Page is loading ...

Instruction

manual

Cylinder pressure

sensor

Type 6634A1

6634A1_002-993e-09.21

Foreword

6634A1_002-993e-09.21 Page 1

Foreword

Thank you for choosing a Kistler quality product

characterized by technical innovation, precision and long

life.

Information in this document is subject to change without

notice. Kistler reserves the right to change or improve its

products and make changes in the content without

obligation to notify any person or organization of such

changes or improvements.

© 2021 Kistler Group. Kistler Group products are protec-

ted by various intellectual property rights. For more

details visit www.kistler.com. The Kistler Group includes

Kistler Holding AG and all its subsidiaries in Europe,

Asia, the Americas and Australia.

Kistler Group

Eulachstraße 22

8408 Winterthur

Switzerland

Tel. +41 52 224 11 11

www.kistler.com

Content

Page 2 6634A1_002-993e-09.21

Content

1.Introduction .................................................................................................................................. 3

2.Important information ................................................................................................................. 4

2.1Protection and standards .................................................................................................... 4

2.2Precautions ......................................................................................................................... 5

2.3Disposal ............................................................................................................................... 5

2.4Disposal Instructions for electrical and electronic equipment ............................................. 5

3.Description ................................................................................................................................... 6

3.1Introduction ......................................................................................................................... 6

3.2Dimensions Type 6634A1 ................................................................................................... 7

5.3 Working principle ................................................................................................................. 8

4.Installation .................................................................................................................................... 9

4.1General ................................................................................................................................ 9

4.2Recommended mounting .................................................................................................... 9

4.2.1Sealing ................................................................................................................. 10

4.2.2Installing the sensor ............................................................................................. 10

4.2.3Installing the charge amplifier .............................................................................. 10

4.2.4Cable between charge amplifier and data acquisition unit ................................... 10

4.2.5Electric block diagram .......................................................................................... 11

4.2.6Bandwidth as function of load capacity ................................................................ 11

4.2.7Sensitivity error as a function of load resistance (Input ECU).............................. 11

4.2.8Pin Allocation ........................................................................................................ 12

4.2.9Mounting tools ...................................................................................................... 12

4.2.10Accessories .......................................................................................................... 12

5.Operation .................................................................................................................................... 13

6.Maintenance ............................................................................................................................... 14

7.Trouble shooting ....................................................................................................................... 15

7.1Repair ................................................................................................................................ 15

7.2Detection of sensor failures ............................................................................................... 15

7.2.1During the power-up period of the sensor (≈ 100s) ............................................. 15

7.2.2After the sensor power-up period of 100s (engine not running) .......................... 15

7.2.3During engine is running ...................................................................................... 16

7.3Working limits of sensor signal ......................................................................................... 16

8.Declaration of conformity ......................................................................................................... 17

Total pages 17

Introduction

6634A1_002-993e-09.21 Page 3

1. Introduction

Please take the time to thoroughly read this instruction

manual. It will help you with the installation, maintenance,

and use of this product.

To the extent permitted by law Kistler does not accept

any liability if this instruction manual is not followed or

products other than those listed under Accessories are

used.

Kistler offers a wide range of products for use in

measuring technology:

Piezoelectric sensors for measuring force, torque,

strain, pressure, acceleration, shock, vibration and

acoustic-emission

Strain gage sensor systems for measuring force and

torque

Piezoresistive pressure sensors

Signal conditioners, indicators and calibrators

Electronic control and monitoring systems as well as

software for specific measurement applications

Data transmission modules (telemetry)

Kistler also develops and produces measuring solutions

for the application fields engines, vehicles, manufac-

turing, plastics and biomechanics sectors.

Our product and application brochures will provide you

with an overview of our product range. Detailed data

sheets are available for almost all products.

If you need additional help beyond what can be found

either on-line or in this manual, please contact Kistler's

extensive support organization.

Cylinder pressure sensor, Type 6634A1

Page 4 6634A1_002-993e-09.21

2. Important information

It is essential to review the following information, which is

intended to ensure your personal safety when working

with cylinder pressure sensors.

To the extent permitted by law Kistler accepts no liability

if this instruction manual is not followed.

2.1 Protection and standards

All equipment is tested and has left the factory in a

perfect, safe condition. In order to maintain this

condition and ensure safe operation, compliance is

required with the instructions and warning notes

contained within this manual or imprinted on the

product itself.

The instruments are CE-compliant within the meaning of:

ISO 9001

2011/65/EU (ROHS)

2014/30/EU (EMC)

The sensor conforms to EC Standard 2004/108/EC and

meets EMC standards. Additionally the following

requirements are met:

EMC Emission

EN 61000-6-3:2007 + A1:2011

EN 61000-6-4:2007 + A1:2011

EN 61326-1:2013 (Class A+B equipment)

EMC Immunity

EN 61000-6-1:2007

EN 61000-6-2:2005

EN 61326-1:2013 (Class A+B equipment)

Complies with the following normatives:

general regulations

EN 60079-0:2012+A11:2013 / IEC 60079-0:2011

EN 60079-15:2010 / IEC 60079-15:2010

Compliance with local safety regulations, which may

apply to the use of power line operated electrical and

electronic equipment, is strongly recommended.

