Page is loading ...

Model AD1684B Receiver

Dual Channel

General Purpose Receiver

Installation Instructions

This manual describes the installation and operating procedures for the AD1684B Dual Channel Receiver. The Receiver

provides for the control of a Pan/Tilt drive and a motorized Lens for two separate cameras. Receivers are designed as the remote

control device for operation of motorized Pan/Tilt and lens units. Since camera sites are often a great distance from the operator's

viewing location, these Receivers provide the operator with positive control of the camera site. Receivers also provide the

operator with control of auxiliary devices such as lights, door, etc, at the camera site. Receivers are individually coded for each

camera site so only the camera under observation will be controlled by the operator.

This software/firmware is confidential to and is copyrighted by SENSORMATIC ELECTRONICS CORPORATION. It is not to

be copied or disclosed in any manner without the express written consent of SENSORMATIC. The software is furnished to the

purchaser under a license for use on a single system.

NOTE: Information furnished by SENSORMATIC is believed to be accurate and reliable. However, no responsibility is

assumed by SENSORMATIC for its use; nor for any infringements of other rights of third parties which may result from its use.

No license is granted by implications or otherwise under any patent or patent rights of SENSORMATIC.

Copyright 1997 by SENSORMATIC. All rights reserved.

The installation of this product should be made by qualified

service personnel and should conform to all local codes.

QA301D

!

WW

WW

AA

AA

RR

RR

NN

NN

II

II

NN

NN

GG

GG

To reduce the risk of fire or shock hazard, do

not expose this product to rain or moisture.

AMERICAN

DYNAMICS

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE COVERS (OR BACK) .

NO USER-SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION

!

The lightning flash with arrowhead

symbol, within an equilateral

triangle, is intended to alert the

user to the presence of uninsulated

"dangerous voltage" within the

product's enclosure that may be of

sufficient magnitude to constitute a

risk of electric shock to persons.

The exclamation point within an

equilateral triangle is intended to

alert the user to the presence of

important operating and maintenance

(servicing) instructions in the

literature accompanying the product.

UU

UU

NN

NN

PP

PP

AA

AA

CC

CC

KK

KK

II

II

NN

NN

GG

GG

AA

AA

NN

NN

DD

DD

II

II

NN

NN

SS

SS

PP

PP

EE

EE

CC

CC

TT

TT

II

II

OO

OO

NN

NN

Unpack carefully. This is an electronic product and should

be handled as such. Compare the items received with the

packing list with your order.

Be sure to save:

1. The shipping cartons and insert pieces. They are the )

safest material in which to make future shipments of

the product.

2. The IMPORTANT SAFEGUARDS sheet.

3. These Installation and Operating Instructions.

MM

MM

AA

AA

II

II

NN

NN

TT

TT

EE

EE

NN

NN

AA

AA

NN

NN

CC

CC

EE

EE

User maintenance of this unit is limited to external cleaning

and inspection. For specific recommendations refer to the

IMPORTANT SAFEGUARDS sheet packaged with this product.

II

II

NN

NN

SS

SS

TT

TT

AA

AA

LL

LL

LL

LL

AA

AA

TT

TT

II

II

OO

OO

NN

NN

AA

AA

NN

NN

DD

DD

SS

SS

EE

EE

RR

RR

VV

VV

II

II

CC

CC

EE

EE

If you require information during installation of this

product or if service seems necessary, contact the

Sensormatic Repair and Service Department at (800)

442-2225. You must obtain a Return Authorization Number

and shipping instructions before returning any product for

service.

Do not attempt to service this product yourself. Opening or

removing covers may expose you to dangerous voltages or

other hazards. Refer all servicing to qualified personnel.

This equipment has been tested and

found to comply with Part 15 of the

FCC Rules.

Operation is subject to the

following two conditions: 1. This

device may not cause harmful

interference, and 2. This device

must accept any interference

received, including interference

that may cause undesired operation.

