Page is loading ...

FormNo.3392-628RevB

T42404-WheelDrive5-Plex

MowerTractionUnit

ModelNo.02750—SerialNo.315000001andUp

Registeratwww.Toro.com.

OriginalInstructions(EN)

*3392-628*B

ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

Introduction

Thismachineisaride-on,reel-bladelawnmower

intendedtobeusedbyprofessional,hiredoperators

incommercialapplications.Itisprimarilydesigned

forcuttinggrassonwell-maintainedturf.Usingthis

productforpurposesotherthanitsintendedusecould

provedangeroustoyouandbystanders.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

Visitwww.T oro.comformoreinformation,including

safetytips,trainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,or

additionalinformation,contactanAuthorizedService

DealerorT oroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Themodel

andserialnumbersareonaplatemountedonthe

leftsideoftheframeunderthefootrest.Writethe

numbersinthespaceprovided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure1),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure1

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

2

Contactusatwww.Toro.com.

PrintedintheUK

AllRightsReserved

Contents

Safety.......................................................................4

GeneralSafety...................................................4

SafetyandInstructionalDecals..........................4

ProductOverview.....................................................9

Controls...........................................................10

BrakingSystem..............................................11

WarningSystems..........................................15

IndicatorLights.............................................16

Specications..................................................17

Attachments/Accessories.................................17

BeforeOperation.................................................17

BeforeOperationSafety...................................17

PerformingDailyMaintenance..........................18

FillingtheFuelTank..........................................18

DuringOperation.................................................18

DuringOperationSafety...................................18

UsingtheOperatorPlatformLatching

Mechanism...................................................20

UnderstandingtheOperatorPresence

Controls........................................................20

StartingtheEngine...........................................21

ShuttingOfftheEngine.....................................21

FoldingtheRollBar..........................................21

CheckingtheInterlockSwitches.......................22

AdjustingtheHeightofCut...............................23

ControllingthePositionofanIndividual

CuttingUnit...................................................23

DualLiftCongurationControl..........................24

EngagingtheCuttingUnitDrive........................24

UsingtheWeight-Transfer/Traction

Assistance....................................................25

ClearingDebrisfromtheCuttingUnits..............25

OperatingTips.................................................25

AfterOperation....................................................26

AfterOperationSafety......................................26

IdentifyingtheTie-DownPoints........................27

HaulingtheMachine.........................................27

JackingPoints..................................................27

TowingtheMachine..........................................27

RecommissioningtheMachineafter

Towing...........................................................28

Maintenance...........................................................29

MaintenanceSafety..........................................29

RecommendedMaintenanceSchedule(s)...........29

DailyMaintenanceChecklist.............................31

Lubrication..........................................................32

GreasingtheBearings,Bushings,and

Pivots............................................................32

EngineMaintenance...........................................33

EngineSafety...................................................33

CheckingtheEngineOverheatWarning

System..........................................................33

ServicingtheAirCleaner..................................33

CheckingtheEngine-OilLevel..........................34

ChangingtheEngineOilandFilter....................34

FuelSystemMaintenance...................................35

DrainingtheFuelT ank......................................35

CheckingtheFuelLinesand

Connections..................................................35

ReplacingtheFuelFilterCanister.....................35

BleedingtheFuelSystem.................................36

BleedingAirfromtheFuelInjectors...................36

ElectricalSystemMaintenance...........................37

ElectricalSystemSafety...................................37

ServicingtheBattery.........................................37

DriveSystemMaintenance..................................38

CheckingtheTirePressure...............................38

CheckingtheT orqueoftheWheel

Nuts..............................................................38

ChangingtheTransmission-OilFilter................38

CheckingtheRearWheelAlignment.................38

CoolingSystemMaintenance..............................39

CoolingSystemSafety.....................................39

CheckingtheCoolingSystem...........................39

RemovingDebrisfromtheCooling

System..........................................................40

BeltMaintenance................................................40

CheckingtheConditionandTensionofthe

AlternatorBelt...............................................40

HydraulicSystemMaintenance...........................41

HydraulicSystemSafety...................................41

CheckingtheHydraulicLinesand

Hoses............................................................41

ServicingtheHydraulicSystem........................41

HydraulicFluidCapacity...................................41

CheckingtheHydraulicFluid............................41

ChangingtheHydraulicOilReturn

Filter..............................................................43

CheckingtheHydraulicOilOverheat

WarningSystem............................................43

CuttingUnitMaintenance.....................................44

BladeSafety.....................................................44

Cleaning..............................................................44

WashingtheMachine.......................................44

Storage...................................................................45

StorageSafety..................................................45

PreparingtheTractionUnit...............................45

PreparingtheEngine........................................45

Troubleshooting......................................................46

3

Safety

Thismachinehasbeendesignedinaccordancewith

ENISO5395.

GeneralSafety

Thisproductiscapableofamputatinghandsandfeet

andofthrowingobjects.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingtheengine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

functioningproperlyonthemachine.

•Keepchildren,bystanders,andpetsoutofthe

operatingarea.Neverallowchildrentooperate

themachine.

•Shutofftheengine,removethekey,waitforall

movementtostopbeforeyouleavetheoperator’s

position.Allowthemachinetocoolbefore

adjusting,servicing,cleaning,orstoringit.

Improperlyusingormaintainingthismachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol

,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

decal70-13-072

70-13-072

1.Jackingpoint

decal70-13-077

70-13-077

1.Warning—stoptheengineandremovetheignitionkey

beforereleasingoroperatingsafetylatches.

decal70-13-078

70–13–078

1.Dieselfuel

4

decal924868

924868

1.Tippinghazard—donotoperatethemachineunlessthe

platformiscorrectlyseatedandthelatchislockedinplace.

decal950832

950832

1.Tirepressure

decal950889

950889

1.Warning—hotsurfaces.

decal953829

953829

1.Crushinghazard,cuttingunit—alwayslowerthecutting

unitsbeforegoingnearthem.

decal953876

953876

1.Differentiallock

4.Reversespeed

2.Pushdowntoengagethe

differentiallock.

5.Forwardspeed

3.Pulluptodisengagethe

differentiallock.