Important info

6634A1_002-993e-09.21 Page 5

2.2 Precautions

Compliance with the following precautionary

measures is vital to ensure safe and reliable

operation:

The equipment should be used only under the

specified operating conditions.

If there is evidence that safe operation is no longer

possible, the instrument must be powered off and

rendered safe against accidental start-up.

Safe operation is no longer possible when the product

• shows visible signs of damage

• is no longer operating

• has been subjected to prolonged storage under

unsuitable conditions

2.3 Disposal

Dispose of packaging and worn components in accor-

dance with the regulations in force in the country in which

the cylinder pressure sensor is installed.

2.4 Disposal Instructions for electrical and electronic equipment

Do not discard old electronic instruments in municipal

trash. For disposal at end of life, please return this

product to an authorized local electronic waste

disposal service or contact the nearest Kistler

Instrument sales office for return instructions.

Cylinder pressure sensor, Type 6634A1

Page 6 6634A1_002-993e-09.21

3. Description

3.1 Introduction

The cylinder pressure sensor consisting of a life time

optimized piezoelectric pressure sensor linked by a

robust fluoropolymer cable to a charge amplifier. The

rugged design and high temperature resistance enables

reliable knock detection. The good linearity and stability

of the sensors ensures reliable and repeatable

measurements over a long period of time. The charge

amplifier provides a galvanic isolated three wire type

voltage output.

The integrated charge amplifier provides a voltage output

signal in a range of 0.2 … 4.8 V. The sensor has a zero

line of about 1.2 V (at dynamic pressure 0 bar). The

output is AC-coupled, therefore static pressure

measurements are not possible.

Description

6634A1_002-993e-09.21 Page 7

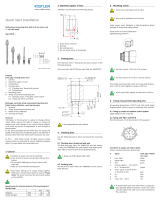

3.2 Dimensions Type 6634A1

Type

Cable length [mm]

6634

A

1 1000

Fig. 1 Dimensions of Types 6634A1

cable length see table

Cylinder pressure sensor, Type 6634A1

Page 8 6634A1_002-993e-09.21

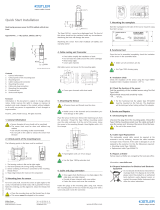

5.3 Working principle

The cylinder pressure is acting on the diaphragm. The

diaphragm converts the pressure in a proportional force

which is transmitted on the sensor element. The

piezoelectric sensor element converts the force into an

electrical charge. The electrical charge is converted by a

charge amplifier into a voltage signal.

The complete cylinder pressure sensor is designed for

easy operation and very long life time.

The advantages of the piezoelectric principle are:

Operates safely up to high temperatures and is

therefore ideally suited for accurate measurements in

harsh conditions

Very small sensitivity change over temperature range

High stiffness, results in small diaphragm stress

High reproducibility since the piezoelectric constant

of the measuring element is a constant of the

material and does not change over time

Fig 2: Schematic cross section of sensor element

Installation

6634A1_002-993e-09.21 Page 9

4. Installation

4.1 General

The quality of the measurement and the sensor life time

depend very much on the correct mounting of the sensor.

The mounting hole must be manufactured within the

tolerances

Avoid mounting at the end of long tubes, it creates

gas acoustic resonance and overheating of the

sensor

Ideal sensor mounting bore in the cylinder head has

ca. 10 … 15 mm distance from the combustion

chamber

Sensor must be tightened according the mounting

torque of 15 Nꞏm

In case of questions regarding the installation, please

contact Kistler.

4.2 Recommended mounting

Fig. 3: Mounting bore for shoulder sealing

Mounting torque: 15 ±1 Nꞏm

Cylinder pressure sensor, Type 6634A1

Page 10 6634A1_002-993e-09.21

4.2.1 Sealing

A leak proof mounting of the sensor is essential to

prevent overheating of the sensor by leaking hot gases.

Good sealing is obtained by

fine-machined sealing surface on the engine (for

surface roughness and angularity please consult the

data sheet)

all sealing surfaces (on engine and on sensor) must

be clean and free of any burrs (e.g. combustion

residuals, soot, etc.)

4.2.2 Installing the sensor

Clean all parts and apply a light film of grease to the thread

and the sealing surface. Use high-temperature paste

MoS2 (e.g. Molycote P74 or 1 000) or copper grease.

Install the sensor into mounting bore with a torque of

15 Nꞏm.

Use a torque wrench for installing the sensor. After

installing the sensor, check that there is no gas leakage

when engine runs on idle speed.

4.2.3 Installing the charge amplifier

Charge amplifier can be fixed with cable strips in the

cable channel. Select a location where the temperature

definitely does not exceed 120 °C. Route and fix the

integrated cable between sensor and charge amplifier so

that it is protected against mechanical damage. Keep it

away from any source of heat such as the exhaust or hot

fuel lines.