CONTENTS

Page

DESCRIPTION............................................................................... 1

FEATURES..................................................................................... 1

Pan/Tilt and Lens Control.......................................................... 1

Auxiliaries.................................................................................. 1

Preset Scene............................................................................... 1

SETUP .............................................................................................2

Receiver Configuration Setup.................................................... 2

Camera Number Setting ............................................................ 3

INSTALLATION............................................................................ 5

Preparation................................................................................. 5

Mounting.................................................................................... 5

CONNECTIONS ............................................................................ 6

Code Line Connections.............................................................. 6

Pan/Tilt and Lens Connections.................................................. 7

Auxiliary Connections............................................................... 9

Pre-position (Preset) Connections ........................................... 10

Power Connections.................................................................. 12

TYPICAL SYSTEM CONNECTIONS

AD2150 to AD1684B............................................................ C-2

AD1996 CPU to AD2091 to AD1684B ................................ C-3

AD1684B to AD1240P Pan/Tilt............................................ C-4

INDEX

SPECIFICATIONS.......................................................... Rear cover

AD1684B DESCRIPTION

DESCRIPTION

The AD1684B Receiver is used with American Dynamics

Matrix Switching Systems to control pan, tilt, zoom, focus,

iris, and auxiliary functions at a camera site. This Receiver is

classified as a dual channel type, since two independent control

channels are supplied. The AD1684B will control two

cameras with no auxiliaries or one camera with auxiliaries.

The output voltage of this unit is 24 VAC.

Receivers obtain control instructions via the common code

lines originating directly from a Matrix Switching System or

an intervening Code Distribution Unit. To enable each

Receiver to identify those control signals intended for it, each

Receiver must be set up at installation to identify the camera

number with which it is to be associated.

In systems over 64 cameras the numbers are block-related, i.e.,

System camera #1 is camera #1 in Block #1, System camera

#65 is camera #1 in Block #2, System camera #129 is camera

#1 in Block #3, etc.

As delivered, the AD1684B is a two-channel controller for

Pan/Tilt and Lens control of two separate cameras. The

channels are designated as Channel A and Channel B.

Channel A always controls the drive motors of a Pan/Tilt and

motorized Lens units. Channel B has a selectable output to

control either the drive motors of a second Pan/Tilt and Lens

or four auxiliaries. The auxiliary outputs are provided as two

latching or two momentary controls.

FEATURES

Pan/Tilt and Lens Control

As delivered, each channel of the Receiver provides drive

outputs at 24 VAC for control of Pan/Tilt motors and 10 VDC

output for Lens control. One ten-pin connector contains all the

connections required for control of the Pan/Tilt and Lens.

Note: Certain Pan/Tilt units require alternate voltages

other than those noted in this manual. If desired,

call the Technical Support Center for information or

assistance (1-800-442-2225).

Table 1 - Pan/Tilt and Lens Ratings

FUNCTION VOLTAGE CURRENT

PAN MOTOR 24 VAC 2.4 Amps (note 1)

TILT MOTOR 24 VAC 2.4 Amps (note 1)

IRIS MOTOR 10 VDC .05 Amps

FOCUS MOTOR 10 VDC .05 Amps

ZOOM MOTOR 10 VDC .05 Amps

Note: Total of all 24 V Pan/Tilt motor currents and Auxiliary

currents (both channels combined) is not to exceed 2.4

Amps. Continuous current for each Pan/Tilt or

Auxiliary output must not exceed 1.5 Amps.

Auxiliaries

If configured for auxiliary operation (Setup, page 2), the

AD1684B Receiver provides two latching and two momentary

outputs. These 24 Volt outputs may be used to operate user

controlled devices, provided that the total current for Pan/Tilt

and Auxiliaries does not exceed 2.4 Amps.

Auxiliary loads are subject to the same constraints as if the

channel was set for Pan/Tilt operation.

Preset Scene

This optional feature allows the operator to save a pre-selected

scene (pre-positioned scene) and recall the scene upon

keyboard command. The programmed scene is stored at the

Receiver and is backed-up in the event of a power failure.

The number of presets allowed by the Receiver is determined

by the Matrix Switching System. Refer to the Matrix

Switching System installation and operation manuals for

programming procedure.

The placement of jumper J9 determines whether the presets are

enabled. All units are factory set with the presets enabled.

