

yourmeasurement(dimensionA)fromthe

maximum-offsetgap4.8mm(0.1875inch).

Note:Theresultistheshim-correctiondimension.

14

3.Usetheshimtabletodeterminethenumberofshims

neededtoaligntheboomwithinthe4.8mm(0.1875

inch)maximum-offsetgap.

ShimTable

NumberofShims

forCorrection

22cm(48inch)

RockBoom

Shim-correction

Dimension

152cm(60inch)

RockBoom

Shim-correction

Dimension

1

7.1mm(0.28inch)9.4mm(0.37inch)

2

14.5mm(0.57

inch)

19.6mm(0.77

inch)

3

21.8mm(0.86

inch)

29.5mm(1.16

inch)

4.Installtheliftingequipmenttotheboomandsupport

it.

5.Removethe2bolts(3/4x6-1/2inch),washers,and

nuts(Figure25).

Figure25

1.Bolt(3/4x6-1/2inch)6.Locknut(3/4inch)

2.Mountingtting(rock

boom)

7.Washer(1inch)

3.Boom-tting(trencher)8.Bolt(1x2inch)

4.Shim(s)9.Left-offsetshimposition

5.Washer(3/4inch)10.Right-offsetshimposition

6.Removethe2bolt(1x2inch)andwashers.

7.Installtheshimsasfollows:

A.Determinetheshim(s)positionatthettingof

therockboom.

•Foraleft-offsetboom,aligntheshim(s)to

themountttingoftherockboomatthe

left-offsetshimposition(Figure25).

•Foraright-offsetboom,aligntheshim(s)to

themountttingoftherockboomatthe

right-offsetshimposition(Figure25).

B.Applyacoupleofdropsoffast-bonding

cyanoacrylatebasedadhesivetotheshim(s);refer

toFigure26.

Figure26

1.Shimlocations5.Locknut(3/4inch)

2.Bolt(3/4x6-1/2inch)6.Shim(s)

3.Mountingtting(rock

boom)

7.Washer(1inch)

4.Washer(3/4inch)8.Bolt(1x2inch)

C.Aligntheholeintheshim(s)withthehorizontal

25mm(1inch)holeinthemountttingofthe

rockboom,andtacktheshimtotheforwardface

tting(Figure26).

8.Aligntheholesinthemountingttingontheboom

withtheholesintheboom-mountttingonthe

trencher(Figure25).

9.Assemblethe2bolts(3/4x6-1/2inch),2washers,and

2nutstotheholesintheboomandtrenchermount

ttings,andtightenthembyhand(Figure25).

10.Applythread-lockingcompoundtothe2horizontal

bolts(1x2inch).

Note:Ifyouskippedtostep9becausethemeasured

Dimension-Agapis0to4.8mm(0to0.1875inch),

youwillhavetoremovethe2horizontalboltsinorder

toapplythethread-lockingcompound.

11.Assemblethe2bolts(1x2inch)and2washerstothe

holesintheboomandtrenchermountttings,and

tightenthembyhand(Figure25).

12.Torquethe2bolts(3/4x6-1/2inch)378to462N-m

(279to341ft-lb).

Torquethe2bolts(1x2inch)525to641N-m(387

to473ft-lb).

15

7

InstallingtheDiggingChain

Partsneededforthisprocedure:

1Diggingchain

Procedure

RefertoInstallingtheDiggingChain(page28).

Operation

SelectingtheProper

ComponentsfortheTrencher

Usingthecorrecttrenchercomponentshelpstoincrease

thetrenchingspeedandextendingthelifeofthetrencher.

ContactanAuthorizedToroServiceDealerformore

informationonpartsforyourtrencher.

SelectingtheProperChain

Itisimportanttohavethecorrectchainforthejob.The

soilconditionswilldeterminethetypeofchainthathasthe

strengthandtensionthatyouneed.Achainthatistoolight

wearsfastorbreaks;achainthatistooheavyincreasesthe

loadonthemachineandreducesthetrencherdiggingspeed;

however,aheavychainhasalongerwearlifethanalighter

chain.

