Toro CT2240 Compact Triple 4-Wheel Drive Turf Mower User manual

- Category

- Lawnmowers

- Type

- User manual

FormNo.3410-785RevA

CT2240CompactTriple4-Wheel

DriveTurfMower

ModelNo.30654—SerialNo.400000000andUp

G025163

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3410-785*A

Introduction

Thismachineisaride-on,reel-bladelawnmowerintended

tobeusedbyprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedforcuttinggrass

onparks,sportselds,caravanparks,cemeteries,and

commercialgrounds.Itisnotdesignedforcuttingbrushor

foragriculturaluse.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyforproductandaccessory

information,helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Themodelandserialnumbersareon

theleftsideoftheframe.Writethenumbersinthespace

provided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure1),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

g000502

Figure1

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contents

Safety...........................................................................3

GeneralSafety.........................................................3

SafeOperatingPractices...........................................3

ToroRidingMowerSafety........................................6

SafetyandInstructionalDecals.................................8

Setup...........................................................................12

ProductOverview.........................................................12

Controls...............................................................13

Specications........................................................19

Attachments/Accessories........................................19

Operation....................................................................19

CheckingtheEngine-OilLevel.................................19

CheckingtheCoolingSystem...................................20

AddingFuel...........................................................21

CheckingtheHydraulicFluid..................................22

CheckingtheTirePressure......................................23

CheckingtheTorqueoftheWheelNuts.....................23

ThinkSafetyFirst...................................................23

UsingtheOperatorPlatformLatching

Mechanism........................................................23

UnderstandingtheOperatorPresence

Controls............................................................24

StartingandShuttingOfftheEngine.........................24

AdjustingtheCenterCuttingUnitHeight-of-Cut

Correction.........................................................26

ControllingthePositionoftheIndividualCutting

Units.................................................................26

AdjustingtheCuttingUnitAutoLimited

Lift...................................................................26

EngagingtheCuttingUnitDrive..............................26

ClearingtheCuttingUnits.......................................27

UsingWeightTransfer/TractionAssistance................27

FoldingtheROPS..................................................27

LocatingtheJackingPoints......................................28

TransportingMachines............................................29

OperatingTips......................................................29

Maintenance.................................................................31

RecommendedMaintenanceSchedule(s)......................31

DailyMaintenanceChecklist....................................32

PreparingtheMachineforMaintenance.....................33

ServiceIntervalChart.............................................33

Lubrication...............................................................34

GreasingtheBearings,Bushings,andPivots...............34

EngineMaintenance..................................................35

CheckingtheEngineOverheatWarning

System..............................................................35

ServicingtheAirCleaner.........................................35

ServicingtheEngineOilandFilter............................36

FuelSystemMaintenance...........................................37

DrainingtheFuelTank...........................................37

CheckingtheFuelLinesandConnections..................37

BleedingtheFuelSystem.........................................37

ReplacingtheFuelFilter..........................................37

ElectricalSystemMaintenance....................................38

CheckingtheElectricalSystem.................................38

CheckingtheBatteryCondition................................38

ServicingtheBattery...............................................39

DriveSystemMaintenance.........................................39

ChangingtheTransmissionOilFilter........................39

ChangingtheHydraulicReturnFilter........................39

CheckingtheRearWheelAlignment.........................40

InspectingtheTransmissionControlCableand

OperatingMechanism.........................................40

CoolingSystemMaintenance......................................41

©2016—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

2

Contactusatwww.Toro.com.

PrintedintheUK

AllRightsReserved

RemovingDebrisfromtheCoolingSystem................41

BrakeMaintenance....................................................42

TowingtheMachine...............................................42

BeltMaintenance......................................................44

TensioningtheAlternatorBelt.................................44

ControlsSystemMaintenance.....................................44

CheckingtheForward/ReverseTravelPedal

Action...............................................................44

CheckingtheOperatorPresenceSeatSwitch..............44

CheckingtheCuttingUnitDriveInterlock

Switch...............................................................44

CheckingtheParkingBrakeInterlockSwitch..............44

CheckingtheTransmissionNeutralInterlock

Switch...............................................................45

HydraulicSystemMaintenance....................................45

ServicingtheHydraulicSystem.................................45

CheckingtheHydraulicFluidOverheatWarning

System..............................................................46

CheckingtheHydraulicLinesandHoses....................46

CuttingUnitsSystemMaintenance...............................47

BackLappingtheCuttingUnits................................47

GrindingtheCuttingUnits......................................48

RaisingTheMowerofftheGround...........................48

DisposingofWaste.................................................48

Storage........................................................................49

PreparingtheTractionUnit.....................................49

PreparingtheEngine..............................................49

Troubleshooting...........................................................50

Safety

ThismachinehasbeendesignedinaccordancewithENISO

5395:2013.