5

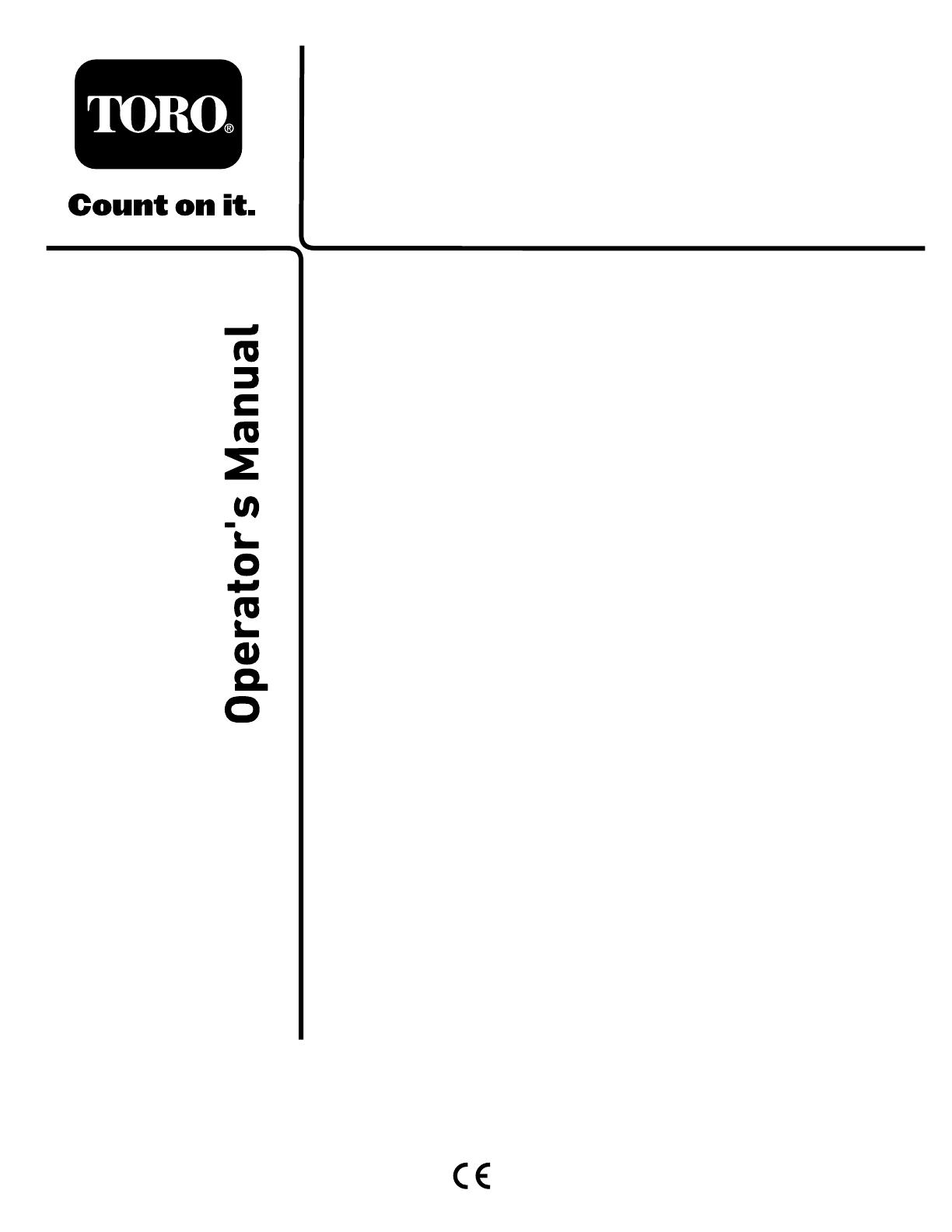

decal953877

953877

1.Forwardspeed

3.Slow

2.Fast

decal994912

994912

1.Engagetheparkingbrake.

7.Raise/lowertheright

cuttingunit.

2.Disengagetheparking

brake.

8.Horn

3.Fast9.Ignitionswitch

4.Slow

10.Engagethereel.

5.Raise/lowertheleftcutting

unit.

11.Disengagethereel.

6.Raise/lowerthecenter

cuttingunit.

12.Engagebacklapping.

decal111-0773

111-0773

1.Warning—crushingofngers,forceappliedfromside.

6

decal111-3901

111-3901

1.Transmissionuid—readtheOperator'sManual.

decal111-3902

111-3902

1.Yourhandcanbecutbythefan;warning

2.Hotsurfaces;readtheOperator'sManual.

decal953812

953812

1.Fuellevel,diesel5.Aircleaner

9.Seatswitch13.Coolantlevel—30to40mm

(1to1.5inches)

2.Engineoil

6.Cutterheads

10.Hoselines

14.Greasepoints

3.Tirepressure

7.Cleanandinspectthe

machine.

11.Hydraulicuid

4.Fasteners

8.Wheelnuttorque—front,

200N∙m(147ft-lb);rear,54

N∙m(40ft-lb)

12.Radiator/screens

7

decal111-8098

111-8098

Note:Thismachinecomplieswiththeindustrystandardstabilitytestinthestaticlateralandlongitudinaltestswiththemaximum

recommendedslopeindicatedonthedecal.ReviewtheinstructionsforoperatingthemachineonslopesintheOperator’sManualas

wellastheconditionsinwhichyouwouldoperatethemachinetodeterminewhetheryoucanoperatethemachineintheconditions

onthatdayandatthatsite.Changesintheterraincanresultinachangeinslopeoperationforthemachine.Ifpossible,keepthe

cuttingunitsloweredtothegroundwhileoperatingthemachineonslopes.Raisingthecuttingunitswhileoperatingonslopescan

causethemachinetobecomeunstable.

1.Tippinghazard—driveslowlywhenturningorgoingupslopes.

4.Warning—readtheOperator'sManual;removethekeyfrom

theignitionbeforeservicingorperformingmaintenance.

2.Tippinghazard—onlydriveupslopesthatarebetween0and

18°;donotdriveupslopesthataregreaterthan18°.

5.Thrownobjecthazard—keepbystandersaway.

3.Tippinghazard—wearaseatbeltwhentherollbarisup;donot

wearaseatbeltwhentherollbarisdown.

