Page is loading ...

Installation Manual

For The

System #V900038

UNDERHOOD AIR COMPRESSOR

TEL: 250-740-3200

FAX: 250-740-3201

TOLL FREE: 800-738-8622

1333 KIPP ROAD, NANAIMO, B.C. V9X 1R3

DOCUMENT 1900673

1997-2000 GMC C5500, C6500, C7500 & C8500

CATERPILLAR 3126

Installation Manual Document 1900673

VR70 Underhood Air Compressor

System Number V900038

Application: 1997-2000 GMC C5500, C6500 C7500 & C8500 CATERPILLAR 3126

Publication Date: Revised by S.Large, August / 2002

Publication Number: 1900673

Origination Documents: #1900673 - Introduction

#1900673a - General information

#1900673b - Installing the compressor and oil cooler

#1900673c - Installing the air tank and lines

#1900673d - Installing the control unit

#1900673e - Installing the throttle controller

#1900673f - Illustrated parts list

#1900130 - Warranty registration

Registered Trademarks:

VR70, VMAC and Throttle Commander are registered trademarks of VMAC.

Loctite, Prime N’ Clean, 242 and PST are registered trademarks of Loctite Corporation.

Nylok is a registered trademark of Nylok Fastener Corporation.

GMC, C5500, C6500 C7500 and C8500 are trademarks of General Motors Corporation.

Caterpillar 3126 is a trademark of Caterpillar Ltd.

Notice:

Manuals and products are subject to change without notice.

Copyright 1999

The contents of this manual may not be reproduced in any form without the express written

permission of VMAC

Contents

GENERAL INFORMATION................................................................................................. 3

INTRODUCTION ........................................................................................................................ 5

INSTALLATION NOTES ............................................................................................................... 6

ORDERING PARTS ..................................................................................................................... 7

WARRANTY ............................................................................................................................. 7

CHANGES AND IMPROVEMENTS ................................................................................................... 7

PART 1: INSTALLING THE COMPRESSOR AND OIL COOLER ................................ 9

1.1 PREPARING FOR INSTALLATION .......................................................................................... 11

1.2 INSTALLING THE BRACKET AND COMPRESSOR ...................................................................... 11

1.3 INSTALLING THE OIL COOLER ............................................................................................ 14

PART 2: INSTALLING THE AIR TANK AND LINES ................................................... 17

2.1 INSTALLING THE TANK MOUNTS AND THE TANK .................................................................. 19

2.2 CONNECTING THE AIR AND OIL LINES ................................................................................ 22

2.3 ADDING OIL TO THE SYSTEM ............................................................................................ 25

2.4 COMPLETING THE INSTALLATION ...................................................................................... 26

PART 3: INSTALLING THE CONTROL UNIT ............................................................... 27

3.1 INSTALLING THE CONTROL UNIT ........................................................................................ 29

3.2 CONNECTING THE WIRING ................................................................................................ 31

PART 4: INSTALLING THE THROTTLE CONTROLLER ........................................... 35

4.1 INSTALLING THE THROTTLE CONTROLLER .......................................................................... 37

4.2 CONNECTING THE CABLE ................................................................................................. 38

ILLUSTRATED PARTS LIST.............................................................................................. 41

WARRANTY REGISTRATION.......................................................................................... 45

1

DOCUMENT 1900634a

2

General Information

System #V900038

1997-2000 GMC C5500, C6500, C7500 & C8500

CATERPILLAR 3126

UNDERHOOD AIR COMPRESSOR

3

DOCUMENT 1900673

4

This symbol indicates that there is additional information or special emphasis

on a specific procedure.

This symbol indicates that there is a possibility of personal injury or damage to

the equipment if the indicated warning is not followed.

General Information

Introduction

This book provides installation instructions for:

VMAC underhood air compressor installation kit

VMAC Pneumatic Throttle Control

This kit has been designed for:

1997-2000 GMC C5500, C6500, C7500 & C8500 W/WOAB

Installation steps

The installation procedure in this manual has four main steps:

Part 1: Installing the Compressor

Part 2: Installing the Oil Cooler, Air Tank and Lines

Part 3: Installing the Control Unit

Part 4: Installing the Pneumatic Throttle Control

Terms and symbols

This manual uses the following terms and symbols:

•OEM - Original Equipment Manufacturer

•HHCS - Hex Head Cap Screw (also called a hex bolt)

•SHCS - Socket Head Cap Screw (also called an Allen head bolt)

NOTE

WARNING

!

5

Installation Notes

1. It is important that you complete all the installation steps before operating the system.

Refer to the Owner’s Manual before operating the system for the first time.