GeneralSafety

Usingthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustoyouandbystanders.

•ReadandunderstandthecontentsofthisOperator’sManual

beforestartingtheengine.

•Donotputyourhandsorfeetnearmovingcomponents

ofthemachine.

•Donotoperatethemachinewithoutallguardsandother

safetyprotectivedevicesinplaceandworkingonthe

machine.

•Keepclearofanydischargeopening.Keepbystanders

andpetsasafedistanceawayfromthemachine.

•Keepchildrenoutoftheoperatingarea.Neverallow

childrentooperatethemachine.

•Stopthemachineandshutofftheenginebeforeservicing,

fueling,oruncloggingthemachine.

Improperlyusingormaintainingthismachinecanresult

ininjury.Toreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safety-alertsymbol,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failuretocomplywith

theseinstructionsmayresultinpersonalinjuryordeath.

Youcanndadditionalsafetyinformationwhereneeded

throughoutthisOperator’sManual.

SafeOperatingPractices

Training

•ReadtheOperator'sManualandothertrainingmaterial

carefully.Befamiliarwiththecontrols,safetysigns,and

theproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstouseorservicethemower.Local

regulationsmayrestricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpetsare

nearby.

•Keepinmindthattheoperatororuserisresponsiblefor

accidentsorhazardsoccurringtootherpeopleortheir

property.

•Donotcarrypassengers.

•Alldriversandmechanicsshouldseekandobtain

professionalandpracticalinstruction.Theowneris

responsiblefortrainingtheusers.Suchinstructionshould

emphasize:

–theneedforcareandconcentrationwhenworking

withride-onmachines;

3

–controlofaride-onmachineslidingonaslopewill

notberegainedbytheapplicationofthebrake.The

mainreasonsforlossofcontrolare:

◊insufcientwheelgrip;

◊beingdriventoofast;

◊inadequatebraking;

◊thetypeofmachineisunsuitableforitstask;

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes;

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtopeopleordamageto

property.

Preparation

•Whilemowing,alwayswearsubstantial,slip-resistant

footwear,longpants,safetyglasses,andearprotection.

Tiebacklonghairanddonotwearjewelry.

•Thoroughlyinspecttheareawheretheequipmentisto

beusedandremoveallobjectswhichmaybethrownby

themachine.

•Replacedamagedorwornsilencers/mufers.

•Onlyuseaccessoriesandattachmentsapprovedbythe

manufacturer.

•Beforeusing,alwaysvisuallyinspecttoseethatthe

cuttingunitsarenotwornordamaged.Replacewornor

damagedblades.

•Takecarerotating1cuttingunitmaycauseothercutting

unitstorotate.

•Checkthattheoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxideandotherexhaustgasses

cancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,engagetheparking

brake,disengagethecuttingunitdrivesystem,andensure

thattheforward/reversespeedcontrolsareintheneutral

positon.

•Machinespeedsshouldbekeptlow .

•Donotturnsharply.Usecarewhenreversing.

•Stayalertforholesintheterrainandotherhiddenhazards.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesrotatingbeforecrossingsurfacesother

thangrass.

•Whenusinganyattachments,neverdirectdischargeof

materialtowardbystandersnorallowanyonenearthe

machinewhileinoperation.

•Neveroperatethemachinewithdamagedguards,shields,

orwithoutsafetyprotectivedevicesinplace.Besureall

interlocksareattached,adjustedproperly,andfunctioning

properly.

•Donotchangetheenginegovernorsettingsorover-speed

theengine.Operatingtheengineatexcessivespeedmay

increasethehazardofpersonalinjury.

•Beforeleavingtheoperator'sposition:

–Parkthemachineonalevelsurface.

–Disengagethedrivetothecuttingunits.

–Raisethecuttingunitstothetransportpositionand

securelylockthesafetylatchesoralternativelylower

thecuttingunitstotheground.

–Ensurethatthetransmissionisinneutralandengage

theparkingbrake.

–Shutofftheengineandremovethekey.

•Whentransportingthemower:

–Disengagethedrivetothecuttingunits.

–Raisethecuttingunitstothetransportposition.

–Engagetheparkingbrake.

–Engagethetransportlatchesandsafetylockingrings.

