TABLE OF CONTENTS

TOC-3

Toro TITAN 2009-2013 Service Manual

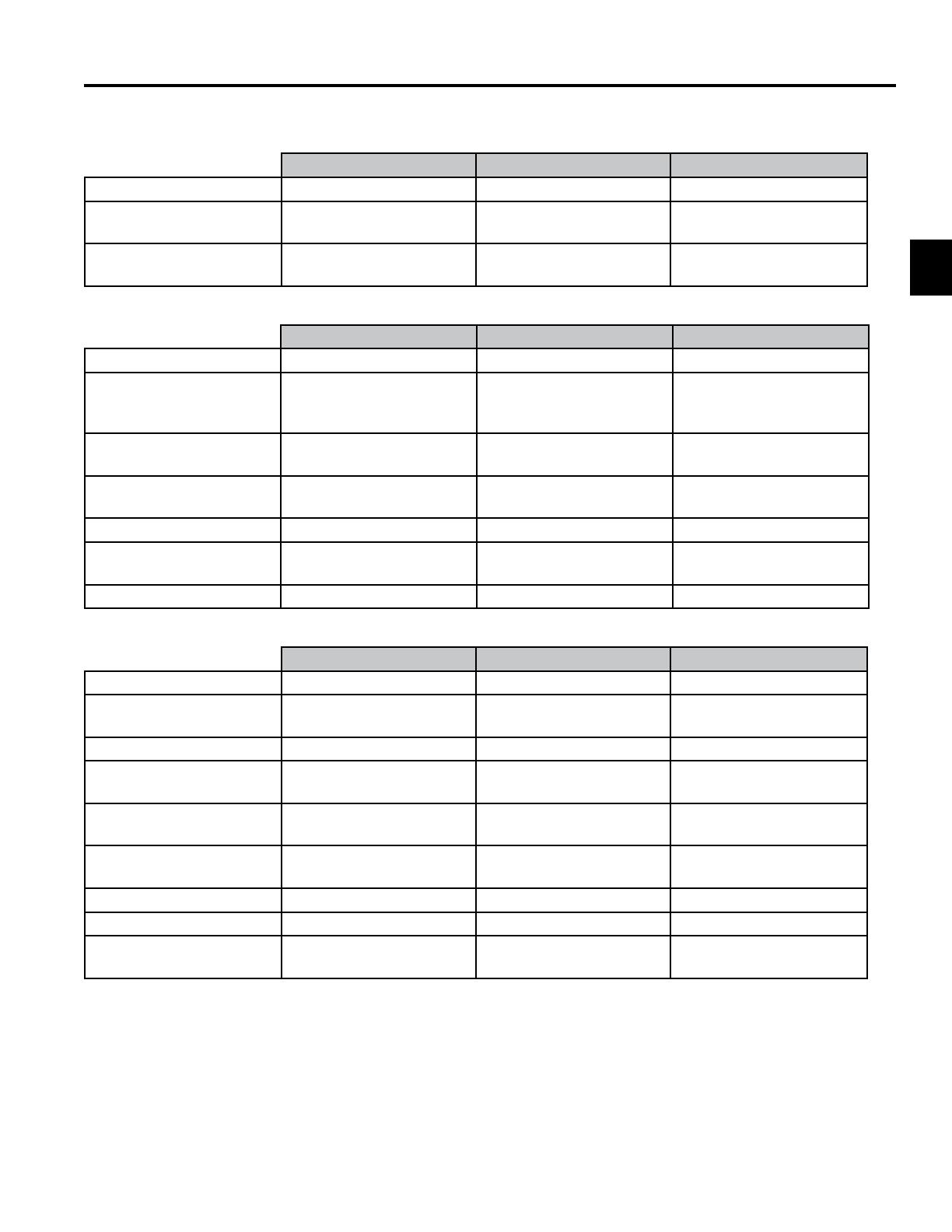

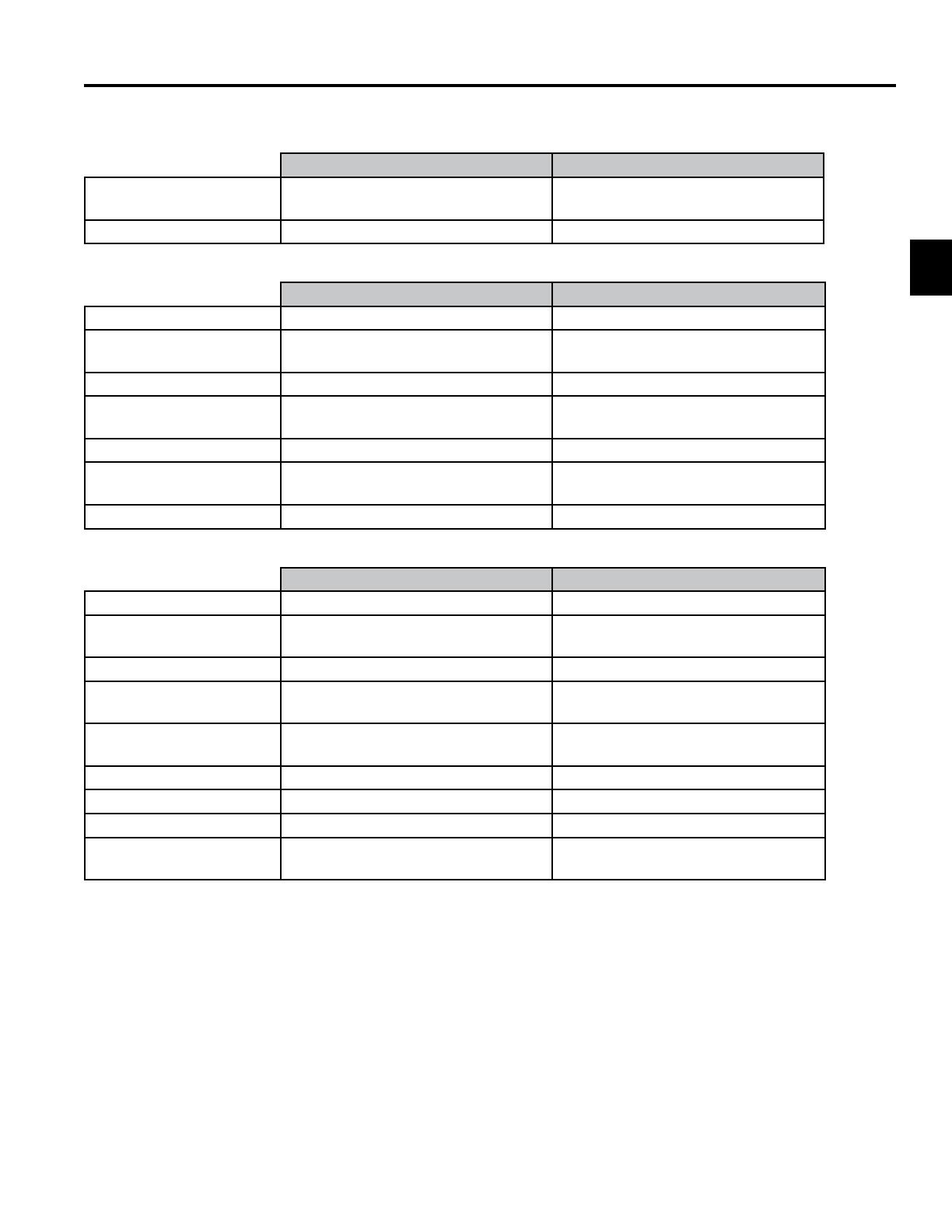

6 - Mower Deck cont.

PTO Belt Replacement - 48, 54 and 60 Inch Deck ..........................................................................................6-6

PTO Belt Replacement - 50 Inch Deck ............................................................................................................6-8

Mower Deck Replacement ..............................................................................................................................6-9

Mower Deck Removal - 48 and 54 Inch Deck ...........................................................................................6-9

Mower Deck Installation - 48 and 54 Inch Deck ......................................................................................6-10

Mower Deck Removal - 60 Inch Deck .....................................................................................................6-10

Mower Deck Installation - 60 Inch Deck .................................................................................................. 6-11

Mower Deck Removal - 50 Inch Deck .....................................................................................................6-12

Mower Deck Installation - 50 Inch Deck ..................................................................................................6-13

Spindle Service..............................................................................................................................................6-14

Spindle Removal .....................................................................................................................................6-14

Spindle Installation ..................................................................................................................................6-14

Spindle Exploded Views ................................................................................................................................6-15

Spindle Assembly - 48, 54 and 60 Inch Deck .........................................................................................6-15

Spindle Assembly - 50 Inch Deck ...........................................................................................................6-15

Spindle Disassembly ...............................................................................................................................6-16

Spindle Assembly ....................................................................................................................................6-16

Idler Arm / Deck Belt Tensioner Service ........................................................................................................6-17

Idler Arm / Tensioner Exploded Views ...........................................................................................................6-17

Idler Arm / Tensioner - 48, 54, 60 Inch Deck ...........................................................................................6-17

