Page is loading ...

F 39° F

C

OFF

ON

33°

1° C 4°

3227498

Rev. A

AUGUST 2012

RNP SERIES

REFRIGERATED COMPRESSED AIR DRYERS

OPERATOR

MANUAL

RNP75 RNP100 RNP125

RNP150 RNP200 RNP250

RNP300 RNP400 RNP500

2

GENERAL SAFETY INFORMATION

1. PRESSURIZED DEVICES:

This equipment is a pressure containing

device.

• Donotexceedmaximumoperating

pressure as shown on equipment

serial number tag.

• Makesureequipmentisdepressurizedbefore

workingonordisassemblingitforservice.

2. ELECTRICAL:

This equipment requires electricity to

operate.

• Installequipmentincompliancewith

all applicable electrical codes.

• Standardequipmentissuppliedwithelectrical

enclosuresnotintendedforinstallationinhazardous

environments.

• Disconnectpowersupplytoequipmentwhen

performinganyelectricalservicework.

3. BREATHING AIR:

• Airtreatedbythisequipmentmay

notbesuitableforbreathingwithout

furtherpurication.

Refertoapplicablestandardsand

specicationsfortherequirements

forbreathingqualityair.

RECEIVING, MOVING, AND UNPACKING

A. RECEIVING

Thisshipmenthasbeenthoroughlychecked,packedand

inspectedbeforeleavingourplant.Itwasreceivedin

goodconditionbythecarrierandwassoacknowledged.

CheckforVisibleLossorDamage.Ifthisshipmentshows

evidenceoflossordamageattimeofdeliverytoyou,

insistthatanotationofthislossordamagebemadeon

the delivery receipt by the carrier’s agent.

B. UNPACKING

Checkforconcealedlossordamage.Whenashipment

hasbeendeliveredtoyouinapparentgoodorder,but

concealeddamageisfounduponunpacking,notifythe

carrier immediately and insist on his agent inspecting

the shipment. Concealed damage claims are not our

responsibilityasourtermsareF.O.B.pointofshipment.

C. MOVING

Inmovingortransportingdryer,donottipdryerontoits

side.

D. STORAGE

IMPORTANT:Donotstoredryerintemperaturesabove

130°F (54.4°C).

3

Compressor

Oil Removal

Filter

Aftercooler

Automatic Drain

Dryer

Separator

Receiver

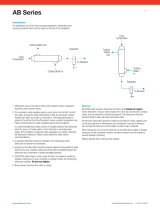

TYPICAL COMPRESSED AIR SYSTEM

INSTALLATION

Ambient Air Temperature

Locatethedryerindoorswheretheambientairtemperature

willbebetween45°Fand110°F.Intermittentoperationat

ambient temperatures up to 113°F will not damage the dryer

but may result in a higher dew point or dryer shutdown

duetohighrefrigerantdischargepressure(seeFieldService

Guide).

Donotoperateair-cooleddryersatambientairtemperatures

below40°F.Suchoperationmayresultinlowsuction

pressure,causingfreeze-up.

Location and Clearance

Mountthedryeronalevelbase.Ifthebasevibrates,bolt

theunitdownusingvibrationdampeners.Ifthedryeris

air-cooled,installitinaclean,well-ventilatedareatoreduce

foulingofthecondensercoilswithdirtanddust.Allowat

least24inchesclearanceonthesidesandthefrontofthe

dryerforcoolingairowandforserviceaccess.

System Arrangement

Liquidwaterintheinletairwilladverselyaffectthe

performanceofthedryer.Installthedryerdownstreamofan

aftercoolerorseparatorsothatthetemperatureofthedryer

inletairdoesnotexceed120°Fandtheinletairdoesnot

contain any liquid water.

Ifthecompressedairowisrelativelyconstantanddoesnot

exceedthedryerowrating,itisrecommendedthatthe

dryerbelocateddownstreamofthereceivertank.Ifthe

natureoftheapplicationissuchthattheairdemandregularly

exceedsthedryerowrating,itisrecommendedthatthe

dryerbelocatedupstreamofthereceiver.

Forsafetyandconvenience,installinletandoutletshutoff

valvesanddepressurizationvalves.Thesevalvesallowthe

dryertobeisolatedanddepressurizedforservicing.Bypass

pipingmaybeinstalledaroundthedryerforuninterrupted

airowwhenthedryerisserviced.Ifthecompressedair

operationcannottolerateundriedairforshortperiods,install

a second dryer in the bypass line.