–Shutofftheengineandremovethekey.

•Whendrivingthemowerbetweenworksitesitis

importanttoensurethatthecuttingunitscannotbe

inadvertentlyloweredandstarted:

–Disengagethedrivetothecuttingunits.

–Raisethecuttingunitstothetransportposition.

–Engagethetransportlatchesandsafetylockingrings.

•Shutofftheengineanddisengagedrivetothecutting

units:

–beforerefuelling;

–beforemakingheightadjustmentunlessadjustment

canbemadefromtheoperator'sposition.

–beforeclearingblockages;

–beforechecking,cleaningorworkingonthemower;

–afterstrikingaforeignobjectorifanabnormal

vibrationoccurs.Inspectthemowerfordamage

andmakerepairsbeforerestartingandoperatingthe

equipment.

•Keephandsandfeetawayfromthecuttingunits.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopthecuttingunitsif

notmowing.

•Donotoperatethemowerwhentired,ill,orunderthe

inuenceofalcoholordrugs.

•Lightningcancausesevereinjuryordeath.Iflightningis

seeninthearea,donotoperatethemachine;seekshelter.

4

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,useextreme

careinhandlingfuel.Fuelisextremelyammableandthe

vaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainer,ratherthanfroma

fueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

Donotuseanozzlelockopendevice.

•Neveroverllfueltank.Replacefuelcapandtighten

securely.

RolloverProtectionSystem(ROPS)

Safety

•DonotremovetheROPSfromthemachine.

•Ensurethattheseatbeltisattachedandthatyoucan

releaseitquicklyinanemergency.

•Checkcarefullyforoverheadobstructionsanddonot

contactthem.

•KeeptheROPSinsafeoperatingconditionbythoroughly

inspectingitperiodicallyfordamageandkeepingallthe

mountingfastenerstight.

•ReplaceadamagedROPS.Donotrepairoralterit.

MachineswithaFoldableRollBar

•Alwaysusetheseatbeltwiththerollbarintheraised

position.

•TheROPSisanintegralsafetydevice.Keepafoldingroll

barintheraisedandlockedposition,andusetheseat

beltwhenoperatingthemachinewiththerollbarinthe

raisedposition.

•Lowerafoldingrollbartemporarilyonlywhennecessary.

Donotweartheseatbeltwhentherollbarisfolded

down.

•Beawarethatthereisnorolloverprotectionwhena

foldedrollbarisinthedownposition.

•Checktheareathatyouwillbemowingandneverfold

downafoldingrollbarinareaswherethereareslopes,

drop-offs,orwater.

SlopeSafety

•Establishyourownspecialproceduresandrulesfor

operatingonslopes.Theseproceduresmustincludea

surveyofthesitetodeterminewhichslopesaresafefor

machineoperation.Alwaysusecommonsenseandgood

judgmentwhenperformingthissurvey.

•Slopesareamajorfactorrelatedtoloss-of-controland

tip-overaccidents,whichcanresultinsevereinjuryor

death.Operationonallslopesrequiresextracaution.

•Uselowerspeedwhileoperatingonslopes.

•Donotturnthemachinesharply.Usecarewhenreversing

themachine.

•Ifyoufeeluneasyonaslope,donotoperateonit.

•Watchforholes,ruts,bumps,rocks,orotherhidden

objects.Uneventerraincouldoverturnthemachine.Tall

grasscanhideobstacles.

•Whenoperatingthemachineonaslope,alwayskeepall

cuttingunitslowered.

•Chooselowgroundspeedsoyouwillnothavetostopor

shiftwhileonaslope.

•Rollovercanoccurbeforethetireslosetraction.

•Avoidoperatingonwetgrass.Tiresmaylosetraction,

regardlessifbrakesareavailableandfunctioning.

•Avoidstarting,stoppingorturningonaslope.

•Keepallmovementonslopesslowandgradual.Donot

makesuddenchangesinspeedordirection.

•Donotoperatethemachineneardrop-offs,ditches,

embankments,orbodiesofwater.Themachinecould

suddenlyrolloverifawheelgoesovertheedgeorthe

edgecavesin.Leaveasafetyareabetweenthemachine

andanyhazard(2machinewidths).

•Thismachinecomplieswiththeindustrystandard

stabilitytestinthestaticlateralandlongitudinaltests

withthemaximumrecommendedslopeindicatedonthe

decal.Itisimportantthateachoperatorreviewtheslope

operationsinstructionsintheOperator’sManualandreview

theconditionsinwhichthemachineisbeingoperated

todetermineifthemachinemaybeoperatedinthe

conditionsthatdayandonthatsite.Changestoterrain

canresultinachangeinslopeoperationforanymachine.