Youcancongurethetrencherwithananti-backexdigging

chainthatisdesignedforharddiggingconditionsorawelded

H-platechainforextremeconditions.Thesideplatesofthe

anti-backexdiggingchainareclosetogether.Asthechain

leavesthesprocket,eachlinkcomestogetherandformsa

soliddiggingchannel.Thisactionkeepseachtoothatthe

correctdiggingangle.TheweldedH-platechainisfordigging

inthemostextremeconditions.

Important:Maintainthecorrectchaintension.Ifthe

chainistootightortooloose,thediggingefciency

decreasesandthepartswearmorequickly.Referto

CheckingtheChainTension(page23).

Note:Trencherchainsareratedbytheirtensilestrength;for

example,a34019kg(75,000lb)chaintakesaminimumof34

019kg(75,000lb)ofpulltobreakthechain.

Selectthechaintype;chooseeitheraanti-backexchainora

weldedH-platechain(Figure27andFigure28).

Figure27

1.Anti-backexchain

16

Figure28

1.H-platechain

SelectingtheProperDiggingTeeth

Themostimportantcomponentofthetrencherarethe

diggingteeth;thetypeofteeththatyouselectandthe

arrangementofteeththatyouusegreatlyaffectsthedigging

efciencyandtoothwear.

•Choosetheteethtype:

–cuppedteeth

–rock/frostbit

–sharkteeth

–cuppedteethandrock/frostbitcombination

–cuppedandsharkteethcombination

•Choosethetootharrangementwidth:

–152mm(6inch)

–203mm(8inch)

TypesofDiggingTeeth

Thetypesofdiggingteethareasfollows:

•Cuppedteeth(Figure29)arethebestforcutting

throughlighttomediumsoil.Thecuppeddesignofthe

toothcutsthroughthesoilandthenmovesitupandout

ofthetrench.

1

G02191 1

Figure29

1.Cuppedteeth

•Rockandfrostteeth(Figure30)orsharkteeth(Figure

31)arebestforcuttinggroundthatisveryhard,rocky,or

frozen;itisalsousedforcuttingthroughasphalt.

G021912

1

Figure30

1.Sharktooth

1

G021972

Figure31

1.Rockandfrosttooth

ArrangementsoftheDiggingTeeth

Thearrangementofdiggingteethinvolvesbothwhereand

howeachtoothisattachedtothediggingchain.Usethe

followingguidelineswhenyouselectthearrangementsof

teeth:

•Installteeththatarethesamewidthandarespaced

equallyaroundthechain.

•Usefewerteethonthechainwhenyouareoperatingthe

trencherinwetclayorgumbo.

•Usemoreteethonthechainwhenyouareoperatingthe

trencherinsandyloamorrockyground.

Note:Youcanusedifferenttypesandcombinationsofteeth

toincreaseproductivityinvariousdiggingconditions.The

rockandfrostteethorthesharkteethpenetratethesoilwell,

andthecuppedteethhelptoremovethesoil.Tryseveral

combinationstodeterminetheonebestsuitedforyoursite.

17

CombinationsofBoom,Chain,andTeethforVariousSoilTypesandConditions

SoilTypeChainType

DiggingTeethType

HeavyDuty

Anti-backex

H-Plate

CupCutterRock/Frost

MiningBit

Shark

Mixed

Sand

X

SandyLoam

X

LooseShale

XX

TopsoilX

Caliche(Hard)

XXXXX

Clay(Gumbo)

XX

Coral

XXXX

Rock(Loose)

XXXX

AsphaltXXXX

HardClay

XXXXX

FrozenSoil

XXXXX

Note:Youneedarockwheeltocutsolidrockorconcrete.