8

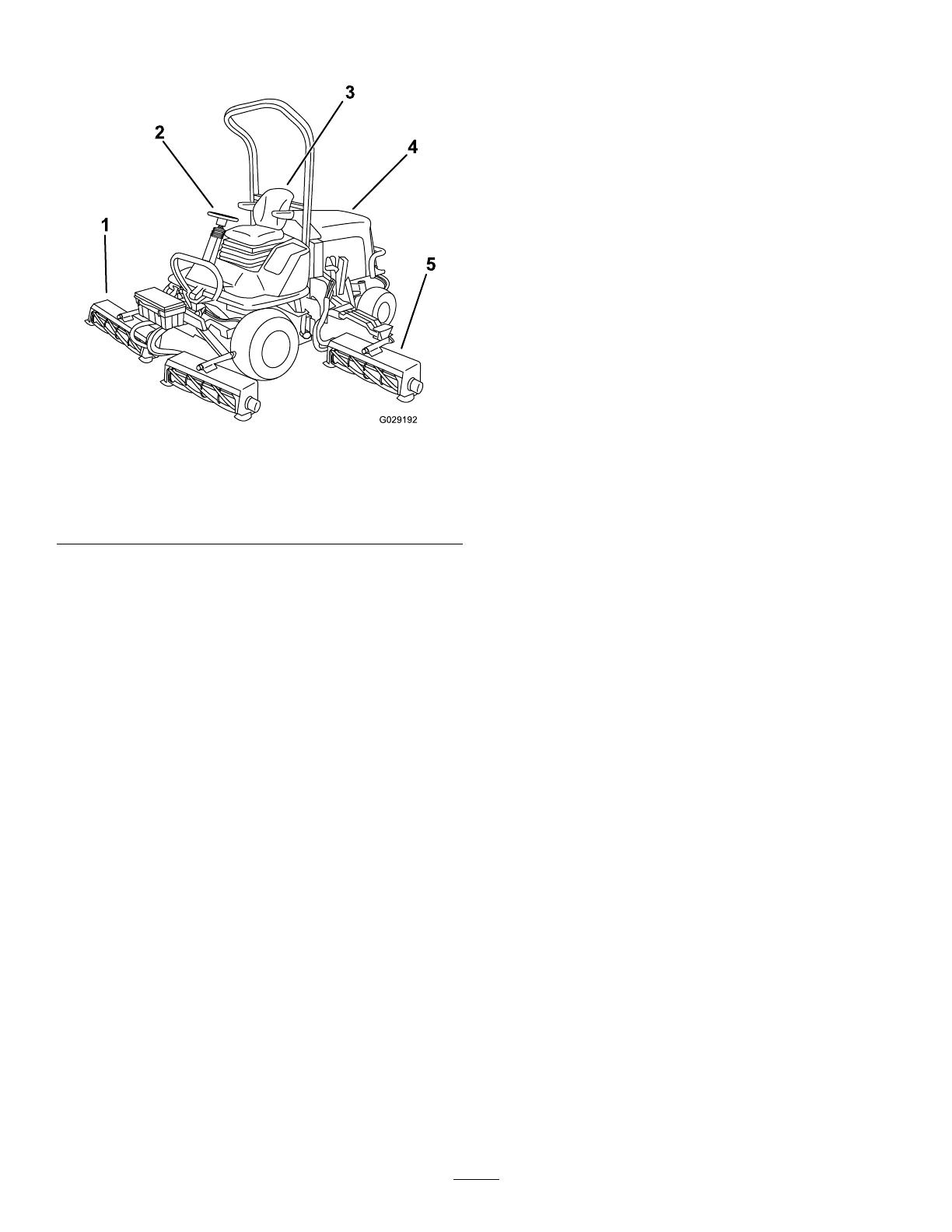

ProductOverview

g029192

Figure2

1.Frontcuttingunits4.Enginehood

2.Steeringwheel

5.Rearcuttingunit

3.Operator'sseat

9

Controls

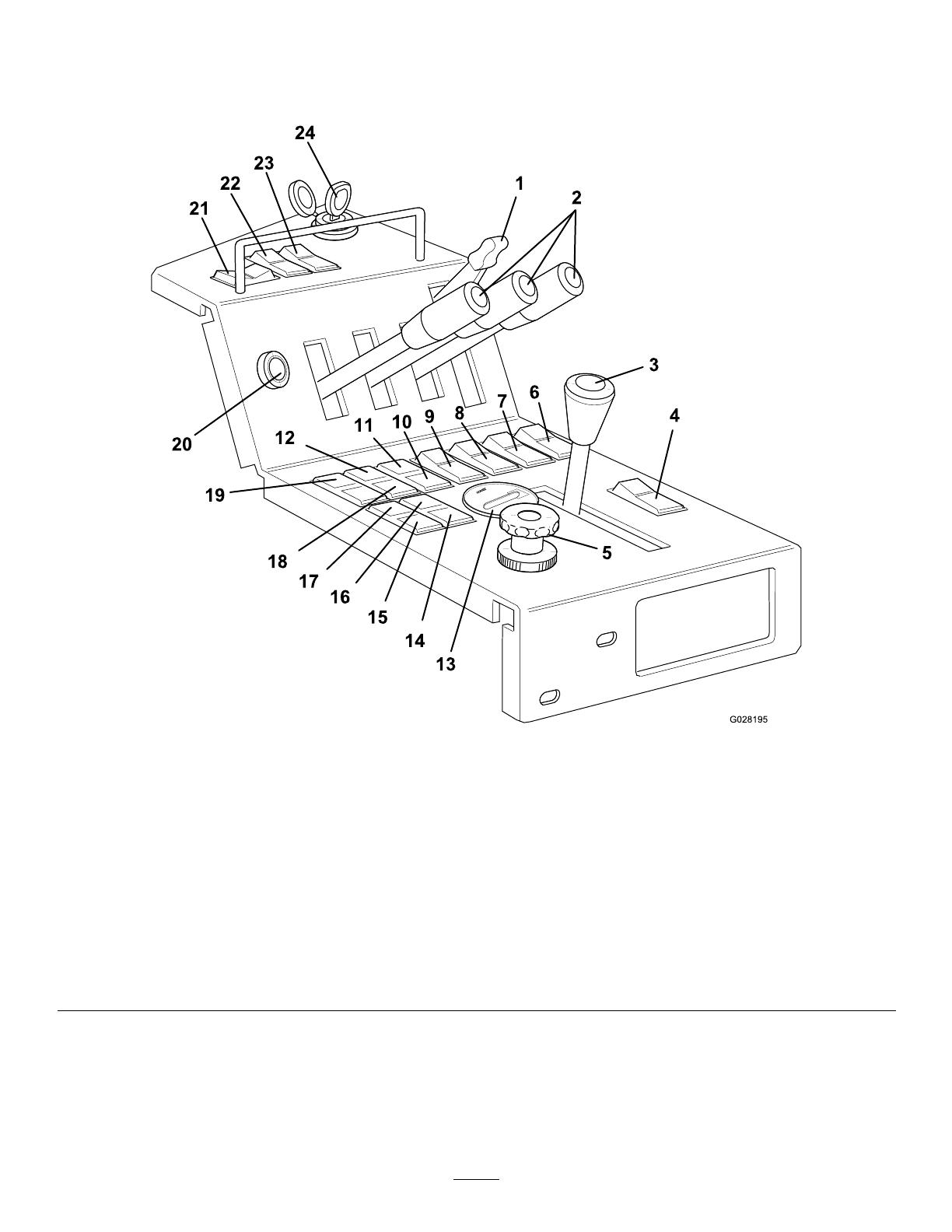

ControlPanelComponents

g029346

Figure3

1.Throttle-controllever

7.Lightingswitch(supplied

withlightingkit)

13.Hourmeter

19.Transmission-oillter

indicator

2.Cutting-unit-positionlever

8.Warning-beaconswitch

(suppliedwithbeaconkit)

14.Transmission-neutral

indicator

20.Hornbutton

3.Parking-brakelever9.Hazard-warningswitch

(suppliedwithlightingkit)

15.Parking-brakeindicator21.Direction-indicatorswitch

(suppliedwithlightingkit)

4.Work/Transportmode

switch

10.Engine

temperature-warning

indicator

16.Cutting-unitdrive-off

indicator

22.Dipbeam/mainbeam

lightswitch(suppliedwith

lightingkit)

5.Weight-transfercontrol

11.Transmission-temperature

indicator

17.Glow-plugindicator23.Cutting-unitdriveswitch

6.Duallift-conguration

switch

12.Oil-pressureindicator

18.Battery-warningindicator24.Ignitionkey

10

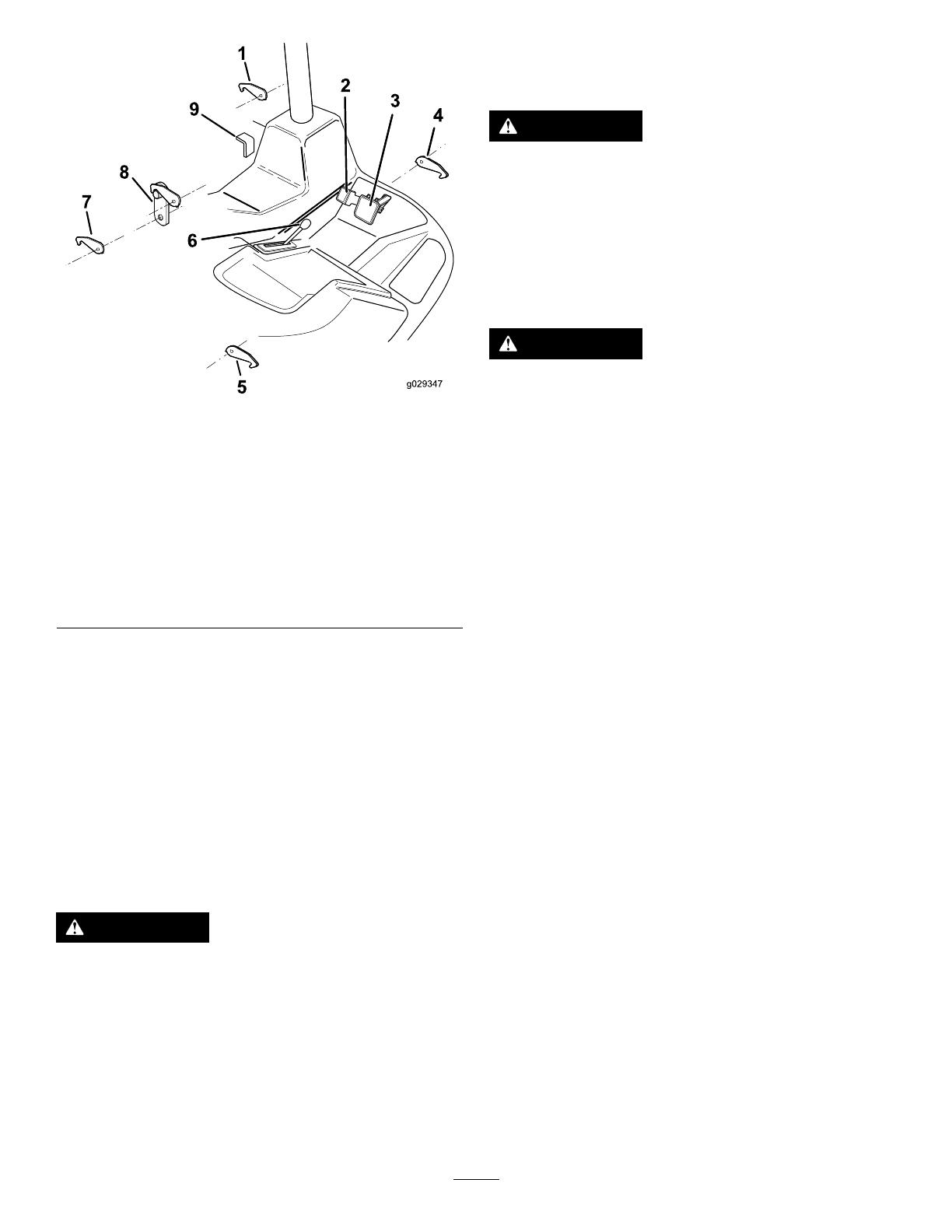

g029347

Figure4

1.Left,frontcutting-unit

transportlatch

6.Forwardtravelspeed

backstoplever

2.Reverse-travelpedal

7.Leftwing-unittransport

latch

3.Forward-travelpedal

8.Centercutting-unit

transportlatch

4.Right,frontcutting-unit

transportlatch

9.Differentiallockpedal

5.Rightwing-unittransport

latch

BrakingSystem

ParkingBrake

Movetheparkingbrakeswitchtotherearwardposition

bypressingthesmallerlockingbuttonandmovingthe

switchforwardtoengagetheparkingbrake(Figure3).