Compressedairsystemscommonlyrequirelterstoremove

compressoroils,particulates,condensedliquidsandother

contaminants.Whenanoil-removallterisused,itshould

beinstalleddownstreamoftherefrigerateddryer.At

thislocation,thelifeofthereplaceablelterelementis

prolongedsincesomeoftheentrainedoilisremovedbythe

dryer and drained through the separator.

Piping and Connections

Pipingmustbefurnishedbytheuserunlessotherwise

specied.Connectionsandttingsmustberatedforthe

maximumoperatingpressuregivenonthedryerdataplate

andmustbeinaccordancewithapplicablecodes.Support

allpiping;donotallowtheweightofanypipingtostressthe

dryerorlterconnections.Inletandoutletshutoffvalvesand

avalvedbypassvalvearerecommended.Pipingshouldbeat

leastthesizeoftheinletandoutletconnectionstominimize

pressuredropintheairsystem.SeeEngineeringDatasection

fordryerinletandoutletconnections.

Removing Condensate

Condensatemustbedrainedfromthedryertopreventre-

entrainment. The dryers are equipped with automatic drain

valves and internal drain hoses up to the drain connections

on the dryer cabinets. The user must install a separate

dischargelineatthedrainconnectiontocarryoffcondensate

to an environmentally approved condensate collection/

disposalsystem.Pipingorcoppertubing1/2inchorlarger

isrecommendedforcondensatedischargelines.Installthe

drain lines so that condensate can be seen as it drains.

Electrical Connections

ThedryersareconstructedaccordingtoNEMAType1

electrical standards. Field wiring must comply with local and

nationalre,safetyandelectricalcodes.Installationmust

beinaccordancewiththeNationalElectricalCode.Conrm

that your line voltage is the same as the voltage listed on the

dryerdataplate.RefertoFigure1forelectricalschematics.

Operation of dryers with improper line

voltage constitutes abuse and could affect the dryer

warranty.

4

INSTRUMENTATION

ON/OFF Switch

ThedryerisequippedwithanON/OFFswitchonthefront

panel.Alightsignalswhenthedryerison.

Dew Point Indicator

(75 through 150 scfm models)

Alldryersareequippedwithadewpointindicatorwhich

indicatesdryerconditionsasfollows:

Itisnormalforthedewpointindicatortobeintheredzone

whenthedryerisrstturnedonandthenmovetothe

greenzonewhenthedryerreachesitsnormaloperating

temperature.Ifthisindicatorisintheredzoneduring

normaloperation,turnthedryerofftoavoidcompressor

damage.RefertotheFieldServiceGuideforadditional

information,orcallyourlocaldistributor.

Dryer System Monitor (DSM)

(200 through 5000 scfm models)

TheDryerSystemMonitor(DSM)hasLEDtypedewpoint

temperature indicators and electronic drain valve timing

controls.Whenthedryerisrunningnormally,thegreenLEDs

willilluminate.IftheredLEDisilluminated,thereisaneed

forthedryer'soperatingconditiontobechecked.

NOTE:Whenthedryeristurnedon,allLEDswillbe

illuminated.Allow15minutesfortheredandyellowLEDsto

beextinguished.

Theautomaticdrainvalvecontrolsallowtheperiodofdrain

openingtobesetfrom0.5secondsto9secondsanddrain

valveclosedtimetobesetfrom0.5minutesto9minutes.

Whenthe"PUHTOTEST"buttonispushed,thedrainvalve

opensandremainsopenfortheadjusted"open"time.

Automatic Drain Valve

Allmodelsareequippedwithanelectronicdrainvalvethat

automaticallydischargescondensatefromthedryer.Drain

valve operation is controlled by a drain valve timer. The drain

openingcanbesetfrom0.5secondsto9seconds.Thedrain

cyclecanbesetfrom0.5minutesto9minutes.

Models75through150havethetimermounteddirectlyon

thedrainvalve.Formodels200through500,drainvalve

adjustmentsaremadeontheDryerSystemMonitor(DSM).

Electronic Drain Valve Adjustment

Tominimizeairlosses,thedrainvalvecontroltimeshould

beadjustedtoopenthedrainportjustlongenoughto

dischargeaccumulatedcondensate.Setthedrainvalve

operatingtimesothatonlyairdischargesattheendofthe

open period. Recommended initial settings are a 1 to 2

seconddrainopeningand30secondsdrainclosedtime.If

liquidstilldischargesastheportisclosing,setthetimerfora

shorter cycle or a longer opening.

timershouldbeadjustedtoopenthedrainportjustlong

enoughtodischargeaccumulatedcondensate.Setthetimer

sothatonlyairdischargesattheendoftheopenperiod.