1

SETUP AD1684B

SETUP

Receiver Configuration Setup

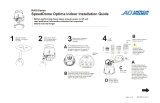

AD1684B Receivers may be configured as a two-channel

Pan/Tilt and Lens control unit or a single channel unit with

four auxiliaries. A two-position Berg jumper, labeled J5 (see

Figure 1), is provided to establish this configuration.

The Receiver is factory set for two-channel operation. The

output configuration can be changed to single-channel with

four auxiliaries by moving the jumper from the “NO AUX”

position to the “AUX” position. In this position, Channel B

(J6 and J3 connectors) is for auxiliary functions only.

2

J7

J4

J1

J6

J3

CODE

POWER

CAM/AUX

CHANNEL

A

CHANNEL

B

G

N

D

N

E

U

T

R

A

L

H

O

T

F1 F2

S1 S2

6

1

6

1

CAMERA I.D.

CHANNEL

A B

CABLE INPUT HOLES

J9

J5

R4

BLACK

WHITE

SHIELD

Figure 1 - AD1684B Connector and Switch Location

CAUTION - Due to the presence of non-

insulated components with hazardous

voltages, the following internal adjustments

should be performed by qualified service

personnel only.

!

Camera Number Setting

There are two DIP switches which associate the camera

number with the respective channel, A or B. DIP switch S1 is

for Pan/Tilt and lens control of Channel A, and DIP switch S2

is for Pan/Tilt and lens or auxiliary control of Channel B. The

location of S1 and S2 are shown in Figure 1, page 2.

The switch settings for the camera number assigned to these

channels are shown in Tables 3 and 4 (pages 3 and 4).

Camera numbers for AD1684B Receivers are set to 1 - 64

only. For camera numbers above 64, a block number (in

multiples of 64 cameras per block) is used at the Control Code

source (system bay, code distributor, or similar unit).

To determine the camera number setting for the AD1684B

Receiver, the multiple of 64 (64 times the block number) must

be subtracted from the actual camera number, as shown in the

following calculation:

Actual Camera Number

- 64 x (n-1) (where n is the block number)

= Receiver Camera Number

Example: If the actual Camera Number is 150, the block

number set at the Control Code source is 3 and the AD1684B

Receiver camera number setting is 22, calculated as follows:

150 (Actual Camera Number)

- 128 [64 x (3-1)]

22 (Receiver Camera Number)

AD1684B SETUP

3

Table 3 - S1 Pan/Tilt and Lens Camera Number Switch Settings

Channel A

L =left ("off"); R = right ("on")

CAMERA SWITCH CAMERA SWITCH

NUMBER 1 2 3 4 5 6 NUMBER 1 2 3 4 5 6

01 LLLLLL 33 LLLLLR

02 RLLLLL 34 RLLLLR

03 LRLLLL 35 LRLLLR

04 RRLLLL 36 RRLLLR

05 LLRLLL 37 LLRLLR

06 RLRLLL 38 RLRLLR

07 LRRLLL 39 LRRLLR

08 RRRLLL 40 RRRLLR

09 LLLRLL 41 LLLRLR

10 RLLRLL 42 RLLRLR

11 LRLRLL 43 LRLRLR

12 RRLRLL 44 RRLRLR

13 LLRRLL 45 LLRRLR

14 RLRRLL 46 RLRRLR

15 LRRRLL 47 LRRRLR

16 RRRRLL 48 RRRRLR

17 LLLLRL 49 LLLLRR

18 RLLLRL 50 RLLLRR

19 LRLLRL 51 LRLLRR

20 RRLLRL 52 RRLLRR

21 LLRLRL 53 LLRLRR

22 RLRLRL 54 RLRLRR

23 LRRLRL 55 LRRLRR

24 RRRLRL 56 RRRLRR

25 LLLRRL 57 LLLRRR

26 RLLRRL 58 RLLRRR

27 LRLRRL 59 LRLRRR

28 RRLRRL 60 RRLRRR

29 LLRRRL 61 LLRRRR

30 RLRRRL 62 RLRRRR

31 LRRRRL 63 LRRRRR

32 RRRRRL 64 RRRRRR

SETUP AD1684B

4

Table 4 - S2 Pan/Tilt and Lens Camera Number Switch Settings or Auxiliary Settings

Channel B

L = left ("off"); R = right ("on")