Note:Donotoperatethemachinewiththeparking

brakeengagedanddonotengagetheparkingbrake

whilethemachineismoving.

Thislightilluminateswhentheparkingbrakeis

engagedandtheignitionkeyisturnedtopositionI.

WARNING

Theparkingbrakeoperatesonthefront

wheelsonly.Donotparkthemachineona

slope.

ServiceBrake

Servicebrakingisachievedbythehydraulic

transmissionsystem.Whentheforwardorreverse

travelpedalsarereleasedortheenginespeed

reduced,servicebrakingbecomeseffectiveandtravel

speedisautomaticallyreduced.T oincreasethe

brakingeffect,pushthetransmissionpedalintothe

neutralposition.Servicebrakingiseffectiveonthe

frontwheelsonly.

WARNING

Theservicebrakingsystemisnotabletohold

themoweratastandstill.Alwaysensurethe

parkingbrakeisengagedtoparkthemower

atastandstill.

EmergencyBrake

Intheeventofservicebrakefailure,turntheignition

offtobringthemowertoastandstill.

WARNING

Takecarewhenusingtheemergencybraking.

Remainseatedandholdontothesteering

wheeltopreventejectionfromthemower

causedbythefrontwheelbrakesbeing

appliedsuddenlywhentraveling.

ThrottleControl

Operatethethrottlecontrolinaforwarddirection

toincreasetheenginespeed.Operatethethrottle

controlinarearwarddirectiontoreduceenginespeed

(Figure3).

Note:Theenginespeeddictatesthespeedofthe

otherfunctions,i.e.travel,cuttingcylinderrotation

speedandcuttingunitliftspeed.

TravelPedals

Forwardtravel:Presstheforwardtravelpedalto

increaseforwardtravelspeed.Releasethepedalto

reducespeed(Figure4).

Reversetravel:Pressthereversetravelpedalto

increasereversetravelspeed.Releasethepedalto

reducespeed(Figure4).

Stop(Neutral):Releasetheforwardorreversetravel

pedal.

Work/TransportMode

SelectWORKmodewhenoperatingthemachinein

poortractionconditionswhenyouneedmaximum

tractiveperformance(Figure3).SelectingWORK

modewillenabletheuseofthedifferentiallock.

SelectTRANSPORTmodewhenoperatingthemachine

ingoodtractioncondition(i.e.,whentravelingon

publichighwayormowinglarge,level,openareas).

SelectingTRANSPORTmodeintheseconditionswill

reducetransmissionsystemwearandtear.

11

Note:Thedifferentiallockisnotavailableforuse

whentheTRANSPORTmodeisselected.

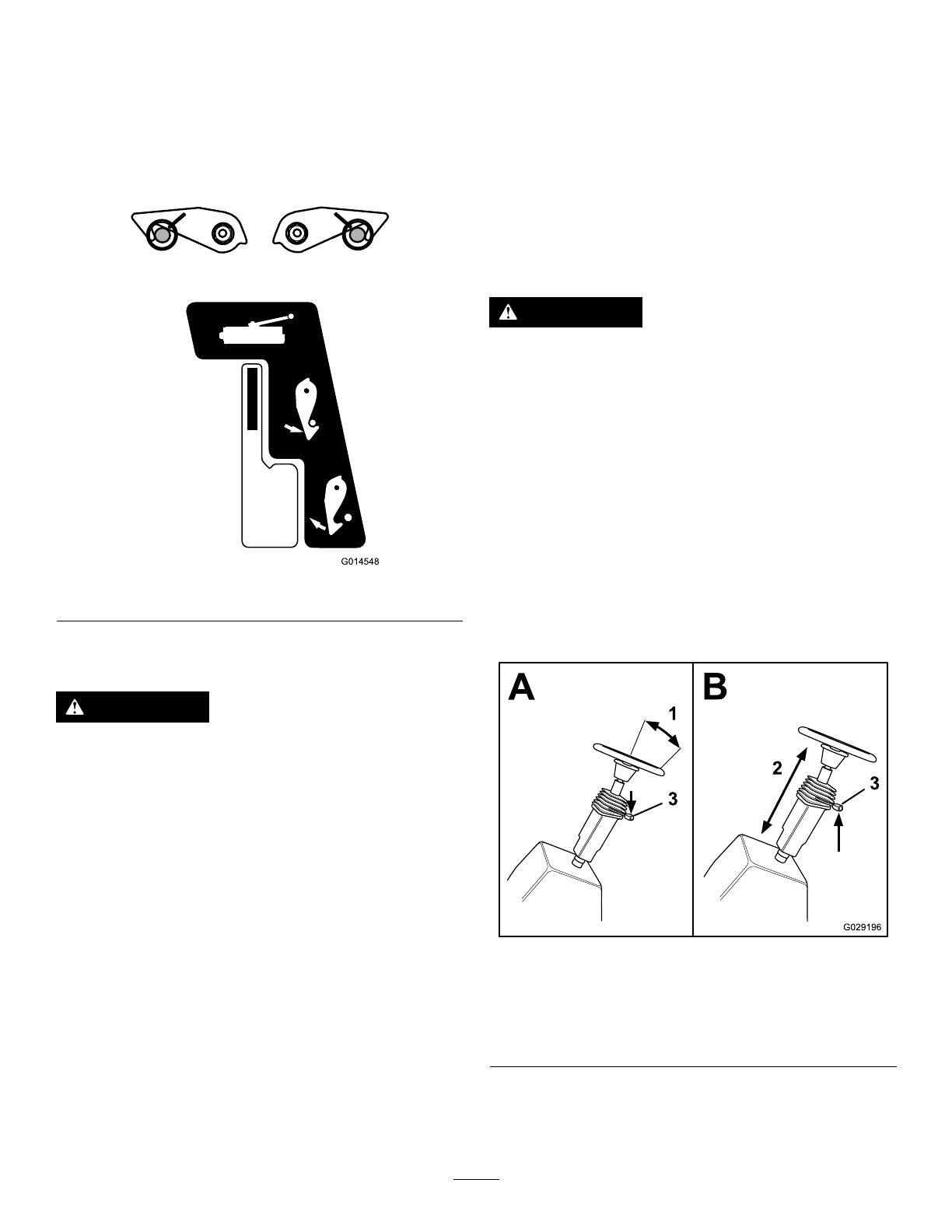

TransportLatches

Alwaysraisethecuttingunitstothetransportposition

andsecurewiththetransportlatchesandsafetylocks

whentravelingbetweenworkareas(Figure5).

g014548

Figure5

DifferentialLock

WARNING

Donotengagethedifferentiallockathigh

speed.Theturningcirclewillincreasewith

thedifferentiallockengaged.

Engagethedifferentiallocktoincreasetractiveeffort.

Onlyengagethedifferentiallockatslowspeeds

(Figure4).Itwilloperatewhilethemachineismoving

forwardandreverse.

Toengagethedifferentiallock,pressthedifferential

lockpedal.T odisengagethedifferentiallock,release

thedifferentiallockpedal.

Note:Thedifferentiallockiseffectiveonlywhen

WORKisselected.

ForwardTravelSpeedBackstop

Lever

Usethebackstoplevertolimitthemovementofthe

forwardpedalforaccurateforwardtravelspeedand

tolimittheclipraterequired(Figure4).