4.2.4 Cable between charge amplifier and data acquisition unit

Use a shielded cable, otherwise the sensor does not

comply with the CE directives.

The cable shield should only be connected on sensor

side via the M12 plug (do not connect cable shield at the

ECU side).

The power supply for the sensor should be floating, -Exct

must not be connected to ECU housing.

If the cable shield and/or ground (-Exct) are connected to

the ECU housing, the galvanic isolation is not given

anymore and disturbances in the signal can be the

consequence. In worst case the electronics can get

damaged.

Installation

6634A1_002-993e-09.21 Page 11

4.2.5 Electric block diagram

Fig. 4: Electric block diagram

4.2.6 Bandwidth as function of load capacity

High capacitive load (> 50 nF) from the cable between

the sensor and the data acquisition unit, as well as a high

input capacity of the data acquisition unit affects the

sensor bandwidth (gets < 10 kHz).

4.2.7 Sensitivity error as a function of load resistance (Input ECU)

Small input resistance of the data acquisition unit affects

the sensor sensitivity.

The additional sensitivity error as a function of the input

resistance is shown below:

R input

[kΩ]

Sensitivity error (in addition)

[%]

>1 000 < 0.01

100 0.1

10 1

Cylinder pressure sensor, Type 6634A1

Page 12 6634A1_002-993e-09.21

4.2.8 Pin Allocation

Fig. 5: Pin allocation of connector

Important

Incorrect wiring can destroy the sensor unless the

excitation current is limited to ≤ 50 mA.

4.2.9 Mounting tools

Torque wrench 8 … 40 Nm Type 1300A11

Fork wrench SW 12 for 1300A11 Type 1300A13

Tubular socket Hex 12/16, l = 350 mm Type 1300B6

4.2.10 Accessories

Dummy plug shoulder sealed Type 6442

Operation

6634A1_002-993e-09.21 Page 13

5. Operation

After starting up the engine check for any gas leakage at

once. If there is any gas leaking out, stop the engine and

rectify the mounting to achieve a complete sealing (see

chapter 4).

Cylinder pressure sensor, Type 6634A1

Page 14 6634A1_002-993e-09.21

6. Maintenance

After installation, the sensor needs no maintenance. Do

not use a steam or high-pressure cleaner for cleaning

purposes.

Trouble shooting

6634A1_002-993e-09.21 Page 15

7. Trouble shooting

In case the sensor does not give a proper output signal,

please disconnect the cable for a couple of seconds and

connect it again.

The amplifier works with a so-called time constant to

ensure a reliable signal without drift. Due to the time

constant, the sensor may be out of range for a short

period of time after powering up. It may take 1 … 2

minutes until the signal is within the specified range.

7.1 Repair

The sensor cannot be repaired on site. It must be

returned to factory, in case of incorrect function or

damaged parts.

7.2 Detection of sensor failures

Detection of sensor failures must be handled differently

during the sensor power-up period and during the regular

operation after the power-up period.

7.2.1 During the power-up period of the sensor (≈ 100s)

No failure detection possible

7.2.2 After the sensor power-up period of 100s (engine not running)

Nominal value: Signal output = 1.1 … 1.3 V

Failure mode: Signal output = 0 V

Possible error causes:

No power supply from the ECU to the charge amplifier

Incorrect wiring between the ECU and the charge

amplifier

Short circuit between Signal output and GND

Charge amplifier electronics defect

Cylinder pressure sensor, Type 6634A1

Page 16 6634A1_002-993e-09.21

Failure mode: Zero line > 1.3 V (engine not running, constant value)

Possible error causes:

Low electrical insulation (<106 Ohm) in the sensor or in

the cable between the sensor and the charge amplifier

(due to e.g. overheating of the sensor)

Charge amplifier electronics temperature > 120 °C

Charge amplifier electronics defect

7.2.3 During engine is running

Failure mode: Signal output ≈ 1.2 V (constant nominal zero line)

Possible error causes:

Engine not running

Sensor broken (open circuit)

Broken cable between the sensor and the charge

amplifier (open circuit)

Charge amplifier electronics defect

Failure mode: Signal output is clipping (0.2 V > Uout > 4.8 V)

Possible error causes:

Engine is knocking

Fast load changes occur

Low electrical insulation (<106 Ohm) in the sensor or in

the cable between the sensor and the charge amplifier

(due to e.g. overheating of the sensor)

Charge amplifier electronics defect

Failure mode: Sensor sensitivity / phase out of specification

Possible error causes:

Sensor broken / damaged (sometimes not visible)

Charge amplifier electronics defect

=> detection only possible with SW intelligence in

ECU

7.3 Working limits of sensor signal

After the sensor power-up period of 100s (5 * time

constant)

Lower limit 0.4 V

The zero line may temporarily slide down to 0.4 V during

the engine start, engine stop and fast load changes

Upper limit 5.1 V

The signal output may temporarily reach up to 5.1 V

during knocking events

Declaration of con

6634A1_002-993e-09.21 Page 17

8. Declaration of conformity

/