Dew Point Indicator

(Models RNP75, RNP100, RNP125 and RNP150)

3 4

2

1

5

Drain Timer

(Models RNP75, RNP100, RNP125 and RNP150)

1. Adjustmentknobforthedrainvalveopentime.The

values on the dial correspond to the time in seconds

that the valve is open in each drain cycle.

2. Adjustmentknobforthedrainvalveclosedtime.The

values on the dial correspond to the time in minutes

that the valve is closed in each drain cycle.

3. LEDtoindicatewhenthedrainvalveisopen.

4. Draintestbutton.Whenthebuttonispressed,the

drainvalveopensforthetimecorrespondingtothe

setting on item 1.

5.LEDtoindicatewhenthedrainvalveisclosed.

5

2

1

10 9 8

7

6

543

Dryer System Monitor

(Models RNP200, RNP250, RNP300, RNP400 and RNP500)

1. On/OffSwitch:Pressthetopoftheswitch(I)toturn

thedryeron.Pressthebottomoftheswitch(O)to

turnthedryeroff.Whenthedryerison,theswitchis

illuminated.

2. ThisisagraphicsymbolfortheAirDryercompressor.

Itsimplyindicatesthattheswitchisusedtoturnthe

compressor(dryer)onandoff.

3. Partofthegraphicforthedewpointtemperature

scale.Thesnowflakeindicatesthelow(cold)endof

the scale.

4. Mainportionofthegraphicforthedewpoint

temperaturescale.Greenindicateslow,orange

indicatesmedium,redindicateshigh.

5. Partofthegraphicforthedewpointtemperature

scale. The thermometer indicates the high (hot) end

ofthescale.

6. Six(6)LEDsthatindicatedewpointtemperature

accordingtothegraphicscaleabovetheLEDs.The

colorofeachLEDmatchesthecoloredbars

7. Adjustmentknobforthedrainvalveopentime.The

values on the dial correspond to the time in seconds

that the valve is open in each drain cycle.

8. Adjustmentknobforthedrainvalveclosedtime.The

values on the dial correspond to the time in minutes

that the valve is closed in each drain cycle.

9. LEDtoindicatewhenthedrainvalveisopen.

10. Draintestbutton.Whenthebuttonispressed,the

drainvalveopensforthetimecorrespondingtothe

settingonitem7.

6

START-UP/OPERATION

Follow the procedure below to start your dryer. Failure

tofollowtheprescribedstart-upprocedurewillinvalidate

thewarranty.Ifproblemsariseduringstart-up,callyour

distributor.

RefertoSerialNumberTagfordryeroperating

capacity.Donotexceedrecommendedcapacity.

Drainconnectionsmustbemadebeforethedryercanbe

operated.Thedryersarefullyautomaticandrequireno

auxiliarycontrols.

1. TurnthedryerON/OFFswitchtoOFF.

2. Checkthatthemainelectricalsupplyvoltagematches

thevoltagespeciedonthedryerdataplate.

3. Checkproperconnectionandsupportofcompressedair

linestothedryer;checkbypassvalvesystem,ifinstalled.

4. SLOWLYpressurizethedryer.Theoutletvalvesofthe

dryershouldbeclosedtopreventowthroughthe

dryer.

5. Turn on the main electrical power to the dryer.

6. Ensureadequateventilationforair-cooleddryers.

To start dryer:

1. Turn the power switch to ON.Therefrigerantcompressor

will turn on.

2. Allowthedryertorun15minutes.Conrmthatthe

temperatureindicatorsareinthegreenzone.

3. SLOWLYopenthedryeroutletvalvespermittingow

through the dryer.

4. Conrmthatcondensateisdischargingfromthedrain

valvebypressingthe"TEST"button.

5. Checkdrainvalvetiming.SeeAUTOMATICDRAINVALVE

sectionfordrainvalveadjustmentprocedure.

6. Conrmthattheinletairtemperature,pressureand

airowtothedryermeetthespeciedrequirements(see

EngineeringDatasection).

7. Conrmthatthecondensatelinesfromthedrainvalve

dischargeintoacollectiontankoranenvironmentally-

approved disposal system.