Movetheleverforwardtoincreasethetravelspeed

settingandrearwardtodecreaseit.

Note:Thisisnotacruise-controldevice.Releasing

theforwardtravelpedalwillallowittoreturntoneutral.

CuttingUnitDriveSwitch

AlwaysputthecuttingunitdriveswitchintheOFF

positionwhentravelingbetweenworkareas.

AdjustableSteeringColumn

WARNING

Neveroperatethemachinewithoutrst

checkingthatthesteeringcolumnadjuster

mechanismisingoodworkingorderandthat,

onceadjustedandlocked,thesteeringwheel

remainssecurelyinposition.

Onlyadjustthesteeringwheelandsteeringcolumn

whenthemachineisatastandstillwiththeparking

brakeengaged.

Toadjusttheangleofthesteeringwheel,movethe

leverdown,adjusttheangle,andreleasethelever

(Figure6).

Toadjusttheheightofthesteeringcolumn,move

theleverup,adjusttheheight,andreleasethelever

(Figure6).

g029196

Figure6

1.Adjusttheangleofthe

steeringwheel.

3.Lever

2.Adjusttheheightofthe

steeringcolumn.

12

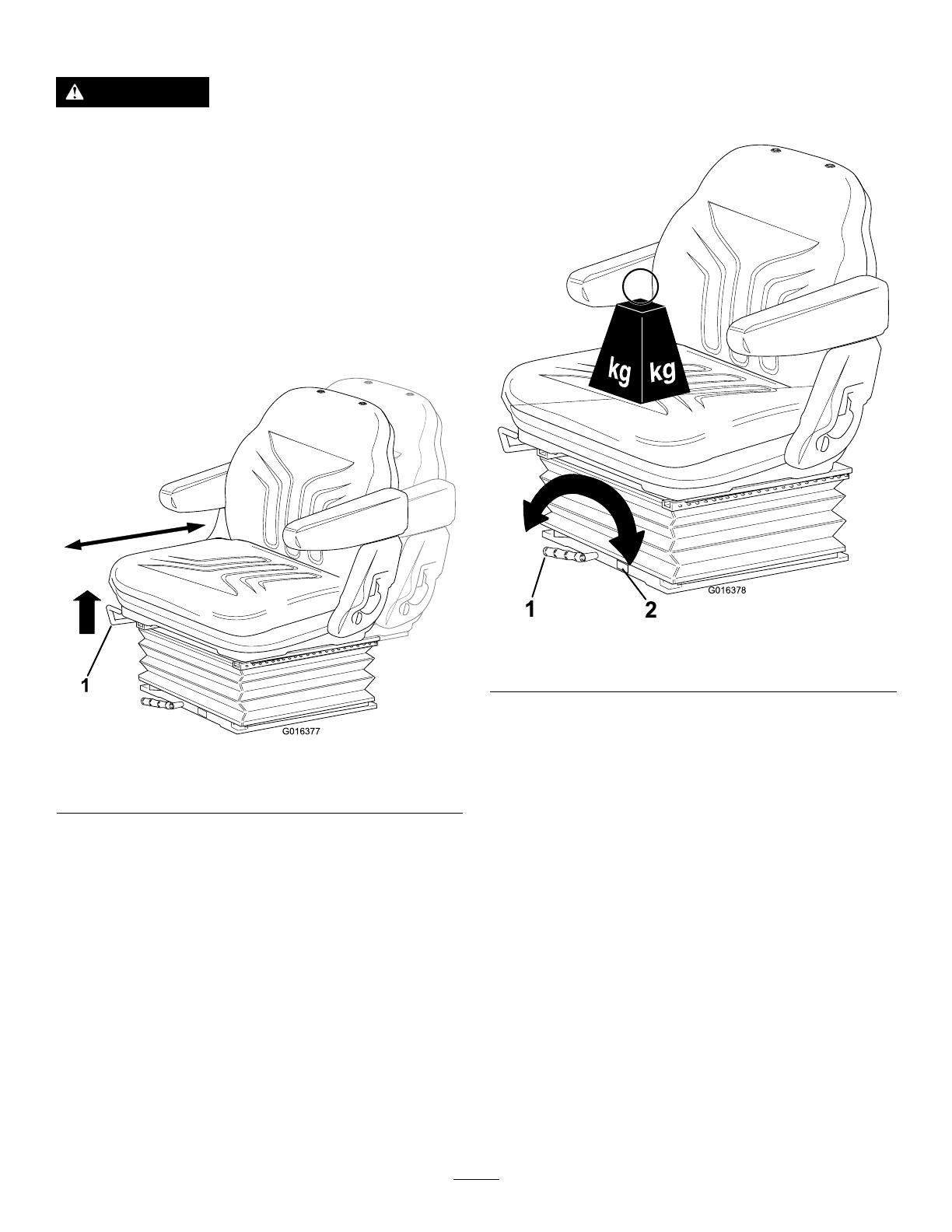

OperatorSeat

WARNING

Neveroperatethemachinewithoutrst

checkingthattheoperatorseatmechanisms

areingoodworkingorderandthat,once

adjustedandlocked,theseatremains

securelyinposition.

Onlyadjusttheseatmechanismswhenthe

machineisatastandstillwiththeparking

brakeengaged.

•Fore/AftAdjustment:Movetheleverupwardto

adjustthefore/aftpositionoftheseat.Releasethe

levertolocktheseatinposition(Figure7).

g016377

Figure7

1.Lever

•Operatorweightadjustment:Rotatethehandle

clockwisetoincreasesuspensionstiffnessand

counter-clockwisetodecrease.Thedialindicates

whentheoptimumsuspensionadjustmenthas

beensetaccordingtooperatorweight(Figure8).

