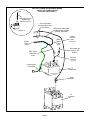

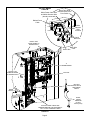

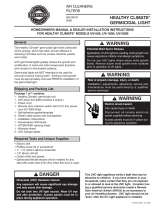

The Lennox C1UVCL10A-2 is a germicidal light kit designed to reduce microbial life forms (viruses, bacteria, yeasts, and molds) in the air. It uses ultraviolet (UVC) energy to effectively combat mold growth and proliferation on illuminated surfaces. The enhanced rapid start ballast provides UVC lamp operation at a full range of operating conditions, indicated by LED status lights. The kit includes a door switch that de-energizes the UVC light when the door is opened, ensuring safety.

The Lennox C1UVCL10A-2 is a germicidal light kit designed to reduce microbial life forms (viruses, bacteria, yeasts, and molds) in the air. It uses ultraviolet (UVC) energy to effectively combat mold growth and proliferation on illuminated surfaces. The enhanced rapid start ballast provides UVC lamp operation at a full range of operating conditions, indicated by LED status lights. The kit includes a door switch that de-energizes the UVC light when the door is opened, ensuring safety.

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

The Lennox C1UVCL10A-2 is a germicidal light kit designed to reduce microbial life forms (viruses, bacteria, yeasts, and molds) in the air. It uses ultraviolet (UVC) energy to effectively combat mold growth and proliferation on illuminated surfaces. The enhanced rapid start ballast provides UVC lamp operation at a full range of operating conditions, indicated by LED status lights. The kit includes a door switch that de-energizes the UVC light when the door is opened, ensuring safety.

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Lennox D-Box User manual

-

Lennox Healthy Climate UVC-24V/UVC-41W-S/UVC-41W-D Germicidal Lights Installation guide

-

Lennox UV0 Installation guide

-

Lennox UVO3 Healthy Climate Ozone-Emitting Germicidal Lamp Installation guide

-

Lennox Germicidal Lamp Base Kit Installation guide

-

Lennox Rooftop Unit Operating instructions

-

Lennox LC1077 Sustainable Rooftop Units User guide

-

Lennox SSB User manual

Other documents

-

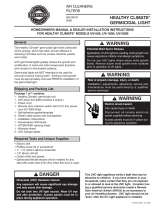

Healthy Climate UV-2000 Homeowners Manual & Dealer Installation Instructions

Healthy Climate UV-2000 Homeowners Manual & Dealer Installation Instructions

-

FIELD CONTROLS FlexMountUV UV-13FM and UV-17FM Air Purifier Installation guide

-

FIELD CONTROLS FlexMountUV UV-AIRE Series Operating instructions

-

Bard 46441700 User manual

-

FIELD CONTROLS TRIO-16, TRIO-20, TRIO-16HHS and TRIO-20HH User manual

-

Reznor SDH Installation guide

-

FIELD CONTROLS Duo-2000 User manual

-

CFM CX3000GS User manual

-

Healthcare Lighting 2403413 User manual

-

Atari gvrSX User manual