Instruction | Disassembling and assembling APP S 5.1-9.0 / APP S 674 5.1-9.0

© Danfoss | DCS (im) | 2015.12

180R9258 | 521B1227 | DKCFN.PI.014.X3.02 | 20

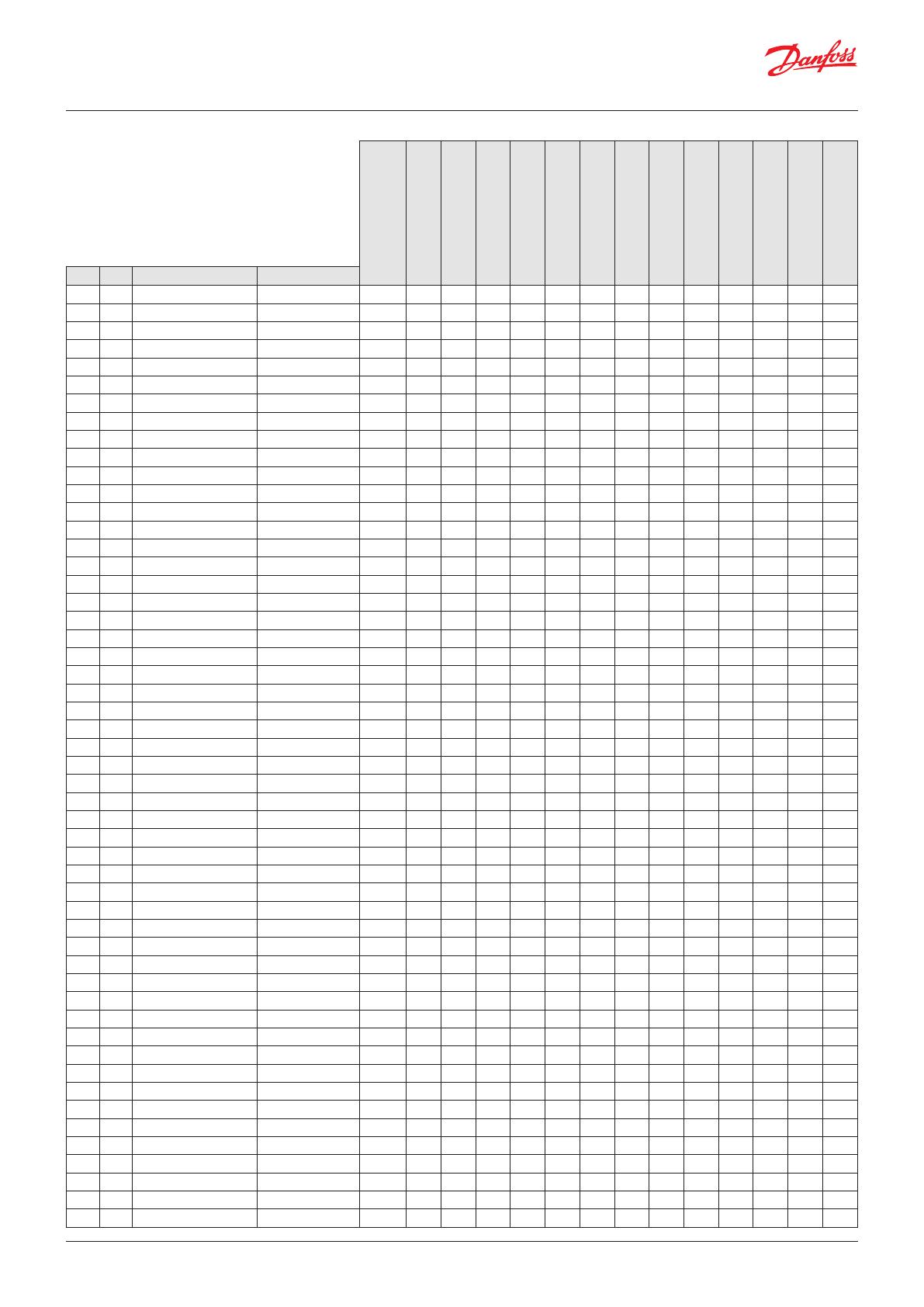

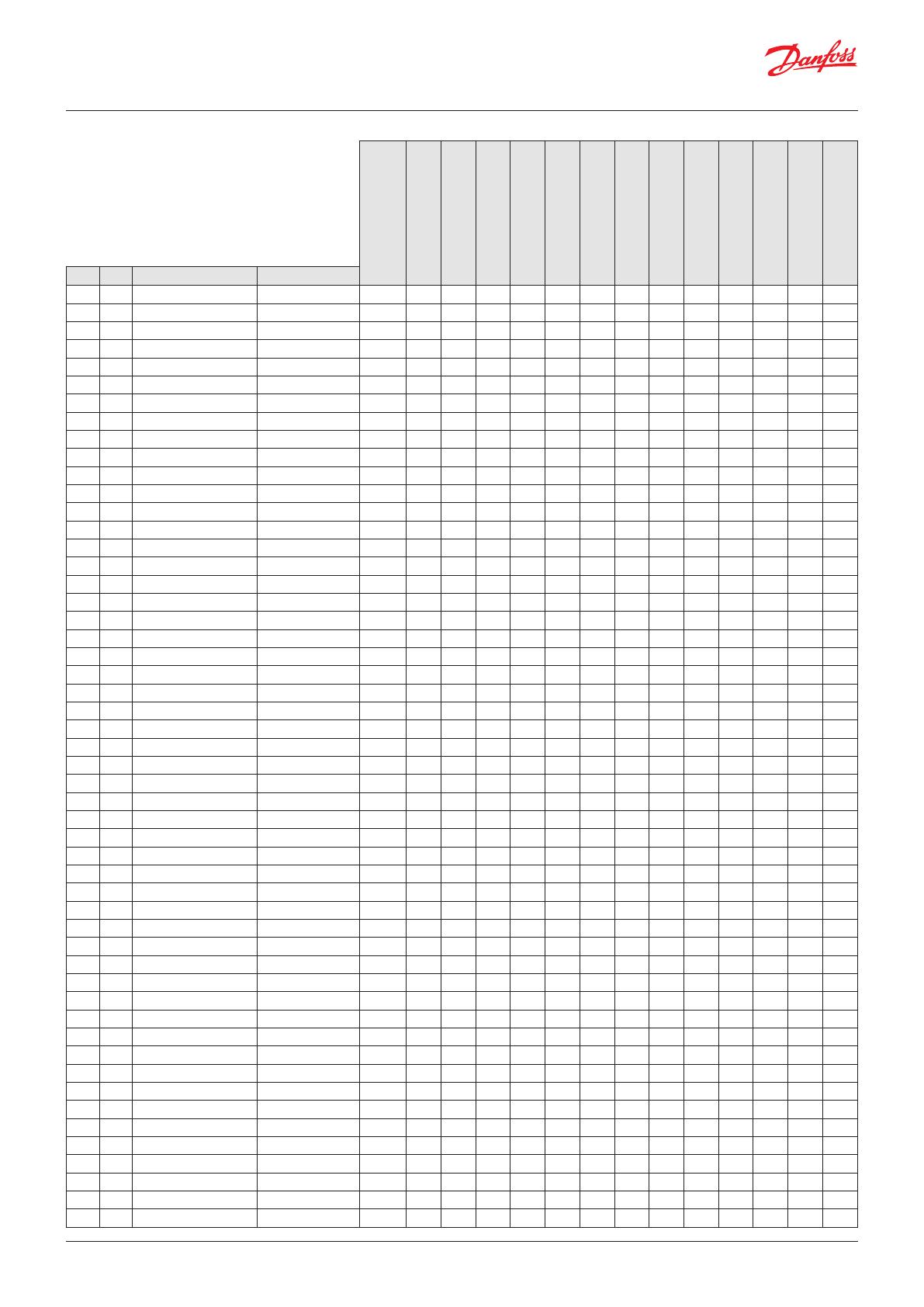

9. Spare parts list APP S (674) 5.1-9.0

Pressure Containing Parts,

3.1 Material Certicate

Available and Traceable

Metallic Process Wetted Parts,

PMI Rapport Available

180B4261 Seal & screw set

APP S (674) 5.1-9.0

180B4243 Shaft seal set

APP S (674) 5.1-9.0

180B4244 Cylinder barrel set

APP S (674) 5.1-9.0

180B4245 Valve plate set

APP S (674) 5.1-9.0

180B4246 Retainer set

APP S (674) 5.1-9.0

180B4247 Piston set

APP S (674) 5.1-9.0

180B4262 Swash plate set

APP S (674) 5.1

180B4263 Swash plate set

APP S (674) 6.5

180B4264 Swash plate set

APP S (674) 7.2

180B4248 Swash plate set

APP S (674) 8.2

180B4249 Swash plate set

APP S (674) 9.0

180B4250 Flushing valve set

APP S (674) 5.1-9.0

Pos. Qty. Designation Material

1 1 Housing Super Duplex/PEEK X X

2 2 Pin AISI 316

3 4 Bleeding plug, G1/4” Super Duplex X

2)

X X

4 4 O-ring NBR X

5 14 Screw M8x25 AISI 316 X

9 1 O-ring NBR X

11 1 End ange Super Duplex X X X

12 1 Lifting eye Duplex

31 1 Swash plate Super Duplex X X X X X X

32 1 Screw M8x20 Super Duplex X X X X X X

34 2 Pin Super Duplex X X