Thedryerisdesignedtoruncontinuously.Letthedryerrun

evenwhenthedemandforcompressedairisinterrupted;

thedryerwillnotfreezeup.

SHUTDOWN

Whenthedryermustbeshutdownformaintenanceorother

reasons,usethefollowingprocedure.

Ifelectricalrepairsmustbemade:

1. Turnoffthepowerswitch.

2. Disconnectthemainpowersupply.

3. Lockoutandtagthepowersupplyinaccordancewith

OSHArequirements.

Ifmechanicalrepairsaretobemadeorserviceisperformed,

venttheinternalpressureofthedryertoatmospheric

pressure.Restartthedryeraccordingtothestart-up

instructions.

Disconnectpowersupplyanddepressurize

dryerbeforeservicing.Dismantlingorworkingonany

componentofthecompressedairsystemunderpressure

maycauseequipmentfailureandseriouspersonalinjury.

MAINTENANCE

Thedryersrequirelittlemaintenanceforsatisfactory

operation.Gooddryerperformancecanbeexpectedifthe

followingroutinemaintenancestepsaretaken.

Dismantlingorworkingonanycomponent

ofthecompressedairsystemunderpressuremaycause

equipmentfailureandseriouspersonalinjury.Before

dismantlinganypartofthedryerorcompressedairsystem,

completely vent the internal pressure to the atmosphere.

General

Forcontinuedgoodperformanceofyourrefrigerateddryer,

allrefrigerationsystemmaintenanceshouldbeperformedby

acompetentrefrigerationmechanic.

NOTE:Beforecorrectivemaintenanceisdoneduringthe

warrantyperiod,callyourlocaldistributorandproceed

accordingtoinstructions.Refertothewarrantyforlimitsof

your coverage.

Daily Maintenance

Checktheoperationoftheautomaticdrainvalveatleast

oncedaily.SeetheFieldServiceGuideforremediestodrain

valvemalfunctions.SeetheAUTOMATICDRAINVALVE section

fordrainvalveadjustment.

7

Weekly Maintenance

Inspecttheambientairlterweeklyandcleanitifnecessary.

Dirtyairlterscauselossofefciencyandmayresultin

damage to the product.

AirFilter—Cleanaccumulateddustanddirtfromairlter

weeklyasrequired.

1. Openambientltersidedoor.

2. Removeairlterbyslidingupwards.

3. Washwithsoapandwaterandallowtodrybefore

reinstalling.

NOTE:Donotusesolventstocleanlter.

4. Reinstallairlterandrightsidedoor.

5. Ifthelterisdamaged,replaceitwithanewlter.

Contact your distributor.

Donotoperatethedryerwithouttheambient

airlter.Permanentcondenserdamagemayresult.

Monthly Maintenance

Forair-cooledcondensers,itisrecommendedtoinspect

thecondensercoilsmonthly.Ifnecessary,removedirtor

otherparticleswithcompressedairfromanOSHA-approved

airnozzlethatlimitsitsdischargepressureto30psig

(2.1kgf/cm²).

Electronic Drain Valve Disassembly and Servicing

Donotdisassembledrainvalvetimerorattempt

torepairelectricalparts.Replacetimerifdefective.

Thedrainvalvedischargecondensatethroughafull-port

drain opening. The valve body may need to be cleaned under

conditionsofgrossparticulatecontamination.

Todisassemblethedrainvalvebodyforcleaningandother

maintenance:

1. Turnpowerswitchoff.

2. Disconnectmainpowersupplytodryer.

3. Depressurizeunit.

4. LockoutandtagpowersupplyinaccordancewithOSHA

requirements.

Ifpowersupplyisnotconnectedandunitis

notdepressurizedbeforedisassembly,seriouspersonalinjury

and valve damage may result.

5. Removes hoses that connect the drain valve to the drain

valve strainer.

6. Removescrewandwasherfromfrontofthedrainvalve.

7. Removethepowersupplyconnectorandgasket(with

thetimerassemblyifattached)fromthesolenoidcoil

housing.Donotdamageorlosethegasket.

8. Removecoilxingnutandspringwasherfromtopof

solenoid coil housing.

9. Liftsolenoidcoilhousingoffsolenoidcoreinvalvebody.

10. Unscrewsolenoidcorefromvalvebody.

Oncethedrainvalveisdisassembled,thefollowing

maintenancecanbeperformed.

1. Inspectinternalpartsofvalvebody;cleanorreplaceas

required.