CAMERA SWITCH CAMERA SWITCH

NUMBER 1 2 3 4 5 6 NUMBER 1 2 3 4 5 6

01 LLLLLL 33 LLLLLR

02 RLLLLL 34 RLLLLR

03 LRLLLL 35 LRLLLR

04 RRLLLL 36 RRLLLR

05 LLRLLL 37 LLRLLR

06 RLRLLL 38 RLRLLR

07 LRRLLL 39 LRRLLR

08 RRRLLL 40 RRRLLR

09 LLLRLL 41 LLLRLR

10 RLLRLL 42 RLLRLR

11 LRLRLL 43 LRLRLR

12 RRLRLL 44 RRLRLR

13 LLRRLL 45 LLRRLR

14 RLRRLL 46 RLRRLR

15 LRRRLL 47 LRRRLR

16 RRRRLL 48 RRRRLR

17 LLLLRL 49 LLLLRR

18 RLLLRL 50 RLLLRR

19 LRLLRL 51 LRLLRR

20 RRLLRL 52 RRLLRR

21 LLRLRL 53 LLRLRR

22 RLRLRL 54 RLRLRR

23 LRRLRL 55 LRRLRR

24 RRRLRL 56 RRRLRR

25 LLLRRL 57 LLLRRR

26 RLLRRL 58 RLLRRR

27 LRLRRL 59 LRLRRR

28 RRLRRL 60 RRLRRR

29 LLRRRL 61 LLRRRR

30 RLRRRL 62 RLRRRR

31 LRRRRL 63 LRRRRR

32 RRRRRL 64 RRRRRR

AD1684B INSTALLATION

INSTALLATION

This installation should be made by qualified service personnel

and should conform to all local codes. Safeguards must be

taken to avoid unintentional operation by employees and

maintenance personnel working about the premises, by falling

objects, by customers, by building vibration, and by similar

causes.

Preparation

There are several switches to be set on this unit (Setup, pages 2

through 4). If the unit is not setup correctly damage to this unit

and any other device connected to it may result. The

installation and setup of this device should be made by a

qualified person and should conform to all local codes.

Check all wiring and cabling before applying power.

Mounting

Receivers are surface mounted and when used indoors can be

mounted with any orientation. Units to be mounted outdoors

must be securely mounted to a suitable surface, with the

hinged side facing to the left.

The housing is a standard NEMA 4, fiberglass reinforced

polyester, non-corrosive enclosure. The housing is 11.5” H x

9.3” W x 5.5” D. See Figure 2 for mounting dimensions.

Mount the unit with four 1/4" bolts appropriate to the type of

mounting surface.

For mounting to wood studs use lag bolts (with a drilled pilot

hole) or wood screws which will penetrate the wood for at

least 2 inches. In concrete use lead or plastic anchors, or

expansion bolts, with at least a 50 pound pullout rating,

installed according to the manufacturer's instructions. For

mounting to steel surfaces, drill four bolt clearance holes and

use bolts with lockwashers and nuts. When mounting to

drywall (gypsum) wallboard, material must be at least 1/2"

thick, and the unit must be mounted with toggle bolts.

The box should be mounted near the camera(s) to be controlled

to minimize voltage drop in the wiring.

5

Figure 2 - Mounting Hole Dimensions

10.75"

5/16" (0.3125) DIA

6.0"

CONNECTIONS AD1684B

CONNECTIONS

Code Line Connections

The Code Line connection to the Receiver is made with user-

supplied, shielded 2-wire twisted pair, Belden 8760 or

equivalent (for Plenum use Belden 88760 or equivalent). The

maximum code line length is 5000 feet.

The code line connector, labeled J1, is located on the right side

of the unit (see Figure 1 page 2). The pin positions are marked

BLACK (black code wire), WHITE (white code wire) and

SHIELD (cable shield). A mating three-pin screw-terminal

connector is provided for plug-in to J1.

BEFORE STARTING:

1. Check power line to verify that the power is off.

2. Open the Receiver and find the Code terminal connector

located on the PCB (see Figure 1).

WIRING INSTRUCTIONS:

3. Pass the code wire through a bushing to the code connector

- do not tighten bushing.