g016378

Figure8

1.Lever2.Dial

13

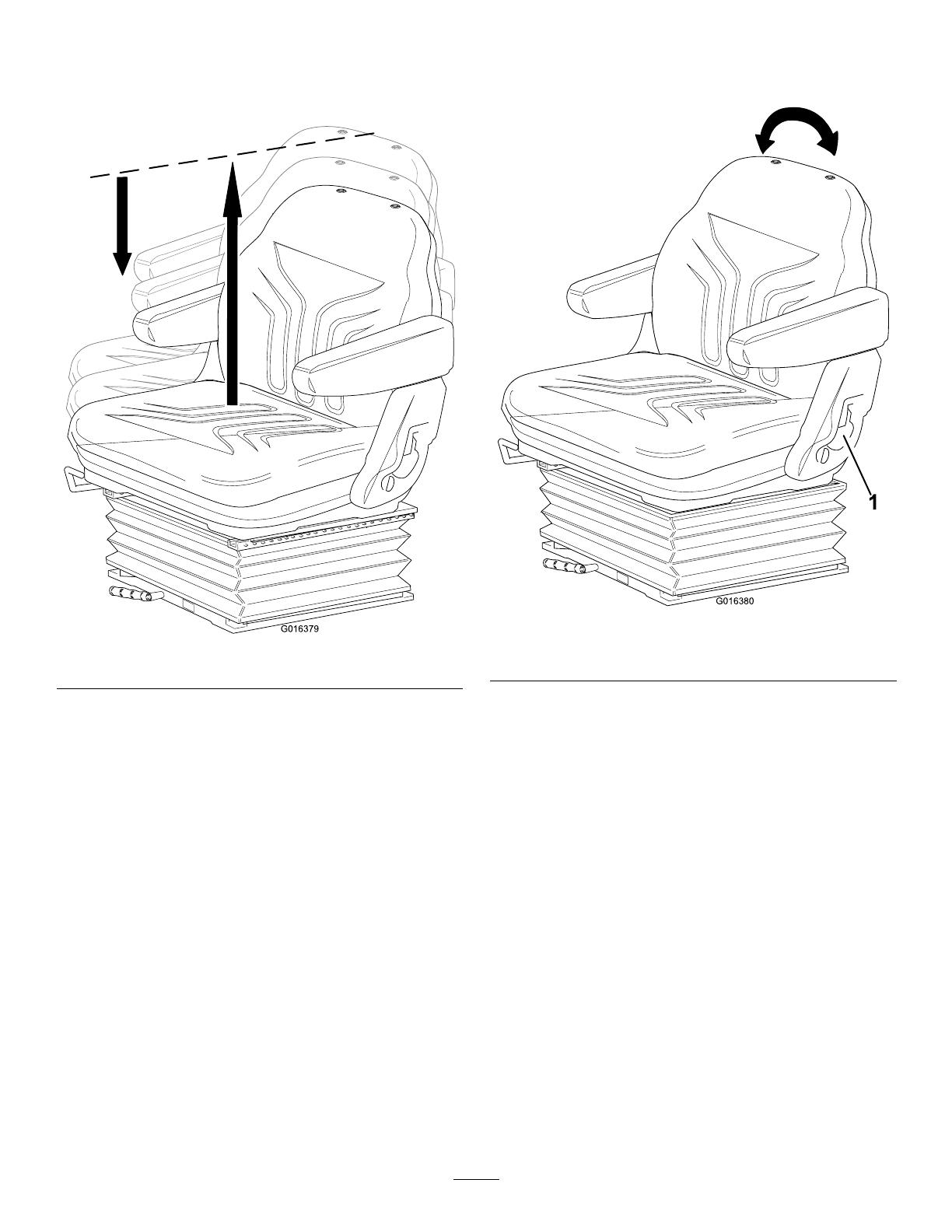

•Heightadjustment:Manuallylifttheseatfor

incrementalheightadjustment.Tolower,liftthe

seatbeyonditshighestsetting,thenallowitto

droptothelowestsetting(Figure9).

g016379

Figure9

•Backrestadjustment:Pullthehandleoutward

toadjusttheseatbackrestangle.Releasethe

handletolocktheseatbackrestinposition.

g016380

Figure10

1.Handle

14

WarningSystems

Engine-CoolantOverheatingWarning

Theengine-coolantwarninglight(Figure11)

illuminatesandthehornsoundsiftheenginecoolant

overheats.

g029201

Figure11

HydraulicOilOverheatingWarningLight

Thehydraulic-oilwarninglight(Figure12)illuminates

andthehornsoundswhenthehydraulicoilinthe

reservoirexceeds95°C(203°F).

g029220

Figure12

LowBatteryChargeWarningLight

Thebattery-chargewarninglight(Figure13)

illuminateswhenthebatterychargeislow.

g029207

Figure13

LowEngine-OilPressureWarningLight

Theengine-oilpressurewarninglight(Figure14)

illuminateswhentheoilpressureistoolow.

g029208

Figure14

AudibleWarningHorn

ServiceInterval:Beforeeachuseordaily—Check

thehorn.

PresstheHORNbutton(Figure15)toprovidean

audiblewarning.

Important:Thehornautomaticallysoundswhen

anenginecoolantorhydraulicuidoverheat

conditionoccurs.Shutofftheengineimmediately

andxthemachinebeforestarting.

g029209

Figure15

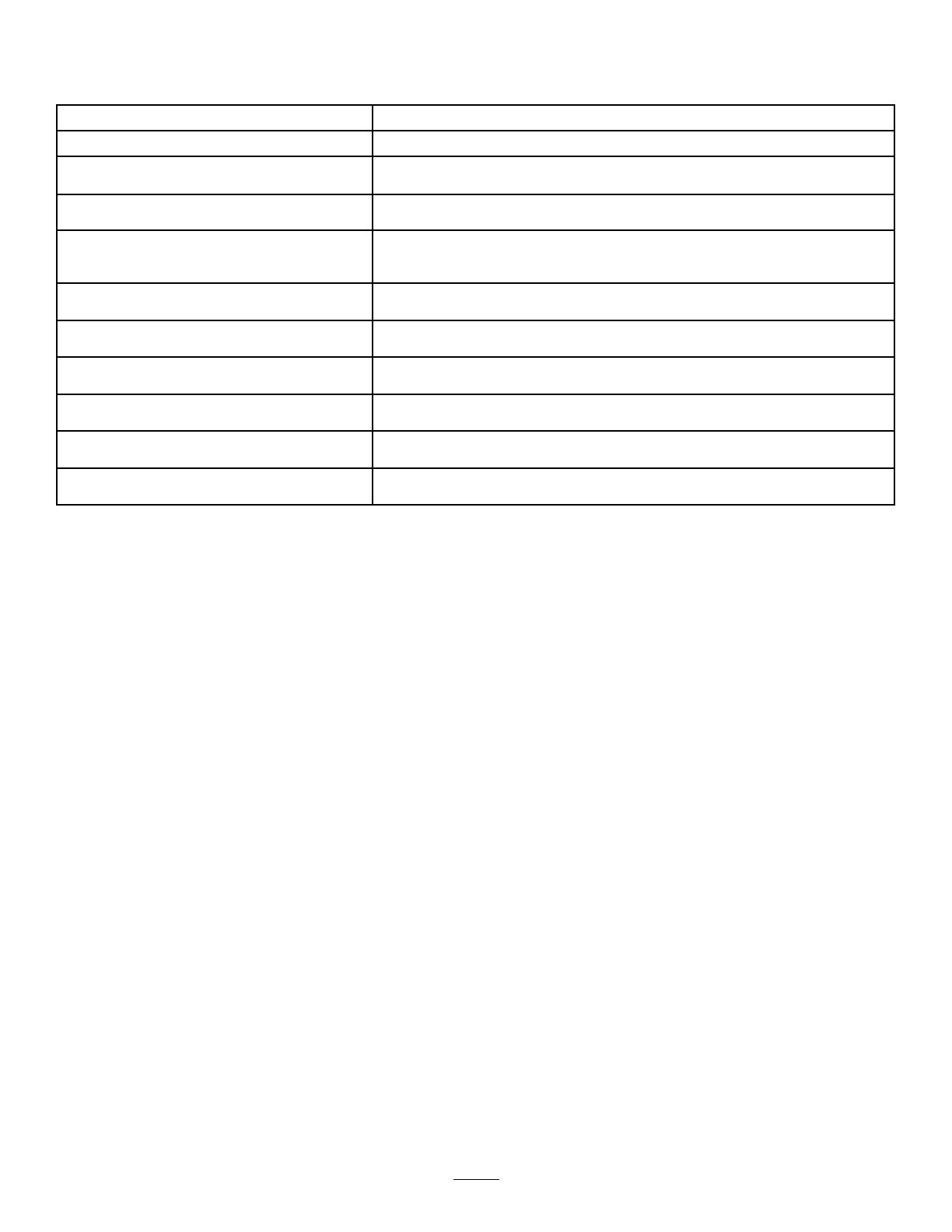

IgnitionKey

Theignitionkeypositionsareasfollows:

0=Engineoff

I=Enginerun/auxiliaryon

II=Enginepre-heat

III=Enginestart

g029198

Figure16

WARNING

Alwaysremovetheignitionkeywhenthe

machineisnotinuse.

Important:Alwaysinstalltheprotectivecapwhen

theignitionkeyisremovedtopreventingressof

dirtandmoisturedamagingthemechanism.

15

FuelGauge

Thefuelgaugeshowstheamountoffuelinthetank

(Figure17).

g014558

Figure17

HourMeter

Thehourmetershowsthetotalhoursthatthemachine

hasbeenoperated(Figure3).

IndicatorLights

EnginePre-HeatIndicatorLight

TurntheignitionkeytopositionII.Theenginepreheat

indicatorlightwillilluminate(Figure18)andheatthe

glowplugs.

Important:Attemptingtostartacoldengine

beforeusingthepre-heatcancauseunnecessary

weartothebattery.

g029199

Figure18

Transmission-Neutral-IndicatorLight

Thetransmission-neutral-indicatorlight(Figure19)

illuminateswhenthetravelcontrolpedalisinthe

NEUTRALpositionandtheignitionkeyisturnedto

positionI.