NOTE:Replacesolenoidvalveifcomponentdamageis

observed.

2. Removedebrisfromvalvebody.

3. Wipesolenoidcorecomponentswithacleanclothor

blowoutdebriswithcompressedairfromanOSHA-

approvedairnozzlethatlimitsitsdischargepressureto

30 psig.

4. Checkthattheplungerassemblyiscleanandmoves

freelyinhousing.

5. Iftimerisattachedtovalvebody,checkelectrical

continuity across timer assembly.

Toreassemblethedrainvalve,reversethesequence

oftheprecedingsteps.Afterthedrainvalveis

reassembled,connectthemainpowersupplytothe

dryer.Whenthedryerisreturnedtoservice,check

thedrainvalveforairorcondensateleaks;tighten

connectionsasrequiredtocorrectleaks.Checkthedrain

cycle;adjustthetimeraccordingtotheprocedureinthe

drainvalveadjustmentsection.

Returns to Manufacturer

Ifthedryeroracomponentofthedryermustbereturnedto

themanufacturer,rstcallyourlocaldistributorforareturn

authorizationnumberandshippingaddress.Yourdistributor

willinformyouwhetherthedryeroronlyacomponentmust

bereturned.Markthepackagewiththereturnauthorization

numberandshipfreightprepaidasdirectedbyyourlocal

distributor.

8

FIELD SERVICE GUIDE

Problemsmostfrequentlyencounteredwithrefrigerated

dryersarewaterdownstreamofthedryerandexcessive

pressuredrop.Mostcausescanbeidentiedandremedied

byfollowingthisguide.

Closedrefrigerationsystemsarepotentially

dangerous.Workontherefrigerationsystemmustbedone

onlybyacompetentlicensedrefrigerationmechanic.Donot

releaseuorocarbonrefrigerantstotheatmosphere.Donot

dischargeliquidrefrigerantsintooordrains.Refrigerant

vaporsmayaccumulateinlowplaces.Inhalationofhigh

concentrationsmaybefatal.Allrefrigerantsmustbe

recoveredperEPArequirements.

Donotsmokewhenarefrigerationleakissuspected.Burning

materialsmaydecomposerefrigerants,formingatoxicgasor

acidsthatmaycauseseriousinjuryandpropertydamage.

Beforedismantlinganypartofthedryerorcompressed

airsystem,completelyventtheinternalpressuretothe

atmosphere.

PROBLEM SYMPTOM POSSIBLE CAUSE REMEDY

Water Downstream of

Dryer

Refrigerantcompressornot

running.

Lossofpowertodryer Checkpowersupply,fusesand/orbreakers.Check

forlooseconnections.

Dryerturnedoff. CheckOn/Offswitchposition.

Dryeroverloaded. Conrmthatinletow,inlettemperatureandinlet

pressurearewithinacceptablerangeofdryer.

Condenser clogged with debris. Check/cleanambientairlterandcondenser.

Fan motor inoperative Checkfanmotoroperation.Replaceifnecessary.

Ambienttemperaturetoohigh. Verifyambienttemperaturethroughoutday.

Highpressureswitchactivated

(models 200 to 500 only)

Pressmanualresetbuttontoswitchtoresetbutton.

Compressor overheated. Turndryeroff.Contactlocaldistributor.

Compressordefective. Turndryeroff.Contactlocaldistributor.

Nocondensatedischargingfrom

dryer.

Drainstrainerclogged. Clean drain strainer.

Drainvalveinoperative. Check/rebuilddrainvalve.

DraintimerorDSMinoperative. ConrmthereispowertothetimerorDSM.

ReplacetimerorDSM,ifnecessary.

Drainsolenoidinoperative. Conrmthereispowertothecoil.Replacecoil,if

necessary.

Condensatedischargingfromdryer. Incorrectdraintimersetting. Adjustdraintimer-increaseopentimeand/or

decrease closed time.

Liquidwaterenteringdryer. Aftercoolerdrainvalvemalfunction. Check,repairaftercoolerdrainvalve.

Excessive Pressure

Drop Across Dryer

Frozencondensateinevaporator. Incorrecthotgasbypassvalve

setting.

Contact local distributor.

Inletairpressurelow. Upstreamrestrictioninairsystem. Checkallupstreamairsystemcomponents(valves,

regulators,etc.)

Dryerundersized. Excessivecompressedairow. Resizedryer.

Dew Point Indicator

Out of Green Zone

Dryeroverloaded. Conrmthatinletow,inlettemperatureandinlet

pressurearewithinacceptablerangeofdryer.

