Quick installation guide – ACS850-04

3

Quick installation guide –

ACS850-04

About this guide

This guide contains the very basic information

about the mechanical and electrical installation

of the ACS850-04 drive module (55 to 160 kW).

For complete documentation see ACS850-04

Drive Modules (55…160 kW, 75…200 hp)

Hardware Manual (code: 3AUA0000045487

[English]).

Safety instructions

WARNING! All electrical installation

and maintenance work on the drive

must be carried out by qualified

electricians only.

Never work on the drive, the braking chopper

circuit, the motor cable or the motor when input

power is applied to the drive. Always ensure by

measuring that no voltage is actually present.

A rotating permanent magnet motor can

generate a dangerous voltage. Lock the motor

shaft mechanically before connecting a

permanent magnet motor to the drive, and

before doing any work on a drive system

connected to a permanent magnet motor.

Mechanical installation

WARNING! If the drive is to be

connected to an IT power system

(i.e. ungrounded, or high-resistance-

grounded [over 30 ohms] power

system), the internal EMC filtering of

the drive must be disconnected. This should be

done before the drive is mechanically installed.

Refer to the Hardware Manual for detailed

instructions.

Fasten the drive module onto the wall with four

screws.

Installing the power cables

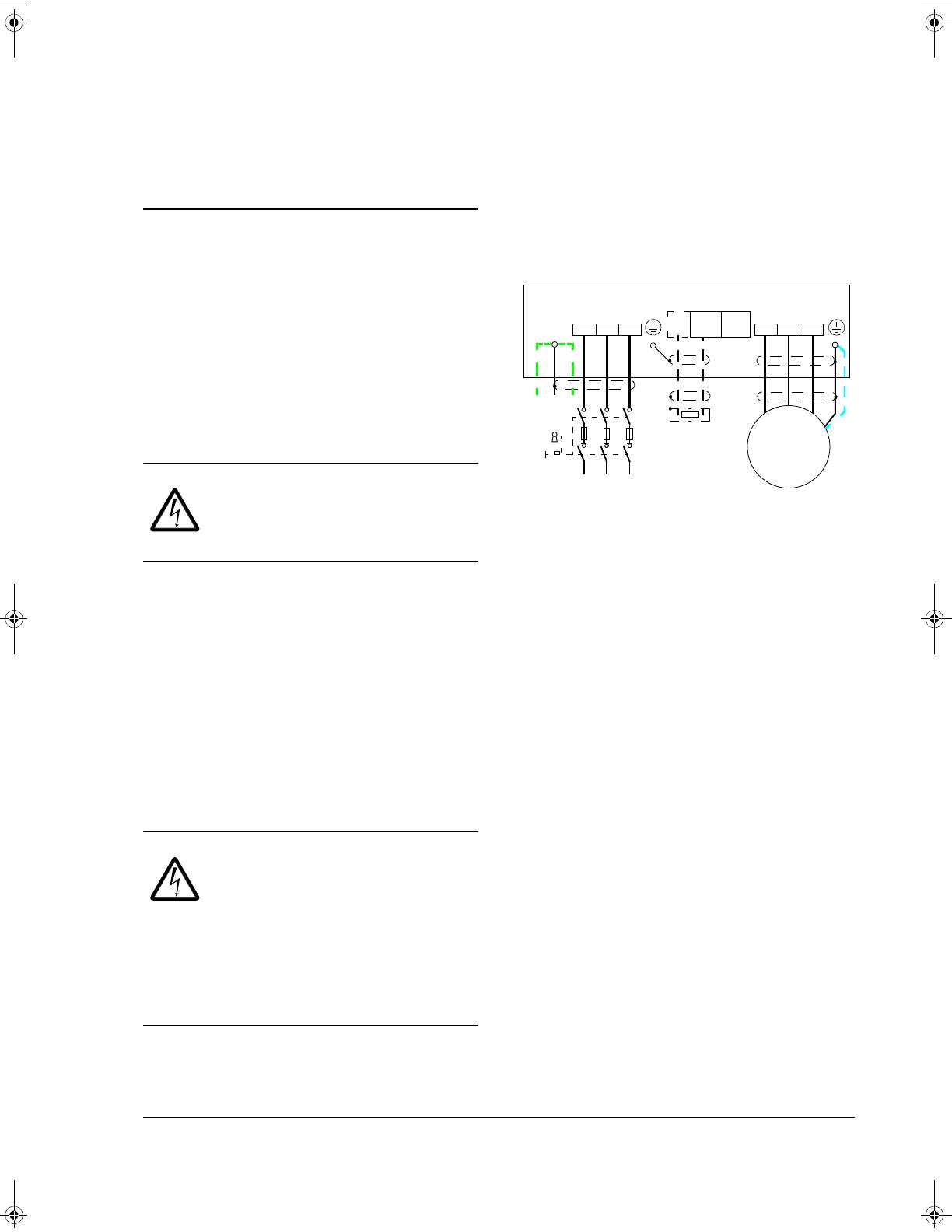

Connection diagram

Notes:

– Do not use a non-shielded or asymmetrically-

constructed motor cable. It is recommended to

use a shielded cable also as an supply (input)

cable.

– If shielded supply (input) cable is used, and

the conductivity of the shield is less than 50%

of the conductivity of a phase conductor, use a

cable with a ground conductor (1) or a separate

PE cable (2).

– For motor cabling, use a separate ground

cable (3) if the conductivity of the cable shield

is less than 50% of the conductivity of a phase

conductor and the cable has no symmetrical

ground conductors.

If there is a symmetrically-constructed ground

conductor in the motor cable in addition to the

conductive shield, connect it to the ground

connectors at both the drive and motor ends.

INPUT OUTPUT

U1

V1

W1

3

~

Motor

U1

1)

UDC+

R+

UDC

-

R

-

L1 L2 L3

(PE) (PE)PE

2)

3)

PE

Optional

braking resistor

(360°

grounding

required)

ACS850-04

V1 W1 U2 V2 W2

PE

ACS850-04_E0_E_quickguide.book Page 3 Tuesday, February 21, 2012 10:41 AM