4. Strip the ends of code wires, 1/4" (6mm) from the end.

5. Insert the BLACK CODE wire into the mating screw-

terminal connector pin location for BLACK.

6. Insert the WHITE CODE wire into the WHITE pin location.

7. Insert the cable shield into the SHIELD pin location.

8. Remove any excess cable and tighten the bushing.

9. Insert the screw-terminal connector into the J1 connector.

The Receiver has a 120-ohm terminating resistor installed on

the PCB and is designed for “Star” connection to a Code

Distribution Unit, illustrated in Figure 3.

A maximum of three AD1684B Receivers can be connected in

a “Daisy Chain” connection, as illustrated in Figure 4. If the

Receiver is to be connected in a Daisy Chain, the 120-ohm

terminating resistor must be removed from all but the last

Receiver. A 120-ohm termination must be provided on the last

piece of equipment on each code line.

The 120-ohm terminating resistor for the AD1684B is located

on the right side of the PCB, near the J1 connector, and is

designated R4 (see Figure 1, page 2).

The green Code LED on these Receivers (located on the left

side of the PCB, near the J7 connector) is lit when the unit is

receiving good code. A flickering Code LED indicates a

problem in the transmission of the code, poor or loose

connection, improper termination or defective Receiver.

Refer to the Typical System Connections illustrations, pages

C-2 and C-3, for Code Line connections.

6

Figure 3 - Code Line Star Connections

Figure 4 - Code Line Daisy Chain Connections

Code Distribution Unit

* 120-Ohm Termination

Other

Receivers

Receiver

*

Receiver

*

Receiver

*

W

B

S

W

B

S

W

B

S

W

B

S

W

B

S

W

B

S

* 120-Ohm Termination

Receiver

W

B

S

Receiver

W

B

S

Receiver

W

B

S

*

Code Source

W

B

S

CAUTION - Due to the presence of non-

insulated components with hazardous

voltages, the following internal adjustments

should be performed by qualified service

personnel only.

!

AD1684B CONNECTIONS

Pan/Tilt and Lens Connections

The Receiver connection to a Pan/Tilt and a motorized Lens is

with a 10-pin connector. This connector is located on the left

side of the PCB and is labeled J7 (see Figure 1, page 2). When

the unit is set for dual operation (see Setup, page 2) a second

10-pin connector labeled J6, located on the right side of the

PCB opposite to J7, is used for the second Pan/Tilt and Lens.

Table 5 (page 8) lists the pin designations from the Receiver to

the Pan/Tilt and Lens and provides space for the installer to

record the pinouts for the specific installation. Match the

Pan/Tilt and lens pinouts from the manufacturer’s installation

manuals to Table 5 (on the following page).

Mating 10-pin screw-terminal connectors are provided for each

PCB connector (see Figure 5). The connector terminals accept

wire gauge sizes from 22-AWG to 14-AWG, stripped 1/4"

(6mm) from the end.

The following are the pin definitions for pan/tilt drive:

• The voltage on the pin marked "LEFT" physically pans the

camera view to the left.

• The voltage on the pin marked "RIGHT" physically pans

the camera view to the right.

• The voltage on pin marked "UP" physically tilts the camera

lens view upward.

• The voltage on the pin marked "DOWN" physically tilts the

camera lens view downward.

BEFORE STARTING:

1. Check the power line to verify that the power is off.

2. Open the Receiver and locate the Pan/Tilt and Lens

connector J7 on the left side of the unit. For dual-channel

operation, also locate connector J6.

WIRING INSTRUCTIONS:

3. Pass the wire through the bushing to the Pan/Tilt and Lens

connector, do not tighten bushing.

4. Strip the Pan/Tilt and Lens wires 1/4" (6mm) from the end.

Pan/Tilt:

5. Insert the PAN LEFT wire of the Pan/Tilt Unit into the

screw-terminal connector pin location for Pan LEFT.

6. Insert the PAN RIGHT wire of the Pan/Tilt Unit into the

pin location for Pan RIGHT.

7. Insert the TILT UP wire of the Pan/Tilt Unit into the pin

location for Tilt UP.

8. Insert the TILT DOWN wire of the Pan/Tilt Unit into the

pin location for Tilt DOWN.