Condenser clogged with debris. Check/cleanambientairlterandcondenser.

Loosesensorconnection. ConrmgaugeorDSMsensoristightlyconnected

to dryer tubing.

Defectivegauge,DSMorDSM

sensor.

Replacegauge,DSMorDSMsensor.

9

ENGINEERING DATA

MODEL 75 100 125 150 200 250 300 400 500

SPECIFICATIONS

Rated Capacity

a

-(scfm) 75 100 125 150 200 250 300 400 500

Inlet/OutletConnections-(inches) 3/4 1 1 1 1-1/2 1-1/2 1-1/2 2 2

Dimensions

Height-(inches) 20.1 20.6 20.6 20.6 30.0 30.0 29.9 29.9 31.5

Length-(inches) 19.7 28.3 28.3 28.3 35.4 35.4 37.4 37.4 41.3

Width-(inches) 18.9 13 13 13 16.1 16.1 19.3 19.3 23.2

PowerSupply-(V/Ph/Hz) 115/1/60 115/1/60 115/1/60 115/1/60 460/3/60 460/3/60 460/3/60 460/3/60 460/3/60

RefrigerantCompressorCapacity

c

-

(BTU/hr)

3,414 3,953 3,953 5,406 8,787 13,969 13,969 17,574 22,151

InputPower-(kW) 0.72 0.74 0.76 1.11 1.42 1.98 2.05 2.50 3.06

RefrigerantType

b

R-134a R-134a R-134a R-134a R-134a R-134a R-134a R-134a R-134a

a

Rating conditionsare100°Finlettemperature,100psiginletpressure,100%inletrelativehumidity,100°Fambienttemperature@60Hz.PerCAGIADF-100.

b

Refertodryerdataplateforrefrigerantcharge.

c

Compressorcapacity@35°Fevaporatingtemperature,130°Fcondensingtemperature.

MINIMUM - MAXIMUM OPERATING CONDITIONS ALL MODELS

Min.-Max.InletAirPressure(compressedairatinlettodryer) 10-232psig

Min.-Max.InletAirTemperature(compressedairatinlettodryer) 40°F-120°F

Min.-Max.AmbientTemperature 40°F-110°F

NOTE:Continuousoperationintheabovemaximumandminimumoperationconditionsisnotallowable.

SUCTION PRESSURE REFRIGERANT PRESSURE SWITCH SETTINGS

Refrigerant Without Airflow

Models75to500

R-134a 31 psig

Fan Cycle Control

FanPressureSwitchSetting

R-134a

Cut-In Cut-Out

199psig 142 psig

Models200to500

RefrigerantCompressorControl

HighPressureSwitchSetting

SensorLocation

R-134a

Cut-Out Cut-In

CompressorDischarge

298psig

Manual Reset

201 psig

10

ELECTRICAL SCHEMATICS

Figure 1b

100 to 125 scfm models

115V / 1PH / 60Hz

ON/OFF SWITCH

WITH RUNNING LAMP

R

2

5

CS CR

1

3

6

PTC STARTER

F. P. S.

FAN

MOTOR

T

ELECTRONIC AUTO DRAIN VALVE

OVERLOAD

PROTECTOR

COMP.

1PH

S

M

C

Figure 1a

75 scfm models

115V/1PH/60Hz

5

6

ON/OFF SWITCH

WITH RUNNING LAMP

R

2

F. P. S

MS

C

COMP.

1PH

OVERLOAD

PROTECTOR

PTC STARTER

FAN

MOTOR

ELECTRONIC

AUTO DRAIN

VALVE

T

11

ELECTRICAL SCHEMATICS

Figure 1d

200 to 500 scfm models

Figure 1c

150 scfm models

115V/1PH/60Hz

R

ON/OFF SWITCH

WITH RUNNING LAMP

ELECTRONIC

AUTO DRAIN

VALVE

Starting

Capacitor

S

R

COMP.

1~

C

P.R-b

Potential

Relay

FAN

MOTOR

Overload

protector

(OLP)

P. R

T

F. P. S

H.P. S

* FUSE FOR ELECTRO

AUTO DRAIN VALVE

SENSORELECTRO AUTO

DRAIN VALVE

* FUSE

U1

RL1

DSM

SOL

21

21

24

3

F1(2A)

ON/OFF SWITCH

WITH RUNNING LAMP

SRT

0V

R

440V

T

380V

TR 150VA

115V

0V

MC1

11

460V/3Ø/60Hz

F. P. S

31

21

24 24

1

2

3

4

5

6

7

o

o

o

o

o

o

o

R

MC1

REF. COMP.