Ifavailable,keepcuttingunitsloweredtogroundwhile

operatingonslopes.Raisingcuttingunitswhileoperating

onslopescancausethemachinetobecomeunstable.

5

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetankinsidea

buildingwherefumesmayreachanopenameorspark.

•Allowtheenginetocoolbeforestoringinanyenclosure.

•Toreducetherehazard,keeptheengine,

silencer/mufer,batterycompartmentandfuelstorage

areafreeofgrass,leaves,orexcessivegrease.

•Keepallpartsingoodworkingconditionandallhardware

andhydraulicttingstightened.Replaceallwornor

damagedpartsanddecals.

•Ifthefueltankhastobedrained,dothisoutdoors.

•Becarefulduringadjustmentofthemachinetoprevent

entrapmentofthengersbetweenmovingbladesand

xedpartsofthemachine.

•Onmachineswithmultiplecuttingunits,takecareas

rotating1cuttingunitcancauseothercuttingunitsto

rotate.

•Disengagedrives,lowerthecuttingunits,engagethe

parkingbrake,shutofftheengine,andremovethekey

fromtheignition.Waitforallmovementtostopbefore

adjusting,cleaning,orrepairing.

•Cleangrassanddebrisfromcuttingunits,drives,

silencers/mufers,andenginetohelppreventres.Clean

upoilorfuelspillage.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebatterybeforemakinganyrepairs.

Disconnectthenegativeterminalrstandthepositive

last.Reconnectpositiverstandnegativelast.

•Usecarewhencheckingthecuttingunits.Weargloves

andusecautionwhenservicingthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Chargebatteriesinanopenwellventilatedarea,away

fromsparkandames.Unplugchargerbeforeconnecting

ordisconnectingfrombattery.Wearprotectiveclothing

anduseinsulatedtools.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usefull-widthrampsforloadingmachineintotraileror

truck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

ToroRidingMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

isnotincludedinthesafetystandards.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustouserandbystanders.

WARNING

Engineexhaustcontainscarbonmonoxide,which

isanodorless,deadlypoisonthatcankillyou.

Donotrunengineindoorsorinanenclosedarea.

•Knowhowtoshutofftheenginequickly.

•Handlefuelcarefully.Wipeupanyspills.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Usingthemachinedemandsattention.Topreventloss

ofcontrol:

–Donotdriveclosetosandtraps,ditches,creeks,or

otherhazards.

–Reducespeedwhenmakingsharpturns.Avoid

suddenstopsandstarts.

–Whennearorcrossingroads,alwaysyieldthe

right-of-way.

•Raiseandlatchthecuttingunitswhendrivingfromone

workareatoanother.

•Donottouchtheengine,silencer/mufer,orexhaust

pipewhiletheengineisrunningorsoonafterithas

stoppedbecausetheseareascouldbehotenoughtocause

burns.

•Iftheenginestallsorlosesheadwayandcannotmakeit

tothetopofaslope,donotturnthemachinearound.

Alwaysbackslowly,straightdowntheslope.

•Whenapersonorpetappearsunexpectedlyinornearthe

mowingarea,stopmowing.Carelessoperation,combined

withterrainangles,ricochets,orimproperlypositioned

guardscanleadtothrownobjectinjuries.Donotresume

mowinguntiltheareaiscleared.

MaintenanceandStorage

•Beforeservicingormakingadjustments,stoptheengine

andremovetheignitionkey.

•Ensurethattheentiremachineisproperlymaintained

andingoodoperatingcondition.Frequentlycheckall

nuts,bolts,screws,andhydraulicttings.

•Makesureallhydrauliclineconnectorsaretightandall

hydraulichosesandlinesareingoodconditionbefore

applyingpressuretothesystem.

6

•Keepyourbodyandhandsawayfrompinholeleaksor

nozzlesthatejecthydraulicuidunderhighpressure.

Usepaperorcardboard,notyourhands,tosearchfor

leaks.Hydraulicuidescapingunderpressurecanhave

sufcientforcetopenetratetheskinandcauseserious

injury.Ifuidisinjectedintotheskinitmustbesurgically

removedwithinafewhoursbyadoctorfamiliarwiththis

formofinjuryorgangrenemayresult.

•Beforedisconnectingorperforminganyworkonthe

hydraulicsystem,allpressureinthesystemmustbe

relievedbystoppingtheengineandloweringthecutting

unitstotheground.