9. Insert the Pan/Tilt AC COMMON wire of the Pan/Tilt Unit

into the pin location for AC COMMON.

10. Insert the cable SHIELD of the Pan/Tilt cable into the pin

location for SHIELD on connector J4 or J3 (use J4 for a

Pan/Tilt connected to J7; use J3 for a second Pan/Tilt

connected to J6).

Motorized Lens:

11. Insert the IRIS wire of the motorized Lens unit into the pin

location for IRIS.

12. Insert the FOCUS wire of the motorized Lens unit into the

pin location for FOCUS.

13. Insert the ZOOM wire of the motorized Lens unit into the

pin location for ZOOM.

14. Insert the Lens COMMON wire of the motorized Lens unit

into the pin location for DC GROUND.

Note: DO NOT connect the LENS COMMON to the

PAN/TILT COMMON.

15. Insert the SHIELD of the Lens cable into the pin location

for SHIELD on connector J4 or J3 (use J4 for a lens

connected to J7; use J3 for a second lens connected to J6).

16. Remove any excess cable and tighten the bushing.

17. Insert the screw-terminal connector into the J7 connector.

For dual-channel operation, repeat steps 3 through 17 for

Channel B, using connector J6 on the PCB.

Refer to the Typical System Connections illustration, page

C-4, for Pan/Tilt connections.

7

HOLD DOWN SCREWS

Figure 5 - Screw-Terminal Connector

CONNECTIONS AD1684B

Table 5 - Dual Pan/Tilt and Lens 10-pin Connector Pinout

Channel A - J7

PIN No. FUNCTION Pan/Tilt PINOUT LENS PINOUT

01 Focus __________________ __________________

02 Zoom __________________ __________________

03 Iris __________________ __________________

04 DC Ground __________________ __________________

05 24 VAC Common __________________ __________________

06 Tilt Down __________________ __________________

07 Tilt Up __________________ __________________

08 DC Ground __________________ __________________

09 Pan Right __________________ __________________

10 Pan Left __________________ __________________

Channel B - J6

PIN No. FUNCTION Pan/Tilt PINOUT LENS PINOUT

01 Focus __________________ __________________

02 Zoom __________________ __________________

03 Iris __________________ __________________

04 DC Ground __________________ __________________

05 24 VAC Common __________________ __________________

06 Tilt Down __________________ __________________

07 Tilt Up __________________ __________________

08 DC Ground __________________ __________________

09 Pan Right __________________ __________________

10 Pan Left __________________ __________________

8

AD1684B CONNECTIONS

Auxiliary Connections

The Receiver connection of auxiliary equipment is with a ten

(10) pin connector, labeled J6, located on the right side of the

PCB (see Figure 1, page 2). When the Receiver is setup for

auxiliary (see Setup, page 2), the J6 connector is for Auxiliary

functions, and only one Pan/Tilt can be connected, to the J7

connector. Table 6 lists the pin designations from the Receiver

to the auxiliary and provides space for the installer to record

the pinouts for the specific installation.

The connector terminals accept wire gauge sizes from 22-

AWG to 14-AWG, stripped 1/4" (6mm) from the end.

BEFORE STARTING:

1. Check power line to verify that power is off.

2. Open the Receiver and locate the Auxiliary connector J6,

located on the PCB near the right side of the unit.

WIRING INSTRUCTIONS:

3. Pass the wire through the bushing to the Auxiliary

connector, do not tighten bushing.

4. Strip the ends of auxiliary wires.

5. Insert the Hot wire of the Auxiliary into the screw-terminal

connector pin location for the appropriate auxiliary action.

6. Insert the Return wire of the Auxiliary into the terminal pin

location for the auxiliary voltage, 24VAC Common.

Note: DO NOT CONNECT THE 24 VAC AUXILIARY

COMMONS TO THE 120 VAC COMMONS.

7. Repeat steps 3 through 6 for each Auxiliary (Aux 1, 2, 3,

and 4).

