Page is loading ...

Simple and quick installation

Key features

Important information

Slip resistance

R10

R10

Slip resistance R10

Superguard®

Superguard®

resistant

Scu & stain resistance

Suitable for

bathrooms

Suitable for bathrooms Suitable for

underfloor heating

Suitable for

1316mm x 191mm x 4.2mm

8 Panels per pack

Coverage 2.01m

Pack Weight: 14.95 kg

HJ-050-JC

B

-S

1

Slip resistance: DS

No Pentachlorophenol containing products added

No Formaldehyde containing products added

NPD

IMPORTANT VINYL FLOORING FITTING NOTICE

18°c - 27°c

24

Do not open packs until you are ready to install the flooring

Flooring must be stored in the room of installation for at least

24hrs before fitting

Packs should be stored in a room with a minimum temperature of

18° - 27°C.

The fitting method for this flooring is unique and laying

instructions must be followed on the reverse of this carton

hrs

•

Subfloor must be flat, smooth, clean and permanently dry

•

Use spacers to create the required expansion gap (minimum 5mm)

around the edge of the room and all fixed objects including door frames,

radiator pipes & cabinet legs. Do not install kitchen cabinets on top of

the floor

•

Always use a dedicated LVT underlay (Laminate/real wood flooring

underlays must not be used)

•

Mix/shue panels from dierent packs when laying the floor

•

All short-end joints should be rolled to ensure they’re fully engaged

•

All long joints should be tapped in to place using a mallet and an o-cut

piece of flooring (tapping block). No gaps should be visible on the long

joints

•

Ensure each row is checked for straightness before starting the

following row

•

Short joints should be a minimum of 200mm apart from the short-end

joint on the previous row

HOWDENS

PROFESSIONAL

LUXURY VINYL

FLOORING

General Instructions

Pre-installation

Installation

Care & Maintenance

HOWDENS PROFESSIONAL

LUXURY VINYL FLOORING

Clean the subfloor

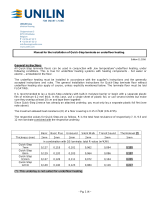

SMOOTH

GRADUALLY INCREASE

TEMPERATURE BY 5° PER DAY

TO A MAX OF 27°

SEEK ADVICE FROM

UNDERFLOOR HEATING

MANUFACTURER

CLEAN

DRY

DPM

Water and electric*

systems can be used

*electric systems must be

encased in a minimum of 9mm

of levelling compound

UNDERFLOOR HEATING

CONCRETE

CEMENT

SCREEDS

ANHYDRITE

MAX

27 C

RH <70%

MOISTURE CONTENT BETWEEN 8-12%

5mm EXPANSION GAP

NOTE:

ADDITIONAL EXPANSION

GAP REQUIRED FOR RUNS

LONGER THAN 20M

SHEET OR PAINTABLE

10mm EXPANSION GAP

(over 200m2)

2m

Max 3mm

ø

0

mins

uv

115kg

MAX

1

18°c - 27°c

24

hrs

LEVELLING

COMPOUND

SECURE PLYWOOD OVER

EXISTING FLOORBOARDS

FLOATING

TOOLS REQUIRED

CHOOSE DIRECTION OF INSTALLATION

DEDICATED LVT UNDERLAY

2

FIRST ROW

Remove the lower

lip from the first row

nearest the wall

Take planks from dierent packs when fitting

Always install a DPM

where there are concerns

over moisture in sub floor

ROLL ALL SHORT JOINTS

Use flooring o-cut to tap on the long side

Fit into long edge, then slide along and drop down Ensure all panels are fully engaged and straight

3

LAY FIRST ROW

4

USE SPACERS AROUND EDGE

5

MEASURE & CUT

6

CHECK ROW IS STRAIGHT

7

USE OFF-CUT FOR NEXT ROW

>200mm

8

FULLY ENGAGED PANEL JOINTS

25°

25°

9

FIT NEXT PANEL

10

REPEAT OF ALL PANELS

Measure width of panel required - cut with knife*

*Ensure expansion gap is maintained

11

LAST ROW

upside down panel

12

CUTTING AROUND PIPEWORK

No rubber or latex backed mats

No steam mops should be used

Well wrung out mop and

cleaning cloth can also be used

Castor cups Felt pads

/