Idler Arm / Tensioner - 50 Inch Deck .......................................................................................................6-18

Idler Arm Inspection .......................................................................................................................................6-19

Idler Arm Removal ..................................................................................................................................6-19

Idler Arm Installation ...............................................................................................................................6-19

Checking for Bent Blades ..............................................................................................................................6-20

Leveling Mower Deck - 48, 54, 60 Inch Deck ................................................................................................6-21

Checking Side-to-Side Level ...................................................................................................................6-21

Checking the Front-to-Rear Blade Slope ................................................................................................6-22

Leveling the Mower Deck ........................................................................................................................6-23

Leveling Mower Deck - 50 Inch Deck ............................................................................................................6-24

Checking Side-to-Side Level ...................................................................................................................6-24

Checking the Front-to-Rear Blade Slope ................................................................................................6-25

Leveling the Mower Deck ........................................................................................................................6-26

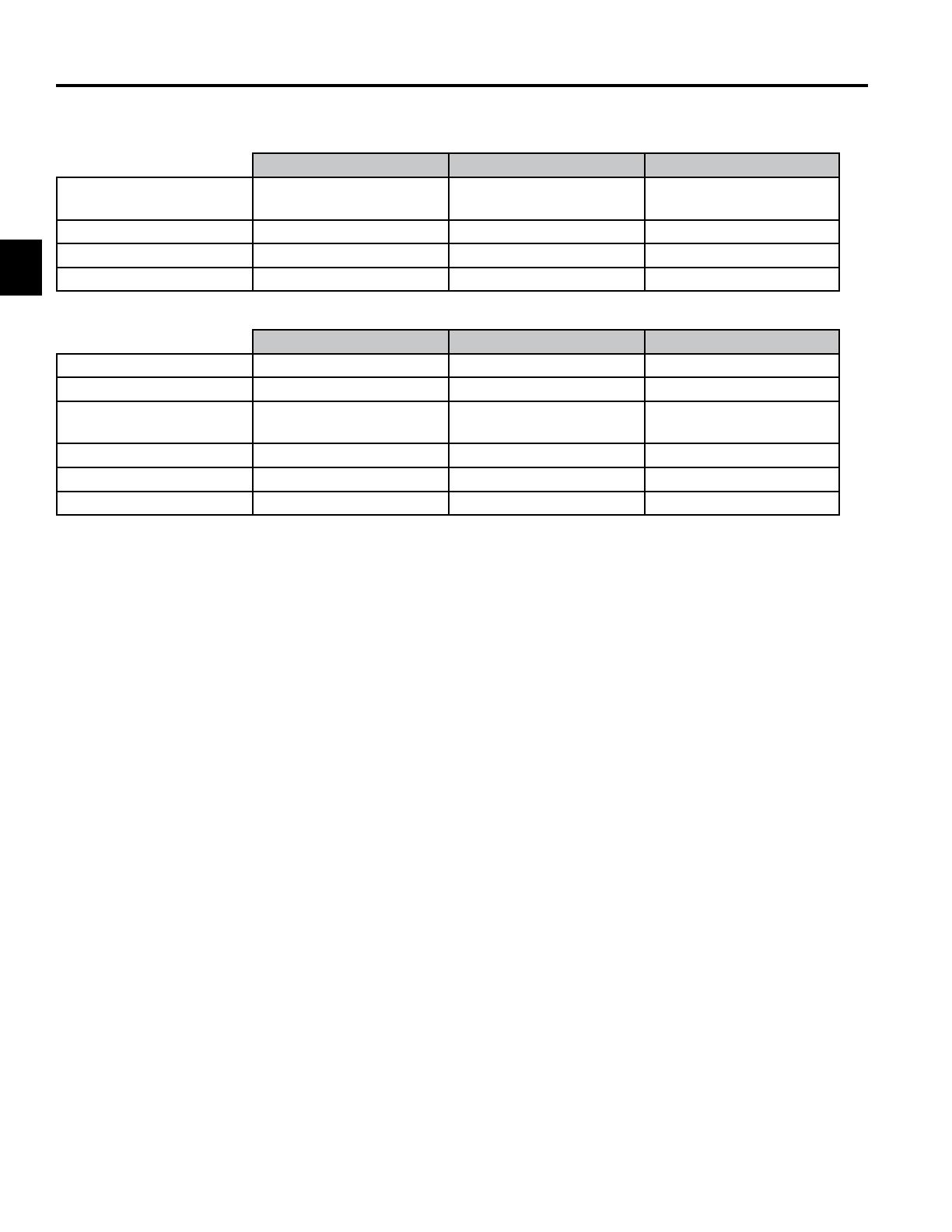

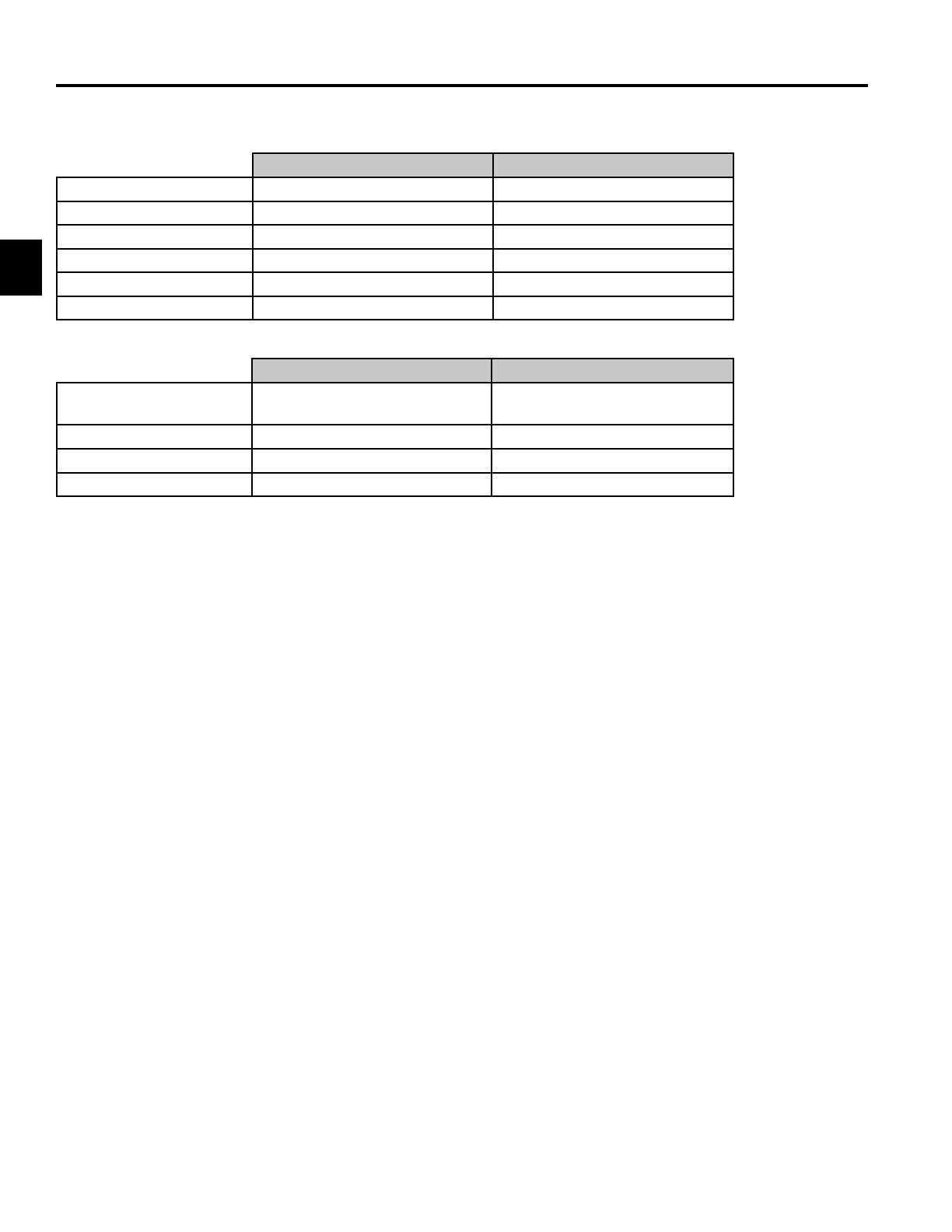

7 - Electrical

Chassis Switches ............................................................................................................................................7-1

Key/Ignition Switch ..........................................................................................................................................7-1

Purpose .....................................................................................................................................................7-1

Location ....................................................................................................................................................7-1

How It Works .............................................................................................................................................7-1

Testing .......................................................................................................................................................7-1

PTO Switch ......................................................................................................................................................7-2

Purpose .....................................................................................................................................................7-2

Location ....................................................................................................................................................7-2

How It Works .............................................................................................................................................7-2

Continuity Testing ......................................................................................................................................7-3

Seat Switch......................................................................................................................................................7-4

Purpose .....................................................................................................................................................7-4

Location ....................................................................................................................................................7-4

How It Works .............................................................................................................................................7-4

Testing .......................................................................................................................................................7-4