61 1 Complete cylinder barrel X

(1) Cylinder barrel Super Duplex X

(1) Shaft Super Duplex X

(9) Bushing PEEK

62 1 Spring Hastelloy C276 X X

64 1 Retainer ball Super Duplex X X

65 1 Retainer plate Super Duplex X X

66 9 Piston Super Duplex/PEEK X X

67 1 Key AISI 316 X

71 1 Retainer guide Super Duplex/PEEK X X

91 1 Port plate Super Duplex/PEEK X

3)

X

92 1 Complete valve plate X

(1) Valve plate Super Duplex X

(9) Valve shoes Super Duplex X

93 9 Back-up ring PTFE X

94 9 O-ring NBR X

121 1 Port ange Super Duplex/PEEK X X

122 1 O-ring NBR X

123 1 O-ring NBR X

124 1 Shaft seal Hastelloy C4 X X

125 1 Cover for shaft seal Super Duplex X X

126 1 Pin Super Duplex X X

127 4 Screw M6 x 16 AISI 316 X

128 14 Screw M8 x 90 AISI 316 X

129 1 Stop bush Polypropylene X

130 1 O-ring FPM X

131 2

Cover for port connection

AISI 316

132 2 O-ring EPDM X

133 16 Screw M8x25 AISI 316 X

140 1 Bearing PEEK

142 1 Stop for shaft seal Super Duplex X

144 4 Tailstock screw M12x60 AISI 316 X

145 4 Check nut M12 AISI 316 X

146 1 Eye bolt M8 AISI 1015

148 1 O-ring NBR

151 1 O-ring FPM X X

152 1 Valve cone Super Duplex X X

153 1 Spring Hastelloy C276 X

3)

X

154 1 Plug/guide Super Duplex X X X

155 1 O-ring NBR X X

Instruction X X X X X X X X X X X X

²

)

3.1 Material certicate not traceable

³

)

PMI rapport not available