•Iftheenginemustberunningtoperformamaintenance

adjustment,keephands,feet,clothing,andanypartsof

thebodyawayfromthecuttingunits,attachments,and

anymovingparts.Keepeveryoneaway.

•Donotoverspeedtheenginebychanginggovernor

settings.Toensuresafetyandaccuracy,havean

AuthorizedToroDistributorcheckthemaximumengine

speedwithatachometer.

•Theenginemustbeshutoffbeforecheckingtheoilor

addingoiltothecrankcase.

•Ifmajorrepairsareeverneededorifassistanceisdesired,

contactanAuthorizedToroDistributor.

•Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacementparts

andaccessoriesmadebyothermanufacturerscouldbe

dangerous,andsuchusecouldvoidtheproductwarranty.

7

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedormissing.

decal70-13-072

70-13-072

1.Jackingpoint

decal70-13-077

70-13-077

1.Warning—shutofftheengineandremovetheignitionkey

beforereleasingoroperatingthesafetylatches.

decal950832

950832

1.Tirepressure

decal950889

950889

1.Warning—hotsurfaces.

decal111-0773

111-0773

1.Warning—crushingofngers,forceappliedfromside.

decal111-3277

111-3277

1.Horn5.Fast

2.Cuttingunits—lower/oat

6.Enginespeed

3.Cuttingunits—hold7.Slow

4.Cuttingunits—raise

8

decal111-3344

111-3344

1.Ignitionswitchindicatingdifferentpositionsofkeyswitch

decal111-3562

111-3562

1.Presspedaltoadjuststeeringwheeltilt.

decal111-3566

111-3566

1.Falling,crushinghazard—ensurethattheoperatorplatform

latchisengagedbeforeoperating.

decal111-3567

111-3567

1.Pedaloperationtocontrolmachinedirection

decal111-3902

111-3902

1.Warning—cuttinghazardofhand,fan.

2.Hotsurfaces—readtheOperator'sManualformore

information.

decal111-3901

111-3901

1.Transmissionoil—readtheOperator'sManualformore

information.

9

decal111-8098

111-8098

1.Tippinghazard—driveslowlywhenturningorgoingupslopes.

3.Tippinghazard—wearaseatbeltwhentheROPSisup;do

notwearaseatbeltwhentheROPSisdown.

2.TIppinghazard—onlydriveupslopesthatarebetween0and

18degrees;donotdriveupslopesthataregreaterthan18

degrees.

4.Warning—readtheOperator'sManual;removethekeyfrom

theignitionandreadtheOperator'sManualbeforeservicing

orperformingmaintenance;thrownobjecthazard;keep

bystandersawayfromthemachine.

10

decal111-7249

111-7249

1.Dailyserviceinterval

6.Checkhydraulicuidlevel11.Checkcuttingunitsetting16.Lubricationpointsfordaily

interval

2.50hourserviceinterval

7.Checkfuellevel12.Checkenginecoolantlevel17.Lubricationpointsfor50

hourinterval

3.Checkthetirepressure8.Checkengineoillevel13.Checkcleanlinessof

radiator

4.Checkallnutsandboltsfor

propertightness

9.Checkoperationofseat

switch

14.Cleanandinspectthe

machine

5.Checkallhosesforleaks10.Checkairlterelement15.Checkwheelnut

tightnessusingatorque

wrench—frontwheels200

N∙m,rearwheels54N∙m

11

Setup

MediaandAdditionalParts

Description

Qty.

Use

Operator'sManual

1

Engineoperator’smanual1

Readthemanualsbeforeoperatingthemachine.

Storealldocumentationinasafeplaceforfutureuse.

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

ProductOverview

G025164

1

2 3 4

5

6

g025164

Figure2

1.Frontcuttingunits

4.Operator'sseat

2.Controlarm

5.Enginehood

3.Steeringwheel

6.Rearcuttingunit

12

Controls

ControlPanelComponents

6

13 16 14 17 8

G014418

18

10

5

19 1

2

9

7

3

4

15

12

11

g014418

Figure3

1.Parkingbrakeswitch11.Hornbutton

2.Limitedliftinreverse

switch

12.Auxiliary12voltsocket

(suppliedwitha12Vkit)

3.Hazardwarningswitch

(suppliedwithlightingkit)

13.Engine-oilpressure

indicator

4.Warningbeaconswitch

(suppliedwithbeaconkit)