8. Remove any excess cable and tighten the bushing.

9. Insert the screw-terminal connector into the J1 connector.

9

Table 6 - Single Pan/Tilt and Auxiliary 10-pin Connector Pinout

Channel A - J7

PIN No. FUNCTION Pan/Tilt PINOUT LENS PINOUT

01 Focus __________________ __________________

02 Zoom __________________ __________________

03 Iris __________________ __________________

04 DC Ground __________________ __________________

05 24 VAC Common __________________ __________________

06 Tilt Down __________________ __________________

07 Tilt Up __________________ __________________

08 DC Ground __________________ __________________

09 Pan Right __________________ __________________

10 Pan Left __________________ __________________

Auxiliary - J6

PIN No. FUNCTION Pan/Tilt PINOUT LENS PINOUT

01 No Connection __________________ __________________

02 No Connection __________________ __________________

03 No Connection __________________ __________________

04 No Connection __________________ __________________

05 24 VAC Common __________________ __________________

06 Auxiliary 2 __________________ __________________

07 Auxiliary 1 __________________ __________________

08 No Connection __________________ __________________

09 Auxiliary 3 __________________ __________________

10 Auxiliary 4 __________________ __________________

CONNECTIONS AD1684B

Pre-position (Preset) Connections

The Receiver connection to a Pan/Tilt or Lens unit with pre-

position servos is with a ten (10) pin connector labeled J4 (see

Figure 1, page 2). For dual-channel operation a second 10-pin

connector labeled J3 is used for channel B. Table 7, page 11,

lists the pin designations from the Receiver to the Pan/Tilt and

Lens servos and provides space for the installer to record the

pinouts for the specific installation.

Mating 10-pin screw-terminal connectors are provided for each

PCB connector (see Figure 5, page 7). The connector

terminals accept wire gauge sizes from 22-AWG to 14-AWG,

stripped 1/4" (6mm) from the end.

BEFORE STARTING:

1. Check power line to verify that power is off.

2. Open the Receiver and locate the Pre-position connector J4,

located on the left side of the PCB. For two-channel

operation, also locate connector J3.

WIRING INSTRUCTIONS:

3. Pass the wire through the bushing to the Pre-position

connector, do not tighten bushing.

4. Strip the ends of Pan/Tilt and Lens servo wires.

5. Insert the PAN (WIPER) wire of the Pan/Tilt servo into the

mating screw-terminal connector pin location for PAN.

6. Insert the TILT (WIPER) wire of the Pan/Tilt servo into the

pin location for TILT.

7. Insert the FOCUS (WIPER) wire of the Lens servo into the

pin location for FOCUS.

8. Insert the ZOOM (WIPER) wire of the Lens servo into the

pin location for ZOOM.

9. Insert the SERVO (+) wire of the Pan/Tilt servo into the pin

location for + REF.

10. Insert the SERVO (-) wire of the Pan/Tilt servo into the

pin location for - REF.

11. Insert the SHIELD of the Pan/Tilt cable into the pin

location for SHIELD.

12. Insert the SHIELD of the Lens cable into the pin location

for SHIELD.

13. Remove any excess cable and tighten the bushing.

14. Insert the screw-terminal connector into the J7 connector.

For dual-channel operation, repeat steps 3 through 13 for

Channel B, using connector J3 on the PCB.

Note: (+) REF and (-) REF are voltage direction indicators.

The definition of direction can be different among

manufacturers. Reversed connections will cause the

Pan/Tilt or the Lens to move in the opposite direction until

it hits the stops. Reversing the (+) REF and the (-) REF

on the effected unit will correct the problem.

Pre-position definitions

PAN:

When the pan pot wiper is negative in reference to the pre-

position stored in a Receiver, a "Call Shot" to that pre-

position pans to the left (wiper pot becomes more

positive). When the pot wiper is positive in reference to

the pre-position stored in a Receiver, a "Call Shot" pans to

the right (wiper becomes more negative).

TILT:

When the tilt pot wiper is negative in reference to the pre-

position stored in a Receiver, a "Call Shot" to that pre-

position tilts down (wiper pot becomes more positive).

When the pot wiper is positive in reference to the pre-

position stored in a Receiver, a "Call Shot" tilts up (wiper

pot becomes more negative).

FOCUS:

When the focus pot wiper is negative in reference to the

pre-position stored in a Receiver, a "Call Shot" to that pre-

position focuses near (wiper pot becomes more positive).

When the pot wiper is positive in reference to the pre-

position stored in a Receiver, a "Call Shot" focuses far

(wiper pot becomes more negative).