2. Follow all safety precautions for underhood mechanical work.

3. Use Loctite 242 or equivalent on all engine-mounted fasteners.

4. All hoses, tubes and wires which are re-routed or shifted during installation must be secured

so that they do not contact excessively hot areas or sharp edges. Where possible, follow

the routing instructions in this manual.

5. These installation instructions are intended as a general guide. In some instances, due to

variations in vehicle manufacture or if prior modifications have been made to the vehicle, it

may be necessary to carry out grinding, bending or rearranging operations for correct fit.

These operations must follow sound, standard shop practices.

6. Left and right definitions in this manual are determined when sitting in the driver’s seat,

facing forward.

7. All fasteners must be of the correct size and torqued according to the specifications shown

below. Torque specifications are in foot pounds (ft-lb).

DANGER

Never operate the system unless the vehicle transmission is in neutral (standard

transmission) or park (automatic transmission) with the park brake fully applied. A

sudden increase in engine RPM when the system is engaged will cause the vehicle to

move suddenly if the transmission is left in drive.

6

STANDARD GRADE 8 NATIONAL COARSE THREAD

Size 1/4 5/16 3/8 7/16 1/2 9/16 5/8 3/4

Foot-pounds 9 18 35 55 80 110 170 280

STANDARD GRADE 8 NATIONAL FINE THREAD

Size 3/8 7/16 1/2 5/8 3/4

Foot-pounds 40 60 90 180 320

METRIC CLASS 10.9

Size M8 M10 M12 M14 M16

Foot-pounds 19 41 69 104 174

WARNING

!

The above fastener torque values are applicable when Loctite is used .

If the threads are dry add 20% to the torque values.

Ordering Parts

To order parts, contact your neares VMAC dealer.

Please quote the VMAC part number, the description and the quantity.

Warranty

The VMAC warranty form is located at the back of this manual. This warranty form must be

completed and mailed or faxed to VMAC at the time of installation for any subsequent warranty

claim to be considered valid.

The enclosed System Identification Number Plate (S/N) must be attached to the vehicle at the time

of installation.

Locate the S/N plate on the drivers side of the radiator fan shroud. Drill the two hole locations

using a 7/64” drill bit. Place the S/N plate in position and fix in place with the two #6 pan head self

tapping screws provided.

IMPORTANT

This S/N plate provides information, which allows VMAC to assist in customer inquiries and/or

ordering of parts. It is important that this S/N plate is affixed to the vehicle.

Changes and improvements

These products and documents are subject to changes or improvements without notice.

7

Mount the system ID plate here

8

Part 1

Installing

the Compressor

and

Oil Cooler

System #V900038

1997-2000 GMC C5500, C6500, C7500 & C8500

CATERPILLAR 3126

UNDERHOOD AIR COMPRESSOR

9

DOCUMENT 1900673

10

Part 1: Installing the Compressor and Oil Cooler

1.1 Preparing for installation

1. Drain the coolant.

2. Remove both fender inserts.

3. Remove the radiator stabilizer bar from the driver’s side of the truck.

4. Remove the intercooler duct from the driver’s side of the engine.

5. Remove the coolant expansion bottle.

6. Remove the upper radiator hose and support bracket.

7. Loosen both clamps on the lower radiator hose, but only remove the end that is attached to

the engine to make removing the fan shroud easier.

8. Remove the fan (the fan has left-hand threads) and the shroud together.

9. Remove the harmonic balancer.

10. Remove and discard the wire harness clamp and bracket bolted to the rear of the timing

cover (in front of the fuel filter).

11. Remove and retain the 10 mm bolt and retaining clamp supporting the OEM compressor

coolant hose at the front of the engine.

12. Clean the engine block in the area where the compressor bracket will be mounted to ensure

that it mounts properly. If there is any contamination behind the bracket, the pulleys may

not line up correctly.

13. Remove the air intake duct connecting the air cleaner to the turbo and remove the air

cleaner. Remove and discard the air cleaner cast support bracket but keep the cap screws.

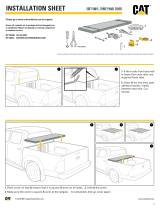

1.2 Installing the bracket and compressor

1. Remove the idler pulley and the tensioner from the VR70 mounting bracket. Fit the

compressor mounting bracket into position on top of the driver’s side timing cover casting

using the four supplied (4) 10 x 30mm hex head cap screws and 3/8” flat washers. Tighten

the caps screws just enough to hold the bracket in place against the engine (Figure 1.1).

2. Mark the location of the fifth hole on the bracket mounting tab where it fits over the engine

lifting plate (Figure 1.2). Make sure that it is centered properly, or the hole will not align

with the threaded hole in the block.

11

12

Figure 1.1

Figure 1.2

3. Remove the VR70 mounting bracket from the engine.

4. Remove the four (4) OEM cap screws from the alternator/air conditioning support bracket

at the center of the engine. These cap screws also retain the engine lifting plate (Figure 1.1).