14.Transmissiontemperature

indicator

5.Cuttingunitsposition

controls

15.Hourmeter

6.Throttlecontrollever16.Batterywarningindicator

7.Ignitionswitch17.Enginetemperature

warningindicator

8.Cuttingunitsdriveswitch18.Glowplugindicator

9.Lightingswitch(supplied

withlightingkit)

19.Transmissionneutral

indicator

10.Directionindicatorswitch

(suppliedwithlightingkit)

g014419

1

g014419

Figure4

1.Weighttransfercontrol

g014420

1 2

g014420

Figure5

1.Reversetravelpedal2.Forwardtravelpedal

BrakingSystem

ParkingBrake

Movetheparkingbrakeswitchtotheforwardpositionby

pressingthesmallerlockingbuttonandmovingtheswitch

forwardtoengagetheparkingbrake(Figure6).

Note:Donotoperatethemowerwiththeparkingbrake

engagedanddonotengagetheparkingbrakewhilethe

mowerismoving.

Thislightilluminateswhentheparkingbrakeisengagedand

theignitionkeyisturnedtopositionI.

13

WARNING

Theparkingbrakeoperatesonthefrontwheels

only.Donotparkthemoweronaslope.

G014421

1

P

g014421

Figure6

1.Parkingbrake

EmergencyBrake

Intheeventofservicebrakefailure,turntheignitionoffto

bringthemowertoastandstill.

WARNING

Takecarewhenusingtheemergencybraking.

Remainseatedandholdontothesteeringwheel

topreventejectionfromthemowercausedbythe

frontwheelbrakesbeingappliedsuddenlywhen

travelling.

ThrottleControl

Operatethethrottlecontrolinaforwarddirectiontoincrease

theenginespeed.Operatethethrottlecontrolinarearward

directiontoreduceenginespeed(Figure7).

Note:Theenginespeeddictatesthespeedoftheother

functions,i.e.travel,reelrotationspeedandcuttingunitlift

speed.

G014547

1

g014547

Figure7

1.Throttlecontrollever

TractionPedals

Forwardtravel:Presstheforwardtravelpedaltoincrease

forwardtravelspeed.Releasethepedaltoreducespeed

(Figure8).

Reversetravel:Pressthereversetravelpedaltoincrease

reversetravelspeed.Releasethepedaltoreducespeed

(Figure8).

Stop(Neutral):Releasetheforwardorreversetravelpedal.

Tostopthemachine,reduceyourfootpressureonthe

tractionpedalandallowittoreturntoneutral.Toincrease

thebrakingeffectpushthetractionpedalintotheneutral

position.

g014420

1 2

g014420

Figure8

1.Reversetravelpedal2.Forwardtravelpedal

14

TransportLatches

Alwaysraisethecuttingunitstothetransportpositionand

securewiththetransportlatchesandsafetylockswhen

travellingbetweenworkareas(Figure9).

G014548

g014548

Figure9

CuttingUnitDriveSwitch

AlwaysputthecuttingunitdriveswitchintheOFFposition

whentravellingbetweenworkareas.

AdjustableSteeringColumn

WARNING

Neveroperatethemowerwithoutrstcheckingthat

thesteeringcolumnadjustermechanismisingood

workingorderandthat,onceadjustedandlocked,

thesteeringwheelremainssecurelyinposition.

Adjustmentofthesteeringwheelandsteeringcolumnshould

onlybecarriedoutwhenthemowerisatastandstillwith

theparkingbrakeengaged.

1.Totiltthesteeringwheel,pressthefootpedaldown.

2.Positionthesteeringtowertothemostcomfortable

positionandreleasethepedal(Figure10).

G014549

g014549

Figure10

OperatorSeat

WARNING

Neveroperatethemowerwithoutrstchecking

thattheoperatorseatmechanismsareingood

workingorderandthat,onceadjustedandlocked,

theseatremainssecurelyinposition.

Adjustmentoftheseatmechanismsshouldonlybe

carriedoutwhenthemowerisatastandstillwith

theparkingbrakeengaged.

Fore/Aftadjustment:Theseatadjustingleverallowsthe

operatortoadjusttheseatforeandaft(Figure11).

Operatorweightadjustment:Rotatethehandleclockwise

toincreasethesuspensionstiffnessandcounter-clockwiseto

decreasethestiffness(Figure11).

15

1

G014550

CW

CCW

2

g014550

Figure11

1.Seatadjustmentlever2.Operatorweighthandle

WarningSystems

EngineCoolantOverheatingWarningLight

Theenginecoolantwarninglightilluminates,thehornis

actuated,andthecuttingunitsstop(Figure12).