Note:Theparkingbrakemustbeengagedforthe

transmissionneutralindicatorlighttoilluminate.

g029211

Figure19

Cutting-Unit-Drive-SwitchIndicatorLight

Thecutting-unit-drive-switchindicatorlight(Figure20)

illuminateswhenthecuttingunitdriveswitchisinthe

OFFpositionandtheignitionkeyisturnedtopositionI.

g029212

Figure20

Parking-Brake-IndicatorLight

Theparking-brake-indicatorlight(Figure21)

illuminateswhentheparkingbrakeisengagedand

theignitionkeyisturnedtopositionI.

g029251

Figure21

Hydraulic-Transmission-Filter-IndicatorLight

Thehydraulic-transmission-lter-indicatorlight(Figure

22)illuminateswhenthetransmissionlterelement

isblocked.

Note:Theenginemustberunningfortheindicator

lighttoilluminate.Theindicatorlightmayilluminate

brieywhenthehydraulicoiliscold.

g029370

Figure22

16

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

Specication

Model02750

TransportWidth

1890mm(74.5inches)

Widthofcut3460mm(136.2inches)

Length

2930mm(115.0inches)

Height

1775mm(70.0inches)withROPSfolded

2385mm(94.0inches)withROPSintheverticaloperatingposition

Weight(with2-postROPS,8-inch/6-blade

cuttingunits,anduids)

1870kg(4123lb)

Engine

Kubota35.3kw(47.3hp)@2800rpmDIN70020V2203diesel4cylindersinline

Fueltankcapacity

70L(18.5USgallons)

Travelspeed

0to24km/h(0to15mph)

Recommendedmaximummowingspeed

11km/h(6.85mph)

Hydraulicsystemcapacity

77L(20.3USgallons)

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesisavailableforusewiththemachine

toenhanceandexpanditscapabilities.Contact

yourAuthorizedServiceDealerorauthorizedToro

distributororgotowww.Toro.comforalistofall

approvedattachmentsandaccessories.

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineT oro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

Operation

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Neverallowchildrenoruntrainedpeopleto

operateorservicethemachine.Localregulations

mayrestricttheageoftheoperator.Theowner

isresponsiblefortrainingalloperatorsand

mechanics.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Shutofftheengine,removethekey(ifequipped),

andwaitforallmovementtostopbeforeyouleave

theoperator’sposition.Allowthemachinetocool

beforeadjusting,servicing,cleaning,orstoringit.

•Knowhowtostopthemachineandshutoffthe

enginequickly.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

functioningproperlyonthemachine.

17

•Beforemowing,alwaysinspectthemachineto

ensurethatthecuttingunitsareingoodworking

condition.

•Inspecttheareawhereyouwillusethemachine

andremoveallobjectsthatthemachinecould

throw.

FuelSafety

•Useextremecareinhandlingfuel.Itisammable

anditsvaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporllthefueltank

whiletheengineisrunningorhot.

•Donotaddordrainfuelinanenclosedspace.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheaterorotherappliance.

•Ifyouspillfuel,donotattempttostarttheengine;

avoidcreatinganysourceofignitionuntilthefuel

vaporshavedissipated.

PerformingDaily

Maintenance

ServiceInterval:Beforeeachuseordaily

Beforestartingthemachineeachday,performthe

EachUse/DailyprocedureslistedinMaintenance

(page29).

FillingtheFuelTank

FuelTankCapacity

70L(18.5USgallons)

FuelSpecication

Failuretoobservethefollowingcautionsmaydamage

theengine.

•Neverusekeroseneorgasolineinsteadofdiesel

fuel.

•Nevermixkeroseneorusedengineoilwiththe

dieselfuel.

•Neverkeepfuelincontainerswithzincplatingon

theinside.

•Donotusefueladditives.

PetroleumDiesel

Useonlyclean,freshdieselfuelorbiodieselfuelswith

low(<500ppm)orultra-low(<15ppm)sulfurcontent.

Theminimumcetaneratingshouldbe40.Purchase

fuelinquantitiesthatcanbeusedwithin180days

toensurefuelfreshness.

Usesummer-gradedieselfuel(Number2-D)at

temperaturesabove-7°C(20°F)andwinter-grade

dieselfuel(Number1-DorNumber1-D/2-Dblend)

below-7°C(20°F).Usingwinter-gradefuelatlower

temperaturesprovidesalowerashpointand

cold-owcharacteristics,whichwilleasestartingand

reducefuel-lterplugging.

Usingsummer-gradefuelabove-7°C(20°F)will

contributetowardlongerfuel-pumplifeandincreased

powercomparedtowinter-gradefuel.

AddingFuel

1.Parkthemachineonalevelsurface.

2.Usingacleanrag,cleanareaaroundthe

fuel-tankcap.

3.Removethecapfromthefueltank.

4.Fillthetankuntilthelevelistothebottomofthe

llerneckwithdieselfuel.

5.Installfuel-tankcaptightlyafterllingtank.

Note:Ifpossible,llthefueltankaftereach

use.Thiswillminimizepossiblebuildupof

condensationinsidethefueltank.

DuringOperation

DuringOperationSafety

GeneralSafety

•Theowner/operatorcanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

•Wearappropriateclothing,includingeye

protection;longtrousers;substantial,slip-resistant

footwear;andhearingprotection.Tiebacklong

hairanddonotwearlooseclothingorloose

jewelry.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Beforeyoustarttheengine,ensurethatalldrives

areinneutral,theparkingbrakeisengaged,and

youareintheoperatingposition.

•Donotcarrypassengersonthemachineandkeep

bystandersandchildrenoutoftheoperatingarea.

18

•Operatethemachineonlyingoodvisibilitytoavoid

holesorhiddenhazards.

•Avoidmowingonwetgrass.Reducedtraction

couldcausethemachinetoslide.

•Keepyourhandsandfeetawayfromthecutting

units.

•Lookbehindanddownbeforebackinguptobe

sureofaclearpath.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscureyour

vision.

•Stopthecuttingunitswheneveryouarenot

mowing.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalkswiththe

machine.Alwaysyieldtheright-of-way.

•Operatetheengineonlyinwell-ventilatedareas.

Exhaustgasescontaincarbonmonoxide,which

islethalifinhaled.

•Donotleavearunningmachineunattended.

•Beforeyouleavetheoperator’sposition,dothe

following:

–Parkthemachineonalevelsurface.

–Disengagethecuttingunit(s)andlowerthe

attachments.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey(if

equipped).

–Waitforallmovementtostop.

•Operatethemachineonlyingoodvisibilityand

appropriateweatherconditions.Donotoperate

themachinewhenthereistheriskoflightning.

RolloverProtectionSystem

(ROPS)Safety

•DonotremovetheROPSfromthemachine.

•Ensurethattheseatbeltisattachedandthatyou

canreleaseitquicklyinanemergency.

•Checkcarefullyforoverheadobstructionsanddo

notcontactthem.

•KeeptheROPSinsafeoperatingconditionby

thoroughlyinspectingitperiodicallyfordamage

andkeepingallthemountingfastenerstight.

•ReplaceadamagedROPS.Donotrepairoralter

it.

MachineswithaFoldableRollBar

•Alwaysusetheseatbeltwiththerollbarinthe

raisedposition.

•TheROPSisanintegralsafetydevice.Keepa

foldingrollbarintheraisedandlockedposition,

andusetheseatbeltwhenoperatingthemachine

withtherollbarintheraisedposition.

•Lowerafoldingrollbartemporarilyonlywhen

necessary.Donotweartheseatbeltwhenthe

rollbarisfoldeddown.

•Beawarethatthereisnorolloverprotectionwhen

afoldedrollbarisinthedownposition.

•Checktheareathatyouwillbemowingandnever

folddownafoldingrollbarinareaswherethere

areslopes,drop-offs,orwater.

SlopeSafety

•Slopesareamajorfactorrelatedtolossofcontrol

androlloveraccidents,whichcanresultinsevere

injuryordeath.Theoperatorisresponsiblefor

safeslopeoperation.Operatingthemachineon

anysloperequiresextracaution.

•Evaluatethesiteconditionstodetermineifthe

slopeissafeformachineoperation,including

surveyingthesite.Alwaysusecommonsense

andgoodjudgmentwhenperformingthissurvey.

•Reviewtheslopeinstructionslistedbelowfor

operatingthemachineonslopesandreviewthe

conditionsinwhichyouwilloperatethemachine

todeterminewhetheryoucanoperateitinthe

conditionsonthatdayandatthatsite.Changes

intheterraincanresultinachangeinslope

operationforthemachine.