UsingtheTrencher

CheckingtheTooth-mountingBolts

ServiceInterval:Beforeeachuseordaily

Checkthemountingboltsofallthechainteeth(Figure32),

andtightentheboltsasneeded.

g021914

1

Figure32

1.Mountingbolts

PositioningtheSeatforTrenching

Fastentheseatbeltandrotatetheseattothetrenching

position.

Note:Youmustbeseatedintheoperatorseatbeforemoving

themachine;otherwise,theenginewillstopin1second.

UsingtheTrencherControls

•Movetherearattachmentspeedcontrolleverforwardto

actuatethediggingchainintheforwarddirection.

•Movetheleverfurtherforwardtoincreasethechain

speed.

•Movetheleverfurtherrearwardtodecreasethechain

speed.

MovethecontroltotheNeutralposition(A)tostopthe

chain;movethecontrolleverrearward(B)toreversethe

chaindirection.

•Tolowerthetrencherboomtothedesireddepth,push

theattachmentcontrolleverawayfromyou;toraisethe

trencherboom,pullthecontrollevertowardyou.When

youreleasethecontrollever,itwillreturntotheNeutral

positionautomatically.

18

PositioningtheBoomforTrenching

Forthebesttrenchingperformanceandthesmoothest

machineoperation,theboommustbeinthefulldown

trenchingposition(Figure33).Havingtheboominthis

positionpullsthemachinedownforbettertraction.The

grounddrivesimplypullsthetrencherteethintothefaceof

thetrench.

g021973

Figure33

Whenyouraisetheboomfromthefulldownposition,the

trenchingloadpullsthemachinerearward.Thispulling

reducesthetractionandmaycausethemachinetobounce

andpullwhenthechaincontactsrootsorrocks.Therearward

pullofthetrenchingoperationalsoworksagainsttheground

drive,causingtheenginetoworkharder.

StartingaTrench

Important:Knowthelocationofallunderground

utilitiesbeforeoperatingthemachineontheworksite.

1.Ensurethatallpersonsareawayfromthemachine

beforeyoustarttheengineandwhileyouaretrenching.

2.Starttheengine;refertothetractionunitOperator’s

Manual.

3.Runtheengineat1/4throttleuntiltheenginereaches

theoperatingtemperature.

4.Movethecrumber(ifequipped)totheTransport

position(Figure34).

Figure34

1.Crumberbar(optional)

5.Whentheenginehasreachedtheoperating

temperature,movethemachinetotheworkareaand

positionthemachinetocutthetrench.

Note:Ensurethattheendofthetrencherboomis

severalfeetbeyondthestartingpointofthetrench.

6.Alignthemachinetothecenterlineofthenewtrench.

7.AdjusttheenginespeedtotheFullthrottleposition,

andlowertheboomtojustabovetheground.

8.Startthediggingchainbymovingtherearattachment

controllevertowardthefrontofthemachine.

Note:Youmustbeseatedintheoperatorseatbefore

movingthemachine;otherwise,theenginewillstop

in1second.

Note:Thecrumber(ifequipped)willautomatically

movefromtheTransportpositionintotheOperating

positionwhenthetrencherattachmentreachesthe

maximumdigdepth.

9.Movetheutility-tractionleverforwarduntilthe

machinestartstomoveforward.

10.Lowertheboomintotheground.

11.Whenthediggingchainisloweredtothedesireddepth,

movetheutility-tractionleverforwarduntiltheengine

speeddecreasesabout10%(200to300rpm).

Note:Rememberthatspeedonthetachometer.

19

12.Decreasethediggingchainspeedandlookatthe

tachometer.

Note:Iftheenginespeedincreases,pushthe

utility-tractionleverforwarduntiltheenginespeedis

thesamethatinstep11.Repeatthissteptoobtain

thebesttrenchingspeed.

Note:Somehardsoilconditionswillallowyoutodig

atrenchfasterbyreducingthechainspeed.

WARNING

Operatingatrencherattachmentwithouta

restraintbaroracrumbercouldseverelyinjure

orkillyouifthechainbreaks.