1

G014551

g014551

Figure12

1.Enginecoolantoverheatingwarninglight

HydraulicFluidOverheatingWarningLight

Thehydraulicuidwarninglightilluminateswhenoverheating

occursandthehornisactuatedwhenthehydraulicuidin

thereservoirexceeds95degreesC(203degreesF);referto

Figure13.

1

G014552

g014552

Figure13

1.Hydraulicuidoverheatingwarninglight

16

LowBatteryChargeWarningLight

Thebatterychargewarninglightilluminateswhenlowbattery

chargeoccurs(Figure14).

1

G014553

g014553

Figure14

1.Lowbatterychargewarninglight

LowEngine-OilPressureWarningLight

Theengine-oilpressurewarninglightilluminateswhentheoil

pressureistoolow(Figure15).

1

G014554

g014554

Figure15

1.Lowengine-oilpressurewarninglight

DisengagementofReels

Thereelsdisengagewhentheoperatingtemperaturereaches

115degreesC(239degreesF).

AudibleWarningHorn

Pressthehornbuttontoprovideanaudiblewarning(Figure

16).

Important:Thehornisautomaticallyactuatedwhen

anenginecoolantorhydraulicuidoverheatcondition

occurs.Shutofftheengineimmediatelyandxthe

machinebeforestartingitagain.

1

G014555

g014555

Figure16

1.Horn

IgnitionKey

0=Engineoff

I=Enginerun/Auxiliaryon

II=Enginepre-heat

III=Enginestart

CAUTION

Ifyouleavethekeyintheignitionswitch,someone

couldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheignition.

G014556

1

I

II

III

g014556

Figure17

1.Ignitionswitch

EnginePre-HeatIndicatorLight

TurntheignitionkeytopositionII.Theenginepreheat

indicatorlightwillilluminateandheattheglowplugs

(Figure18).

Important:Attemptingtostartacoldenginebefore

usingthepre-heatcancauseunnecessaryweartothe

battery.

1

G014557

g014557

Figure18

1.Enginepre-heatindicatorlight

17

FuelGauge

Thefuelgaugeshowstheamountoffuelinthetank

(Figure19).

G014558

FUEL

E

F

g014558

Figure19

HourMeter

Thehourmetershowsthetotalhoursthatthemachinehas

beenoperated(Figure20).

1

G014559

000.0

g014559

Figure20

1.Hourmeter

TransmissionNeutralIndicatorLight

Thislightilluminateswhenthetravelcontrolpedalisinthe

neutralpositionandtheignitionkeyisturnedtopositionI

(Figure21).

Note:Theparkingbrakemustbeengagedforthe

transmissionneutralindicatorlighttoilluminate.

G0014560

1

g014560

Figure21

1.Transmissionneutralindicatorlight

CuttingUnitDriveSwitchIndicator

Light

Thislightilluminateswhenthecuttingunitdriveswitchis

intheFORWARD/REVERSEpositionandtheignitionkeyis

turnedtopositionI(Figure22).

1

G0014561

g014561

Figure22

1.Cuttingunitdriveswitchindicatorlight

18

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

SpecicationCT2240

Transportwidth

138.0cm(54.3inches)

Widthofcut212.0cm(83.5inches)

Overallwidth236.0cm(92.9inches)

Length

286.0cm(112.6inches)

Height

168.1cm(66.2inches)withROPSfolded

211.5cm(83.3inches)withROPSintheverticaloperatingposition

Weight

1240kg(2733lb)*

Withuidsand200mm6-bladecuttingunits

Engine

Kubota19.5kw(26hp)at3000rpmDIN70020

Fueltankcapacity

45L(11.9USgallons)

Transportspeed

22km/h(13.7mph)

Mowingspeed

11km/h(6.8mph)

Hydraulicsystemcapacity

32L(8.5USgallons)

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesisavailableforusewiththemachinetoenhanceandexpandits

capabilities.ContactyourAuthorizedServiceDealerorDistributor.

TobestprotectyourinvestmentandmaintainoptimalperformanceofyourToroequipment,countonTorogenuineparts.

Whenitcomestoreliability,Torodeliversreplacementpartsdesignedtotheexactengineeringspecicationofourequipment.

Forpeaceofmind,insistonTorogenuineparts.

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

CAUTION

Ifyouleavethekeyintheignitionswitch,someone

couldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Lowerthecuttingunitstotheground,engagethe

parkingbrake,andremovethekeyfromtheignition

switchbeforeservicingormakingadjustmentsto

themachine.