With internal T.P

M

FAN MOTOR

With internal T.P

12

Figure 2a

75 to 150 scfm models

AIR AND REFRIGERANT FLOW SCHEMATICS

DRAIN VALVE

STRAINER

FAN PRESSURE SWITCH

FILTER/DRYER

REFRIGERANT

COMPRESSOR

CONDENSER

FAN BLADES

& FAN MOTOR

AIR FLOW

CHILLER

(REF TO AIR HEAT EXCHANGER)

REHEATER

(AIR TO AIR HEAT EXCHANGER)

COMPRESSED AIR INLET

COMPRESSED AIR OUTLET

S

MOISTURE SEPARATOR INTEGRATED BRAZED PLATE HEAT EXCHANGER

ELECTRONIC AUTO

DRAIN VALVE WITH TIMER

CAPILLARY TUBE

HOT GAS

BY-PASS VALVE

F. P. S

13

Figure 2b

200 to 500 scfm models

AIR AND REFRIGERANT FLOW SCHEMATICS

DRAIN VALVE

STRAINER

FILTER/DRYER

REFRIGERANT

COMPRESSOR

CONDENSER

FAN BLADES

& FAN MOTOR

AIR FLOW

CHILLER

(REF TO AIR HEAT EXCHANGER)

REHEATER

(AIR TO AIR HEAT EXCHANGER)

COMPRESSED AIR INLET

COMPRESSED AIR OUTLET

S

MOISTURE SEPARATOR INTEGRATED BRAZED PLATE HEAT EXCHANGER

ELECTRONIC AUTO

DRAIN VALVE

HIGH PRESSURE SWITCH

HOT GAS BY-PASS VALVE

CAPILLARY TUBE

FAN PRESSURE SWITCH

H.P. SF. P. S

14

REPLACEMENT PARTS

Item Description 75 scfm 100 scfm 125 scfm 150 scfm

1 RefrigerantCompressor 3149274 3161249 3161249 3161250

2 Condenser(air-cooled 1283269 3161253 3161253 3161254

3 Fan Blades 3041954 3041954 3041954 3041954

4 FanMotor 3161257 3161257 3161257 3161257

5 FilterDryer 3161259 1283273 1283273 1283273

6 SolenoidValveAssembly 3161263 3161263 3161263 3161263

7 SolenoidValveTimer 3161264 3161264 3161264 3161264

8 SolenoidValveStrainer 3161265 3161265 3161265 3161265

9 DINSocket 3161266 3161266 3161266 3161266

10 On/OffSwitchwithRunningLamp 3161244 3161244 3161244 3161244

11 DewPointIndicator 3041493 3041493 3041493 3041493

12 HotGasBypassValve 3161268 3161268 3161269 3161270

13 HeatExchanger 3161275 3161276 3161277 3161277

14 AmbientAirFilter — 3161260 3161260 3161260

15 FanPressureSwitch 3161274 3161274 3161274 3161274

16 MaintenanceKits RNPJMK3 RNPJMK3 RNPJMK3 RNPJMK3

Item Description 200 scfm 250 scfm 300 scfm 400 scfm 500 scfm

1 RefrigerantCompressor 3161251 3093041 3137014 3090708 3161242

2 Condenser(air-cooled) 3161255 3161255 3161256 3161256 3161245

3 Fan Blades 3041955 3041955 3041957 3041957 3041957

4 FanMotor 5000011 5000011 5000011 5000011 5000011

5 FilterDryer 1283273 1283273 1283369 1283369 1283369

6 SolenoidValveAssembly 3161248 3161248 3161248 3161248 3161248

7 SolenoidValveTimer — — — — —

8 SolenoidValveStrainer 3146976 3146976 3146976 3146976 3146976

9 DINSocket 3161267 3161267 3161267 3161267 3161267

10 On/OffSwitchwithRunningLamp 3161244 3161244 3161244 3161244 3161244

11 DryerSystemMonitor(DSM) 3161282 3161282 3161282 3161282 3161282

12 HotGasBypassValve 3161271 3161271 3161271 3161272 3161272

13 HeatExchanger 3161278 3161279 3161280 3161281 3161246

14 AmbientAirFilter 3161261 3161261 3161262 3161262 3161247

15 FanPressureSwitch 3161274 3161274 3161274 3161274 3161274

16 HighPressureSwitch 3161273 3161273 3161273 3161273 3161273

17 MaintenanceKits RNPJMK4 RNPJMK4 RNPJMK5 RNPJMK5 RNPJMK6

15

AUTHORIZATION FROM THE SERVICE DEPARTMENT IS NECESSARY BEFORE MATERIAL IS

RETURNED TO THE FACTORY OR IN-WARRANTY REPAIRS ARE MADE.