Donotoperateatrencherattachmentwithout

arestraintbar.

Note:Thetrencheroperatesbestwhentheengineis

atfullthrottle.Adjustthegroundspeedtokeepfrom

luggingtheengine.

Important:Allsteeringshouldbegradual.Donot

makesharpturnswiththeboomintheground.

Markingsharpturnswhilediggingwiththe

trencherwilldamagethetrencher.

Note:Checkthechaintensionwhenyouarestarting

anewtrenchineachlocation;refertoCheckingthe

ChainTension(page23).

CuttingaCurvedTrench

Important:Donotmakesharpturnswiththeboomin

theground.Markingsharpturnswhilediggingwiththe

trencherwilldamagethetrencher.

Youcanmakeagradualcurvebyusingtherear-wheelsteering

controlonlyasneededtoslightlyarticulatethemachine.Do

notmakesteeringcorrections,asthiswillswingtheboom

intothesideofthetrenchandundercutit.

StraighteningaCrookedTrench

Asthetrencherisdigging,itmayvaryslightlyfromastraight

line;thiscanoccurifyouarediggingtooquicklyforthesoil

conditions.Tostraightenthetrench,raisetheboom,reverse

thegroundtravelandmovethetrencherforwarduntilthe

diggingchainclearsthetrench.Correctthealignmentofthe

trenchertothetrenchandlowertheboom.

FinishingtheTrench

1.Whenyoucompletethetrench,stopthemachine.

2.Slowlyraisetheboomuntilitisoutofthetrenchabout

15cm(6inches).

3.Movetheattachmentgroundspeedcontrollevertothe

Neutral(disengaged)positiontostopthediggingchain.

4.PulltheattachmentliftleverbacktotheRaiseposition

untiltheboomisintheTransportposition.

5.MovethethrottletotheIdleposition,stoptheengine,

andremovethekey.

OperatingTips

•Cleantheareaoftrash,branches,androcksbefore

trenchingtopreventdamagingtheequipment.

•Alwaysselecttheshortestboom,thelightestchain,and

thelightestteethtohandlethejob.Inharddigging

conditions,selectahightensile-strengthchain,arock

boom,andananti-backexchainwithrockandfrost

teeth.

•Alwaysbegintrenchingwiththeslowestgroundspeed

possible.Increasethetrenchingspeedifconditions

permit.Ifthechainspeedslowsdown,reducetheground

speedtokeepthechainmovingatitsfastestrate.Donot

spinthewheelswhiletrenching.

•Alwaysusefullthrottle(maximumenginespeed)when

trenching.

•Alwaystrenchwhilethemachineismovingintheforward

direction.

•Trenchwiththechainata45-to60-degreeanglefor

bestresults.

•Youcandigatrenchfasterbycontrollingthedepthand

adjustingtheboomperiodically.

•Ifthetrencherbindsinthesoil,reversethechain

direction.Oncethechainisloose,changechaindirections

andcontinuetrenching.

•Ifyouneedthenishedtrenchtobecleanerthanwhatis

possiblewiththetrencher,youcanpurchaseacrumber

fromanAuthorizedToroServiceDealer.Thecrumber,

whichmountsontotherestraintbar,scrapesthetrench

cleanasyoudig.

•Ifthediggingspeedofthetrencheristooslowortoo

fast,adjustit.

•Usethecorrectchainforthegroundconditions;referto

SelectingtheProperChain(page16).

•Toobtainmaximumdiggingefciencyfromthetrencher,

alwayskeepgoodsharpteethatthenecessaryspaces.As

teethbecomeworn,replacethemimmediately.

•Somegroundconditionsmayrequireafasterchainspeed.

Movethechainspeedcontrolfurtherforwardfromthe

Neutralposition.Youcanreducethelifeofthedigging

chainbyusingitathigherchainspeedsforanextended

time.

20

/