ZOOM:

When the zoom pot wiper is negative in reference to the

pre-position stored in a Receiver, a "Call Shot" to that pre-

position zooms telephoto (wiper pot becomes more

positive). When the pot wiper is positive in reference to

the pre-position stored in a Receiver, a "Call Shot" zooms

wide (wiper pot becomes more negative).

Refer to the Typical System Connections, page C-4, for

illustration of Pan/Tilt Preset connections.

10

AD1684B CONNECTIONS

Table 7 - Pre-position Pan/Tilt and Lens 10-pin Connector Pinout

Channel A - J4

PIN No. FUNCTION Pan/Tilt Servo PINOUT Lens Servo PINOUT

01 + REF __________________ __________________

02 Pan __________________ __________________

03 Tilt __________________ __________________

04 Focus __________________ __________________

05 Zoom __________________ __________________

06 - REF __________________ __________________

07 Shield __________________ __________________

08 Shield __________________ __________________

09 No Connection __________________ __________________

10 No Connection __________________ __________________

Channel B - J3

PIN No FUNCTION Pan/Tilt Servo PINOUT Lens Servo PINOUT

01 + REF __________________ __________________

02 Pan __________________ __________________

03 Tilt __________________ __________________

04 Focus __________________ __________________

05 Zoom __________________ __________________

06 - REF __________________ __________________

07 Shield __________________ __________________

08 Shield __________________ __________________

09 No Connection __________________ __________________

10 No Connection __________________ __________________

11

CONNECTIONS AD1684B

Power Input Connections

Refer to the instructions provided with the enclosure for

suitable conduit connectors (when required), and mounting and

caution information.

Two PG-16 liquid-tight bushings are supplied for use with

cord diameters from .395" to .551", and are to be mounted in

the larger holes in the enclosure. A type PG-13 bushing is

included for use with cord diameters from .236" to .472", and

is to be mounted in the small hole in the enclosure.

The use of RTV on the outside of the bushings is

recommended after all wiring is completed, for additional

protection against moisture entry.

BEFORE STARTING:

1. Check power line to verify that power is off.

2. Open the Receiver and locate the AC Power Input

connection located at the end opposite the input bushings

(see Figure 1, page 2, and Figure 6, below).

3. Locate the red power LED at the left side of the PCB near

the jumper switches (see Figure 1, page 2).

WIRING INSTRUCTIONS:

4. Pass the power wire through the bushing to the AC power

connector - do not tighten bushing.

a. Model AD1684B operates on 120 volts, 50/60 Hz. Use

only 14 gauge copper wire for 120 volt AC power input.

b. Model AD1684B-X operates on 230 volts, 50 Hz. Use

wire gauge consistent with local code requirements for

230 volt AC power input.

5. Connect the wires as follows for the applicable model.

120 VAC (AD1684B) (U.S. - N.E.C. Standard)

a. Connect the Ground wire (green) to the Green ground

screw marked GND.

b. Connect the Hot wire (black) to the terminal block

terminal marked HOT.

c. Connect the Return wire (white) to the terminal block

terminal marked NEUTRAL.

230 VAC (AD1684B-X)

a. Connect the Ground wire (green or green with yellow

stripe) to the Green ground screw marked GND.

b. Connect the Hot wire (black or brown) to the terminal

block terminal marked HOT.

c. Connect the Return wire (white or blue) to the terminal

block terminal marked NEUTRAL.

6. Remove any excess power cable and tighten the bushing.

7. Turn on the AC power.

8. Check the red power LED. If this LED is on, the unit is

powered. If the LED is off, check the power source and the

fuses F1 and F2 (see Figure 1, page 2).

Fusing

The transformers, as well as the PCB, have fuses for over-load

protection. If they should fail, check all wiring and

connections and external devices. If the condition persists, the

unit should be serviced.

12

Figure 6 - Power Input Connections

HOT

NEUTRAL

GND

CAUTION - The following instructions

require access to internal terminals and

wiring which involve hazardous voltages and

the risk of electric shock. This connection

should be made only by qualified service

personnel and should conform to local codes.

!

TYPICAL SYSTEM CONNECTIONS

/