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Theengineisshippedwithoilinthecrankcase;however,the

oillevelmustbecheckedbeforeandaftertheengineisrst

started.

Crankcasecapacity:approximately6.0L(6.3USqt)with

thelter

Usehigh-qualityengineoilthatmeetsthefollowing

specications:

•APIClassicationLevelRequired:CH-4,CI-4orhigher

•Preferredoil:SAE15W-40(above0degreesF)

•Alternateoil:SAE10W-30or5W-30(alltemperatures)

ToroPremiumEngineoilisavailablefromyourdistributorin

either15W-40or10W-30viscosity.

Note:Thebesttimetochecktheengineoiliswhenthe

engineiscoolbeforeithasbeenstartedfortheday.Ifithas

alreadybeenrun,allowtheoiltodrainbackdowntothe

19

sumpforatleast10minutesbeforechecking.Iftheoillevel

isatorbelowtheAddmarkonthedipstick,addoiltobring

theoilleveltotheFullmark.Donotoverllthecrankcase.

IftheoillevelisbetweentheFullandAddmarks,nooil

additionisrequired.

1.Parkthemachineonalevelsurface,lowerthecutting

units,engagetheparkingbrake,shutofftheengine,

andremovethekeyfromtheignitionswitch.

2.Openthehood.

3.Removethedipstick,wipeitclean,andinstallit

(Figure23).

g008881

Figure23

1.Dipstick

4.Removethedipstickandchecktheoillevelonthe

dipstick.

TheoillevelshouldbeuptotheFullmark.

5.IftheoillevelisbelowtheFullmark,removethell

cap(Figure24)andaddoiluntilthelevelreachesthe

Fullmarkonthedipstick.Donotoverll.

g004134

Figure24

1.Oil-llcap

6.Installtheoil-llcapandclosethehood.

CheckingtheCoolingSystem

ServiceInterval:Beforeeachuseordaily

CAUTION

Iftheenginehasbeenrunning,thepressurized,hot

coolantcanescapeandcauseburns.

•Donotopentheradiatorcapwhentheengine

isrunning.

•Usearagwhenopeningtheradiatorcap,and

openthecapslowlytoallowsteamtoescape.

Thecoolingsystemislledwitha50/50solutionofwater

andpermanentethyleneglycolantifreeze.

1.Cleandebrisoffofthescreen,oilcooler,andfront

oftheradiatordailyandmoreoftenifconditionsare

extremelydustyanddirty.RefertoRemovingDebris

fromtheCoolingSystem(page41).

2.Checkthelevelofthecoolantintheexpansiontank

(Figure25).

Note:Thecoolantlevelshouldbebetweenthemarks

onthesideofthetank.

20

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

Toro CT2240 Compact Triple 4-Wheel Drive Turf Mower User manual

- Category

- Lawnmowers

- Type

- User manual

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Toro CT2240 Compact Triple 4-Wheel Drive Turf Mower User manual

-

Toro CT2240 Compact Triple 4-Wheel Drive Turf Mower User manual

-

Toro LT3340 Heavy-Duty Triple Turf Mower Traction Unit User manual

-

Toro LT3340 Heavy-Duty Triple Turf Mower Traction Unit User manual

-

Toro 03673 Reelmaster 5410-G User manual

-

Toro T4240 4-Wheel Drive 5-Plex Traction Unit User manual

-

Toro LT-F3000 Heavy-Duty Triple Turf Flail Mower User manual

-

Toro TR-34D Trench Roller User manual

-

Toro 07236TC User manual

-

Toro 3550 User manual

Other documents

-

Shibaura CM314 User manual

-

Baroness LM285 Operating instructions

-

Foley United 384 User manual

Foley United 384 User manual

-

National Mower 68 SR User manual

National Mower 68 SR User manual

-

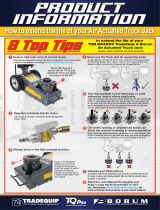

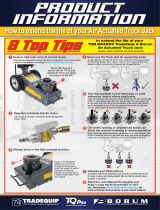

TradeQuip Professional 2026T Product information

-

Cub Cadet chl 500 User manual

-

Cub Cadet chl 500 User manual

-

Shibaura SR525 User manual

-

Borum Industrial B2003T Product information

Borum Industrial B2003T Product information

-

Borum Industrial BTJ60TA Bleed Instructions

Borum Industrial BTJ60TA Bleed Instructions