WARRANTY

Themanufacturerwarrantstheproductmanufacturedbyit,whenproperlyinstalled,operated,applied,andmaintainedinaccordancewithproce-

duresandrecommendationsoutlinedinmanufacturer’sinstructionmanuals,tobefreefromdefectsinmaterialorworkmanshipforaperiodas

speciedbelow,providedsuchdefectisdiscoveredandbroughttothemanufacturer’sattentionwithintheaforesaidwarrantyperiod.

Themanufacturerwillrepairorreplaceanyproductorpartdeterminedtobedefectivebythemanufacturerwithinthewarrantyperiod,provided

suchdefectoccurredinnormalserviceandnotasaresultofmisuse,abuse,neglectoraccident.Normalmaintenanceitemsrequiringroutinereplace-

mentarenotwarranted.Thewarrantycoverspartsandlaborforthewarrantyperiodunlessotherwisespecied.Repairorreplacementshallbemade

atthefactoryortheinstallationsite,atthesoleoptionofthemanufacturer.Anyserviceperformedontheproductbyanyoneotherthanthemanu-

facturermustrstbeauthorizedbythemanufacturer.

Unauthorizedservicevoidsthewarrantyandanyresultingchargeorsubsequentclaimwillnotbepaid.Productsrepairedorreplacedunderwarranty

shallbewarrantedfortheunexpiredportionofthewarrantyapplyingtotheoriginalproduct.

Theforegoingistheexclusiveremedyofanybuyerofthemanufacturer’sproduct.Themaximumdamagesliabilityofthemanufactureristheoriginal

purchasepriceoftheproductorpart.

THEFOREGOINGWARRANTYISEXCLUSIVEANDINLIEUOFALLOTHERWARRANTIES,WHETHERWRITTEN,ORAL,ORSTATUTORY,ANDISEXPRESSLYINLIEU

OFTHEIMPLIEDWARRANTYOFMERCHANTABILITYANDTHEIMPLIEDWARRANTYOFFITNESSFORAPARTICULARPURPOSE.THEMANUFACTURERSHALL

NOTBELIABLEFORLOSSORDAMAGEBYREASONOFSTRICTLIABILITYINTORTORITSNEGLIGENCEINWHATEVERMANNERINCLUDINGDESIGN,MANUFAC-

TUREORINSPECTIONOFTHEEQUIPMENTORITSFAILURETODISCOVER,REPORT,REPAIR,ORMODIFYLATENTDEFECTSINHERENTTHEREIN.

THEMANUFACTURER,HISREPRESENTATIVEORDISTRIBUTORSHALLNOTBELIABLEFORLOSSOFUSEOFTHEPRODUCTOROTHERINCIDENTALORCONSE-

QUENTIALCOSTS,EXPENSES,ORDAMAGESINCURREDBYTHEBUYER,WHETHERARISINGFROMBREACHOFWARRANTY,NEGLIGENCEORSTRICTLIABILITY

INTORT.

Themanufacturerdoesnotwarrantanyproduct,part,material,component,oraccessorymanufacturedbyothersandsoldorsuppliedinconnection

withthesaleofmanufacturer’sproducts.

Warranty Period

Partsandlaborfortwo(2)yearsfromthedateofshipmentfromthefactory;heatexchangersarecovered(partsonly)foranadditionalthree(3)

years(totalofve[5]).Onunitsthatmanufacturerrequestsbereturnedtothefactory,aonetimeremoval/reinstallationlaborallowanceasnotedin

theServiceWarrantyPoliciesandProceduresHandbookwillapply.Freighttothefactoryfromtheinstallationsiteandtotheinstallationsitefromthe

factorywillbepaidbythemanufacturer;meansoftransportationtobespeciedbymanufacturer.

SERVICE DEPARTMENT: (724) 746-1100

Curtis-Toledo, Inc.

1905 Kienlen Avenue, St. Louis Missouri 63133

WWW.FSCURTIS.COM

/