•Avoidstarting,stopping,orturningthemachineon

slopes.Avoidmakingsuddenchangesinspeedor

direction.Maketurnsslowlyandgradually.

•Donotoperateamachineunderanyconditions

wheretraction,steering,orstabilityisinquestion.

•Removeormarkobstructionssuchasditches,

holes,ruts,bumps,rocks,orotherhiddenhazards.

Tallgrasscanhideobstructions.Uneventerrain

couldoverturnthemachine.

•Beawarethatoperatingthemachineonwet

grass,acrossslopes,ordownhillmaycausethe

machinetolosetraction.Lossoftractiontothe

drivewheelsmayresultinslidingandalossof

brakingandsteering.

•Useextremecautionwhenoperatingthemachine

neardropoffs,ditches,embankments,water

hazardsorotherhazards.Themachinecould

suddenlyrolloverifawheelgoesovertheedge

ortheedgecavesin.Establishasafetyarea

betweenthemachineandanyhazard.

•Identifyhazardsatthebaseoftheslope.

Iftherearehazards,mowtheslopewitha

pedestrian-controlledmachine.

•Ifpossible,keepthecuttingunit(s)loweredtothe

groundwhileoperatingonslopes.Raisingthe

19

cuttingunit(s)whileoperatingonslopescancause

themachinetobecomeunstable.

•Useextremecautionwithgrasscollectionsystems

orotherattachments.Thesecanchangethe

stabilityofthemachineandcausealossofcontrol.

UsingtheOperatorPlatform

LatchingMechanism

WARNING

Neveroperatethemachinewithoutrst

checkingthattheoperatorplatformlatching

mechanismisfullyengagedandingood

workingorder.

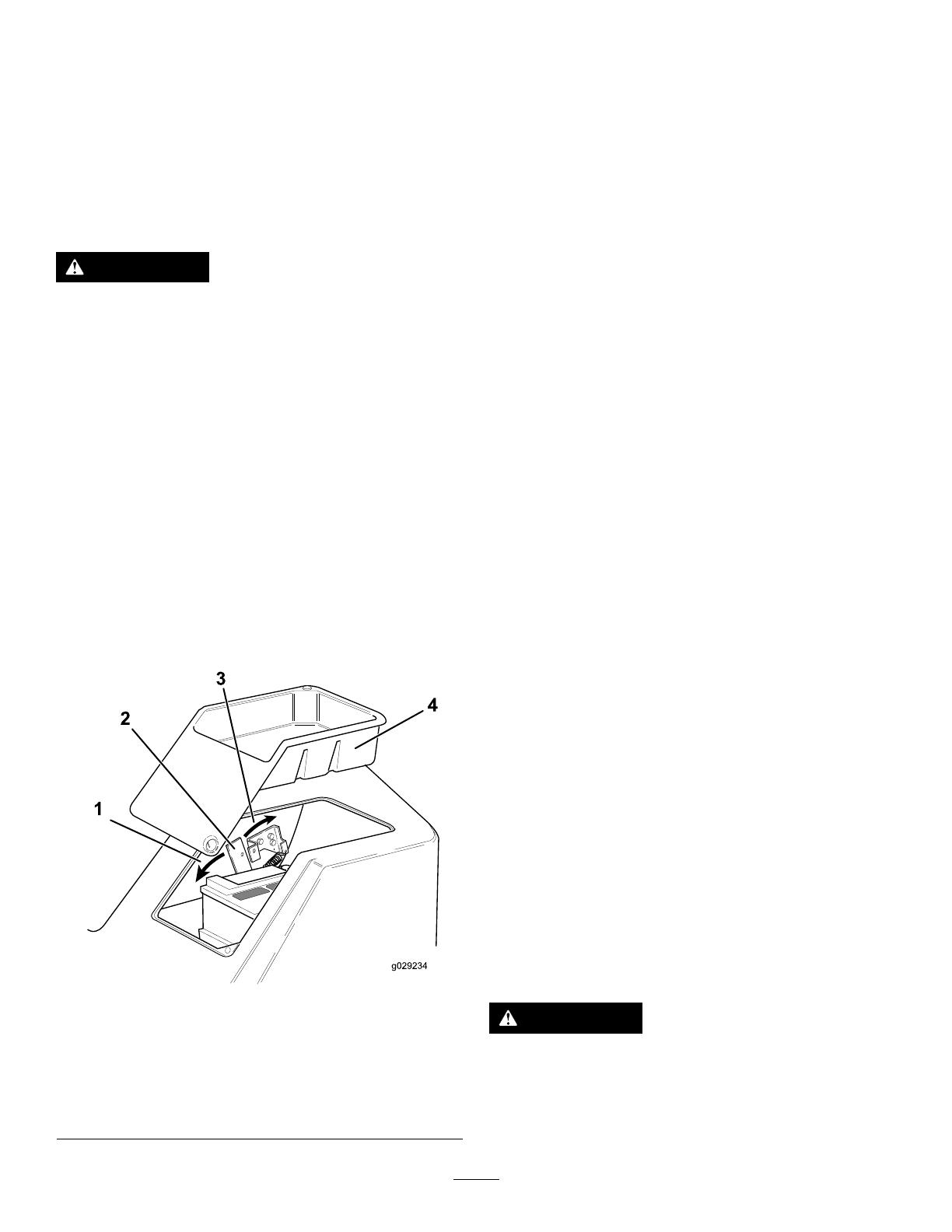

ReleasingthePlatform

1.Ensurethatthefront2cuttingunitsarelowered

totheground.

2.Releaseandremovethetooltrayfromtheleft

sideoftheplatform(Figure23).

3.Releasethepadlocksecuringthelockinglatch

handlewiththekeyprovided.

4.Movethelockinglatchhandletowardthefront

ofthemachineuntilthelatchhooksclearthe

lockingbarandraisetheplatform(Figure23).

Note:Thegasspringwillprovideassistance.

g029234

Figure23

1.Towardfrontofthe

machine

3.Towardrearofmachine

2.Lockinglatchhandle4.Tooltray

SecuringthePlatform

1.Lowertheplatformcarefully.

Note:Thegasspringwillprovideassistance.

2.Movethelockinglatchhandletowardthefront

ofthemachineastheplatformnearsthefully

loweredposition(Figure23).

Note:Thiswillensurethatthelatchhooksclear

thelockingbar.

3.Fullylowertheplatformandmovethelocking

latchhandletowardtherearofthemachineuntil

thelatchhooksfullyengagethelockingbar

(Figure23).

4.Installthepadlocktosecurethelockinglatch

handleinplace.

Understandingthe

OperatorPresence

Controls

Note:Theenginestopsiftheoperatorleavesthe

seatwithoutengagingtheparkingbrake.

EngineStartLockout:Theenginecanonlybe

startedwhentheforward/reversetravelpedalisinthe

NEUTRALposition,thecuttingunitdriveswitchisin

theOFFpositionandtheparkingbrakeisengaged.

Whenthesecircumstancesaresatised,switchesare

activated,permittingtheenginetobestarted.

EngineRunInterlock:Afterstartingtheengine,you

mustbeseatedbeforereleasingtheparkingbrakefor

theenginetocontinuetorun.

CuttingCylinderDriveLockout:Thedrivetothe

cuttingcylindersisonlypossiblewhenyouareseated.

Ifyouraiseofftheseatforaperiodofmorethan1

second,aswitchactivatesandthedrivetothecutting

cylindersautomaticallydisengages.T oengagedrive

tothecuttingcylinders,returntotheseat,thenoperate

thecuttingunitdriveswitchtotheOFFpositionbefore

movingitbacktotheONposition.Ifyouriseoffthe

seatforabriefmomentduringnormalwork,driveto

thecuttingcylindersisnotaffected.

Theenginecanonlybestartedwiththecutting-unit

driveswitchintheOFFposition.

WARNING

Donotoperatetheturfmachineiftheoperator

presencecontrolsaremalfunctioninginany

way.Alwaysreplacedamagedorwornparts

andcheckthattheyfunctioncorrectlybefore

operatingthemachine.

20

/