Zurn Z86300-XL-CP4 Installation guide

- Category

- Sanitary ware

- Type

- Installation guide

This manual is also suitable for

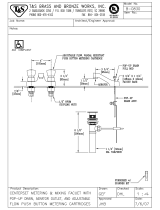

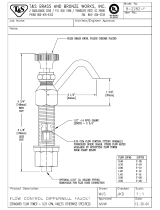

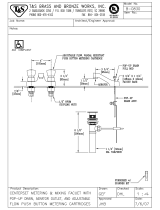

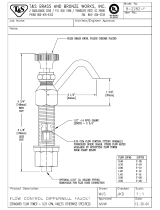

Zurn Z86300-XL-CP43M is a single basin metering faucet with a maximum flow rate of 0.25 GPC and a preset cycle time of 10 to 15 seconds at 80 PSI. It is designed to prevent foreign matter and debris from clogging or damaging internal components and has an integral shank filter assembly that can be removed for back-flushing and cleaning if insufficient flow is detected. The faucet has a highly polished nickel chrome plated finish and is easy to maintain with soap and water or a mild cleaner that is safe for chrome plating.

Zurn Z86300-XL-CP43M is a single basin metering faucet with a maximum flow rate of 0.25 GPC and a preset cycle time of 10 to 15 seconds at 80 PSI. It is designed to prevent foreign matter and debris from clogging or damaging internal components and has an integral shank filter assembly that can be removed for back-flushing and cleaning if insufficient flow is detected. The faucet has a highly polished nickel chrome plated finish and is easy to maintain with soap and water or a mild cleaner that is safe for chrome plating.

-

1

1

-

2

2

-

3

3

-

4

4

Zurn Z86300-XL-CP4 Installation guide

- Category

- Sanitary ware

- Type

- Installation guide

- This manual is also suitable for

Zurn Z86300-XL-CP43M is a single basin metering faucet with a maximum flow rate of 0.25 GPC and a preset cycle time of 10 to 15 seconds at 80 PSI. It is designed to prevent foreign matter and debris from clogging or damaging internal components and has an integral shank filter assembly that can be removed for back-flushing and cleaning if insufficient flow is detected. The faucet has a highly polished nickel chrome plated finish and is easy to maintain with soap and water or a mild cleaner that is safe for chrome plating.

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Zurn Z86300 User manual

-

Zurn Z83600-XL User guide

-

Zurn Z86100-XL Installation guide

-

Zurn Z842X1-XL-AF Installation guide

-

Zurn Z873E2-EVB-IS Installation guide

-

Zurn Z1231-F/K-2032 Installation guide

-

Zurn Z7872C-XL-SO Installation guide

-

Zurn Z826S1-XL Installation guide

-

Zurn Z5358 Dimensions Guide

-

Zurn Z812A4-XL Installation guide

Other documents

-

T & S Brass & Bronze Works B-0830 Datasheet

T & S Brass & Bronze Works B-0830 Datasheet

-

T & S Brass & Bronze Works B-2282-F Datasheet

T & S Brass & Bronze Works B-2282-F Datasheet

-

stufurhome ST3001MB Installation guide

-

stufurhome ST5001CH Installation guide

-

Speakman RPG05-0523 Installation guide

-

Symmons Industries SLS-7000-G Installation guide

-

Symmons SLS-7000-G Installation guide

-

Bobrick B-8876 Installation guide