5. Slide the lifting plate out from behind the alternator/air conditioning bracket.

Mark and drill here

4 of 5 mountin

g

locations

Idler mounting

location

Mark and

drill this hole

Remove these

8 pulley bolts

Remove the OEM

belt and fan pulley,

then remove the 4

bolts holding the

bracket to the front

of the engine

13

6. Center-punch the marked hole, drill a 3/16” pilot hole and then drill the plate out to 1/2”.

7. Slide the lifting plate back into place behind the alternator/air conditioning bracket, apply

Loctite 242 and loosely install the OEM cap screws.

8. Install the VR70 mounting bracket using all five (5) cap screws with Loctite 242.

9. Refit the VR70 belt tensioner and idler (make sure the bolt spacer is installed in the idler)

using Loctite 242 (Figure 1.1).

10. Torque all fasteners to specifications.

11. Install the VR70 crank pulley on the OEM crank pulley and align 8 holes. Place harmonic

balancer in front of both crank pulleys and fit eight (8) 10 x 70 mm supplied hex head cap

screws with Loctite 242 applied to the threads. Torque them to specifications.

12. Install the burred end of the three (3) supplied 8mm studs into the bottom of the VR70

compressor. The burr prevents the stud from loosening and backing-out.

13. Apply Loctite to the other end of the studs, place the compressor onto the bracket and

install the supplied 8 mm nuts and 5/16” flat washers on each of the studs. Torque the nuts

to specifications. Figure 1.3 shows the two outside mounting positions.

Figure 1.3

14. Place the VR70 crankshaft pulley in place on the end of the crankshaft and line up the holes

in the pulley with the holes in the crankshaft.

15. Place the OEM harmonic balancer over the VR70 pulley. Apply Loctite to the eight (8) 10

x 60 mm supplied hex head cap screws. Place 3/8” flat washers over the bolts, thread them

into the crankshaft and torque them to 45 ft-lbs.

14

16. Install the VR70 belt, routing it as shown in Figure 1.4. Make sure that you check

alignment of the pulleys to ensure that the belt runs properly on the pulleys.

Figure 1.4

1.3 Installing the oil cooler

1. Clean the passenger side of the cylinder head and make sure that the threads in the six (6)

10 mm holes on the side of the cylinder head (Figure 1.5) are clean.

2. Mount the oil cooler assembly to the passenger side of the cylinder head using the six (6)

10 x 30 mm hex head cap screws and 3/8” flat washers.

3. Remove the 3/4” OEM heater supply hose at the firewall (inner hose connection). Install

the supplied 3/4” plastic hose barb into the end of the OEM hose and tighten the clamp.

4. Connect the 30” length of supplied 3/4” heater hose to the other end of the plastic hose

barb, install a hose clamp and tighten.

5. Route the hose around to the front brass hose barb on the cooler. Install a hose clamp on

each end of the hose, place it over the brass fitting and tighten the clamp.

6. Install a hose clamp on the supplied 42” piece of 3/4 hose and place it on the rear brass

hose barb on the oil cooler. Tighten the clamp.

7. Route the hose around to the OEM fitting at the firewall. Install a clamp, place the hose on

the fitting and tighten the clamp.

8. Place hose protectors on the cooling hoses to prevent damage

15

Four Mounting Locations Two Locations Behind Here

Figure 1.5

9. Remove the six (6) cap screws holding the fan to the hub and remove the fan.

10. Install the supplied spacer in the fan so that the raised diameter fits into the opening in the

center of the fan hub (Figure 1.6).

11. Fasten the fan and spacer back onto the fan hub using the supplied 5/16” x 1” hex head cap

screws.

12. Apply Loctite to the threads in the fan hub and install the supplied spacer onto the fan hub.

12. Place the fan assembly and shroud in position.

13. Apply Loctite to the threads in the spacer and install the fan to the engine. Figure 1.6 shows

the assembly procedure.

When operating the engine for the first time following installation, be sure to allow the

engine to reach full operating temperature and ensure that the cooling system level is

correct. Failure to do so could result in an overheat condition and possible engine damage.

NOTE

14. Install the fasteners in the fan shroud.

15. Install the coolant expansion bottle.

16. Install the upper radiator hose.

17. Fill the cooling system with the OEM recommended coolant to the correct level.

16

Water pump pulley

Supplied spacer

Fan spacer ring Fan

Fan clutch hub

Figure 1.6

Part 2

Installing the

Air Tank and Lines

System #V900038

1997-2000 GMC C5500, C6500, C7500 & C8500

CATERPILLAR 3126

UNDERHOOD AIR COMPRESSOR

17

DOCUMENT 1900673

18

/